Stabilized lithium metal powder for li-ion application, composition and process

a lithium metal powder and lithium metal technology, applied in the direction of electrochemical generators, cell components, transportation and packaging, etc., can solve the problems of limiting the choice of cathode active materials, raising safety concerns, and unsafe conditions in the battery, so as to improve the stability of air and solvent, improve the storage life, and improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

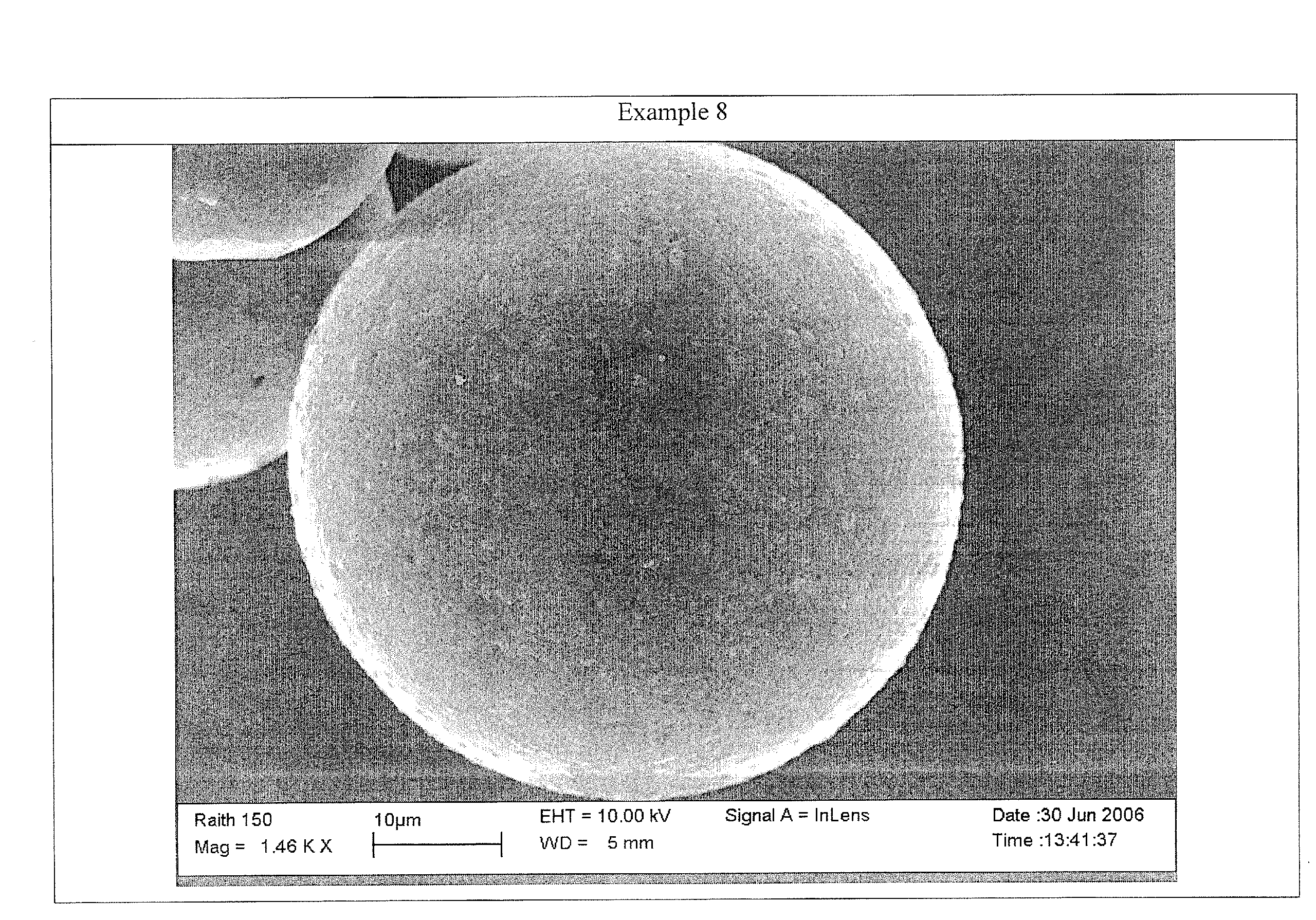

[0034]A lithium dispersion (47.30 g) passivated with CO2 gas in oil (27.5%) containing 13.01 g of lithium with a medium particle size of 45 micron was charged into 120 ml hastelloy can equipped with a 1″ Teflon coated stir bar. 1.3 g of PEO (Polyox WSRN80) dry powder was also added to the can. The solution was heated from ambient to 75° C. at a rate of 5° C. / min and held for 10 minutes. The sample was further heated from 75° C. to 175° C. at 5° C. / min and held for one hour. This mixture was continuously stirred at 200 rpm during the heating phase. Sample was allowed to cool to room temperature and transferred to the storage bottle. Further, lithium dispersion was filtered and washed three times with hexane in an enclosed, sintered glass filter funnel and twice with n-pentane to remove the hydrocarbon oil medium. The funnel was heated with a heat gun to remove traces of the solvents and the resulting free-flowing powder was transferred to tightly capped storage bottles.

example 2

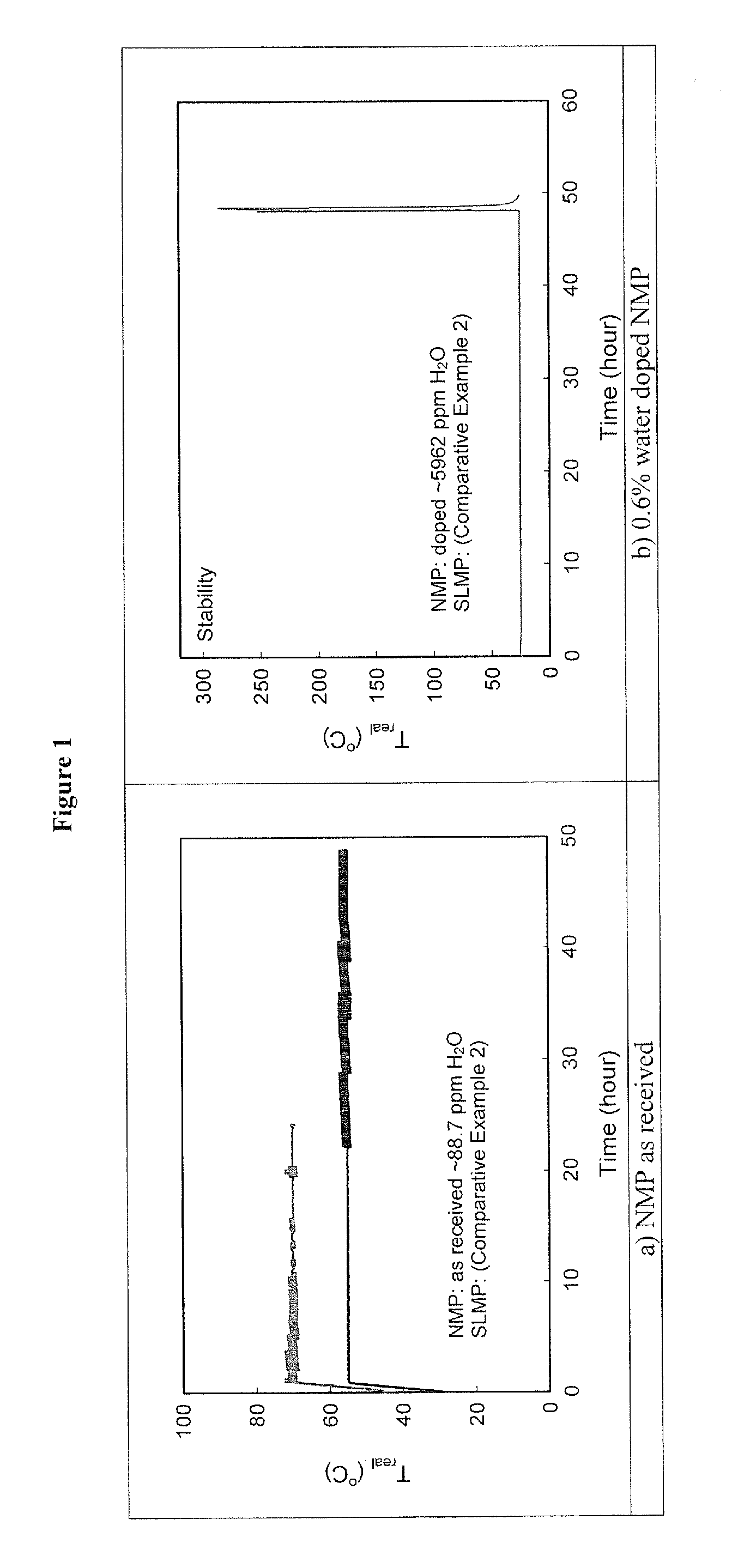

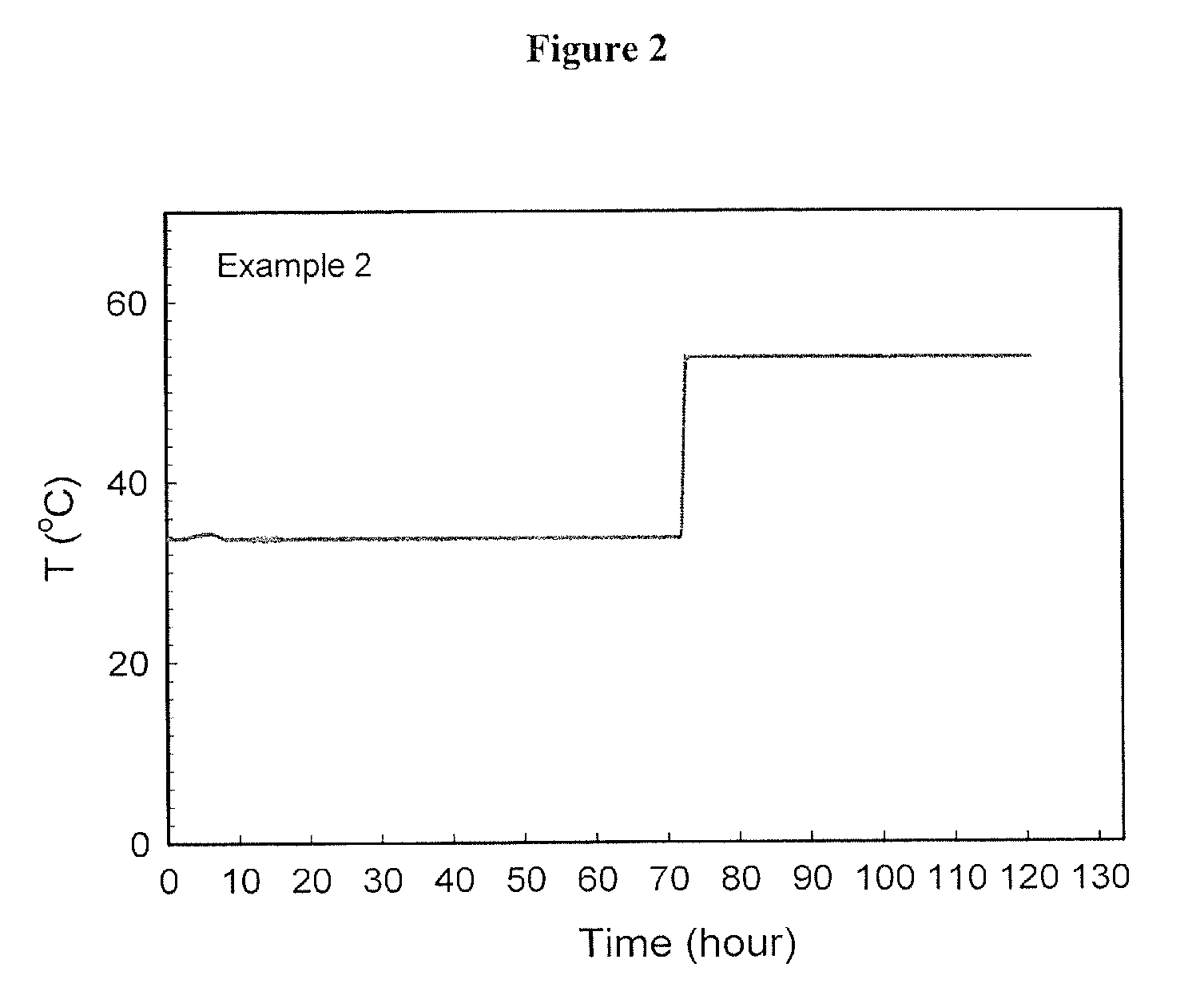

[0035]A lithium dispersion (45.00 g) passivated with CO2 gas in oil (27.5.%) containing 12.37 g of lithium with a medium particle size of 45 micron was charged into 120 ml hastelloy can equipped with a 1″ Teflon coated stir bar. 1.2 g of PEO (Polyox WSRN80) dry powder was also added to the can. The solution was heated from ambient to 75° C. at a rate of 5° C. / min and held for 10 minutes. The sample was further heated from 75° C. to 175° C. at 5° C. / min and held for one hour. Finally the sample was heated from 175° C. to 200° C. at 20° C. / min. This mixture was continuously stirred at 200 rpm during the heating phase. Sample was allowed to cool to room temperature and transferred to a storage bottle. Further, lithium dispersion was filtered and washed three times with hexane and twice with n-pentane in an enclosed, sintered glass filter funnel to remove the hydrocarbon oil medium. The funnel was heated with a heat gun to remove traces of the solvents and the resulting free-flowing pow...

example 3

[0036]A lithium dispersion (44.00 g) passivated with CO2 gas in oil (27.5%) containing 12.10 g of lithium with a medium particle size of 45 micron was charged into 120 ml hastelloy can equipped with a 1″ Teflon coated stir bar. The solution was heated to 75° C. and 1.2 ml of BYK-P 104 S (BYK Chemie) was added to the lithium dispersion. This mixture was continuously stirred at 200 rpm for one hour. Sample was allowed to cool to room temperature and transferred to a storage bottle. Further, lithium dispersion was filtered and washed three times with hexane and twice with n-pentane in an enclosed, sintered glass filter funnel to remove the hydrocarbon oil medium. The funnel was heated with a heat gun to remove traces of the solvents and the resulting free-flowing powder was transferred to tightly capped storage bottles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com