Portable composting toilet system

a composting toilet and portable technology, applied in the field of toilets, can solve the problems of odor and waste disposal, waste hauling to the surface for disposal is both expensive and time-consuming, and current composting toilets suffer from a number of shortcomings, so as to accelerate the bio-degradation of human waste, and accelerate the effect of composting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

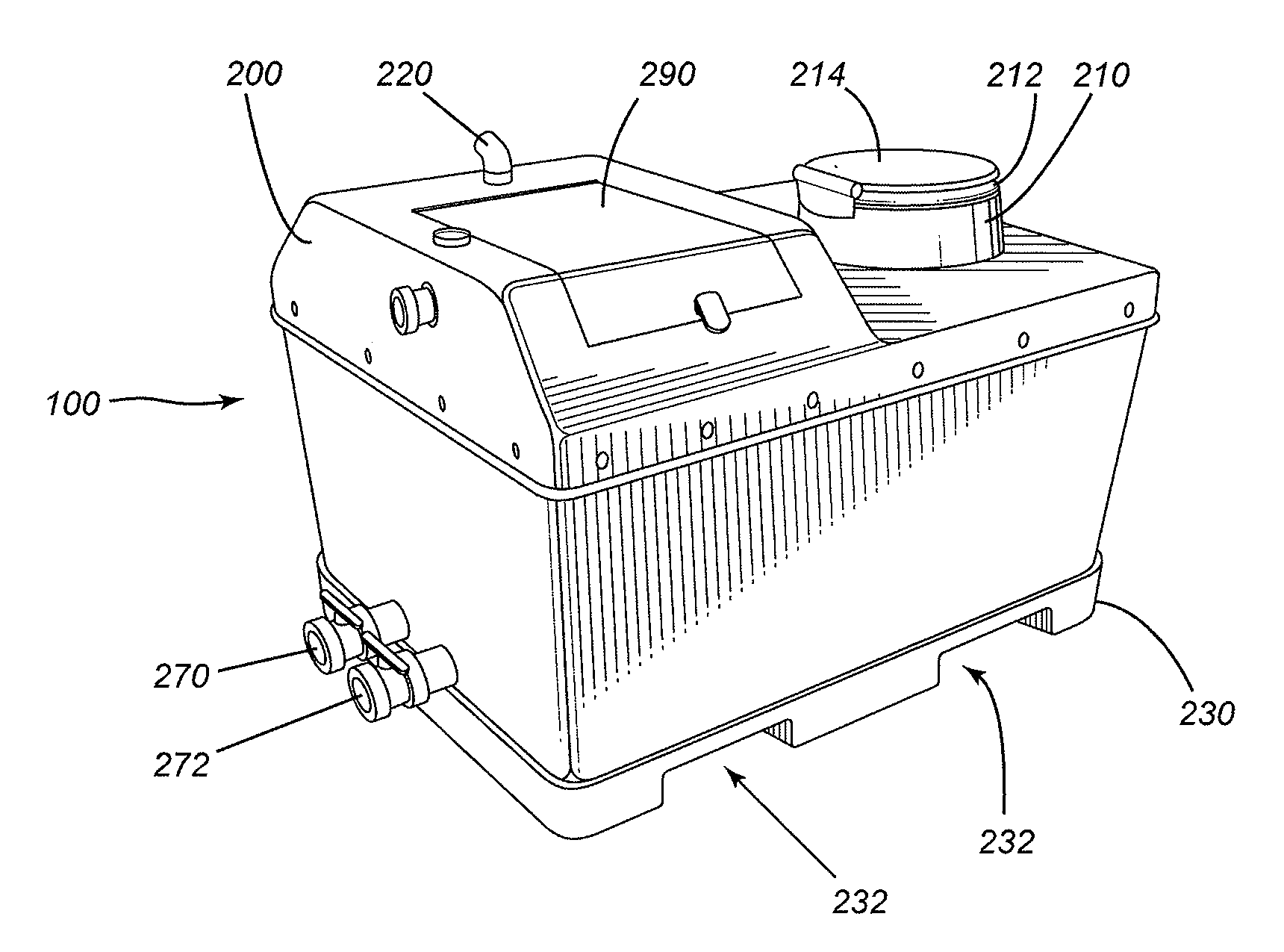

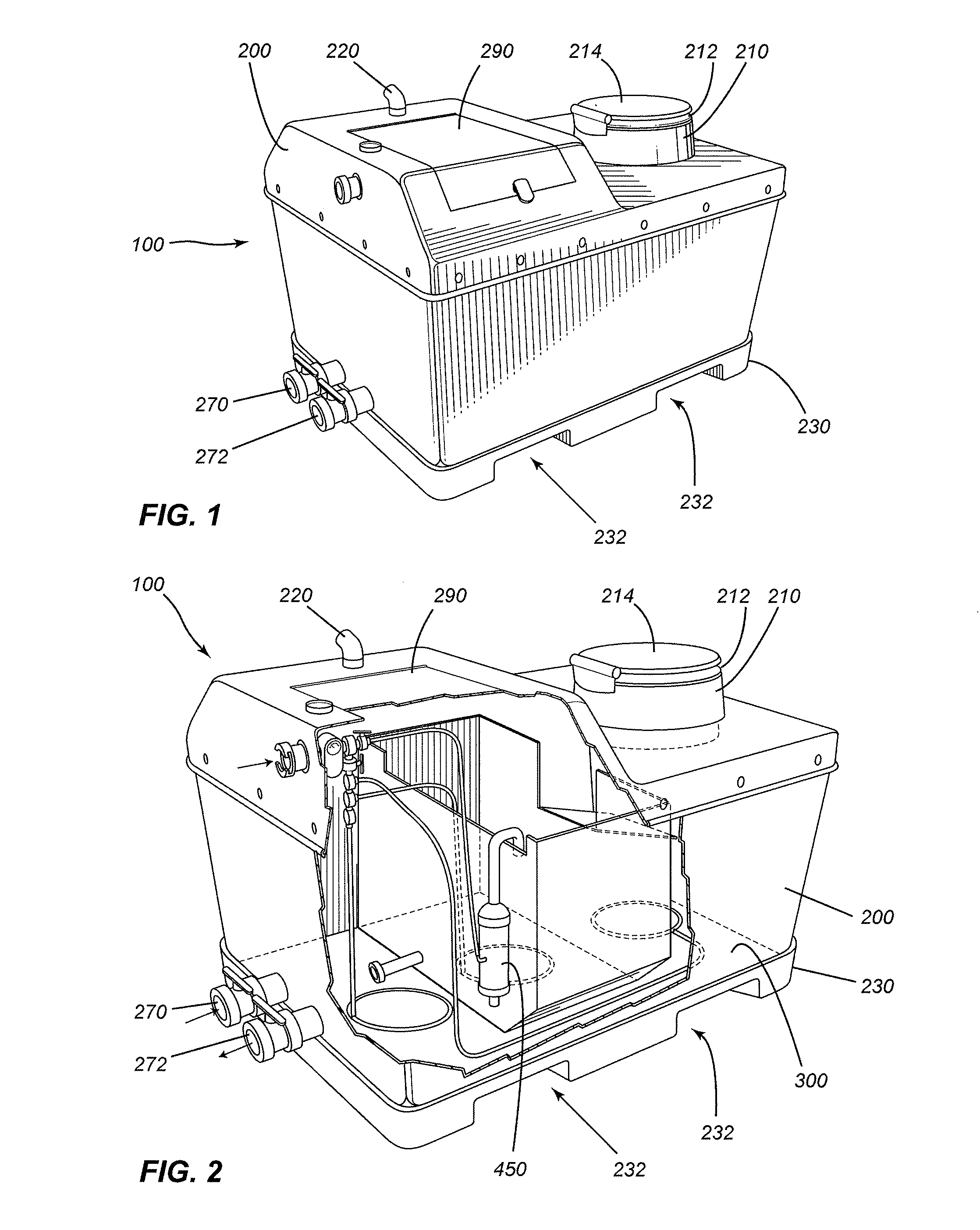

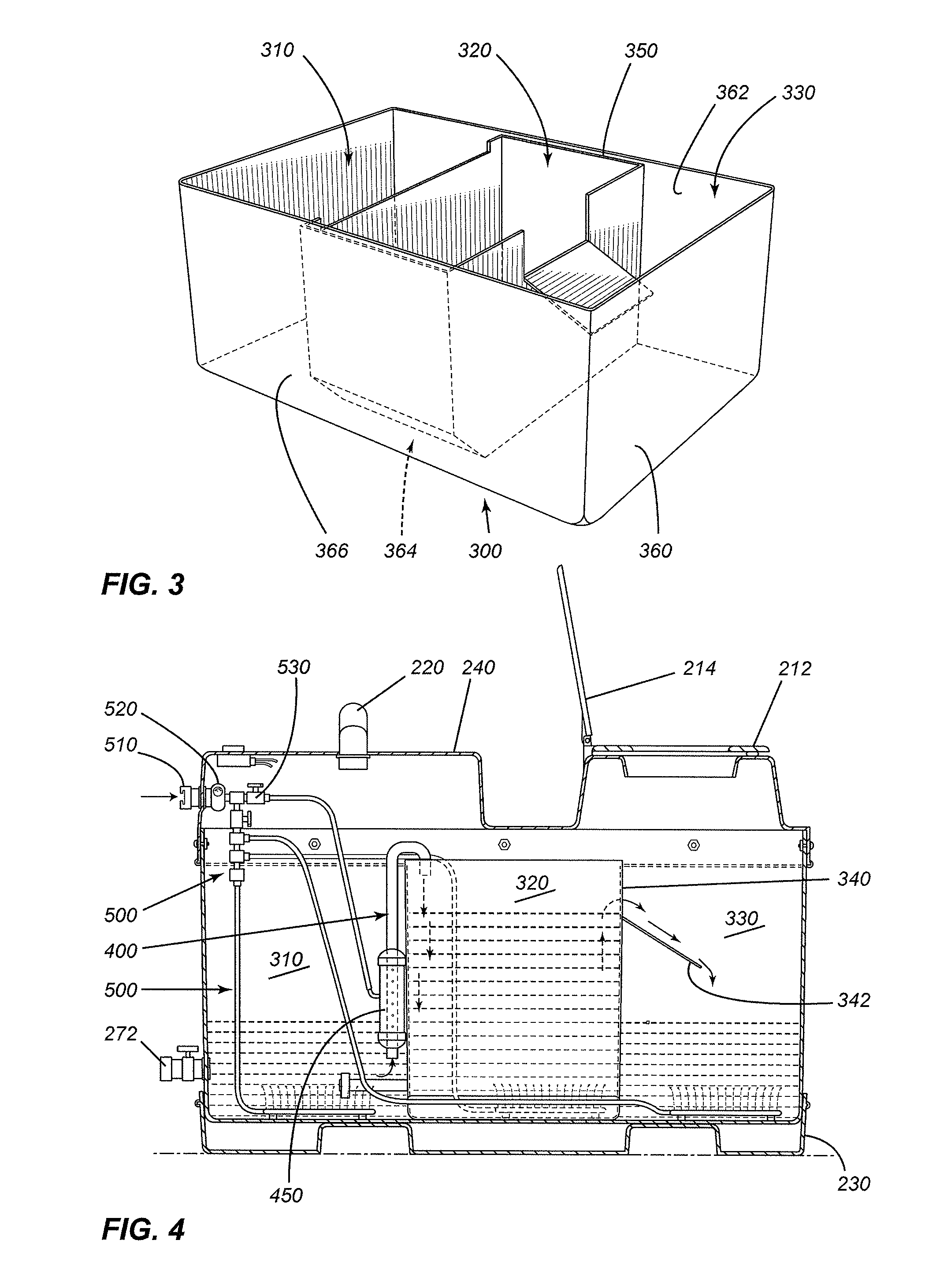

[0021]In general, and as will elaborated below in greater detail, FIGS. 1 to 4 depict a portable composting toilet system designated generally by reference numeral 100. This portable composting toilet system 100 is designed to receive and process human waste. The toilet system 100 comprises a housing 200 having an opening 210 that is disposed above a compartmentalized receptacle 300 for receiving waste (urine, feces, toilet paper, etc.). The compartmentalized receptacle 300 (or tub assembly) can be considered part of the housing. The compartmentalized receptacle 300 is designed to be partly filled with a volume of water into which a biological digesting product and optionally also an anti-foaming agent are added to biologically digest the human waste. The toilet system 100 also comprises a gray water circulation subsystem 400 for circulating gray water (formed by mixing water with human waste) through the compartmentalized receptacle 300 to promote mixing of the waste to thereby acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com