Shim for a turbomachine blade

a technology of turbomachine blades and shims, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of blade bearing surfaces or disk wear phenomena, and achieve the effect of preventing or limiting wear phenomena and increasing the lifetime of blade roots and disks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

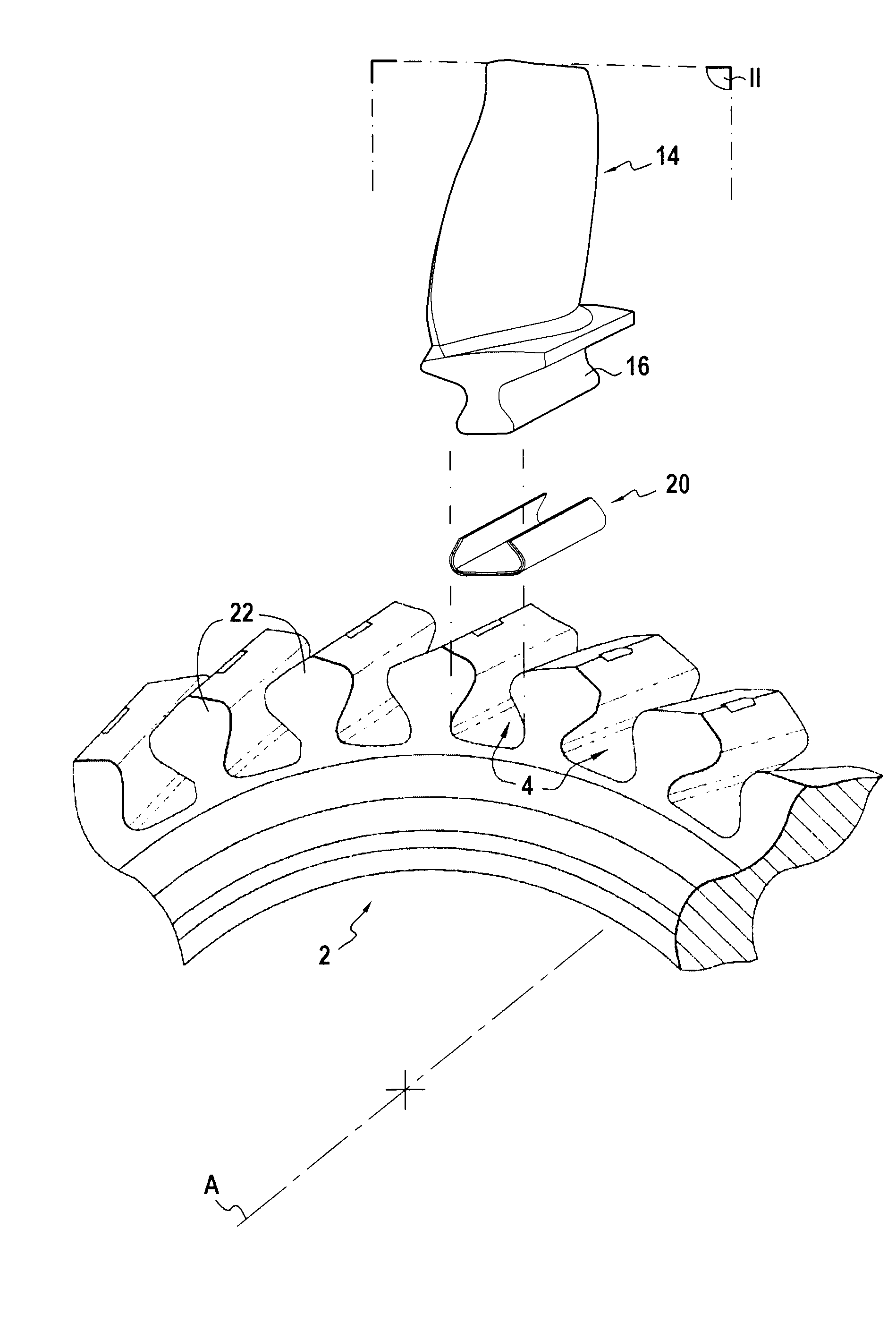

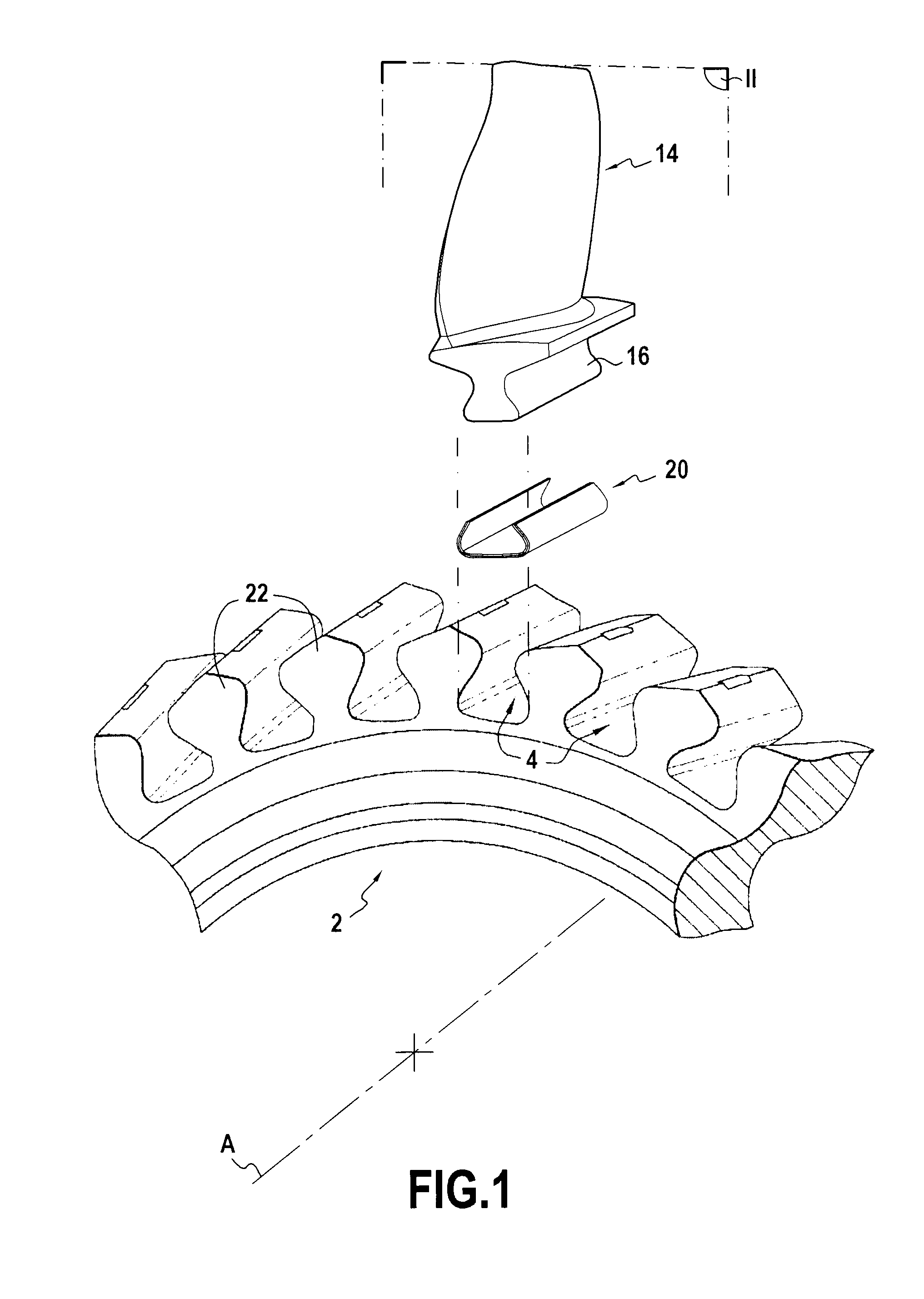

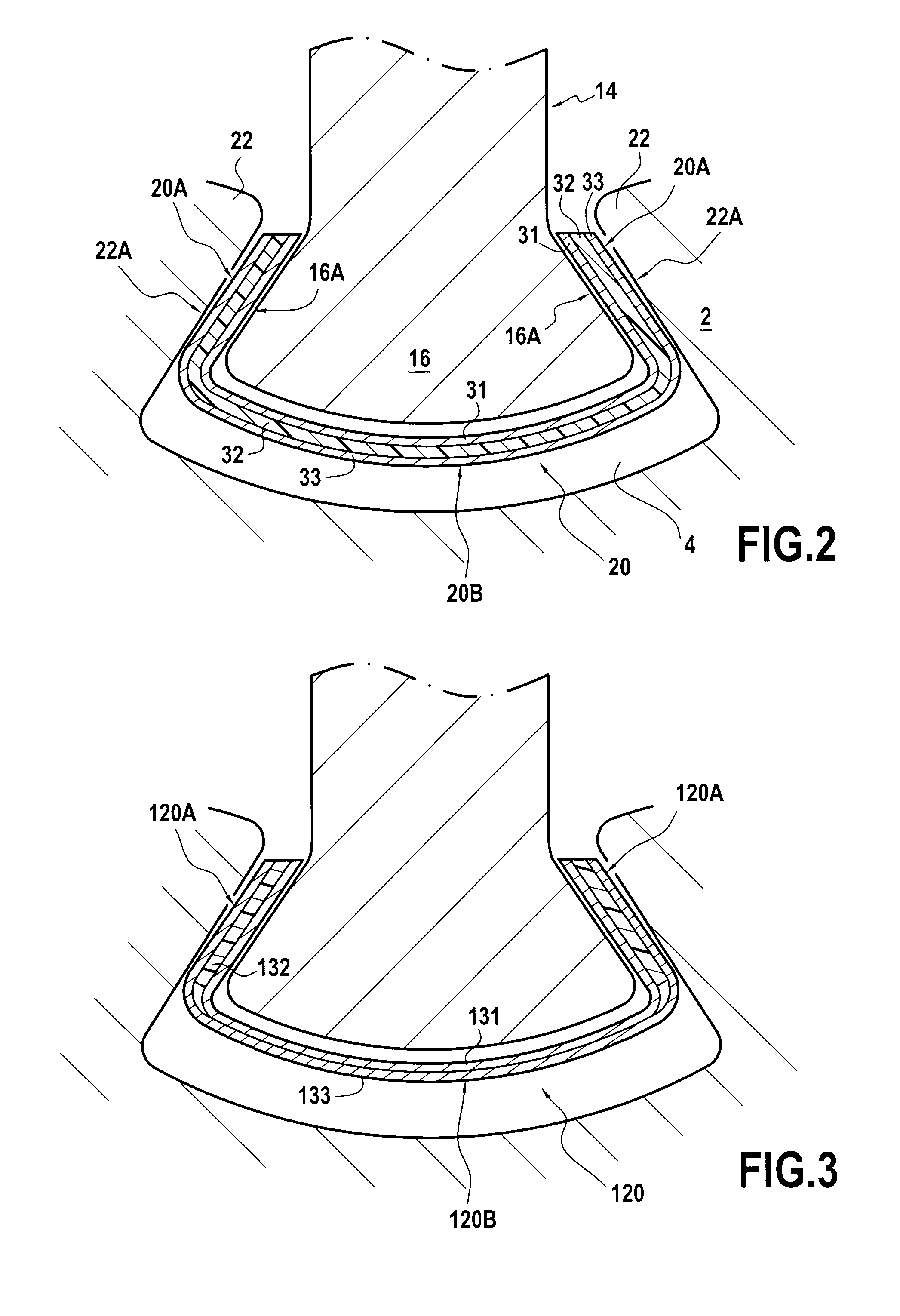

[0029]FIGS. 1 and 2 show: a rotor disk 2 having numerous grooves or “slots”4 in its periphery that define housings, each suitable for receiving the root 16 of a blade 14, the root 16 being surrounded by a shim 20. The blade root 16 and the fan disk 2 are made out of titanium alloy, for example.

[0030]It should be observed that assemblies also exist (not shown) that have a spacer placed between the blade root 16 and the bottom of the slot 4.

[0031]When the disk 2 is set into rotation, the blades 14 are subjected to centrifugal forces, and the bearing surfaces 16A on the blade root 16 become pressed against bearing surfaces 22A of the disk 2. In the example shown, the surfaces 16A constitute the flanks of the blade root 16, while the surfaces 22A constitute the bottom faces of the lip-shaped portions 22 of the disk that extend on either side of the outer opening of each slot 4.

[0032]The shim 20 comprises two side branches 20A for coming against the bearing surfaces 16A of the blade root...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com