Method for heating up of a ceramic glow plug and glow plug control unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

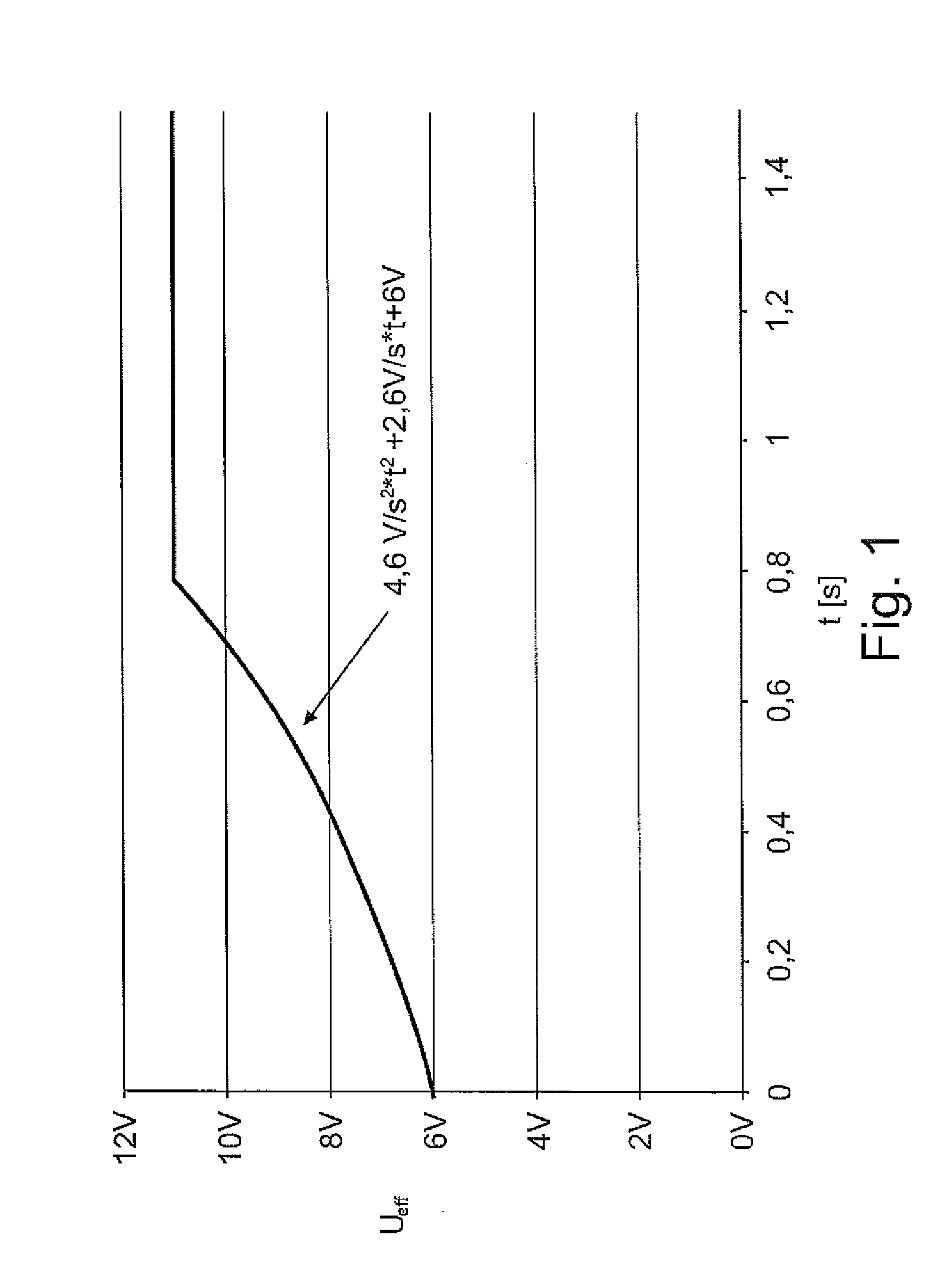

[0020]FIG. 1 shows the course of the effective voltage Ueff in volts over time t in seconds. The voltage is applied to a ceramic glow plug to heat it up to an operating temperature for starting of a motor. At the onset of a heating-up process the effective voltage is applied as a starting voltage which is smaller than the voltage of the vehicle's electrical system, which is today usually about 12V. The starting voltage, which is larger than zero, is chosen as a base value and preferably reached in a jump.

[0021]Thereby a method is realized for heating-up of a ceramic glow plug to an operating temperature for the starting of a motor. During the method a variable voltage is applied to the glow plug. Starting from a base value the voltage increases superproportional to the elapsed heating-up time until a maximum value is reached.

[0022]In FIG. 1 it is shown that the effective voltage Ueff increases in a parabolic manner from a base value of 6 volts to a maximum value of about 11 volts. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com