Can container

a can and container technology, applied in the direction of container discharging methods, vessel construction details, transportation and packaging, etc., can solve the problems of easy rupture of score lines formed on the seamed portion, unstable sealing characteristics of the seamed portion, and easy leakage of contents or propellant from the ruptured portion, so as to relieve the pressure in the can container quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

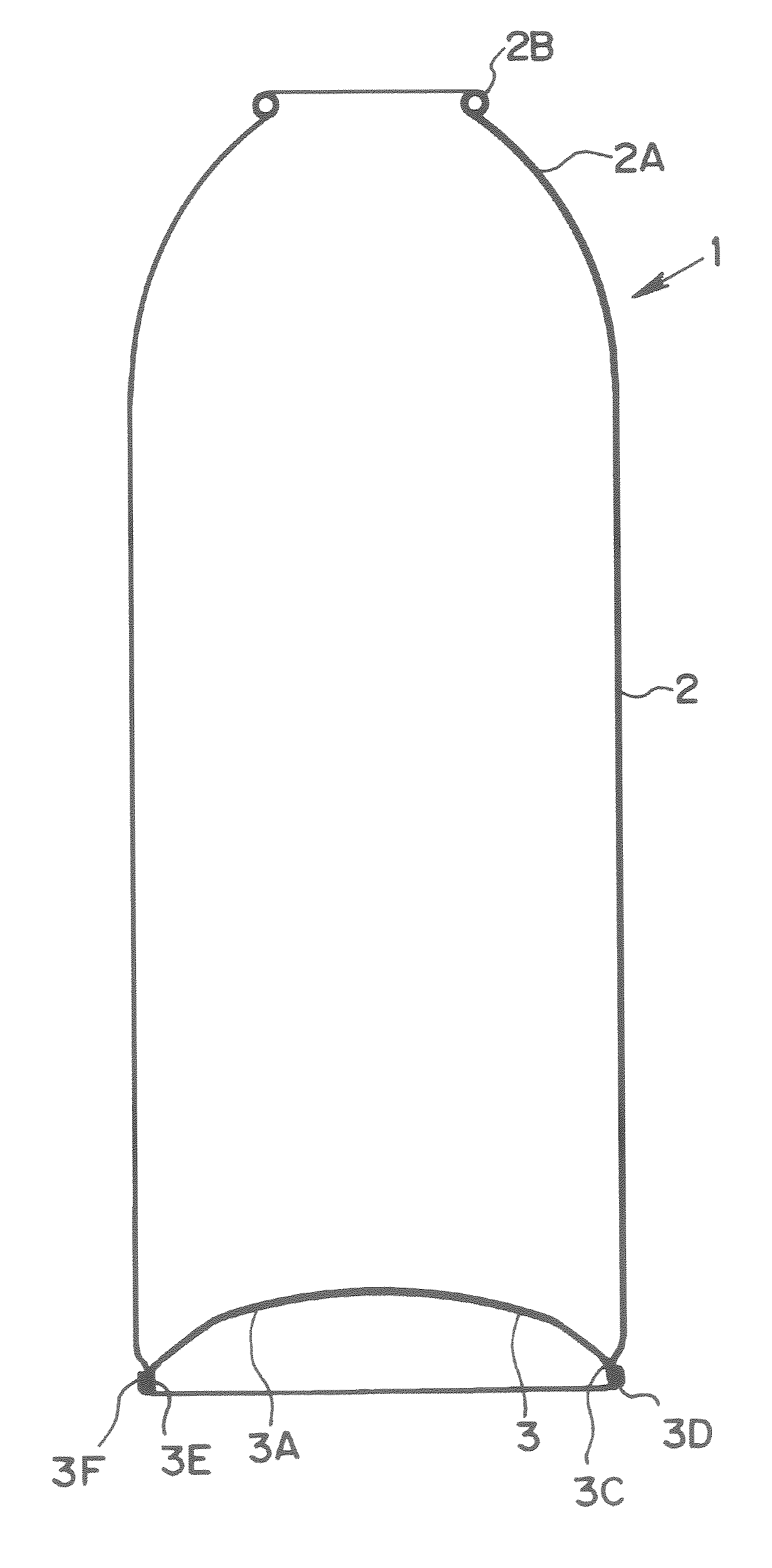

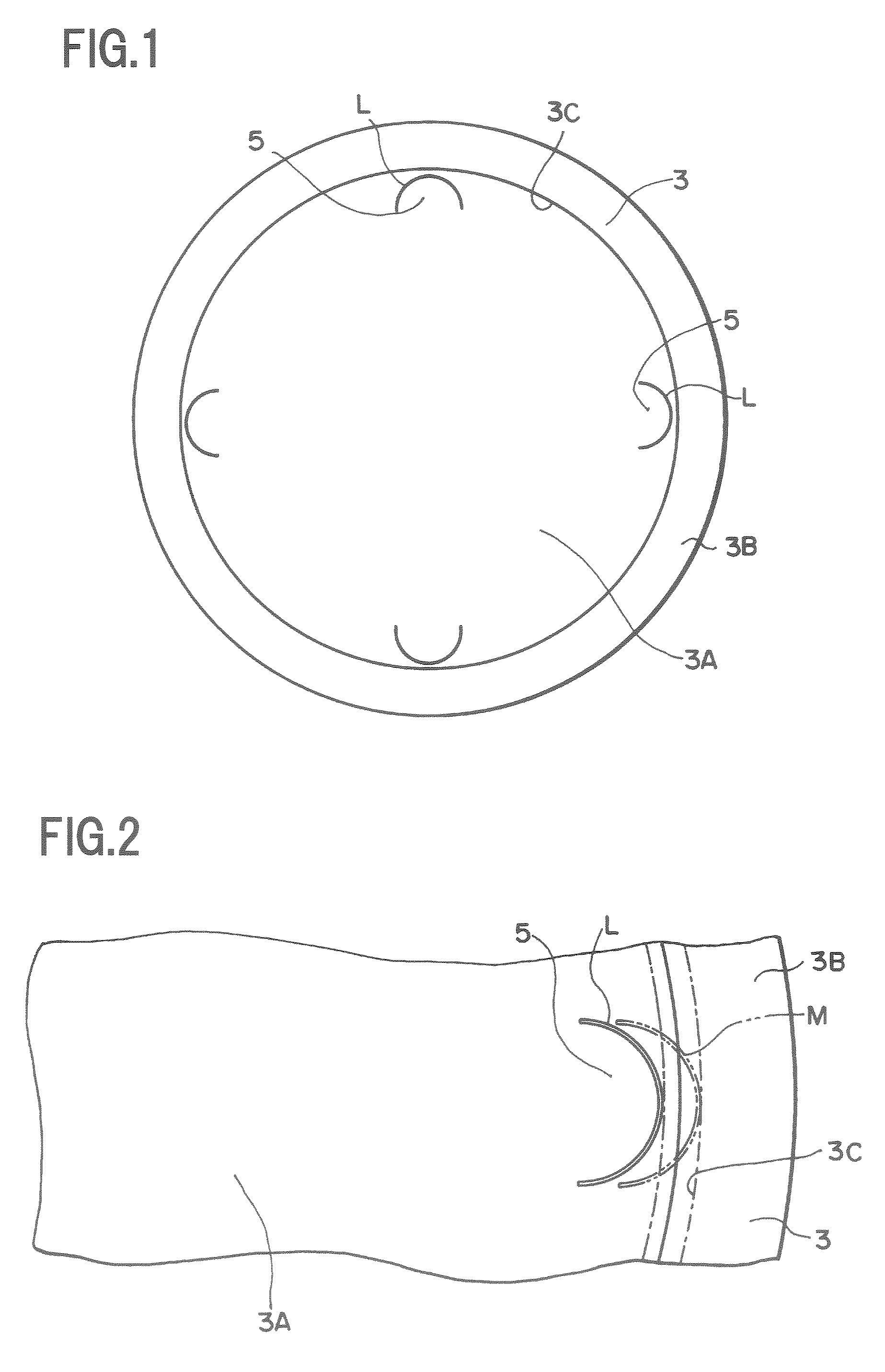

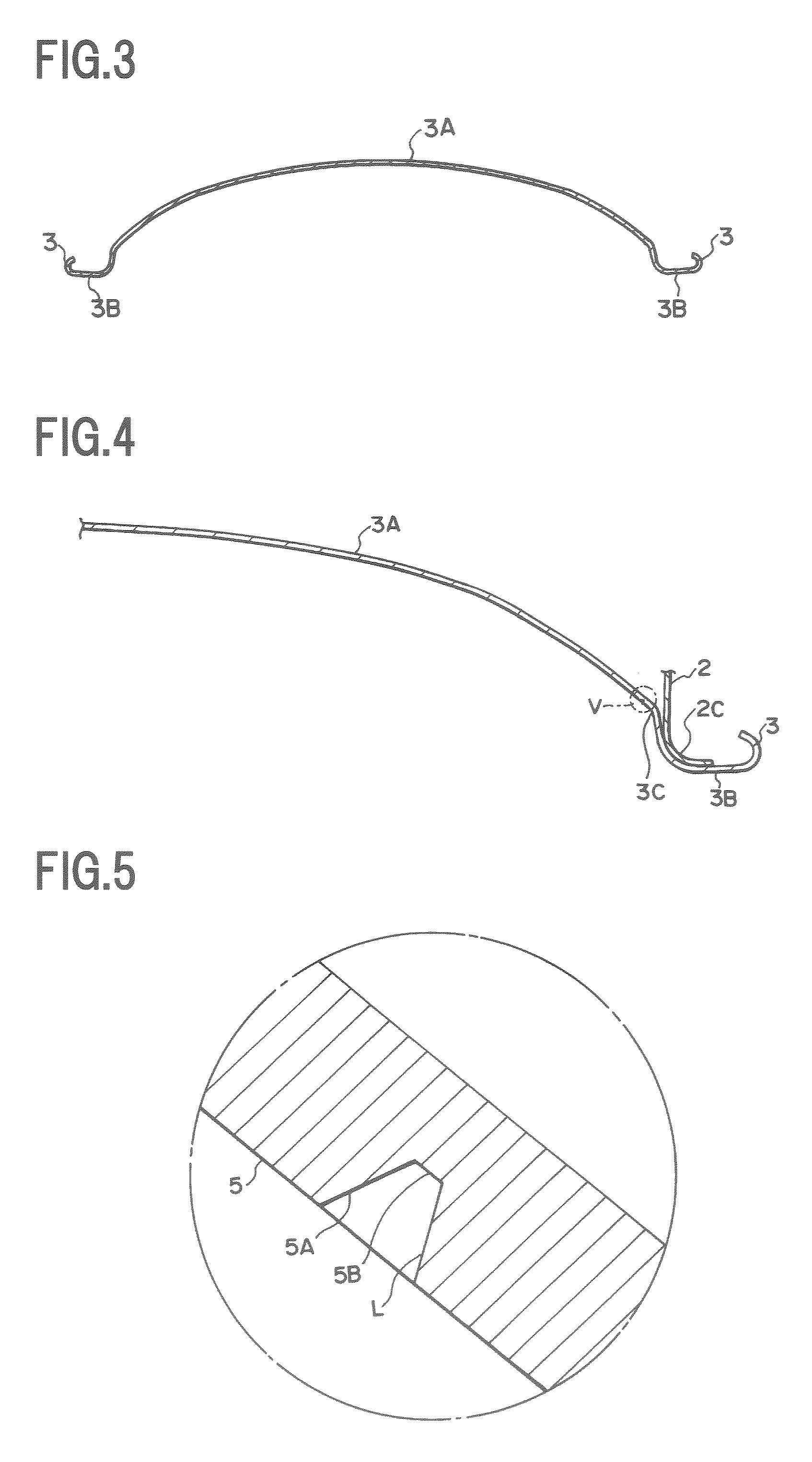

[0025]Hereinafter, embodiments of the present invention will be explained with reference to the accompanying drawings. FIGS. 6 and 7 respectively shows a metal can container such as an aerosol can which is filled with a propellant as a high pressure gas. The can container (i.e., a main body) 1 comprises a cylindrical metal can body (i.e., a trunk portion) 2. An (not shown) aerosol valve member is attached to one of the end portion of the can body 2, and a disc shaped metal bottom lid (or can lid) 3 is fixed to another end portion of the can body 2 by a seaming method. Contents to be filled in the can container 1 can be exemplified by cosmetics, an insecticide, a medical agent, a detergent, coating compositions, a lubricant, foods and so on, and a high pressure gas is also filled therein as a propellant.

[0026]A main material of the can body and the can lid of the can container according to the invention is a metal material, in which a proper surface treatment or plating is applied ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com