Hollow valve for internal combustion engine, and internal combustion engine having the hollow valve

a technology for internal combustion engines and hollow valves, which is applied in the direction of valve arrangements, lift valves, engine cooling apparatus, etc., can solve the problems of medium not being able to contact a wall, medium not necessarily cooled, so as to reduce or prevent the temperature rise of intake air, improve the cooling effect, and improve the cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

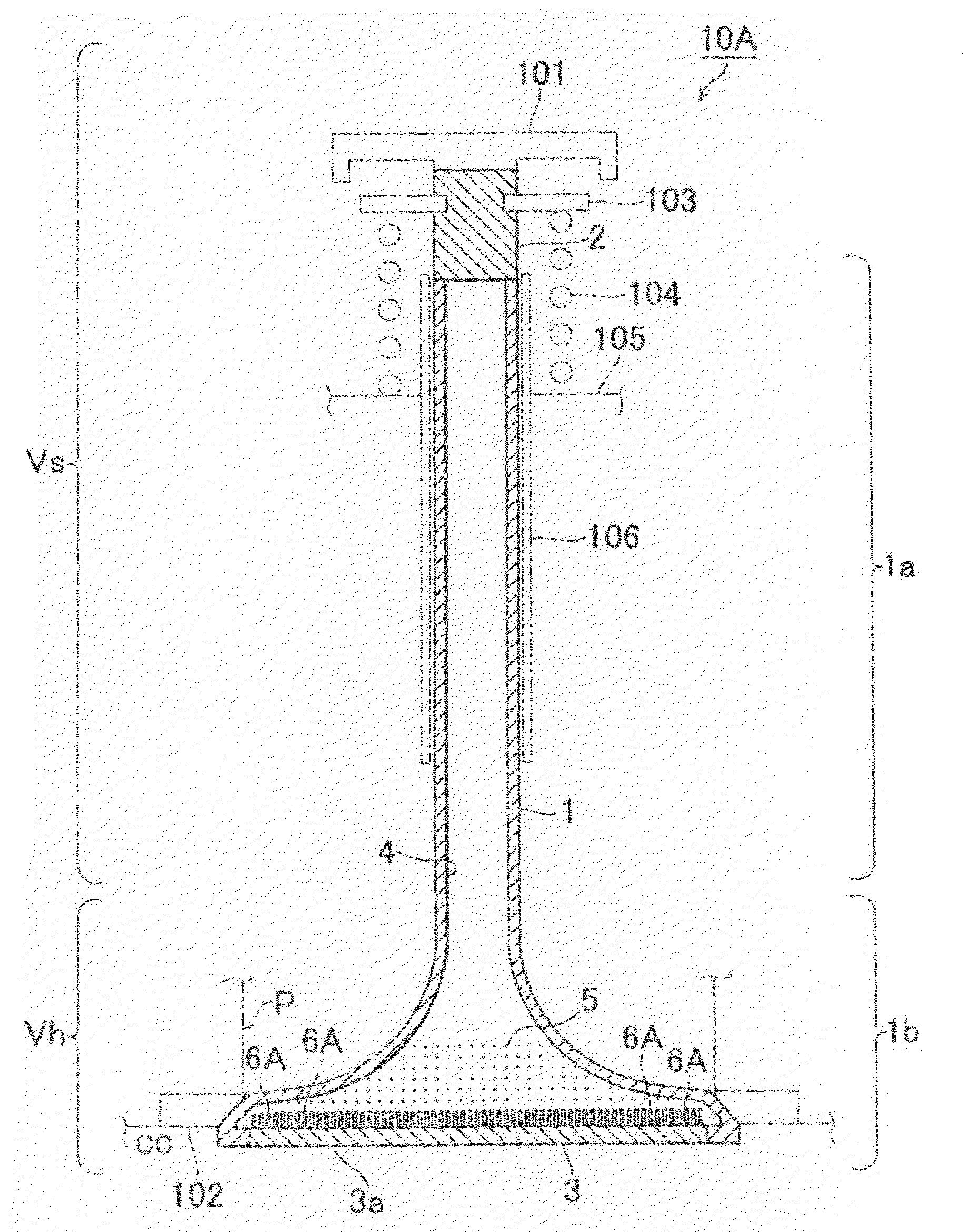

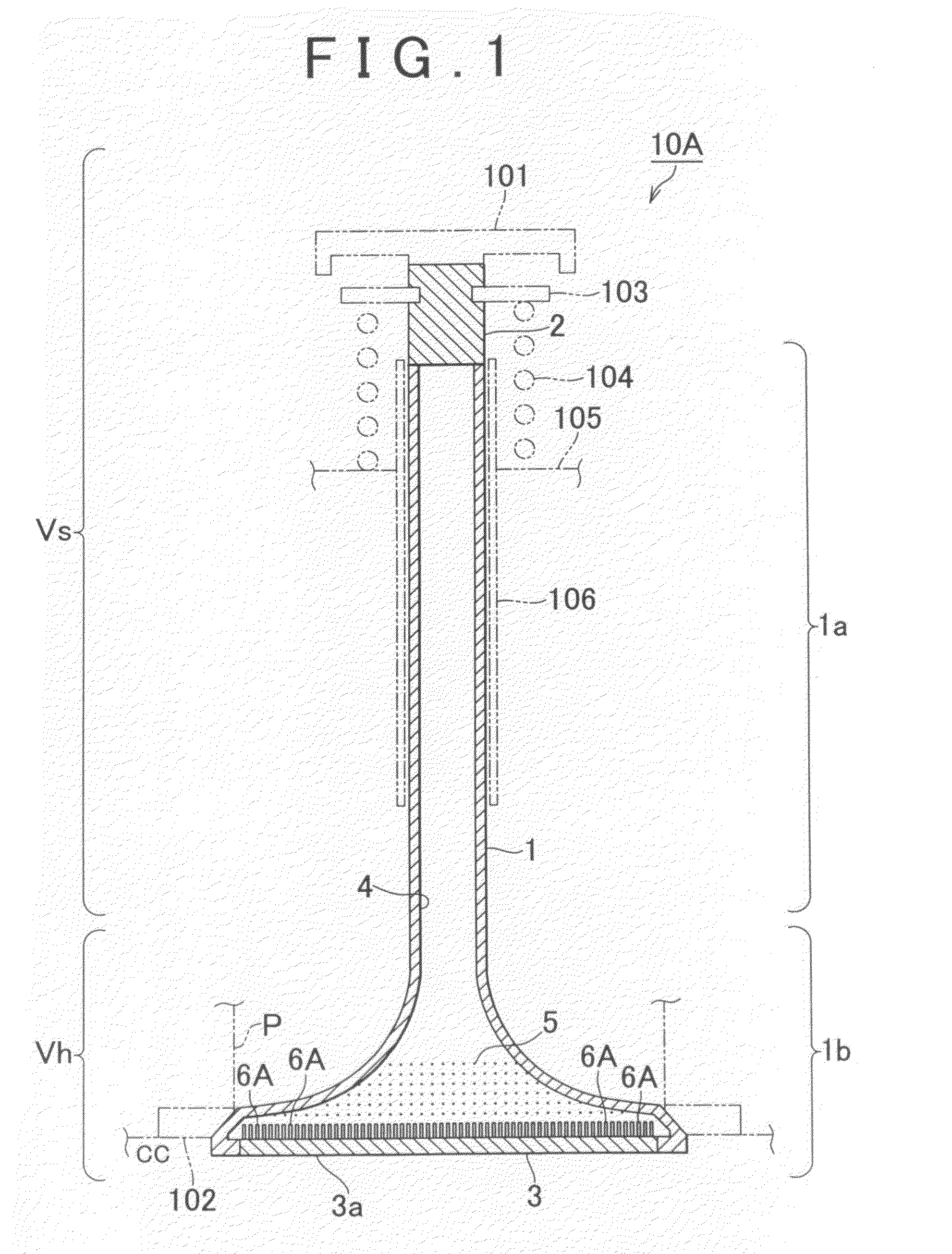

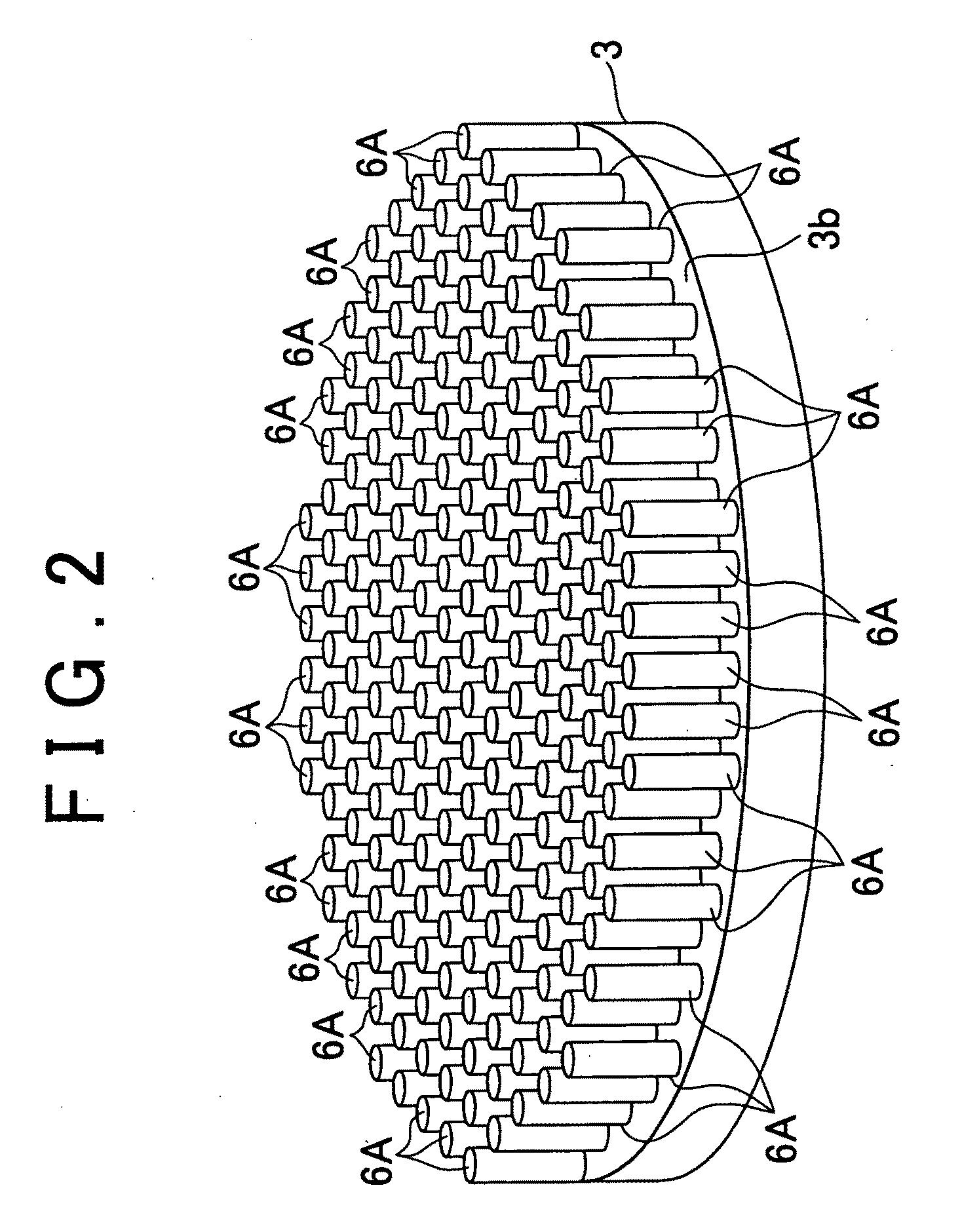

[0037]A hollow valve for an internal combustion engine according to the invention will be described with reference to FIG. 1 and FIG. 2.

[0038]In FIG. 1, reference numeral 10A denotes the hollow engine valve of the first embodiment. The hollow engine valve 10A of the first embodiment may be used in an intake or exhaust valve actuating mechanism (a mechanism including, for example, a valve lifter 101) of the internal combustion engine, which is not illustrated in the drawings. In operation, the hollow engine valve 10A reciprocates in the axial direction so as to communicate a combustion chamber CC of the engine and an intake port P (or the combustion chamber CC and an exhaust port P) with each other or interrupt communication between the combustion chamber CC and the intake or exhaust port P.

[0039]The hollow engine valve 10A of the first embodiment is divided roughly into a stem portion (so-called valve stem) Vs and an umbrella portion Vh provided at one end of the stem portion Vs. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com