Plasma ignition burner

a technology of ignition burner and plasma, which is applied in the direction of burners, plasma techniques, combustion types, etc., can solve the problems of clinkering of pulverized coal, the guide plate cannot completely deflect air flow, and cannot be used further, so as to relieve the problem of clinkering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

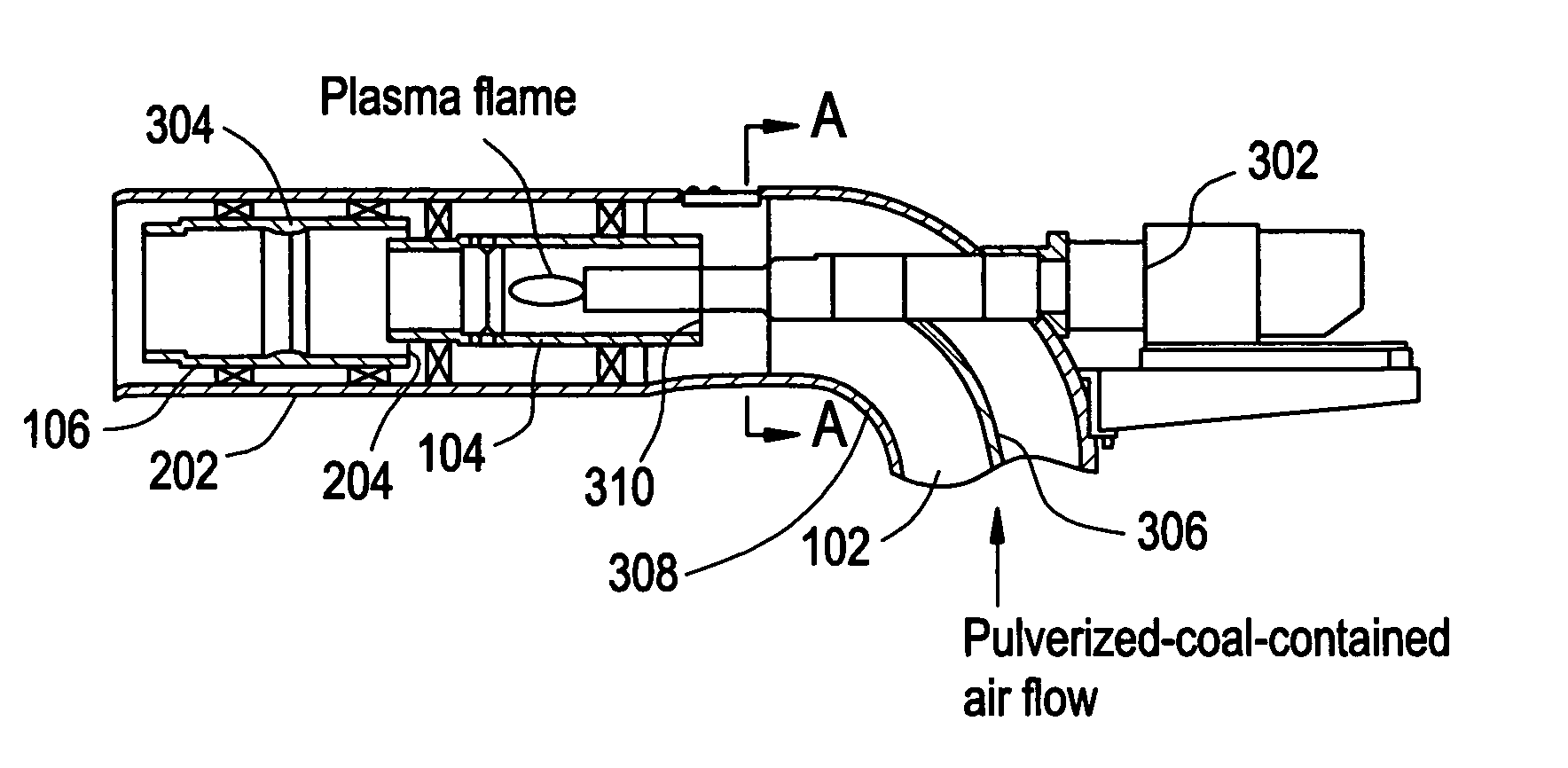

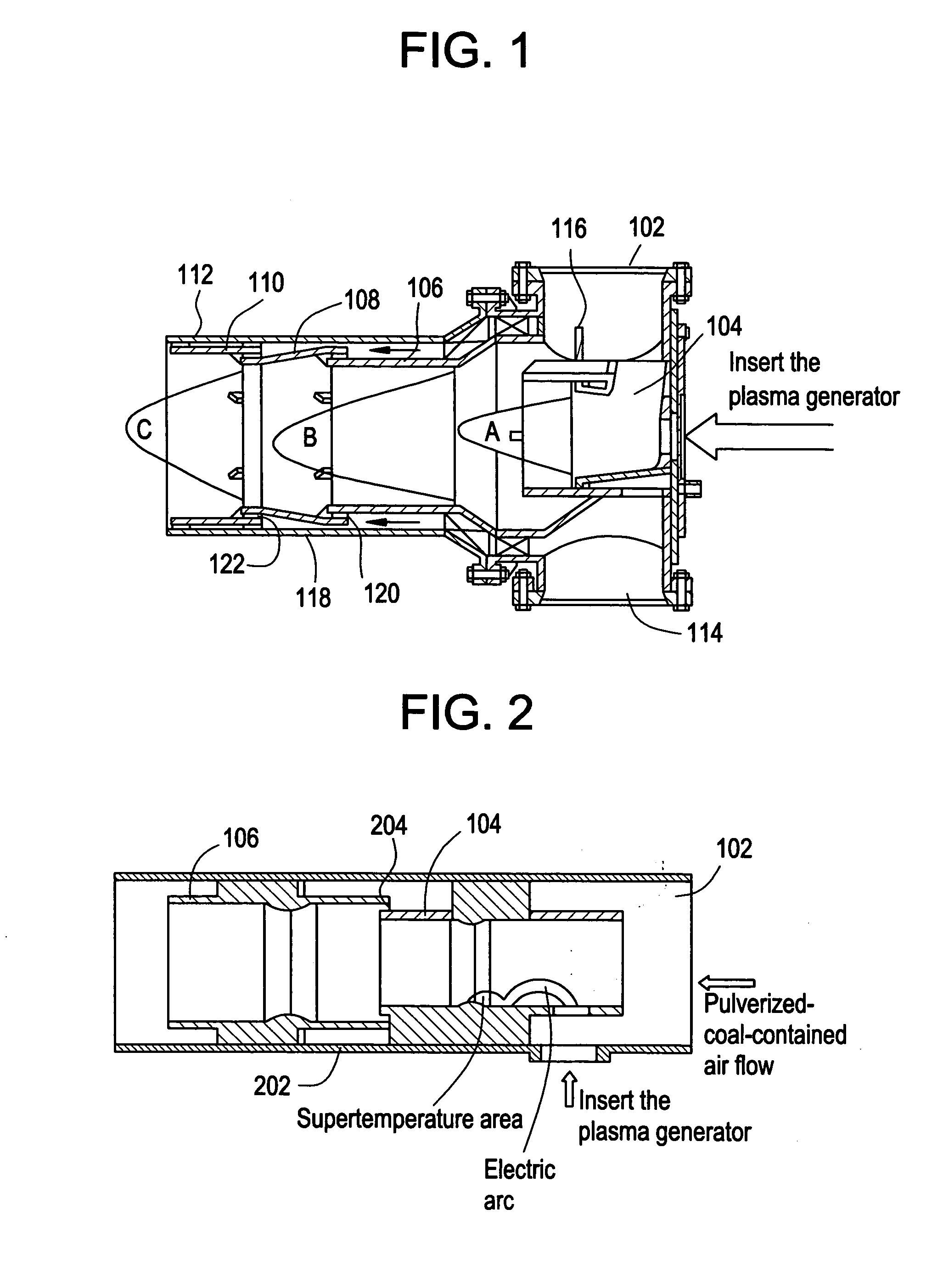

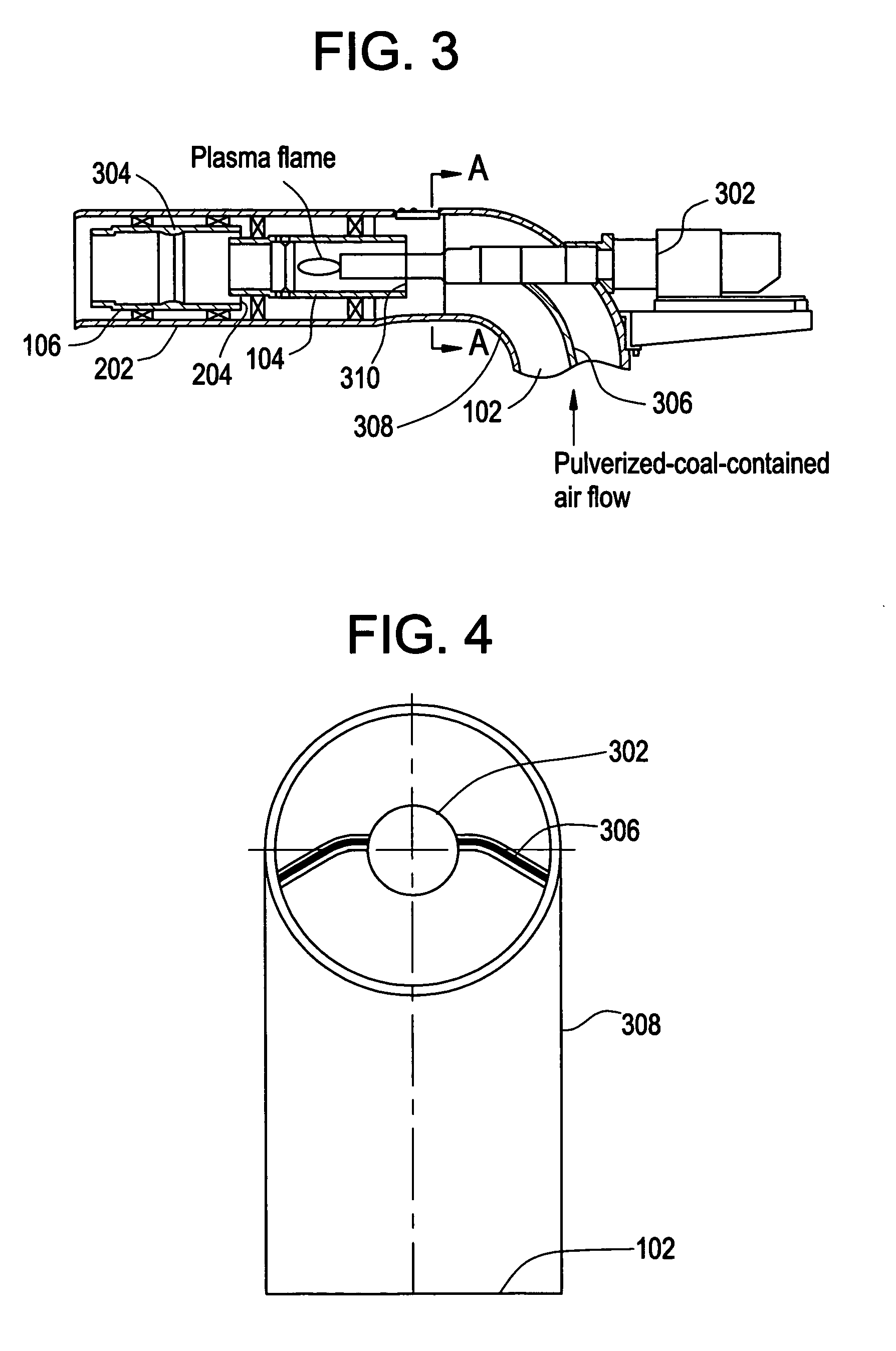

[0020]FIG. 3 illustrates the partial sectional view schematically illustrating the plasma ignition burner according to the first aspect of the present invention. To be concise, this figure also only illustrates the pulverized-coal-contained air flow inlet 102, the first stage burner barrel 104 and the second stage burner barrel 106 similar to those in FIG. 2. Since the structure of the multi-stage structure of burner barrels has been described as above, it is not repeated here. What should be noted is that, as described in the part “BACKGRAOUND ART”, the stage number of the burner barrels into which the pulverized-coal-contained air flow enters, the stage number of the burner barrel into which the air directly enters and the total stage number of the burner barrels are not limited and can be determined depending on power request and the size of the space. The total number of the stages may be from two stages to three, four or more stages and the air flow as shown in FIG. 1 may be al...

second embodiment

[0033]In addition, for those old type burners which have been amounted on the spot, a convenient and low-cost reconstructing means can be provided by using the above-described second embodiment, so that the present invention can be applied.

[0034]For example, the whirling type pulverized coal burner adopted by many burning coal firepower electricity generator has a central barrel and the mixture of the pulverized coal and the air is sent into the hearth from the external of the central barrel. For example, LNASB axial swirl pulverized coal burner (refer to FIG. 6) developed by Mitsui Babcock Energy Ltd in the eighties of 20th century adopts this kind of structure. In this structure, the oil gun is inserted into the central barrel 602 and the pulverized coal sent into the hearth from the external of the central barrel is ignited by the flame of the oil gun. For this kind of burner, if the reconstruction of the plasma ignition technology is to be directly performed, it is necessary to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com