Methods to protect selective catalyst reducer aftertreatment devices during uncontrolled diesel particulate filter regeneration

a selective catalyst and aftertreatment device technology, applied in mechanical equipment, machines/engines, electric control, etc., can solve the problems of premature aging and failure of the catalyst reducer, and achieve the effect of improving the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

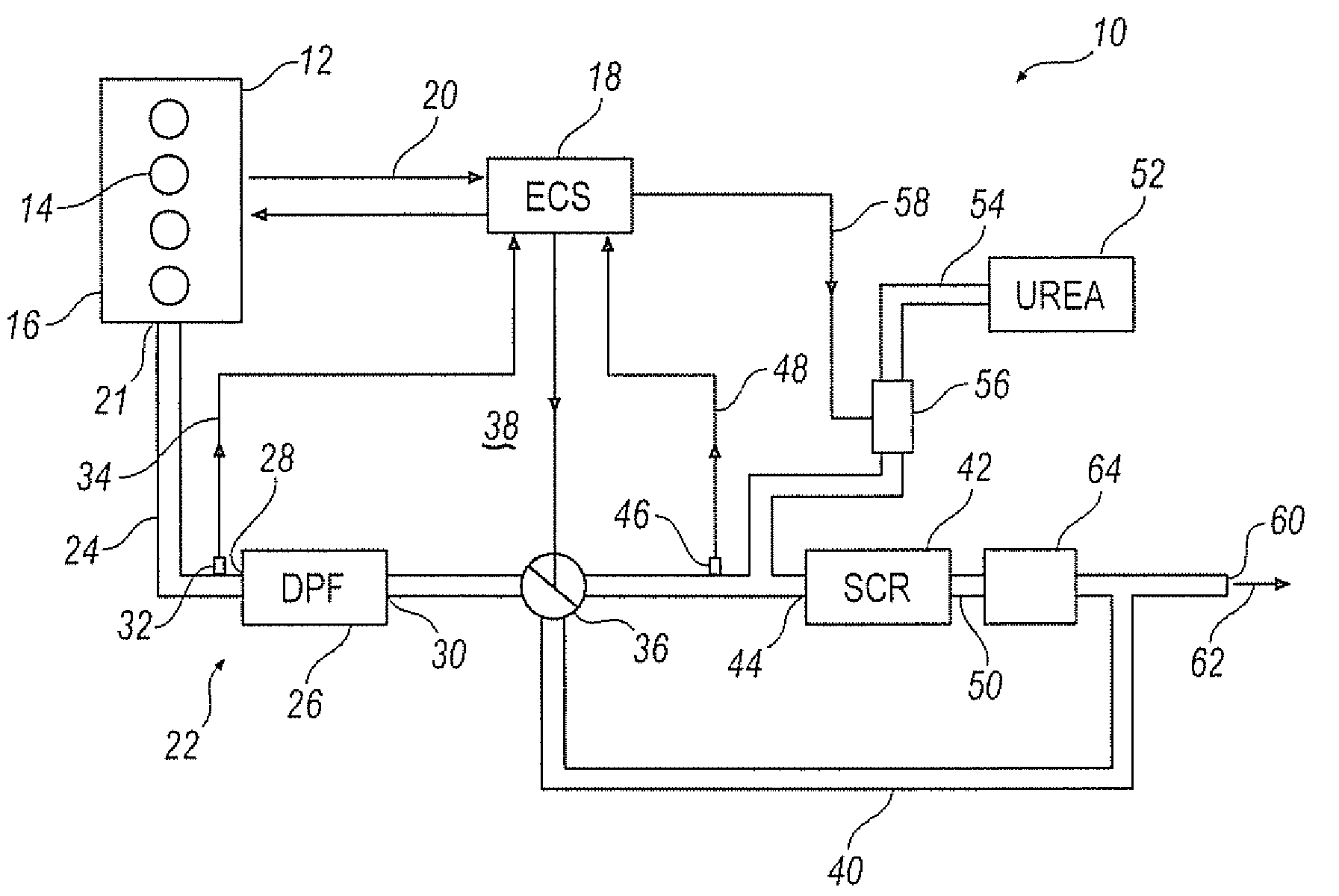

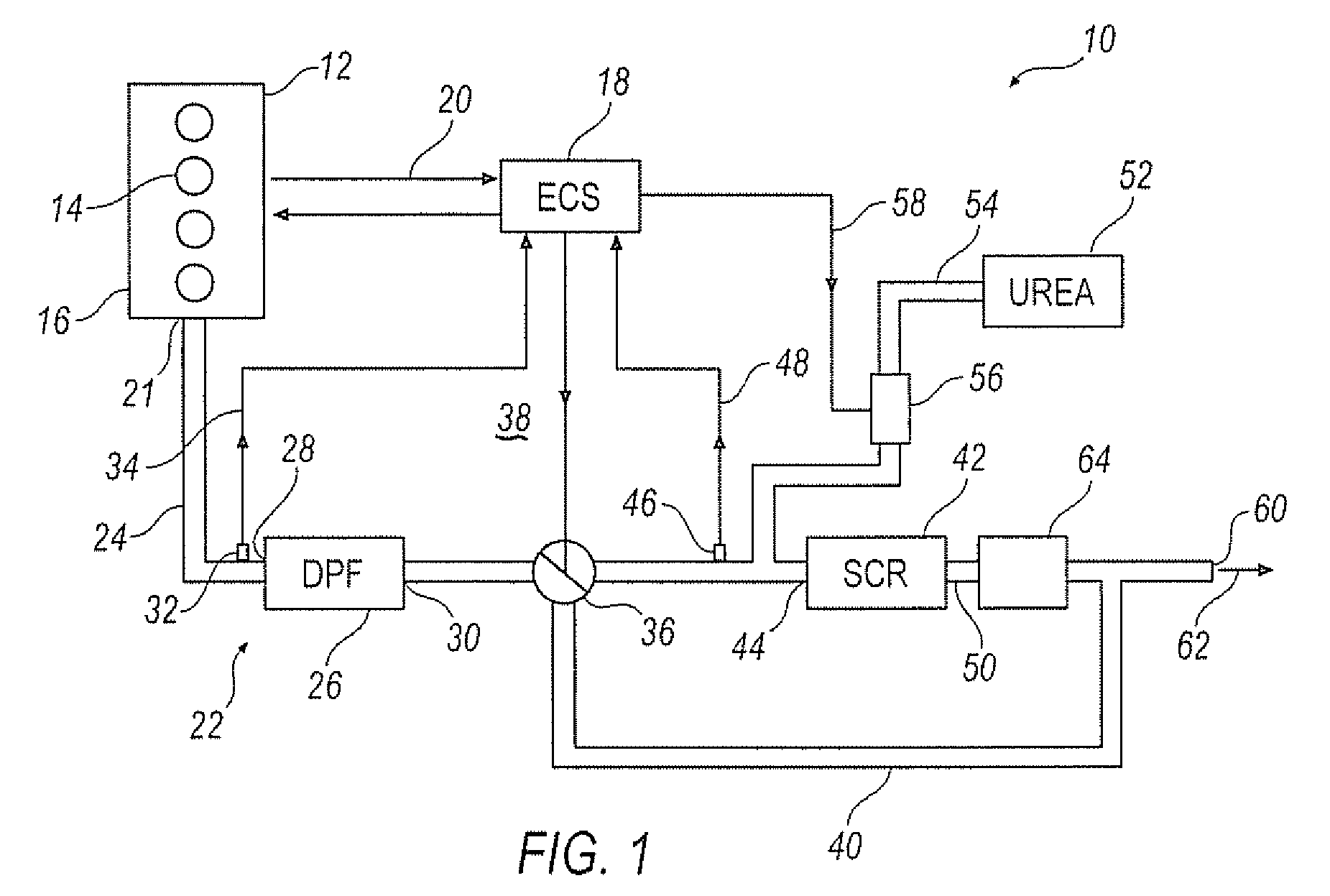

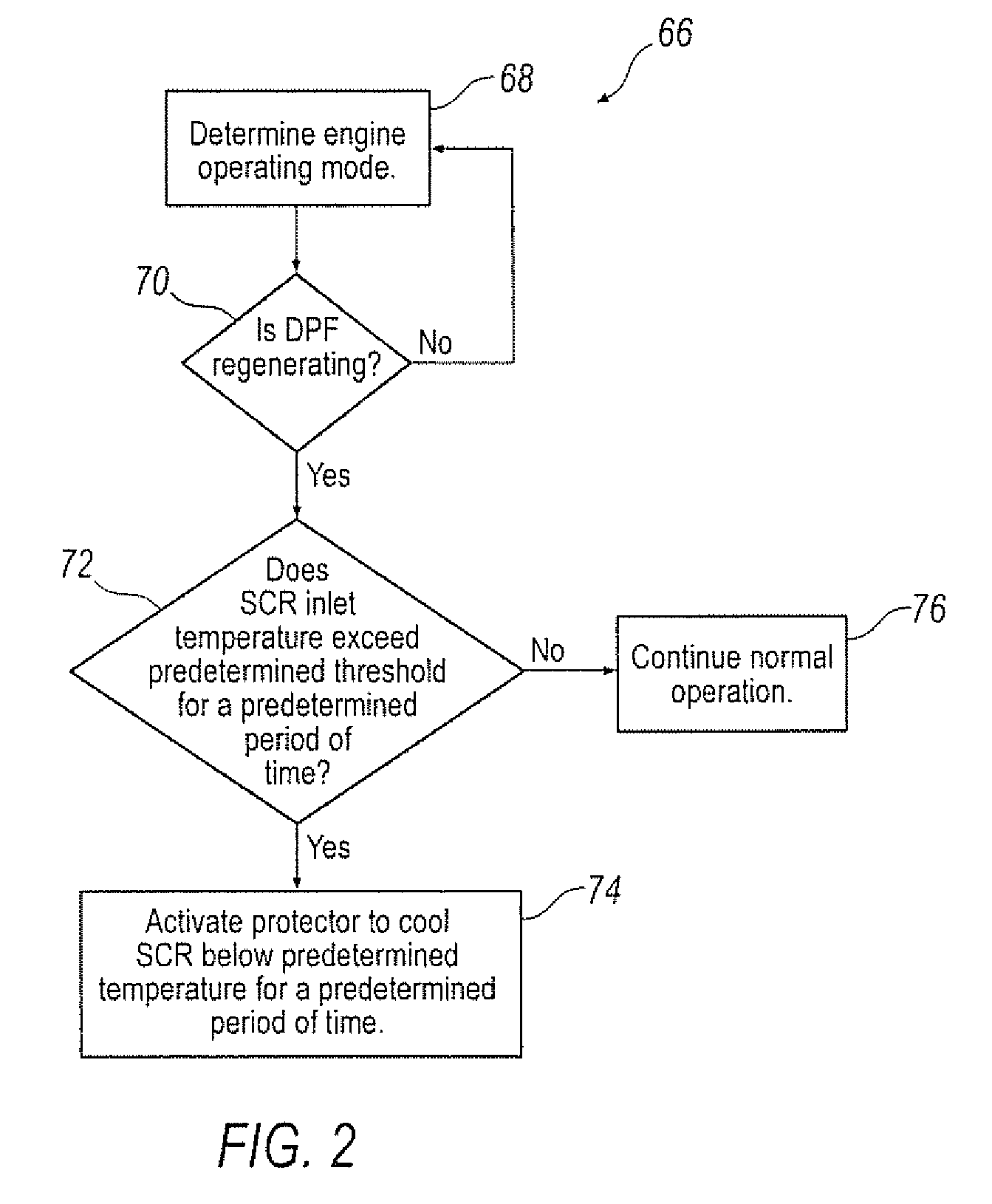

[0019]Turning now to the drawings wherein like numbers refer to like structures, vehicle system 10 includes internal combustion engine 12 having cylinders 14 disposed within block 16 for reciprocal movement therein. The engine may be of any construction, such as a spark ignition engine or a compression ignition engine, and is preferably a compression ignition type engine. The engine is electronically controlled by an Engine Control System 18 (ECS) that may be comprised of a single module or multiple modules, as is well known in the art. The ECS has memory, such as PROM, EPROM, EEPROM, FLASH, volatile and nonvolatile memory, and may also have tables or maps therein within which are loaded operating instructions and other information necessary for the operation and control of the engine and any system. In a preferred embodiment, the Engine Control System has DDEC operating instructions and programs loaded therein such as is available from Detroit Diesel Corporation. The ECS communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com