Electric vacuum head

a vacuum head and electric technology, applied in the field of electric vacuum heads, can solve the problems of insufficient fan in the motor to pass away waste heat, inability to achieve good sealing, etc., and achieve the effect of maximizing the amount of air for the vacuuming effect, reducing the cost of operation, and ensuring the vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

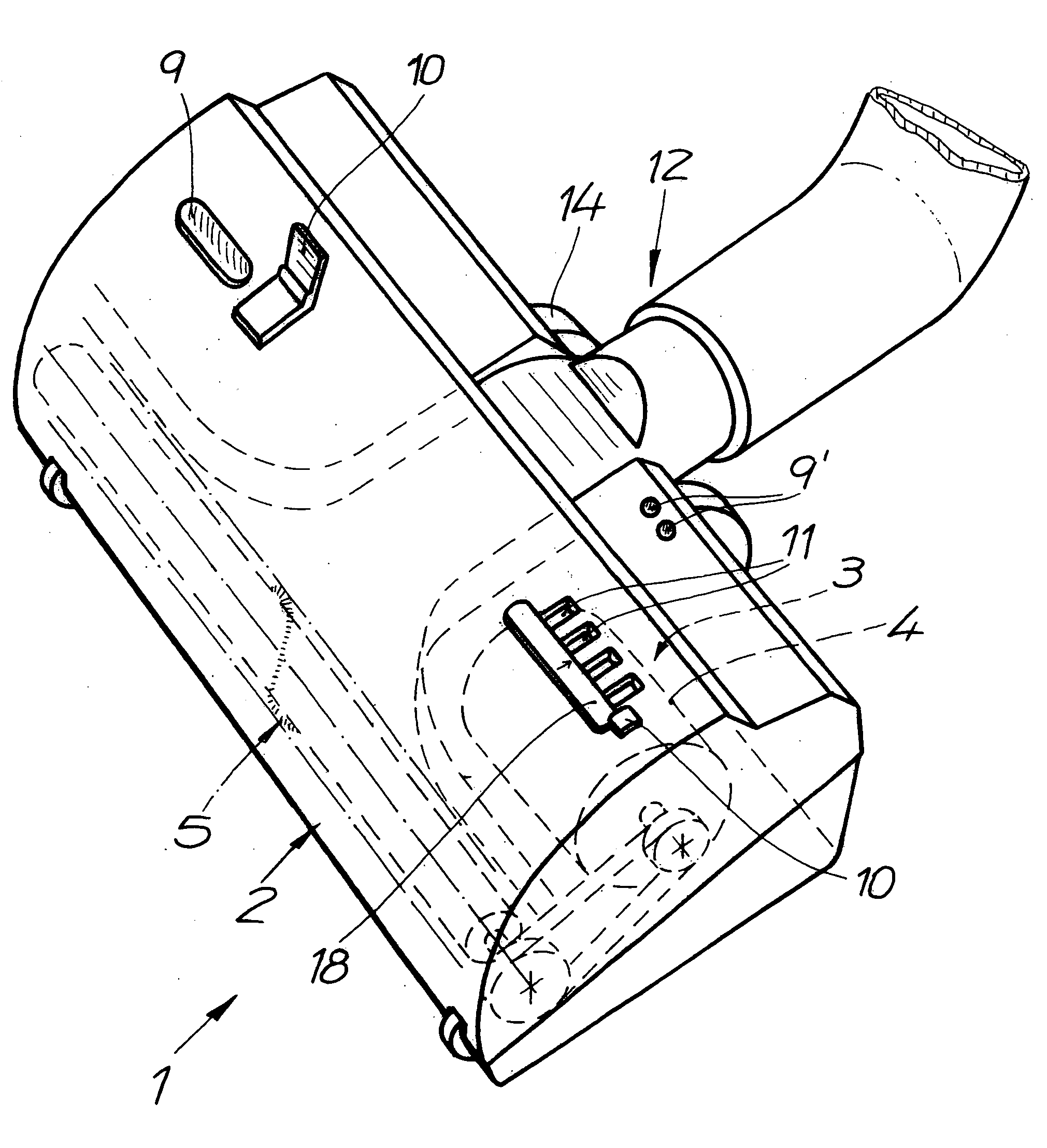

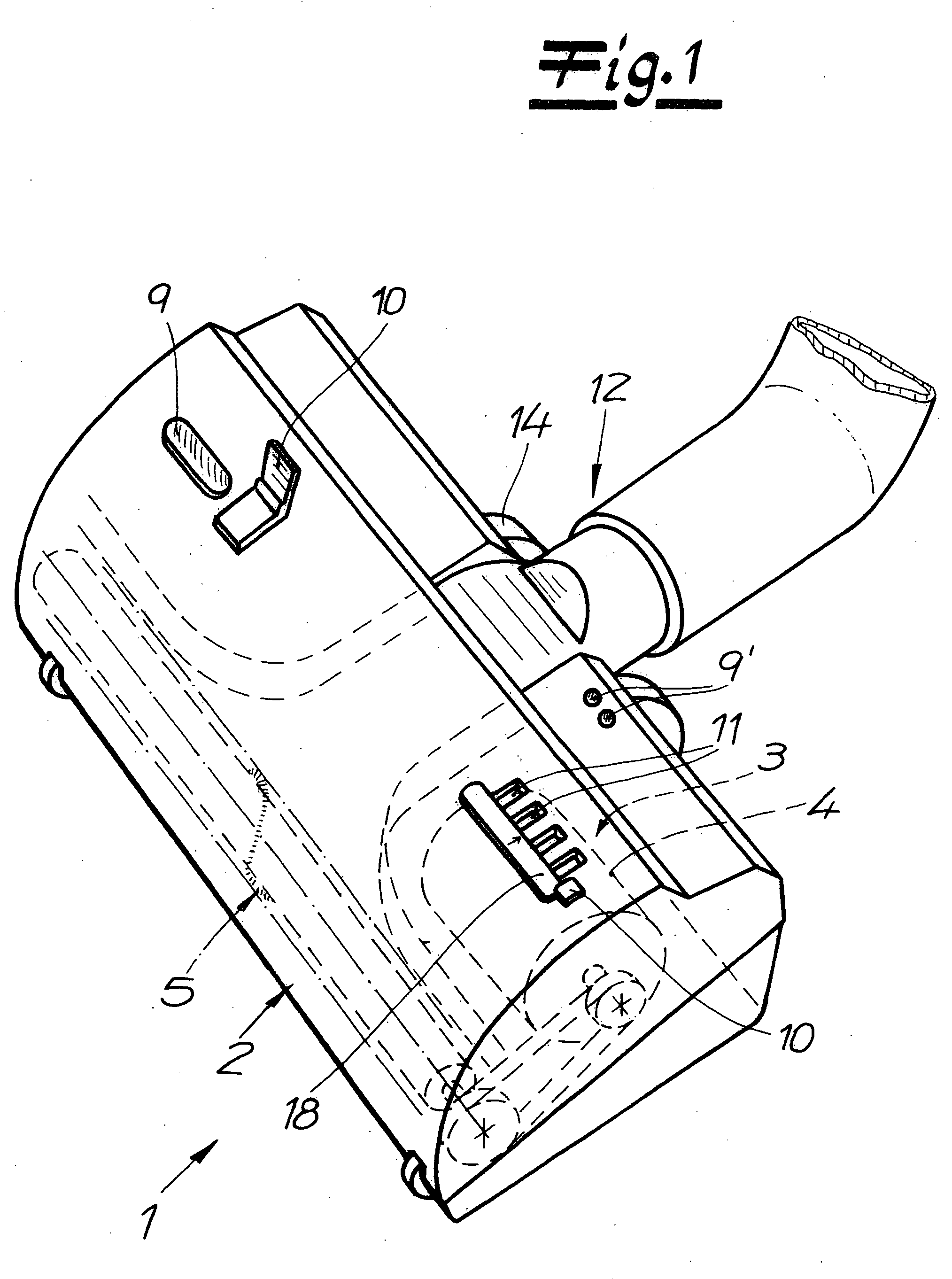

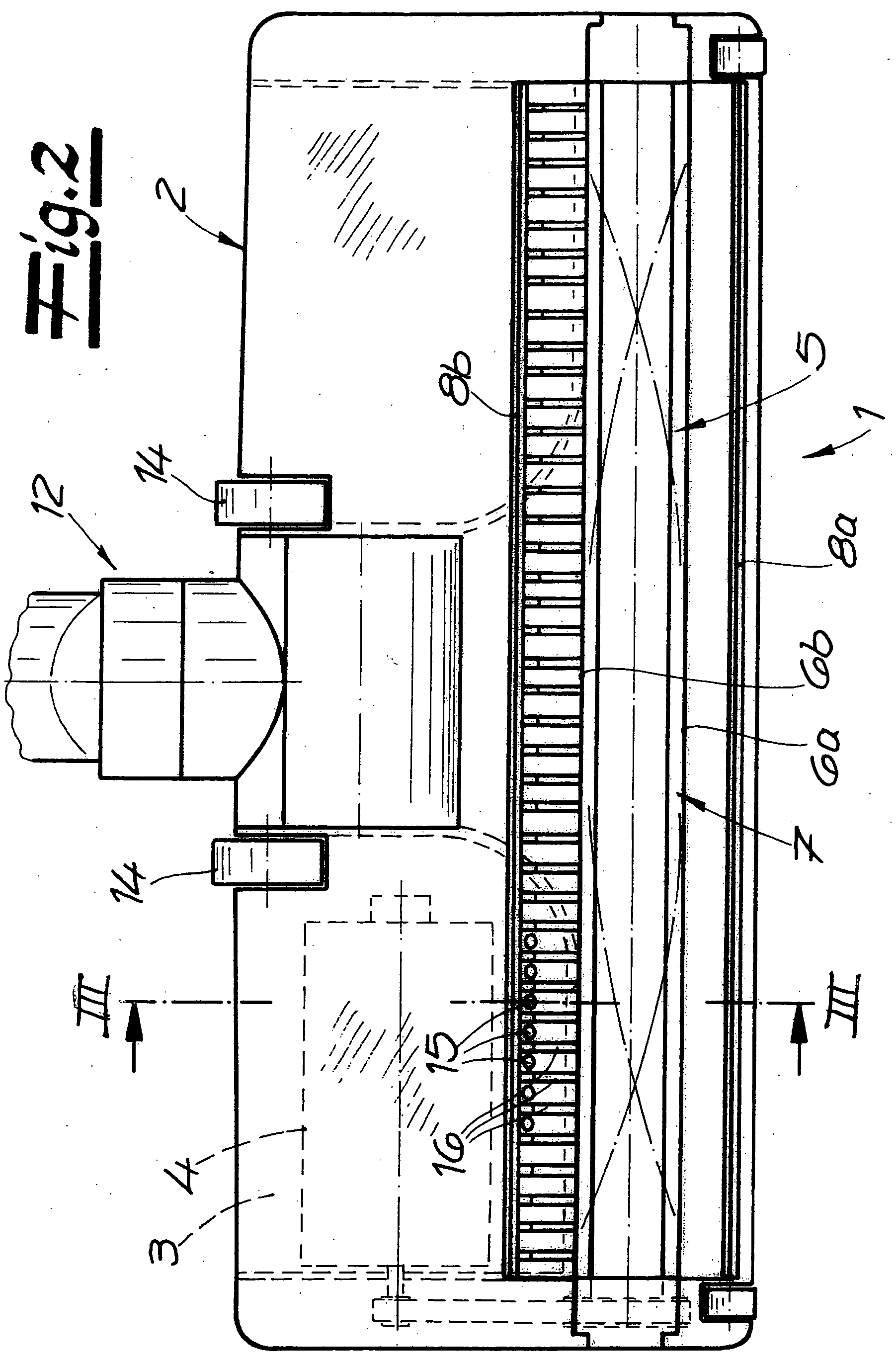

[0026]Referring now in detail to the drawings, FIG. 1 shows an electric vacuum head 1 according to the invention, in a perspective view. The electric vacuum head 1 has a housing 2, in which an electric motor 4 for driving a cleaning device 5 configured as a brush roller is disposed in a motor chamber 3. The bristles of the brush roller pass through a vacuum mouth 7 that runs on the underside of housing 2, over the width of the electric vacuum head 1, and is delimited by a front vacuum mouth edge 6a and a rear vacuum mouth edge 6b. Sealing lips 8a, 8b are disposed in front of front vacuum mouth edge 6a and behind rear vacuum mouth edge 6b, in the movement direction. In addition to display elements 9, 9′, and operating elements 10, air entry openings 11 of motor chamber 3, for passage of air to cool electric motor 4, can be seen at the top of the housing 2. Electric vacuum head 1 has a vacuum connector 12 for a connection to a suction tube 13 or a vacuum cleaner housing, configured as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com