H2-O2-H2O fuel generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

—OPERATION

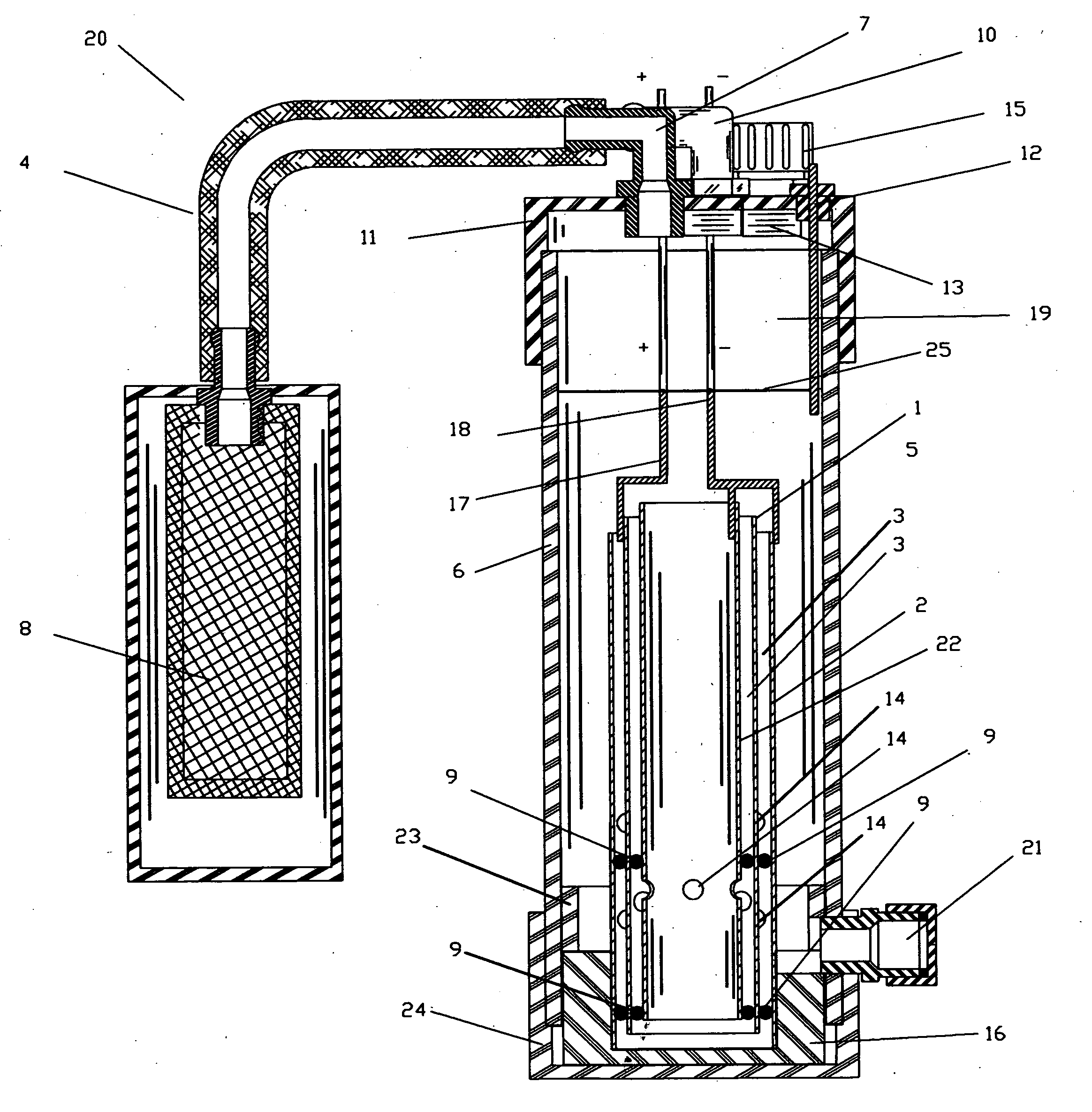

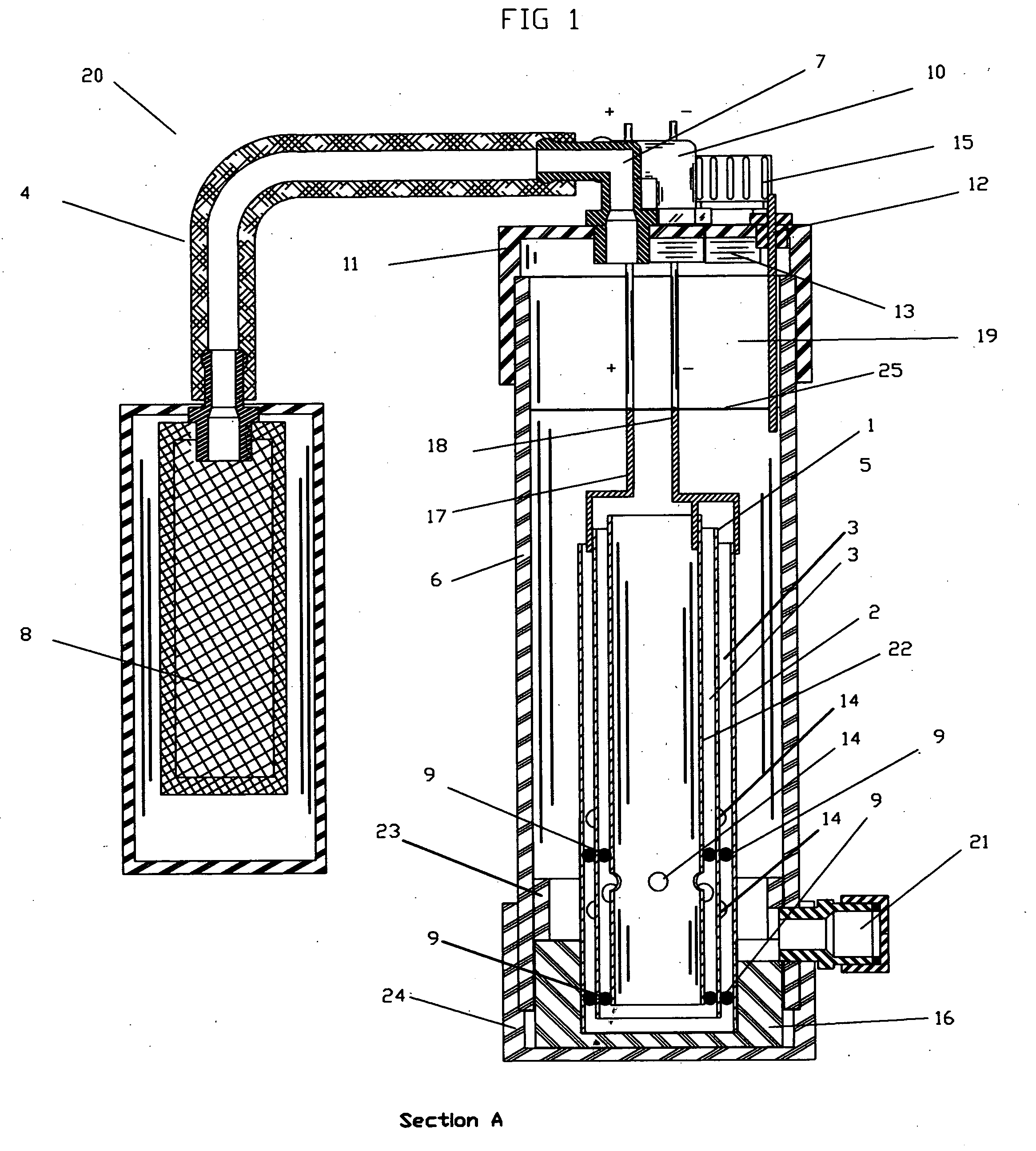

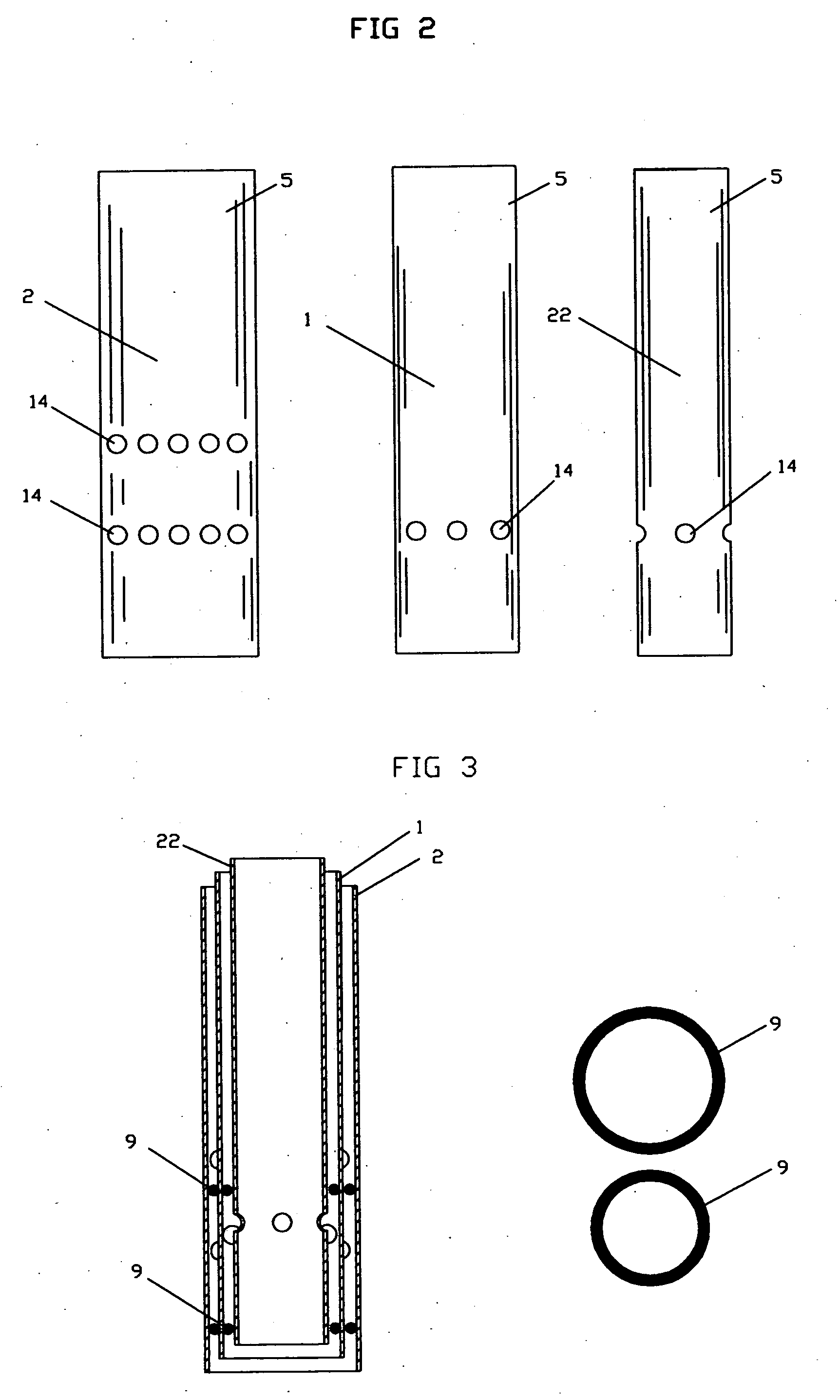

[0003]The invention is an electrolytic hydrogen, Oxygen, producing generator #20, which utilizes three cylindrical elements, FIG. 3 the anode element cylinder #1, cathode elements cylinder #2, and #22 and are arranged, in close proximity one within the other. The anodes have a positive charge that is delivered by anodes connecting wire and jumper #18, and the cathode that is placed in between the cathodes has an negative charge which delivered by cathode connecting wire #17. When the mineral drinking water is added to the generator through water fill cap and fitting #13 to the recommended fluid level the water level sensor #12 indicates full by the LED light FIG. 10 #3. At this point the electrolytic process of hydrogen ions and oxygen ions separate and travel to their opposite charges which is hydrogen at the negative plate the cathode element cylinder #1. The oxygen ions travel to the anodes surrounding the cathode, which is the positive outer anode cylinder 2 and inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com