Method for manufacturing high-strength titanium alloy golf club head part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

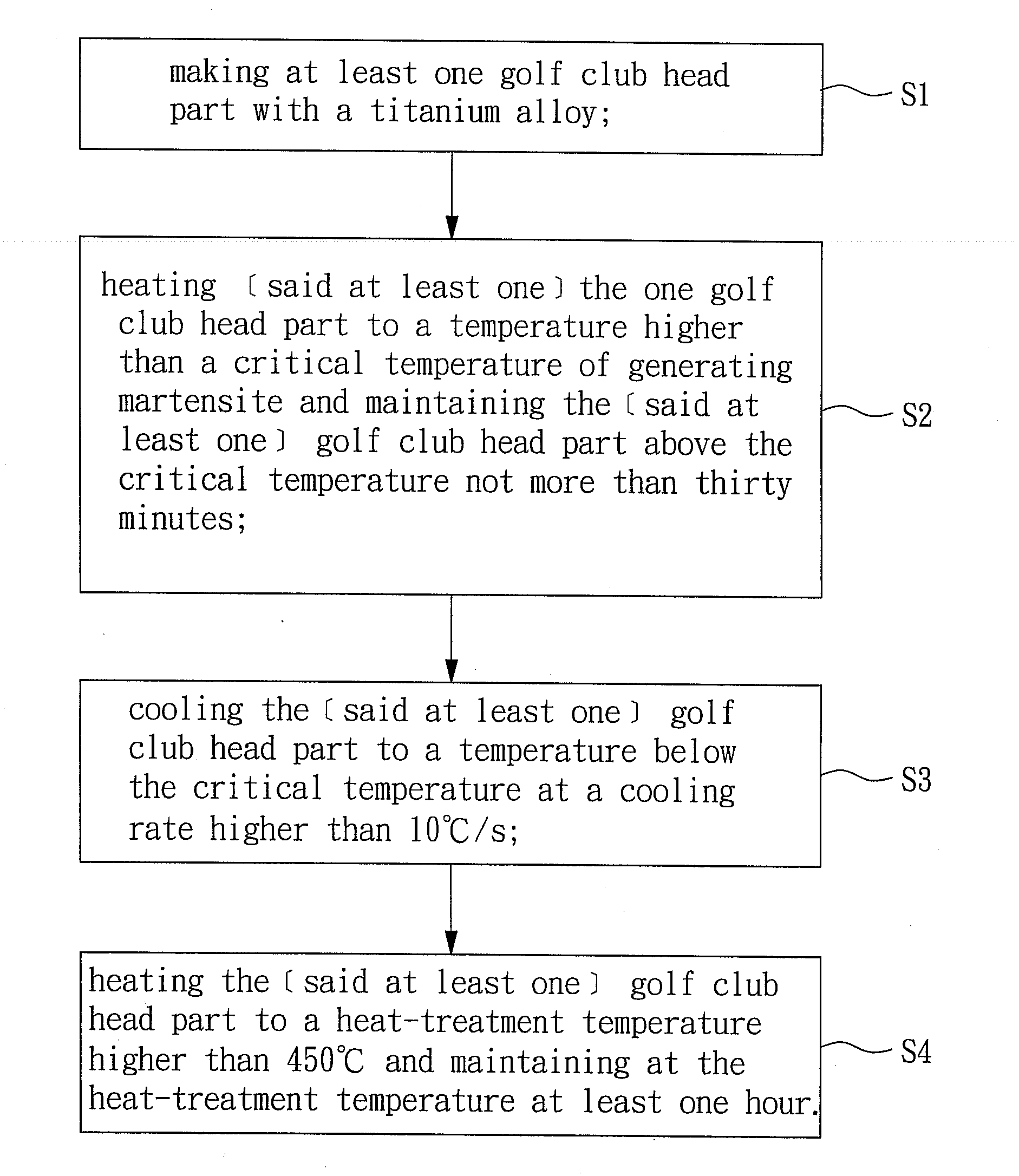

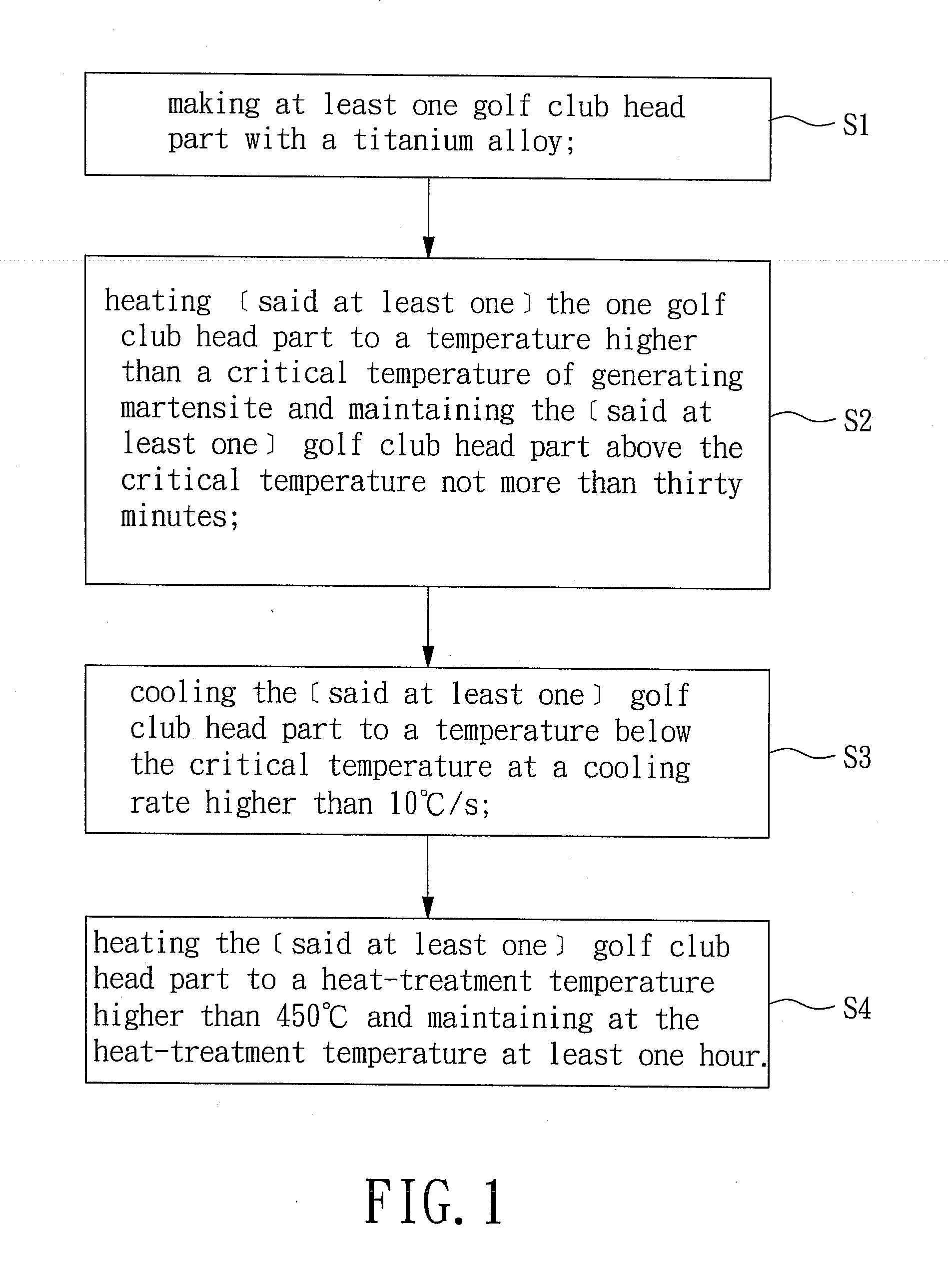

[0014]Referring to FIG. 1, a method for manufacturing a high-strength titanium alloy golf club head part according to the preferred teachings of the present invention includes making at least one golf club head part (such as a faceplate or a portion of a golf club head body) with a titanium alloy; heating the golf club head part to a temperature higher than a critical temperature of generating martensite and maintaining the golf club head part above the critical temperature for a period of time; rapidly cooling the golf club head part to a temperature below the critical temperature at an appropriate cooling rate; heating the golf club head part to a heat-treatment temperature and maintaining at the heat-treatment temperature for a period of time; and cooling the golf club head part to room temperature.

[0015]Specifically, a first step S1 of the method for manufacturing the high-strength golf club head part according to the preferred teachings of the present invention includes making ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com