Refrigerator and operating method of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

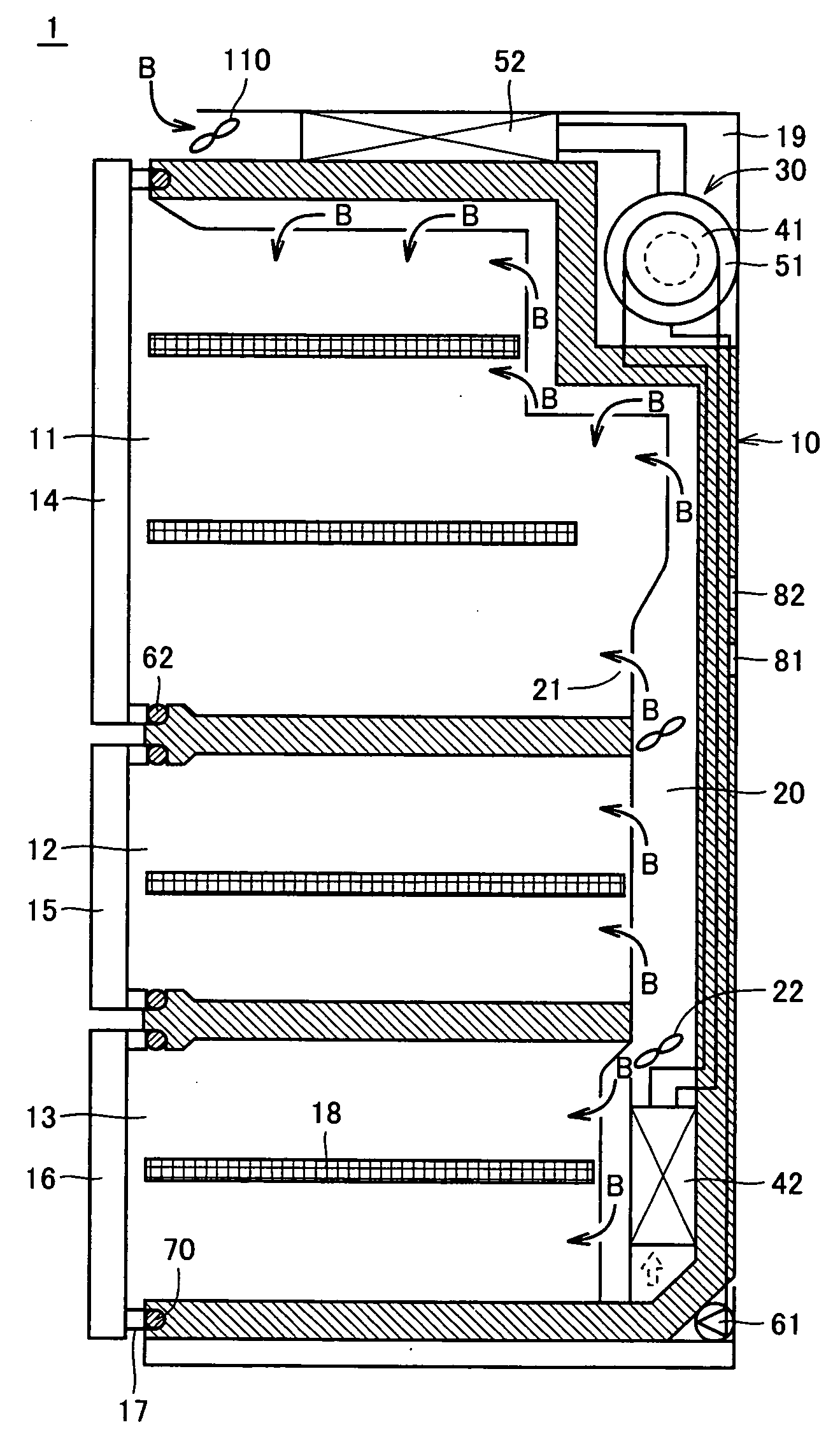

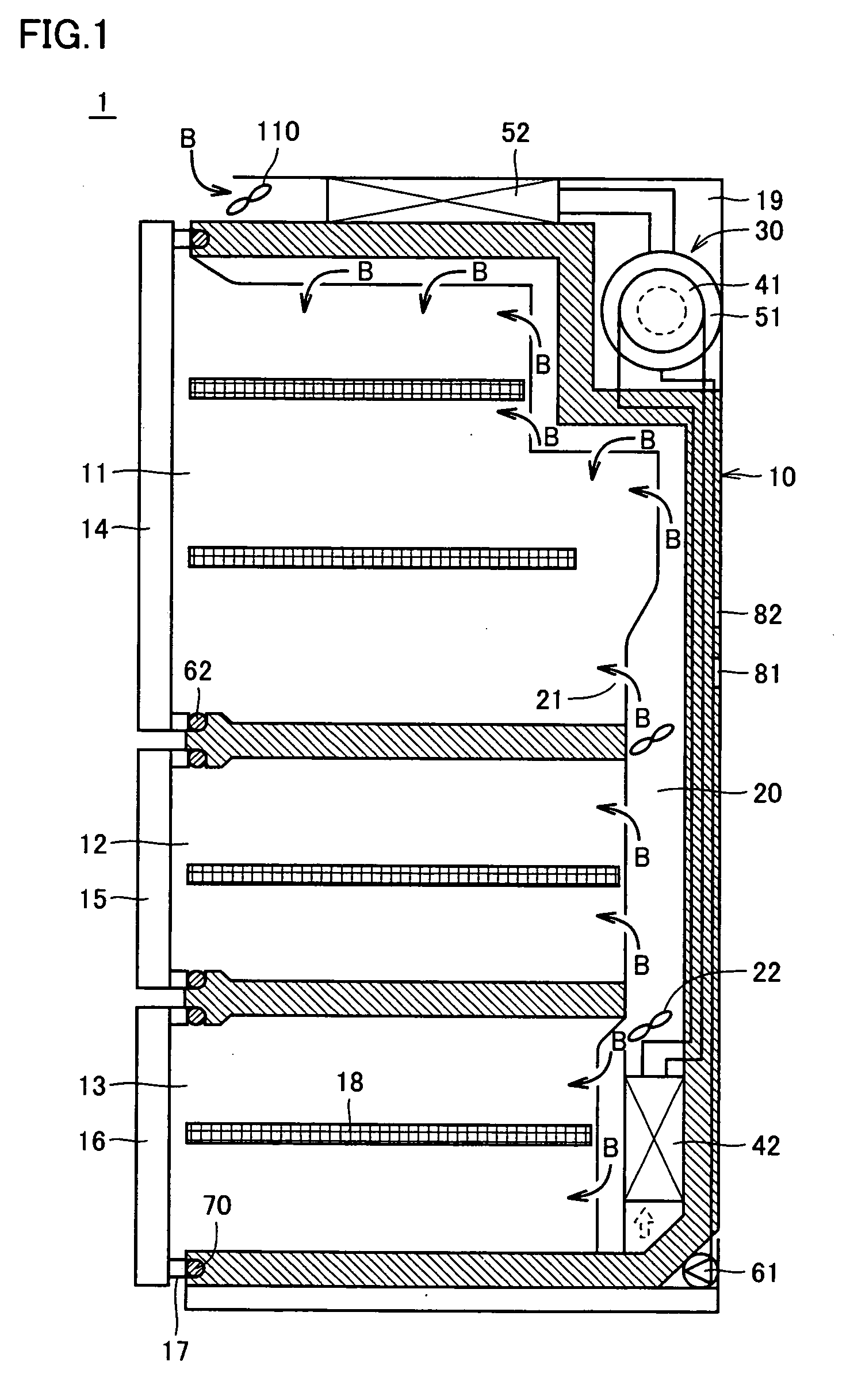

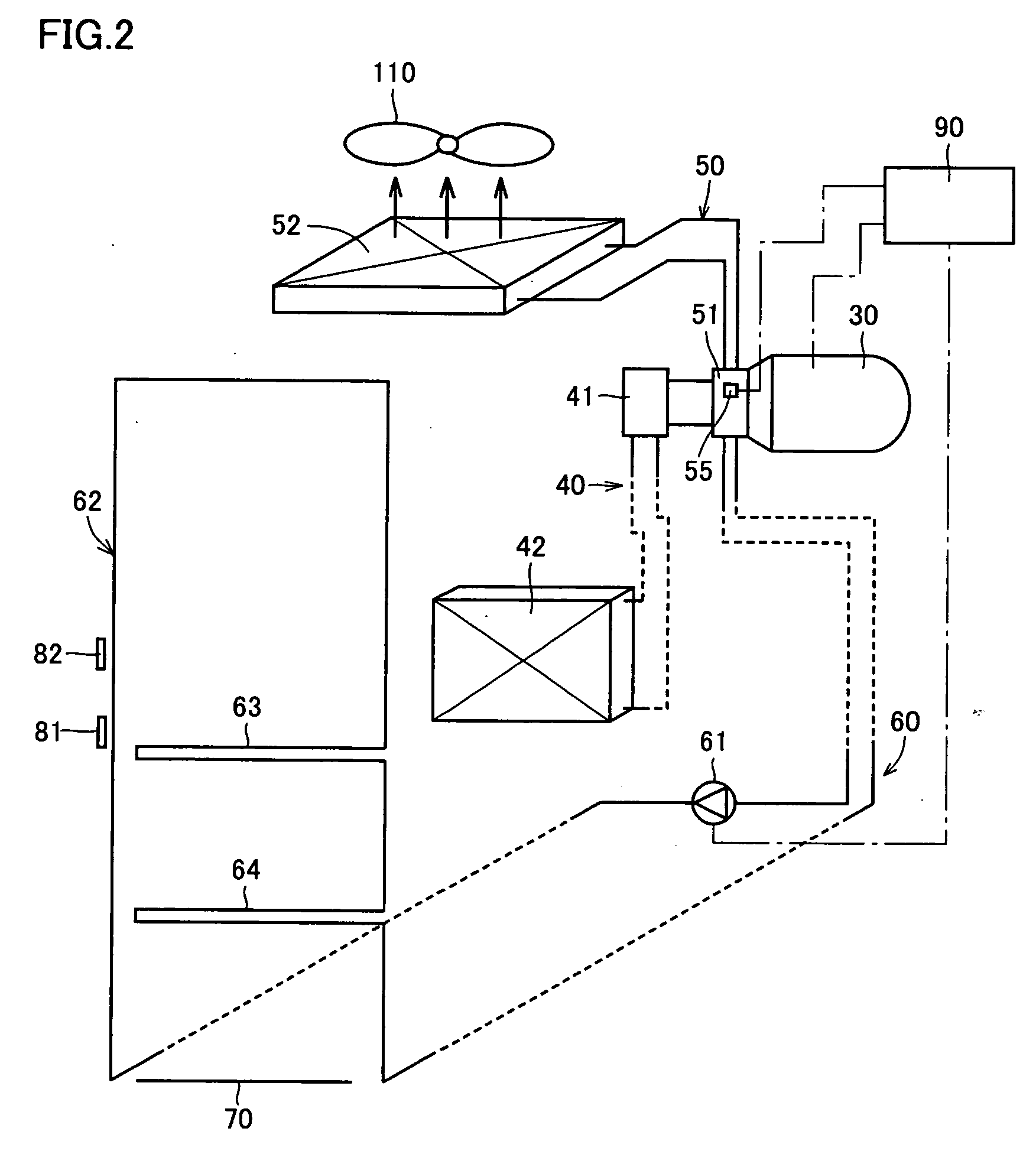

[0045]FIG. 1 is a cross section showing a schematic structure of a refrigerator of this embodiment. FIG. 2 shows a piping structure of the refrigerator of this embodiment. A refrigerator 1 is aimed at food storage, and includes a housing 10 of a heat-insulating structure. Three cooling rooms or compartments 11, 12 and 13 are formed at different levels in housing 10, respectively.

[0046]Cooling rooms 11, 12 and 13 have openings on a front side (left side in FIG. 1) of housing 10, respectively. These openings are closed by openable heat-insulating doors 14, 15 and 16, respectively. Heat-insulating doors 14, 15 and 16 are provided at their rear surfaces with packings 17 surrounding the openings of cooling rooms 11, 12 and 13, respectively. Shelves 18 suitable for types of foods to be stored are appropriately arranged in cooling rooms 11, 12 and 13.

[0047]A cooling system and a heat radiating system that include a Stirling refrigerating engine 30 as a main component are arranged over uppe...

second embodiment

[0088]A refrigerator of a second embodiment will now be described. The refrigerator of the second embodiment has substantially the same structure as that of the first embodiment already described. Therefore, the second embodiment will be described only in connection with portions different from those in the first embodiment.

[0089]In the refrigerator of the first embodiment, the additional and independent heating device is not employed, and the operation method of the refrigerating machine, i.e., freezing machine is changed to apply the pressure to the gas phase fluid flowing in high temperature side natural circulation circuit 50. Instead of these structure and method, the second embodiment employ heating means (e.g., heater) 100 that can apply heat to the gas phase fluid flowing through high temperature side natural circulation circuit 50, as specifically illustrated in FIG. 7. By operating this heating means 100, it is possible to heat and thereby pressurize the gas phase fluid fl...

third embodiment

[0100]A third embodiment of the invention will now be described. The refrigerator of this embodiment has substantially the same structure as the refrigerators of the first and second embodiments. Therefore, the following description will be given on only the portion of this embodiment different from the first and second embodiments.

[0101]The start processing performed by control device 90 of Stirling refrigerating engine 30 of the third embodiment will be described with reference to a flowchart of FIG. 9.

[0102]In the start processing, it is first determined in S21 whether a switch of the freezing machine, i.e., Stirling refrigerating engine 30 is on or not. When the start switch of the refrigerating machine is not on in S21, processing in S33 is executed. When the start switch of Stirling refrigerating engine 30 is on in S21, processing in S22 is executed. In S22, Stirling refrigerating engine 30 starts the operation. Then, in S23, the output of circulation pump 61 is set to 0 or P1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com