Scalable immersed-filtration method and apparatus

a filtration method and immersion technology, applied in the field of filtration systems, can solve the problems of frequent and costly upkeep, affecting aquatic life negatively, and prone to blockage, so as to reduce the potential for preferential flow, easy to scale up or integrate, and easy to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

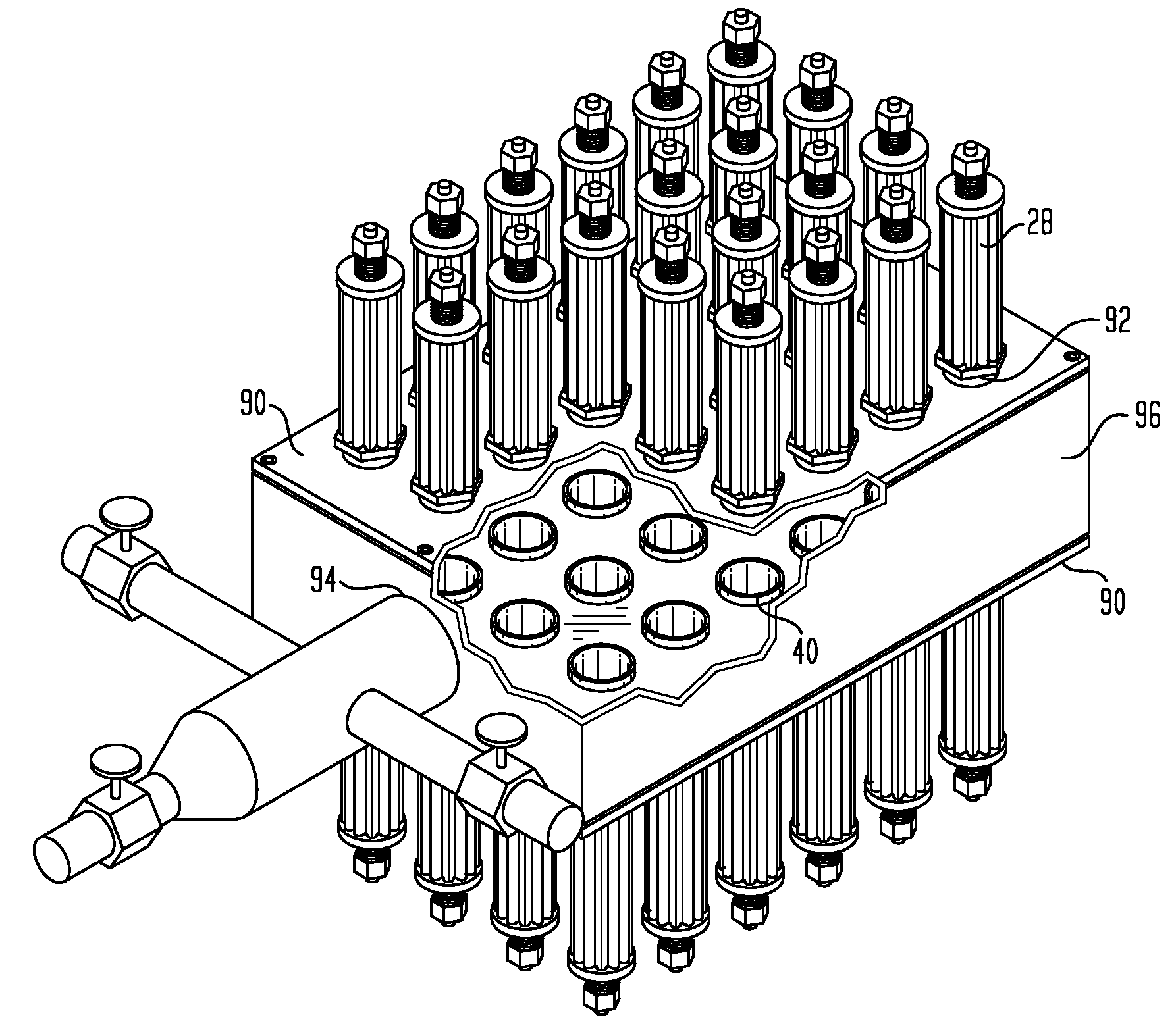

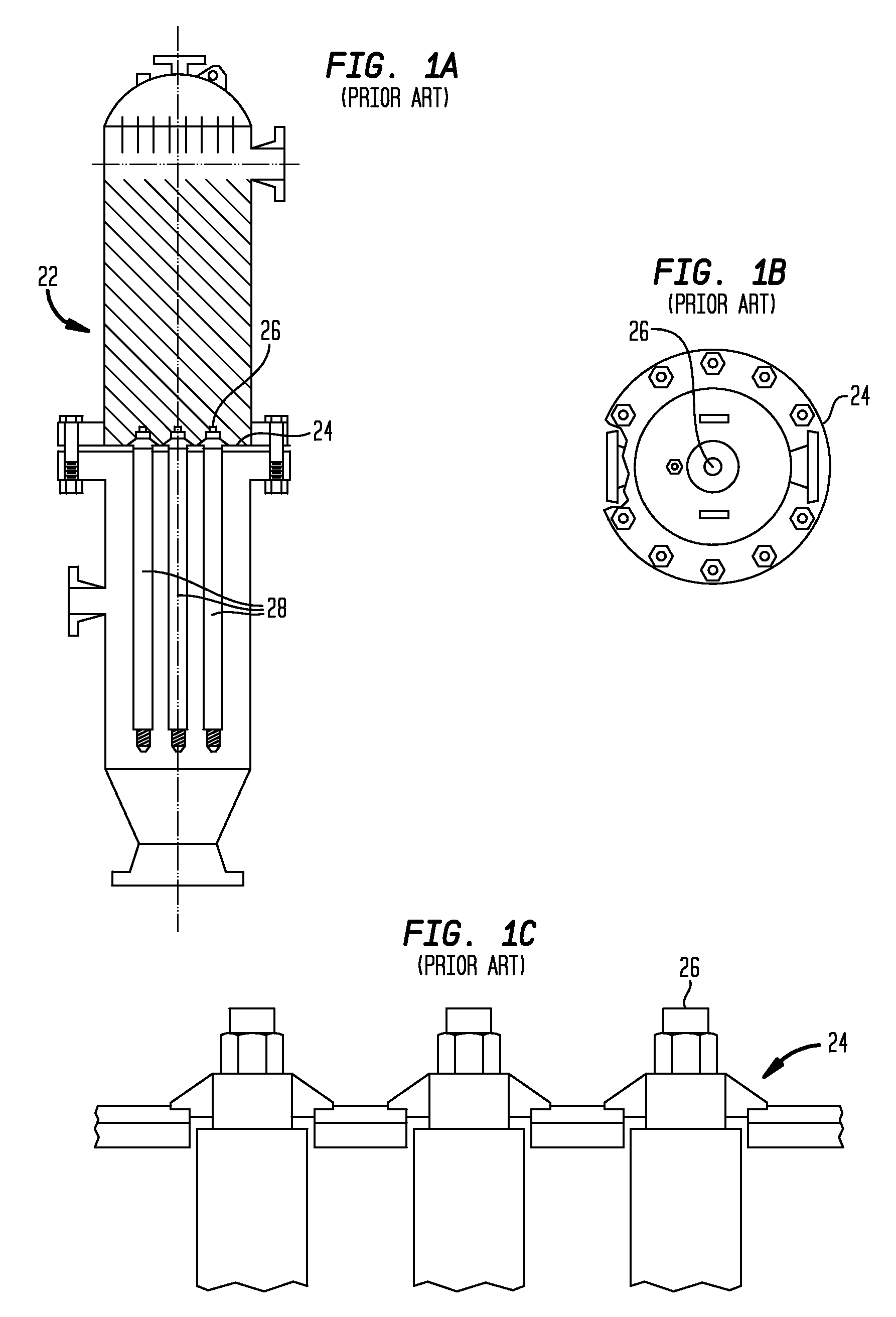

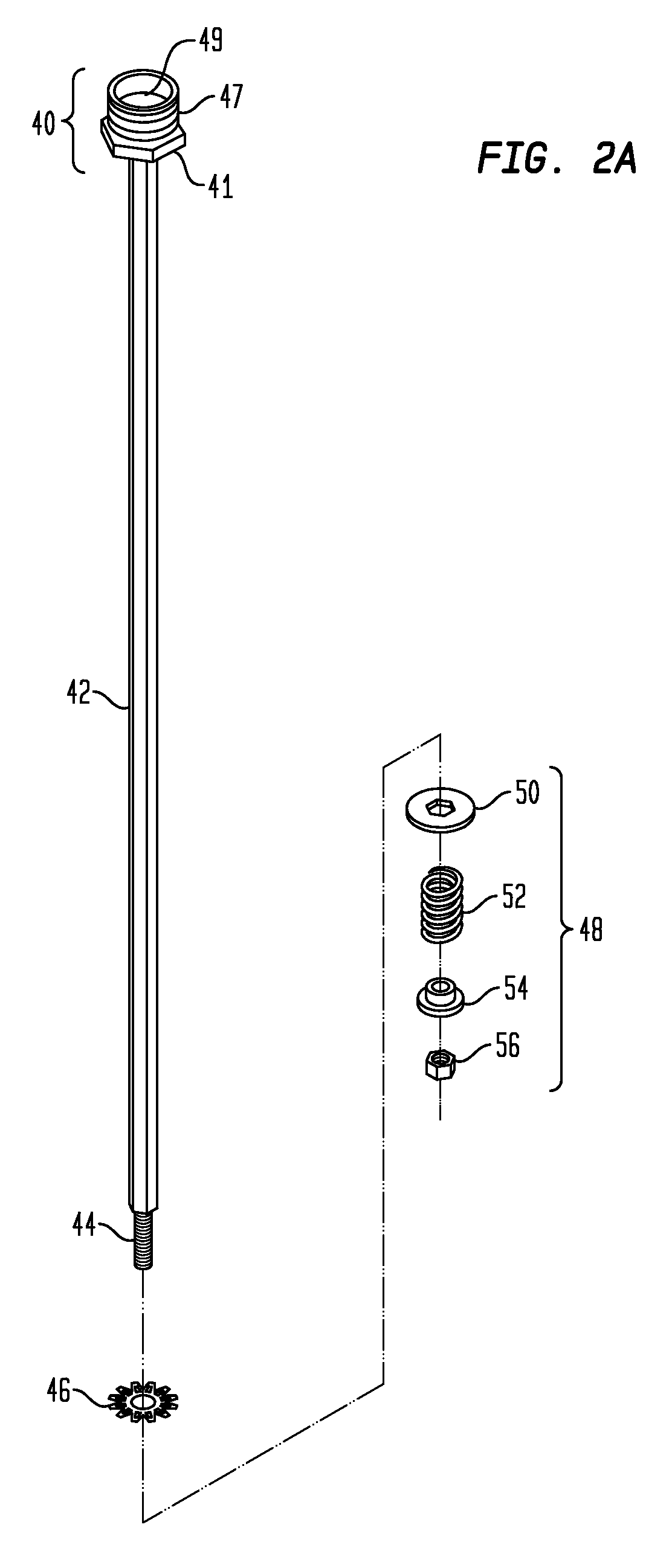

[0029]As illustrated in FIGS. 2-5, an immersed-filtration apparatus according to the invention is comprised of at least one filtration module, which in turn is comprised of a plurality of stacked filter elements. As generally illustrated in FIG. 2A, the filtration module is comprised of a geometric stacking core (42), which holds a plurality of filter elements (46) to form the filter stack (FIG. 3, 62). The stacking core (FIG. 4A, 42) has a geometric shape that corresponds to the inner cavity of the filter element (FIG. 4B, 70), a mating end (FIG. 2A, 40) comprising a mating surface (FIG. 2A, 47) and a conduit for filtrate outflow (FIG. 2A, 49), and a second end comprising an attachment means (44) for affixing a compression means (48).

[0030]As depicted in FIG. 4B, the filter elements are 1½″ wide and generally constructed and configured as described in the '454 patent, consisting of an outer filtration portion (72) and an inner geometrically shaped cavity (70) connected to one anoth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com