Refrigerant system with multi-speed pulse width modulated compressor

a refrigeration system and pulse width technology, applied in the field of refrigerant systems, can solve the problems of inability to precisely control the temperature and humidity of the environment to be conditioned, the demand for cooling or heating capacity is relatively low, and the occupant of the indoor environment is uncomfortable, so as to achieve the effect of reducing the capacity, reducing the cost of refrigerant system, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

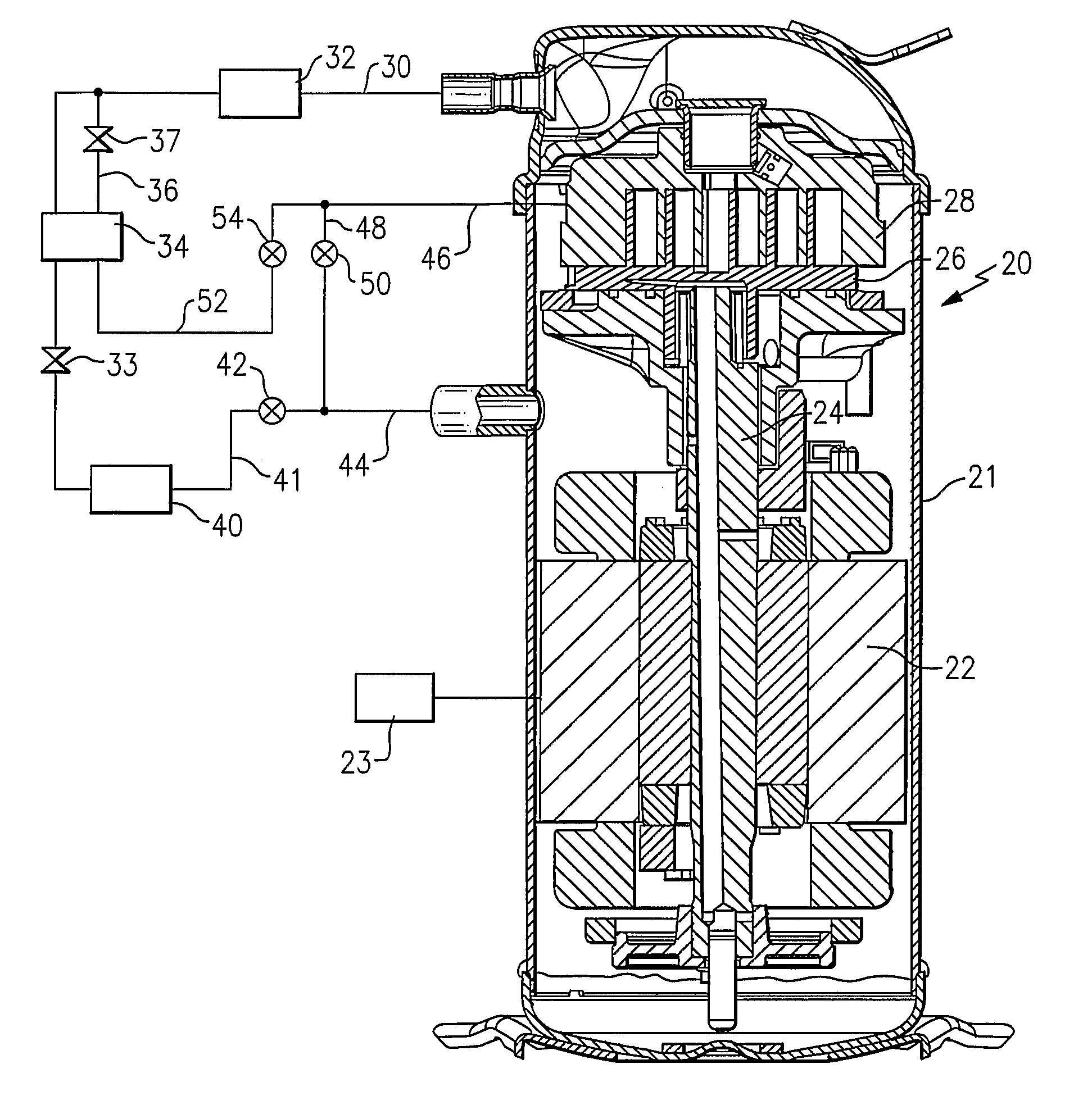

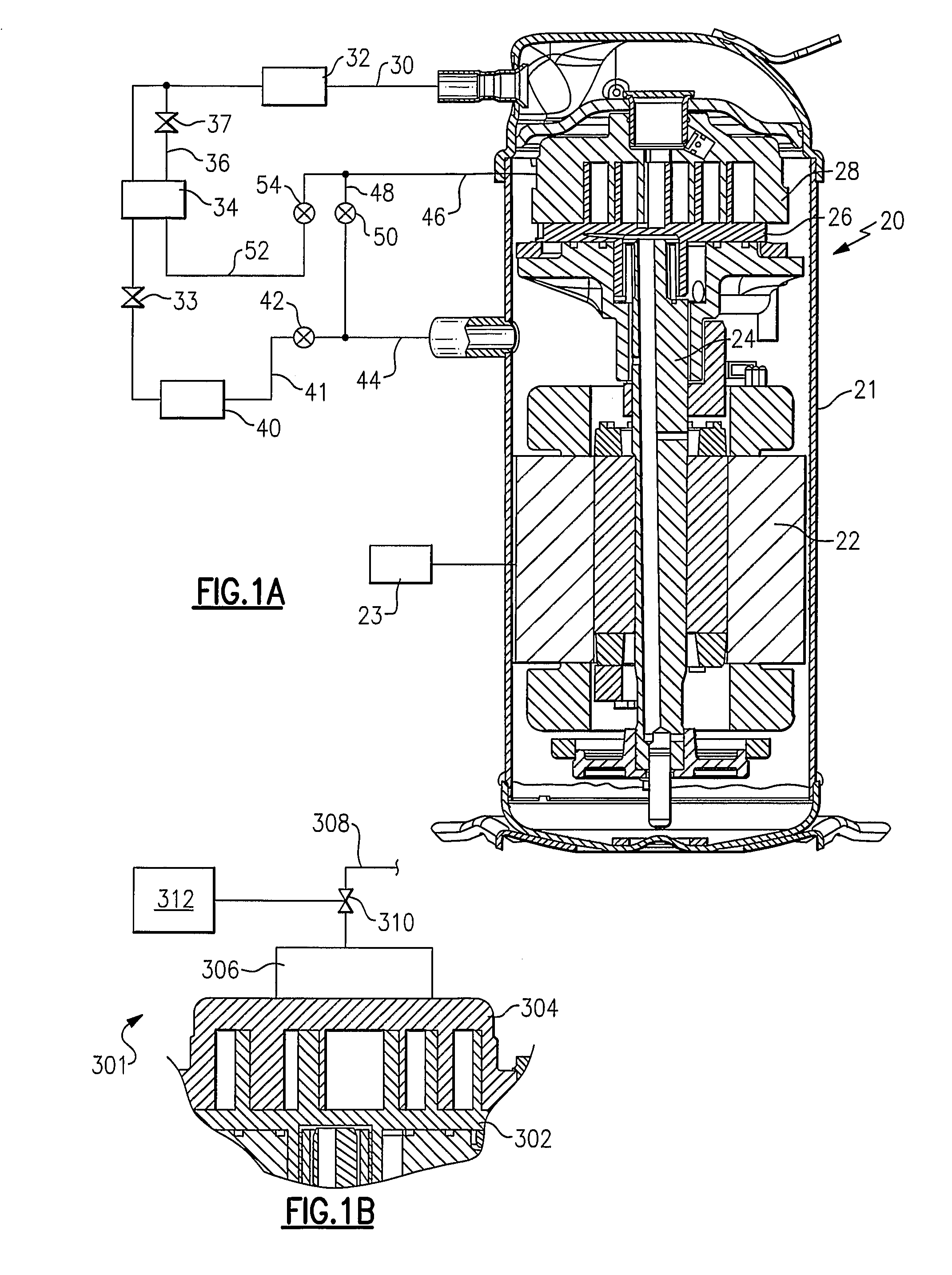

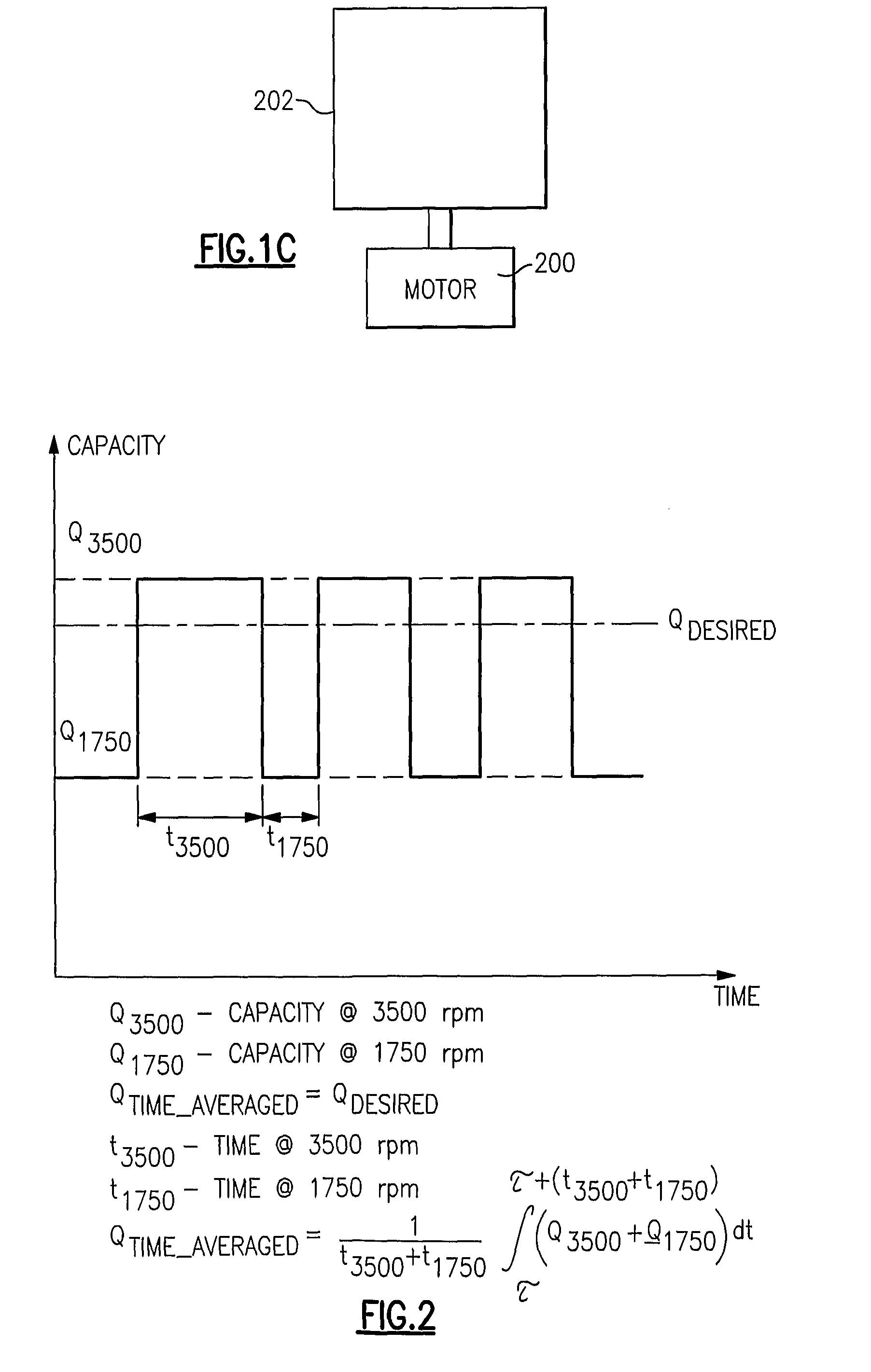

[0010]FIG. 1A shows a refrigerant system 20 incorporating a compressor 21 with a multi-speed motor 22 driving a shaft 24. The compressor 21 is illustrated as a scroll compressor having an orbiting scroll 26 interfitting with a non-orbiting scroll 28. It has to be noted, that although the description is primarily related to a scroll compressor type, any other compressor (screw, reciprocating, rotary, etc.) capable of running at multiple speeds is within the scope of the invention. The present invention would apply to different types of refrigerant systems. For example, these systems may include air conditioning units, heat pump units, chiller systems, and different types of refrigeration units including container units, truck and trailer units and supermarket cabinets and display cases. The present invention would also apply to different compressor-motor configurations, where the motor can be a part of a hermetic or semi-hermetic compressor shell that also includes compressor pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com