Fixed Swirl Inducing Blast Liner

a technology of abrasive slurry and a blast liner, which is applied in the direction of drilling casings, drilling pipes, and accessories of wells, etc., can solve the problems of reducing erosion in exit ports and longer service life, and achieves the effects of reducing turbulence, reducing wear in abrasive slurry service, and reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

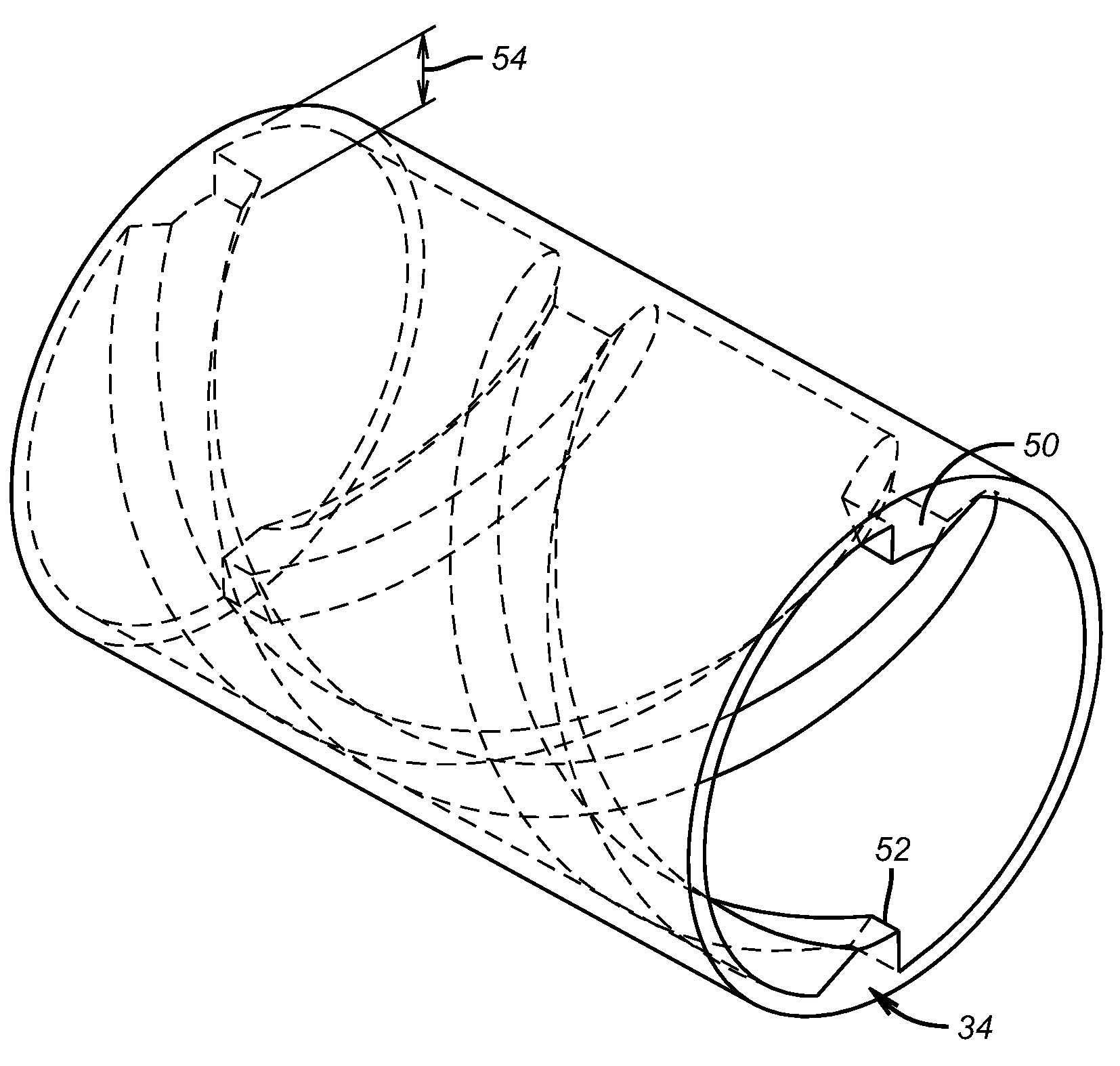

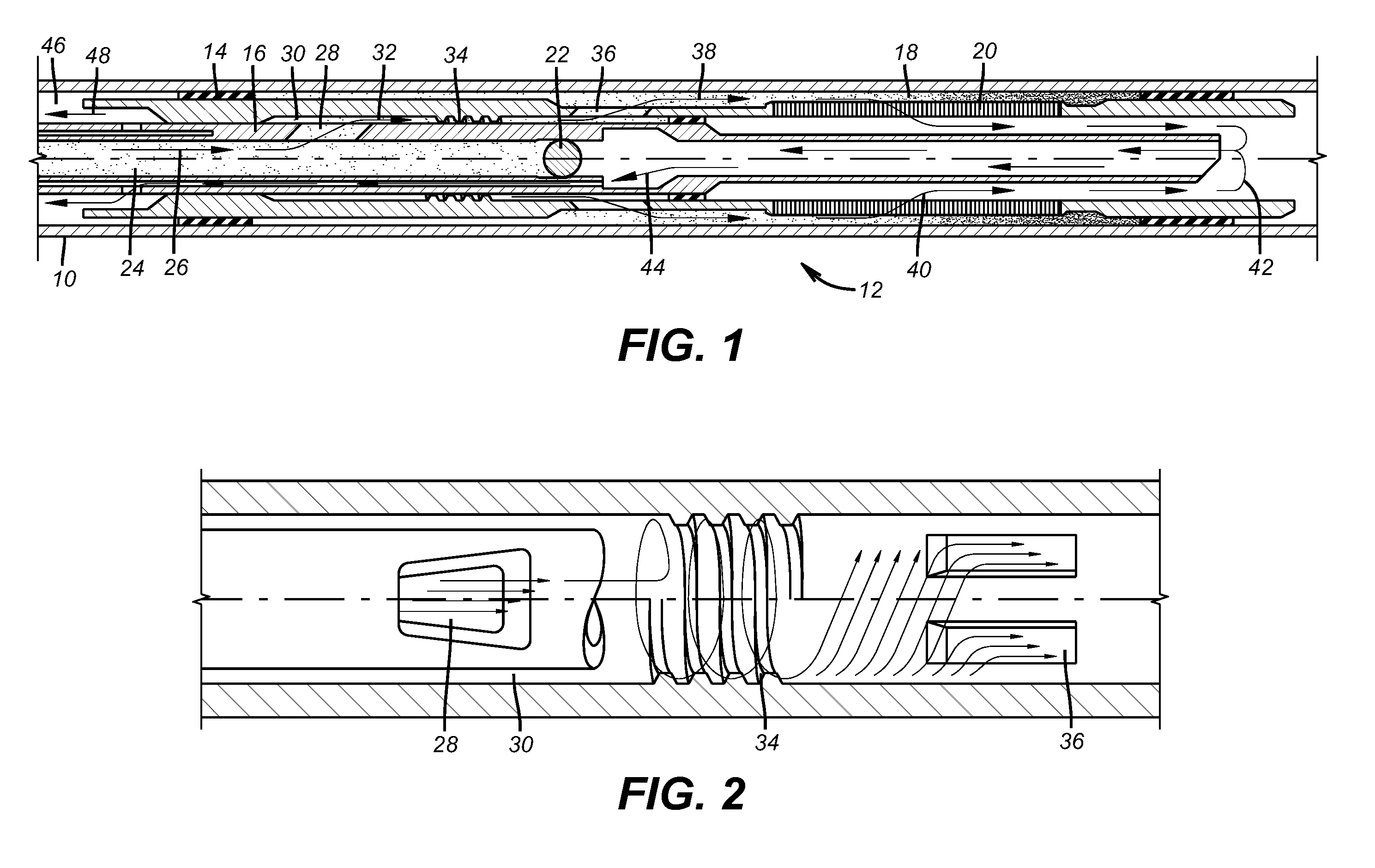

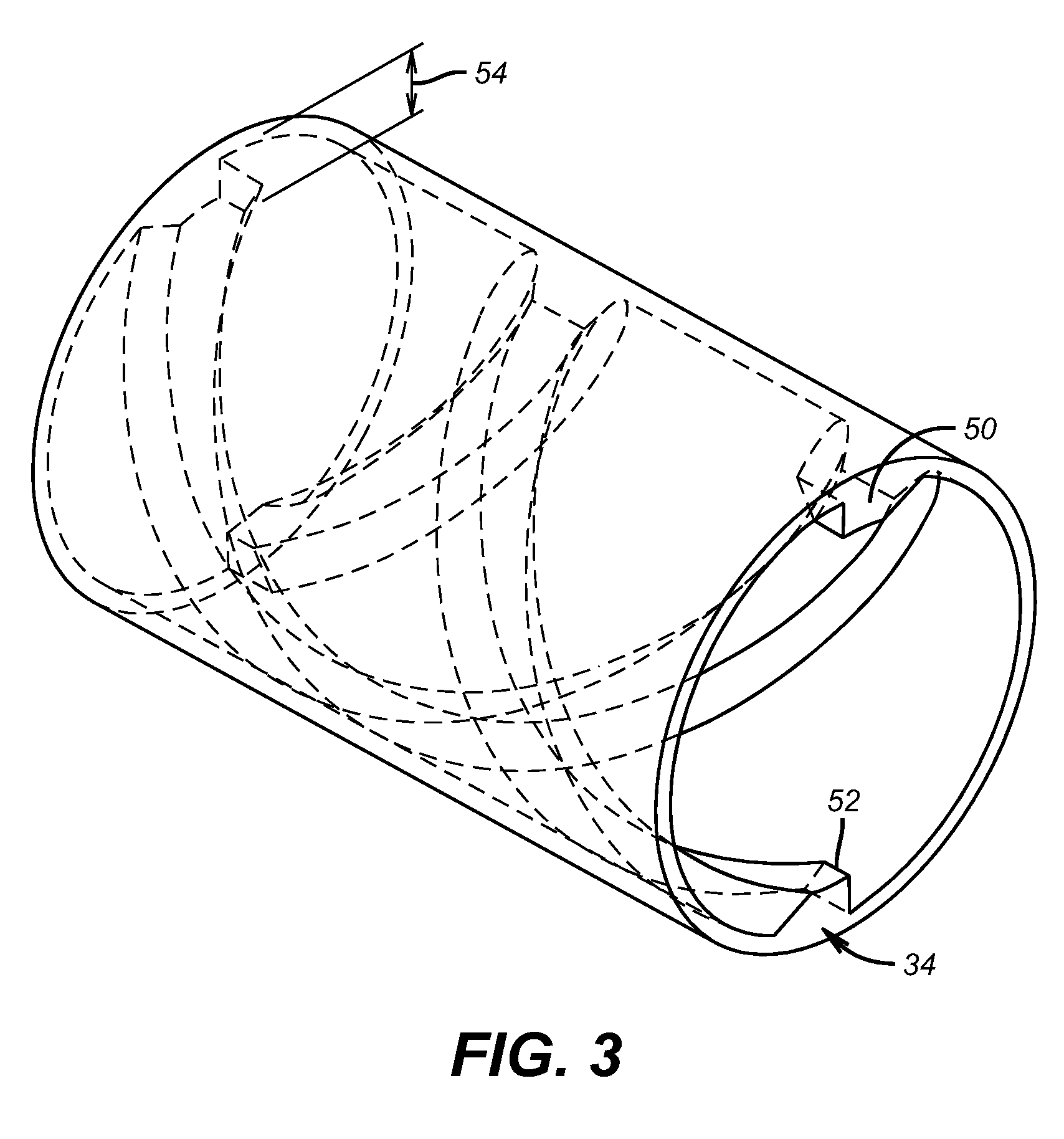

[0011]FIG. 1 shows casing 10 and a gravel packing assembly 12 located within. An external packer 14 is set against the casing 10. A crossover tool 16 is shown in a position for gravel deposition in annulus 18 around screens 20. A ball 22 has been dropped to a seated position blocking off passage 24. Arrow 26 represents slurry being pumped from the surface through passage 24. The flow exits through openings 28 into an inner annulus 30. Arrow 32 represents this flow. In annulus 30 vanes 34, best seen in detail in FIG. 3, impart a swirling motion to the slurry flow in annulus 30. The flow of slurry then exits ports 36 into annulus 18 as illustrated by arrow 38. The solids from the slurry remain in annulus 18 while the carrier fluid goes through screen 20 as represented by arrow 40. Flow continues as represented by arrows 42 and 44 to bypassing ball 22 to exit into annulus 46 above the packer 14 as indicated by arrow 48.

[0012]Focusing now on what happens between ports 28 and 36 in annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com