Method for manufacturing magnetic head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

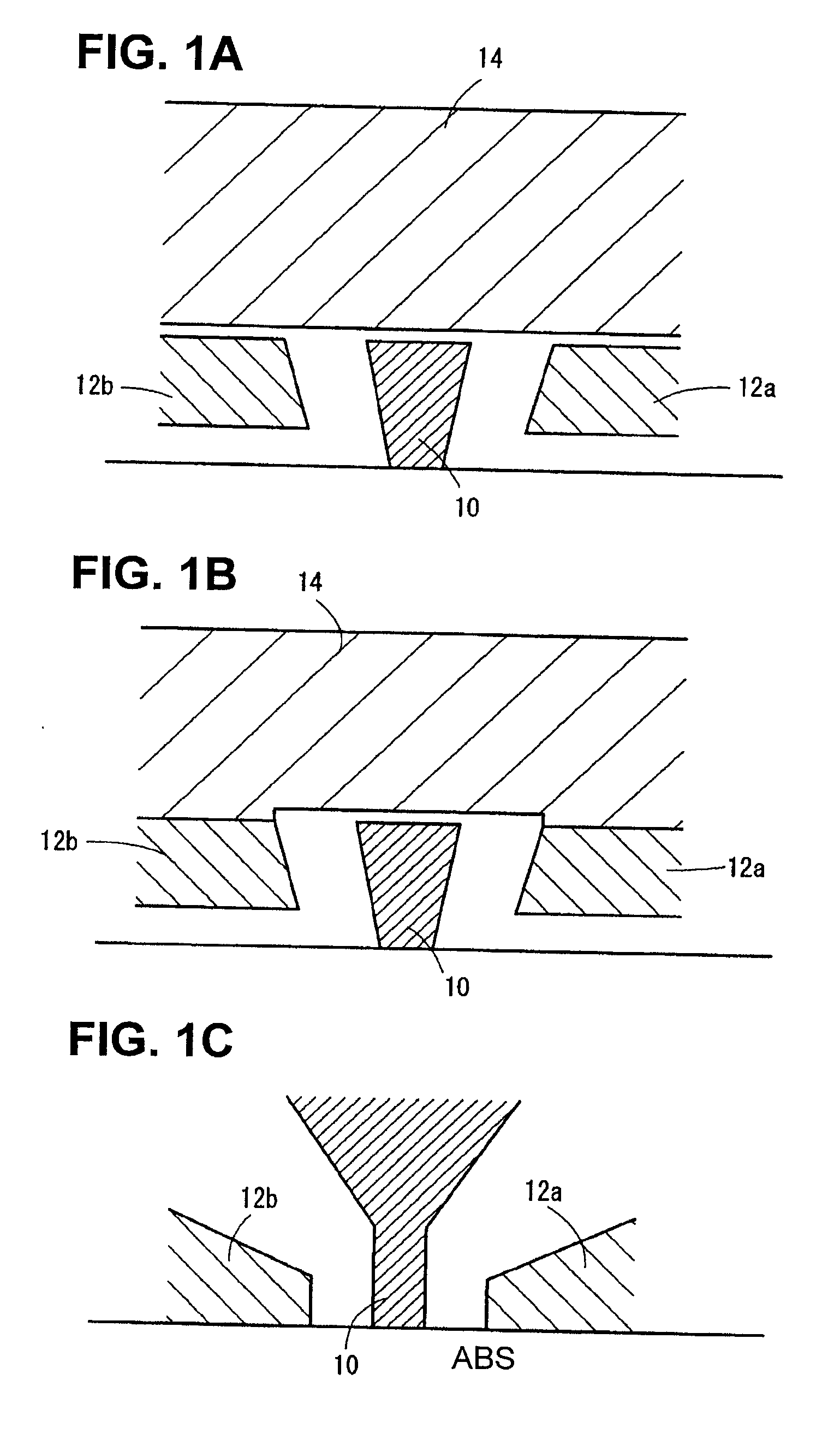

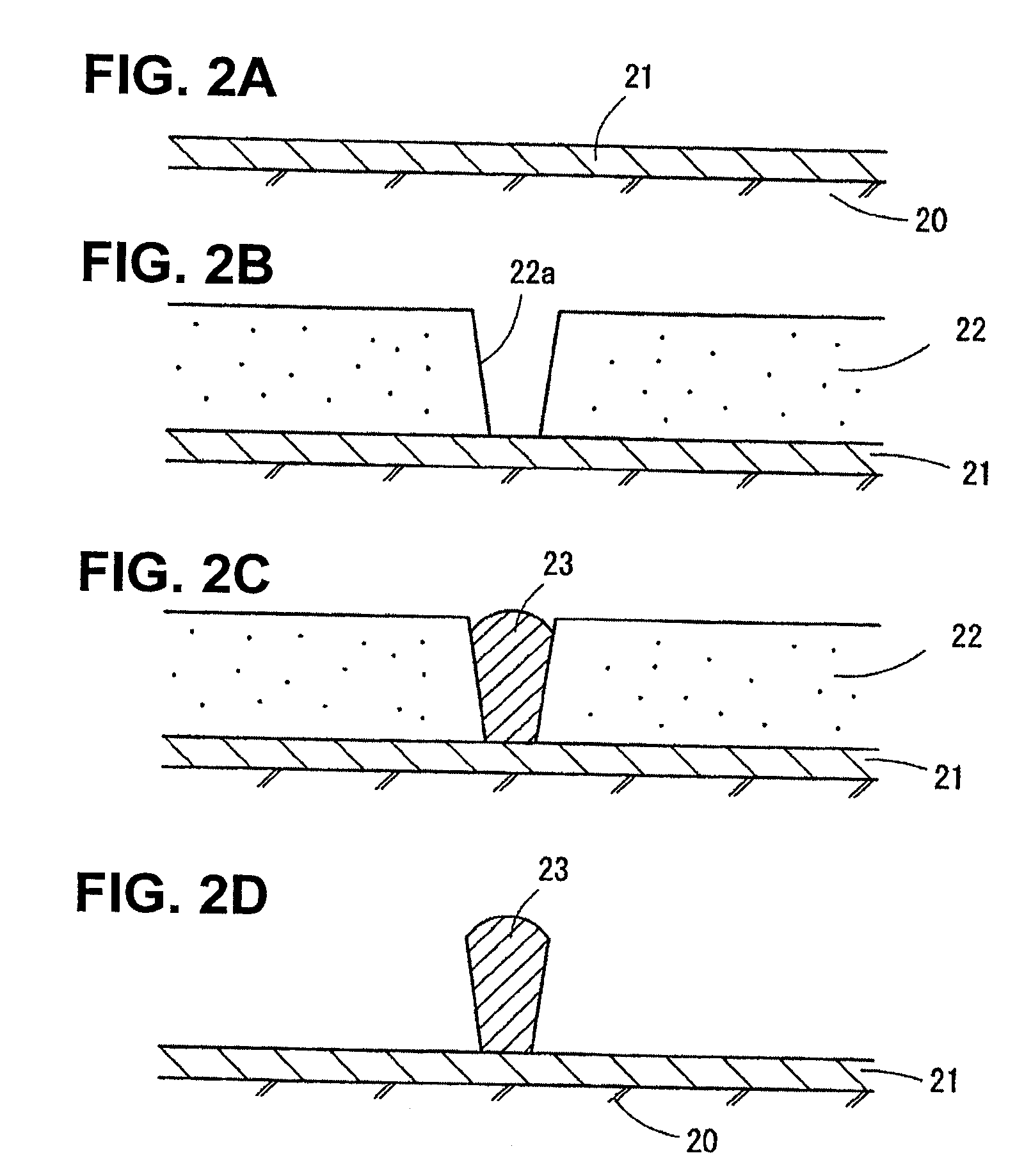

[0023]FIGS. 2A to 5F are representations of a method for manufacturing a magnetic head according to a first embodiment, showing steps for forming a main magnetic pole of a perpendicular magnetic head and side shields disposed with the main magnetic pole in between.

Forming a First Magnetic Layer

[0024]FIGS. 2A to 2D are representation of a process up to the step of forming a first magnetic layer 23 intended for the main magnetic pole on the surface of a substrate. The substrate has a read head including a read element.

[0025]FIG. 2A shows the state in which a plating seed layer 21 has been formed of, for example, ruthenium on a base layer 20 formed on the surface of the substrate by sputtering.

[0026]Then, a resist pattern 22 is formed on the surface of the plating seed layer 21 (FIG. 2B). For forming the resist pattern 22, the surface of the plating seed layer 21 is coated with a resist layer. The resist layer is exposed to light corresponding to a pattern of the main magnetic poles to...

second embodiment

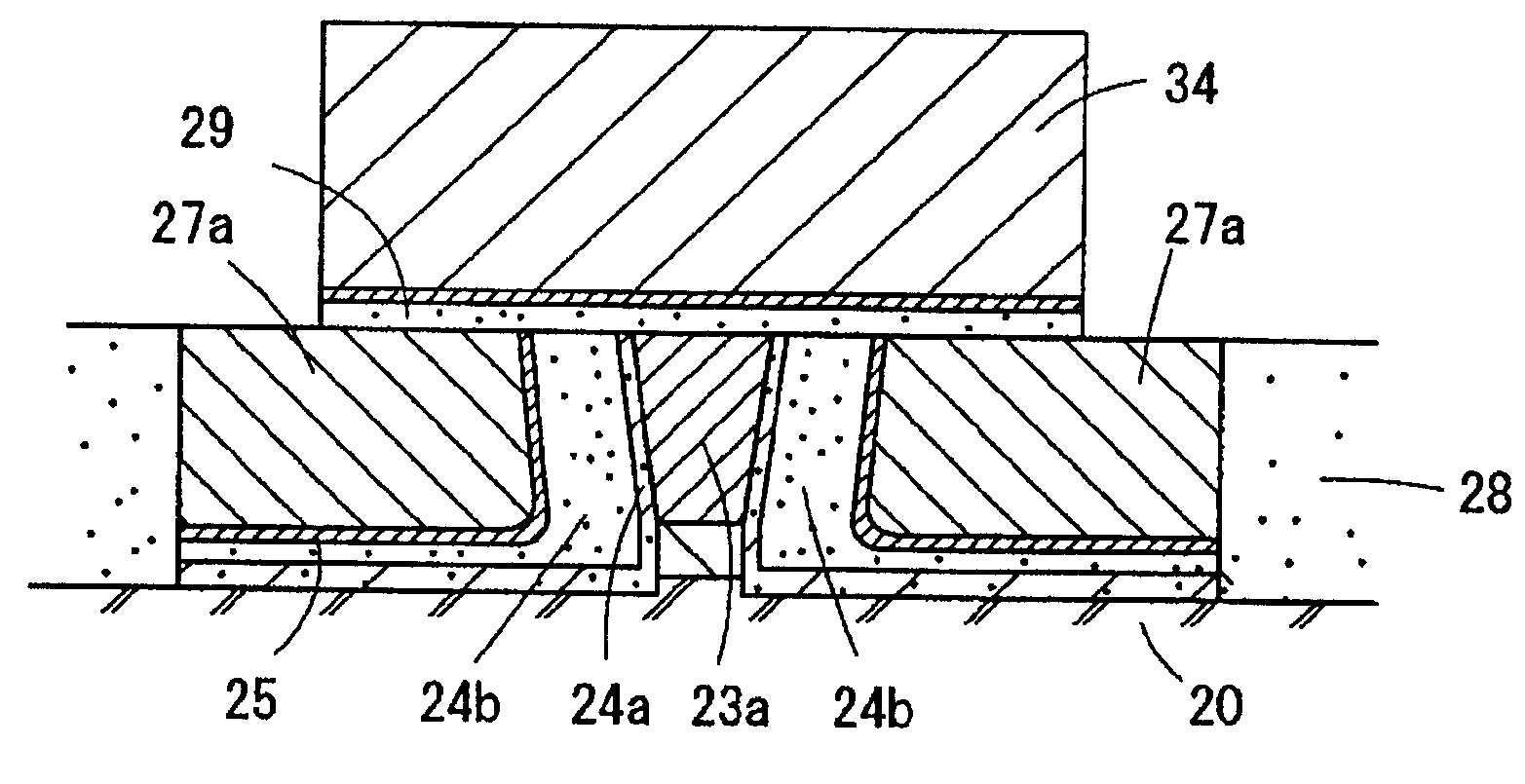

[0068]In the first embodiment, a side gap layer is formed by sputtering a single stopper material after forming the first magnetic layer 23, as shown in FIGS. 3A and 3B, so that the side gap layer can serve as a polishing stopper. In the magnetic head manufacturing method shown in FIGS. 7A to 7F, the stopper layer and the side gap layer are formed of respective materials.

[0069]FIG. 7A shows the state in which a stopper layer 24a has been formed to a thickness sufficient to act as a polishing stopper on the top of the first magnetic layer 23. The stopper layer 24a is formed of a stopper material, such as Ta, by sputtering. The sputtering step deposits the stopper material on the top and side surfaces of the first magnetic layer 23. The thickness of the stopper layer 24a on the sides of the first magnetic layer 23 is smaller than that on the top of the first magnetic layer 23. The stopper layer 24a on the side surfaces of the first magnetic layer 23 defines part of the side gap layer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Magnetism | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com