Composition and method for installing a simulated natural surface

a natural surface and composition technology, applied in the field of compositions and methods for producing a simulated natural surface, can solve the problems of increasing the total prior art methods failing to provide a commercially feasible process, and increasing the cost of a project, so as to reduce the amount of trowelling, reduce labor, and the effect of less tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

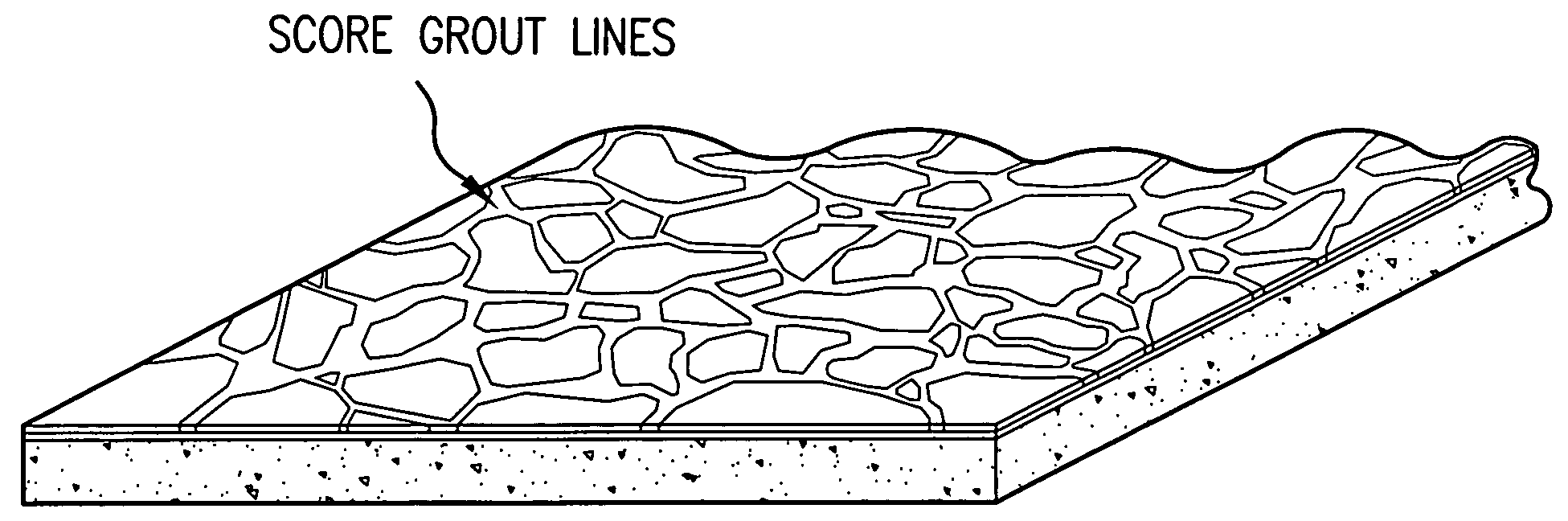

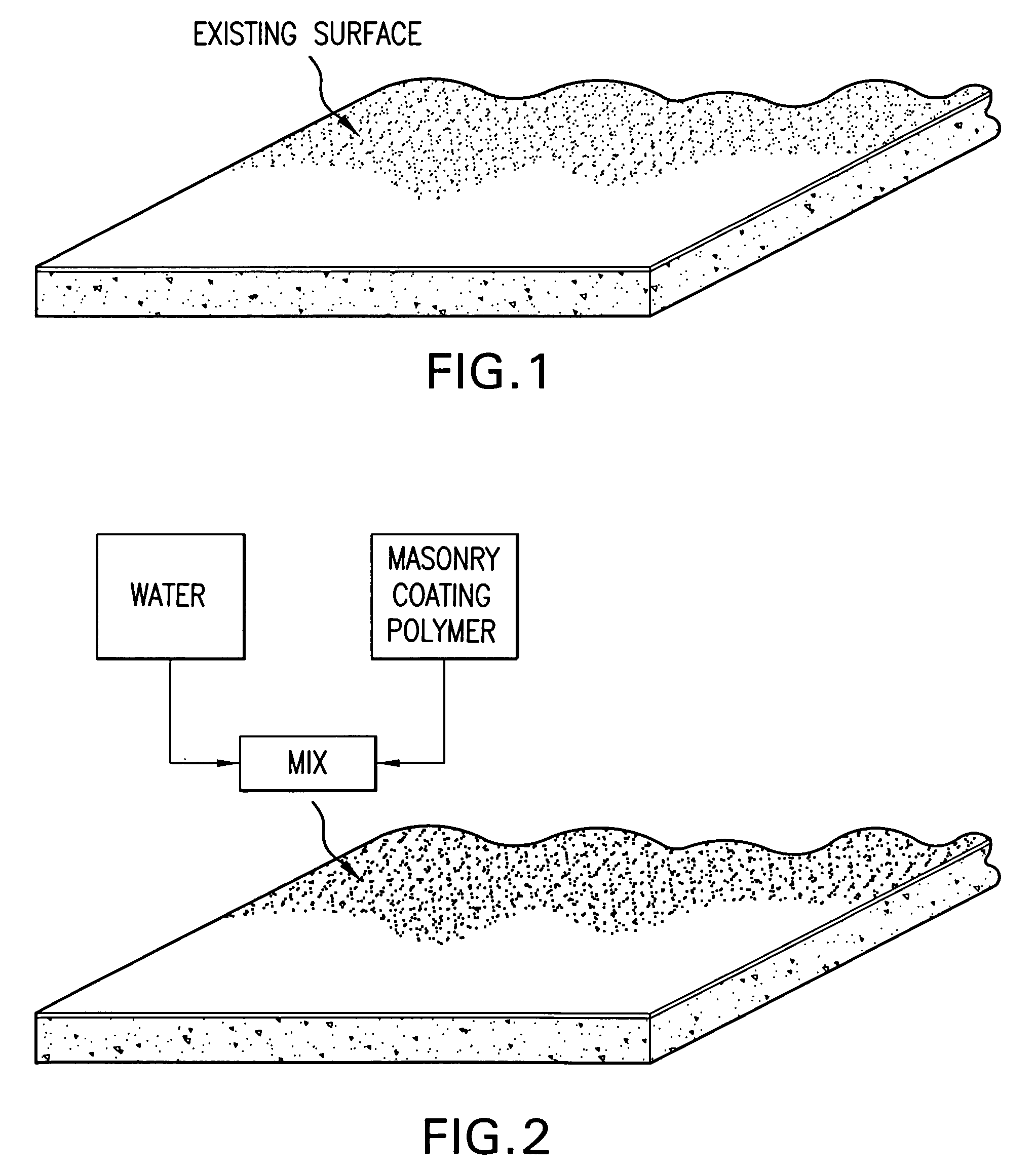

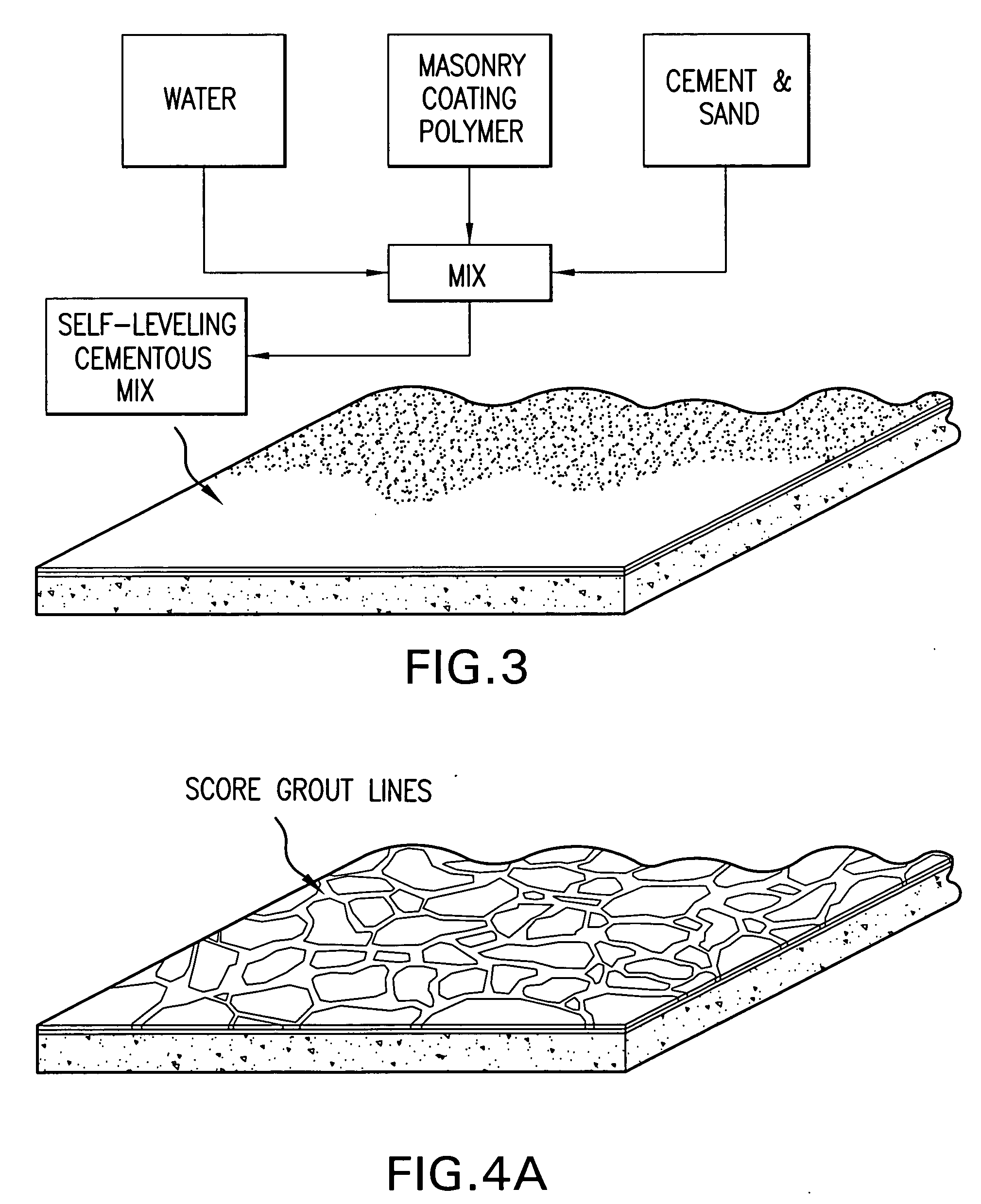

[0018]A first mixture for use in producing a simulated surface is prepared by mixing together a 40% polymer liquid with 60% water. In a preferred embodiment, the polymer liquid is a masonry coating polymer. The first mixture, providing a boding agent, is applied to an existing surface using a roller. Next, a second mixture is prepared by mixing together 80% water with 20% polymer having a self-leveling characteristic. In a preferred embodiment, the polymer is a masonry coating polymer. A cementous mixture comprising 50% Portland cement and 50% sand is combined with the second mixture and fully mixed to provide a self-leveling cementous mixture. The self-leveling cementous mixture is applied to the surface, using a trowel in a minimal action to evenly spread the self-leveling cementous mixture over the surface. When the mixture is partially cured, a tool is used to score in the desired grout pattern by scraping away a portion of the cementous mixture. The created grout lines resemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com