Medical Catheter Tubes and Process for Production Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

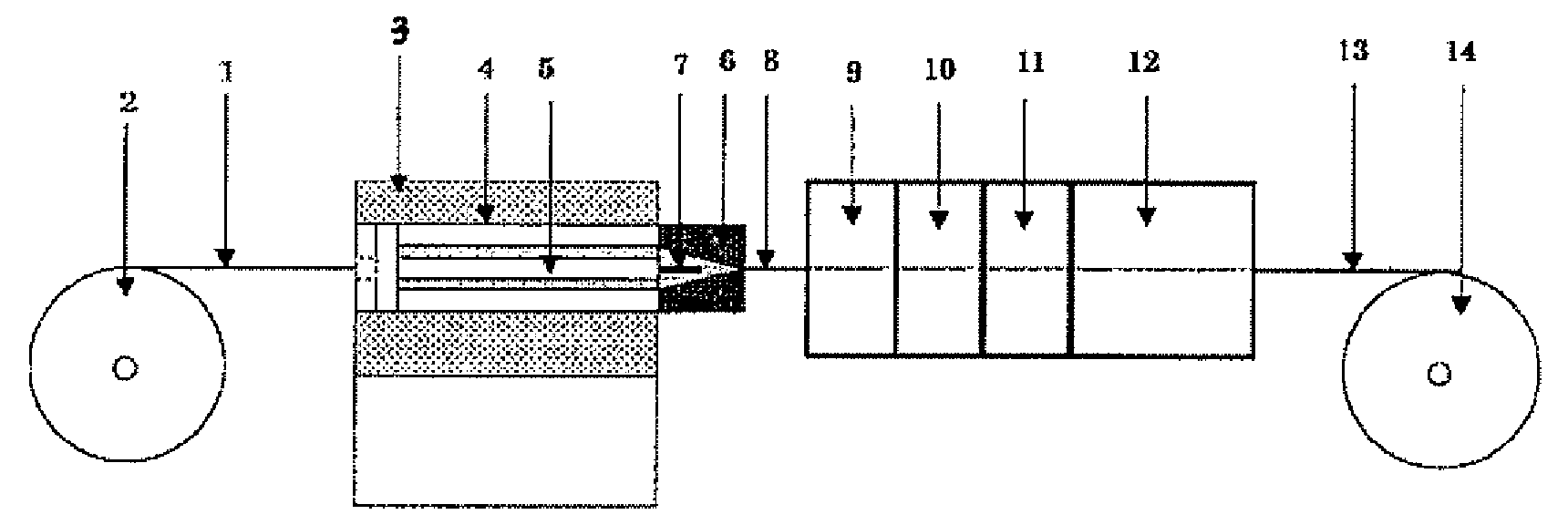

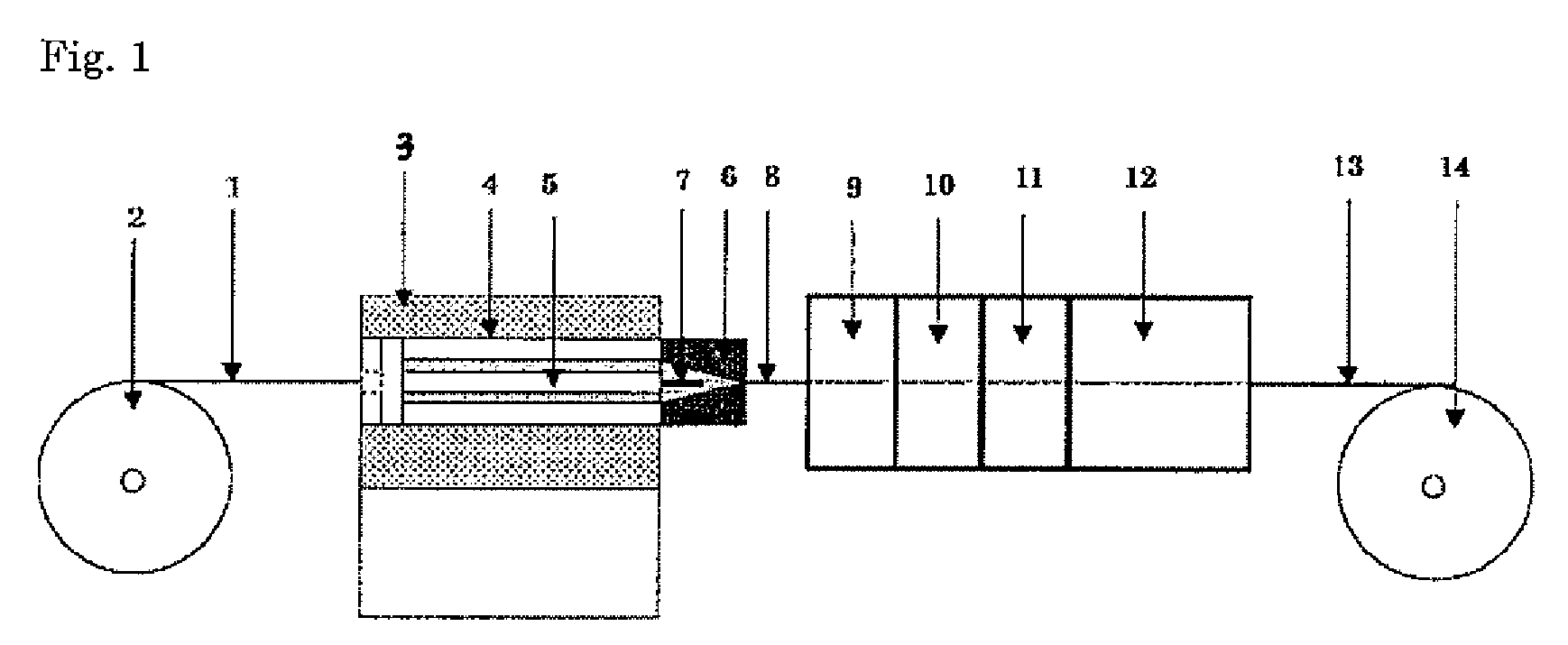

[0095]100 wt parts of a PTFE fine powder A (product name: Polyflon PTFE F-207, produced by Daikin Industries, Ltd) and 56 wt parts of a lubricant A (product name: Kosei Sol FC-1, available from Kosei Trading Co. Ltd., boiling point: 120° C., interfacial tension: 15.5 dyne / cm) were placed in a glass bottle; the mixture was left still in a constant temperature oven at 50° C. for 24 hours for aging, and then, cooled to room temperature and mixed by shaking. After mixing, the mixture was compressed at a pressure of 1.0 MPa for 5 minutes in a performing cylinder of 18 mmφ in width for preparation of a preform. The primary preform obtained was placed in the cylinder of an extrusion molding machine and preformed additionally at a pressure of 28 MPa for 30 seconds with the head closed, for removal of air bubbles in the preform. The internal diameter of the extruder cylinder 4 in the paste extruder 3 was 18 mm; the external diameter of the extruder mandrel 5 was 12 mm; a die 6 having an inte...

example 2

[0098]A PTFE thin-film tube was prepared in a similar manner to Example 1, except that

[0099]56 wt parts of a lubricant B (product name: Fluorinert FC-40, available from Sumitomo 3 M Ltd., boiling point: 155° C., surface tension: 16.0 dyne / cm) was added. The moldability during paste extrusion was rated ◯. The tensile strength of the PTFE thin-film tube obtained, as determined at a displacement of 1.0 mm, was 7.6 N / mm2. The kink length determined was 42 mm. The stress after one reciprocation in the lumen lubricity test was 0.45N, while that after 50 reciprocations was 0.47N.

example 3

[0100]A PTFE thin-film tube was prepared in a similar manner to Example 1, except that

[0101]56 wt parts of a lubricant C (product name: Fluorinert FC-43, manufactured by Sumitomo 3 M Ltd., boiling point: 174° C., surface tension: 16.0 dyne / cm) was added. The moldability during paste extrusion was rated ◯. The tensile strength of the PTFE thin-film tube obtained, as determined at a displacement of 1.0 mm, was 6.4 N / mm2. The kink length determined was 45 mm. The stress after one reciprocation in the lumen lubricity test was 0.43N, while that after 50 reciprocations was 0.45N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com