Semiconductor integrated circuits including grating coupler for optical communication and methods of forming the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

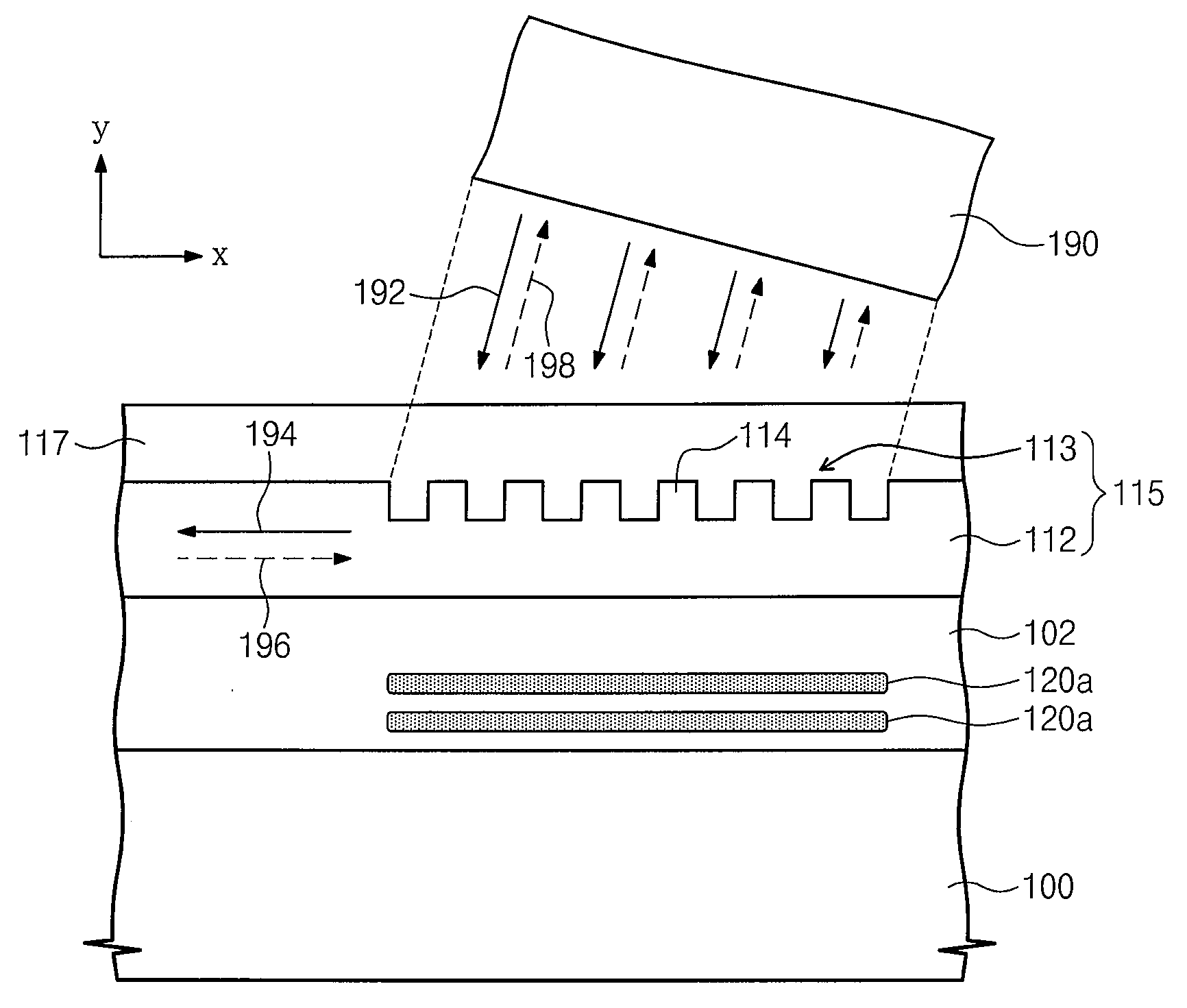

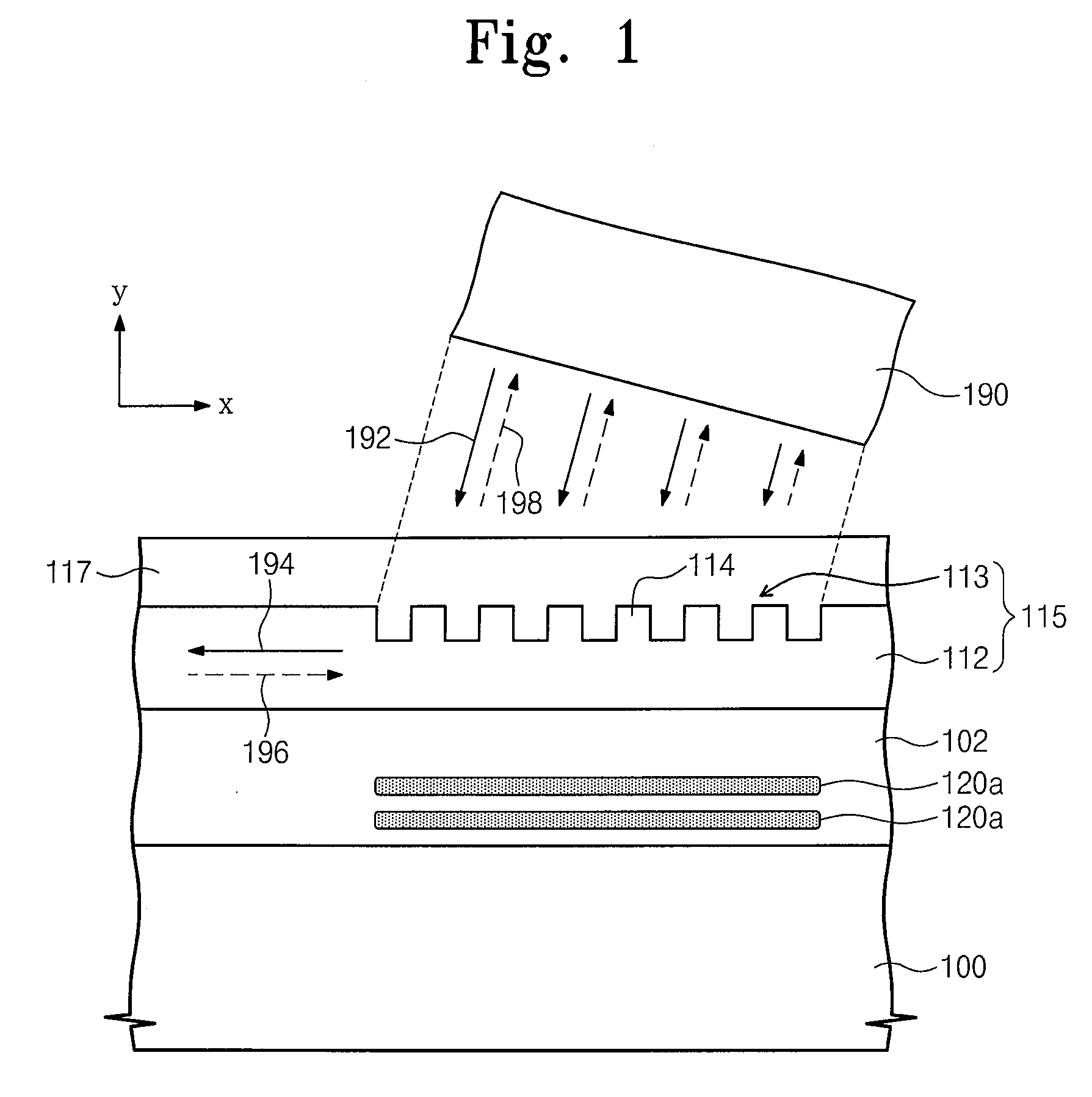

[0066]FIG. 1 is a sectional view of a semiconductor integrated circuit including a grating coupler according to one embodiment of the present invention.

[0067]Referring to FIG. 1, a cladding layer 102 is disposed on a semiconductor substrate 100. A grating coupler 115 is disposed on the cladding layer 102. The grating coupler 115 includes an optical waveguide 112 on the cladding layer 102 and a grating 113 on the optical waveguide 112. The optical waveguide 112 extends along one direction parallel to the top surface of the semiconductor substrate 100. The one direction corresponds to an x-axis direction of FIG. 1. A y-axis direction of FIG. 1 corresponds to a direction vertical to the top surface of the semiconductor substrate 100. The grating 113 includes a plurality of protrusions 114 spaced apart from each other in the one direction. The grating 113 is formed by the spaced protrusions 114. Both sidewalls of the protrusions 114 may be vertical to the top surface of the semiconducto...

second embodiment

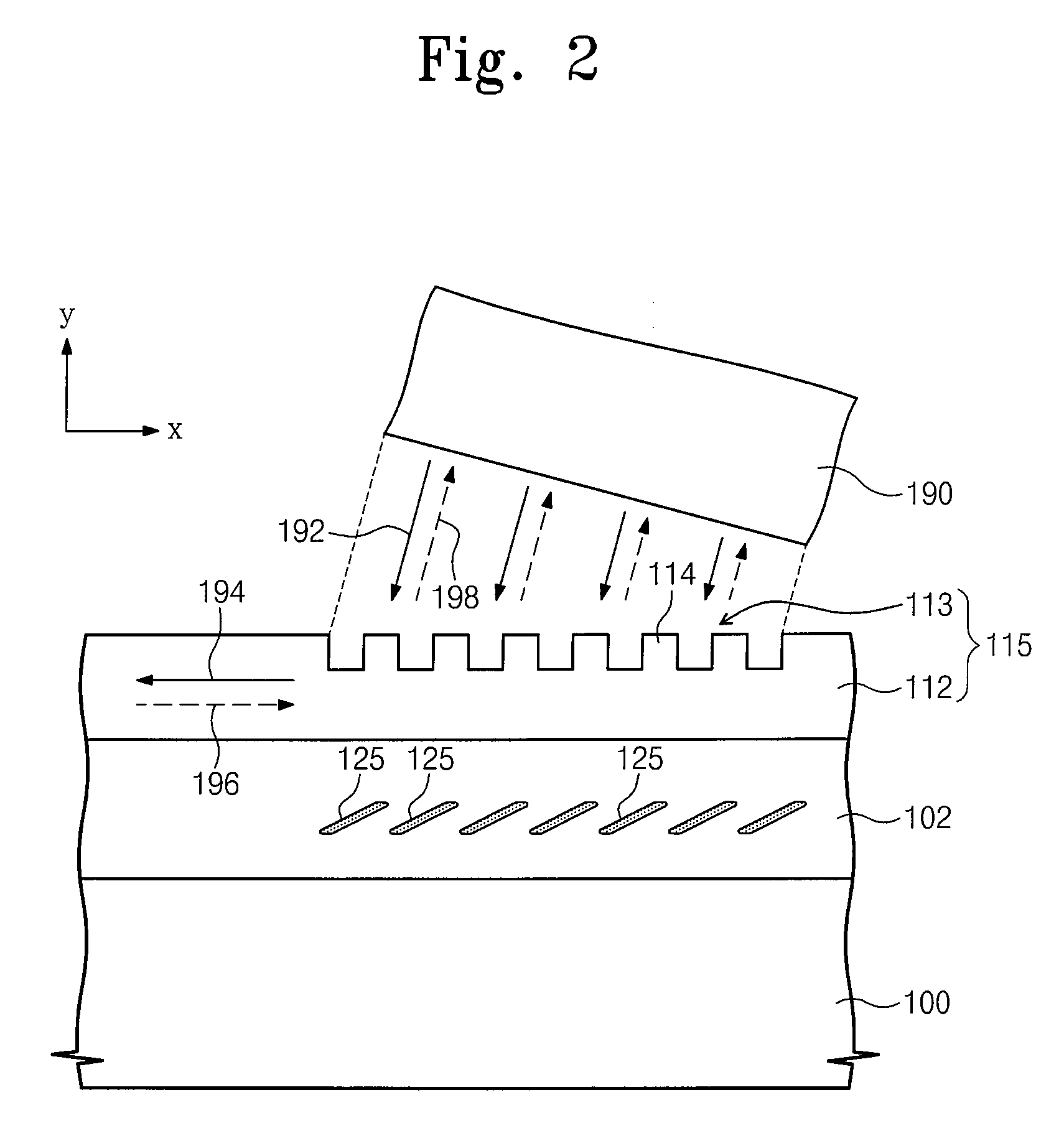

[0120]A semiconductor integrated circuit according to the second embodiment of the present invention includes a reflector in a semiconductor substrate. Like reference numerals refer to like elements throughout.

[0121]FIG. 9 is a sectional view of a semiconductor integrated circuit including a grating coupler according to another embodiment of the present invention.

[0122]Referring to FIG. 9, a cladding layer 102 is disposed on a semiconductor substrate 100, and a grating coupler 115 is disposed on the cladding layer 102. The grating coupler 115 includes an optical waveguide 112 on the cladding layer 102, and a grating 113 on the optical waveguide 112. The semiconductor substrate 100 is formed of at least one of silicon, germanium, silicon-germanium, and a chemical compound, as illustrated in the first embodiment.

[0123]At least one reflector 220a is disposed in the semiconductor substrate 100 below the grating 113. The reflector 220a is formed of a material having a different refractiv...

third embodiment

[0160]According to this embodiment, provided is another method of improving an optical coupling efficiency. Like reference numerals refer to like elements throughout.

[0161]FIGS. 19 through 23 are sectional views illustrating a method of forming a semiconductor integrated circuit including a grating coupler according to further another embodiment of the present invention.

[0162]Referring to FIG. 19, a first mask pattern 302a is formed on a substrate 110 including a semiconductor substrate 100, a cladding layer 102, and a semiconductor layer 105, which are sequentially stacked. The first mask pattern 300a includes a plurality of first openings 302a. The first openings 302a have the first widths. The first openings 302a are arranged and spaced apart from each other along one direction parallel to the top surface of the semiconductor substrate 100.

[0163]Using the first mask pattern 300a as an ion implantation mask, an ion implantation process of a first implantation energy is performed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com