Eyeglass lens processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

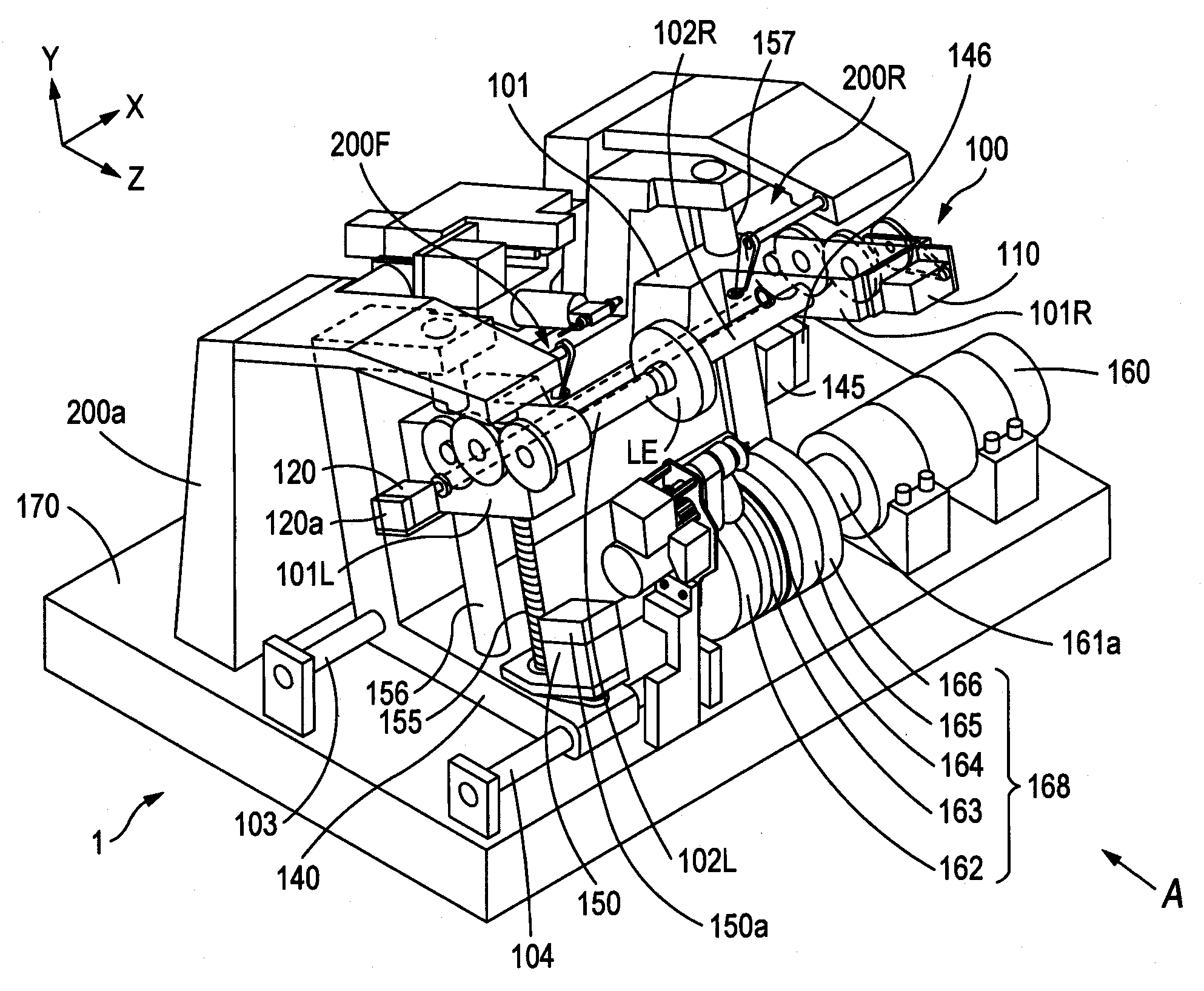

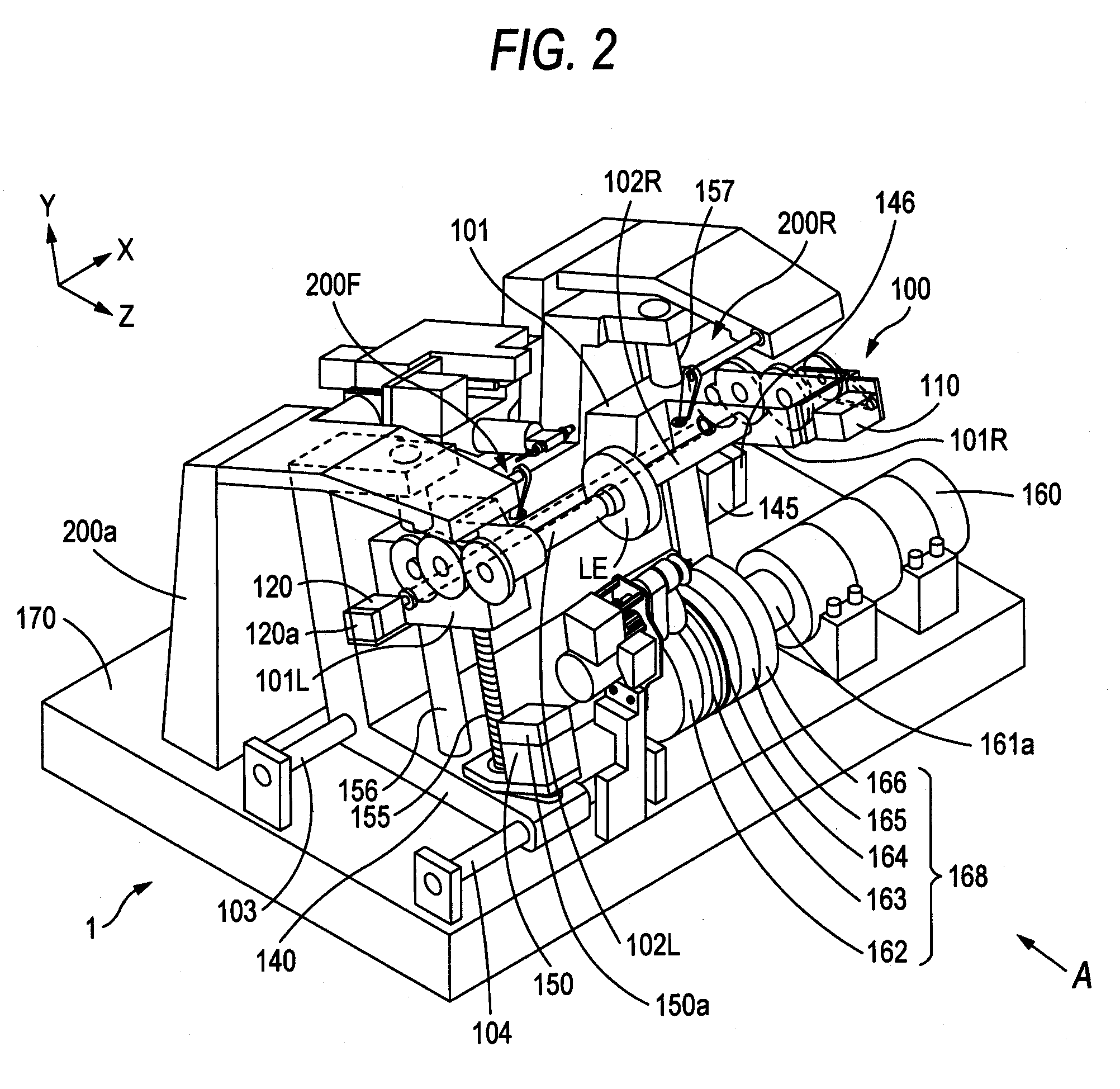

[0028]Hereinafter, an embodiment of the present invention is described based on the drawings. FIG. 2 is a schematic configuration diagram of a processing portion of an eyeglass lens processing apparatus according to the present invention.

[0029]A carriage portion 100 is mounted onto a base 170 of a processing apparatus main body 1. An eyeglass lens LE to be processed is held (chucked) by lens chuck shafts (lens rotating shafts) 102L and 102R of a carriage 101, and a peripheral edge of the lens is pressed and processed by a grindstone group 168 coaxially attached to a grindstone spindle 161a. The grindstone group 168 includes a roughing grindstone 162 for glass, a high curve bevel-finishing (beveling) grindstone 163 having a bevel slope to form a bevel in a high curve lens, a finishing grindstone 164 having a V groove (bevel groove) VG to form a bevel in a low curve lens and a flat processing surface, a flat polishing grindstone 165, and a roughing grindstone 166 for plastic. The grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com