Method and apparatus for creating soil or rock subsurface support

a subsurface support and rock technology, applied in earth drilling, mining structures, construction, etc., can solve the problems of reducing the ability of the support to provide designed support, requiring active support, and unstable earth surrounding or near a man made structure, etc., to achieve cost-effective, high-resistance corrosion resistance, and simple shortened body length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

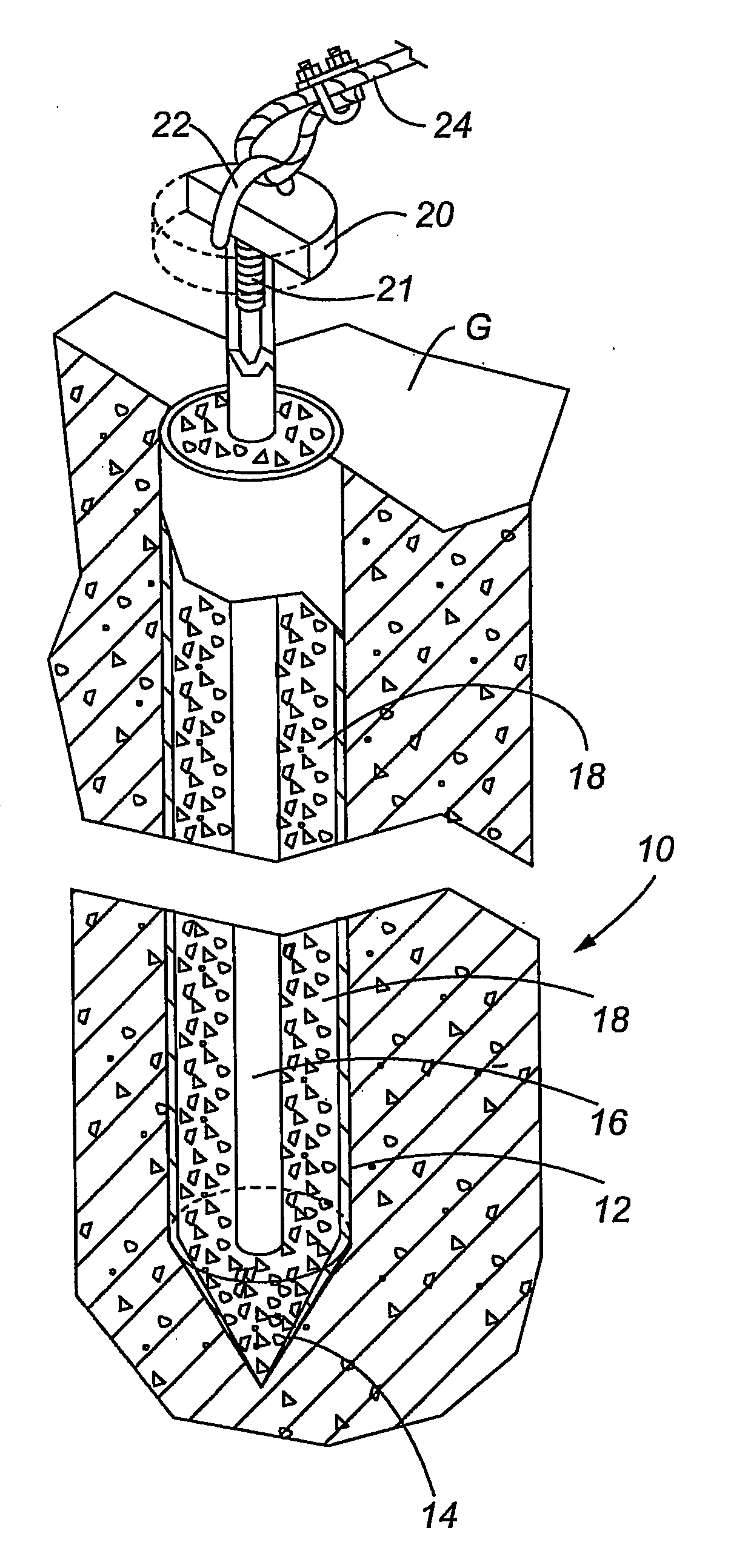

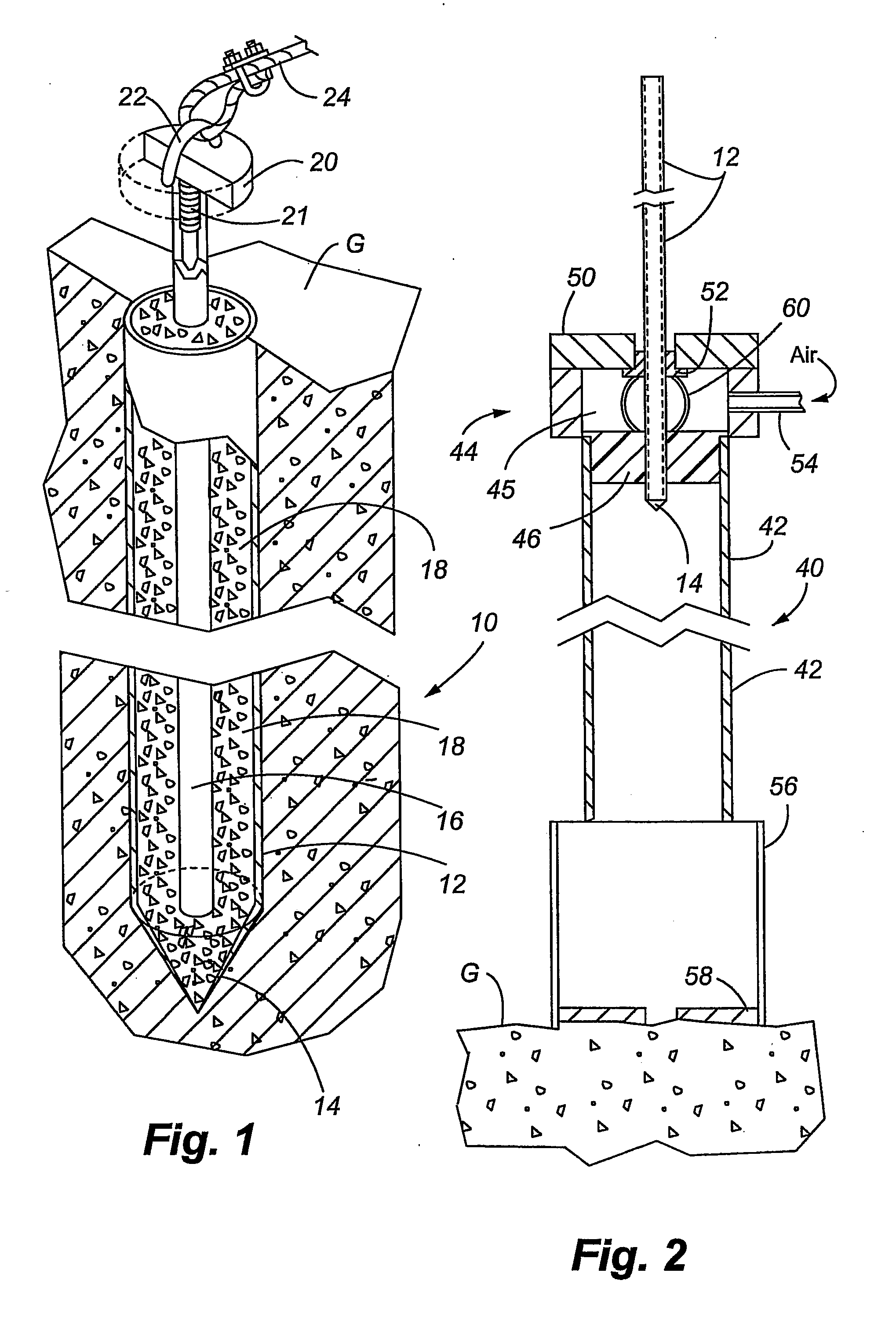

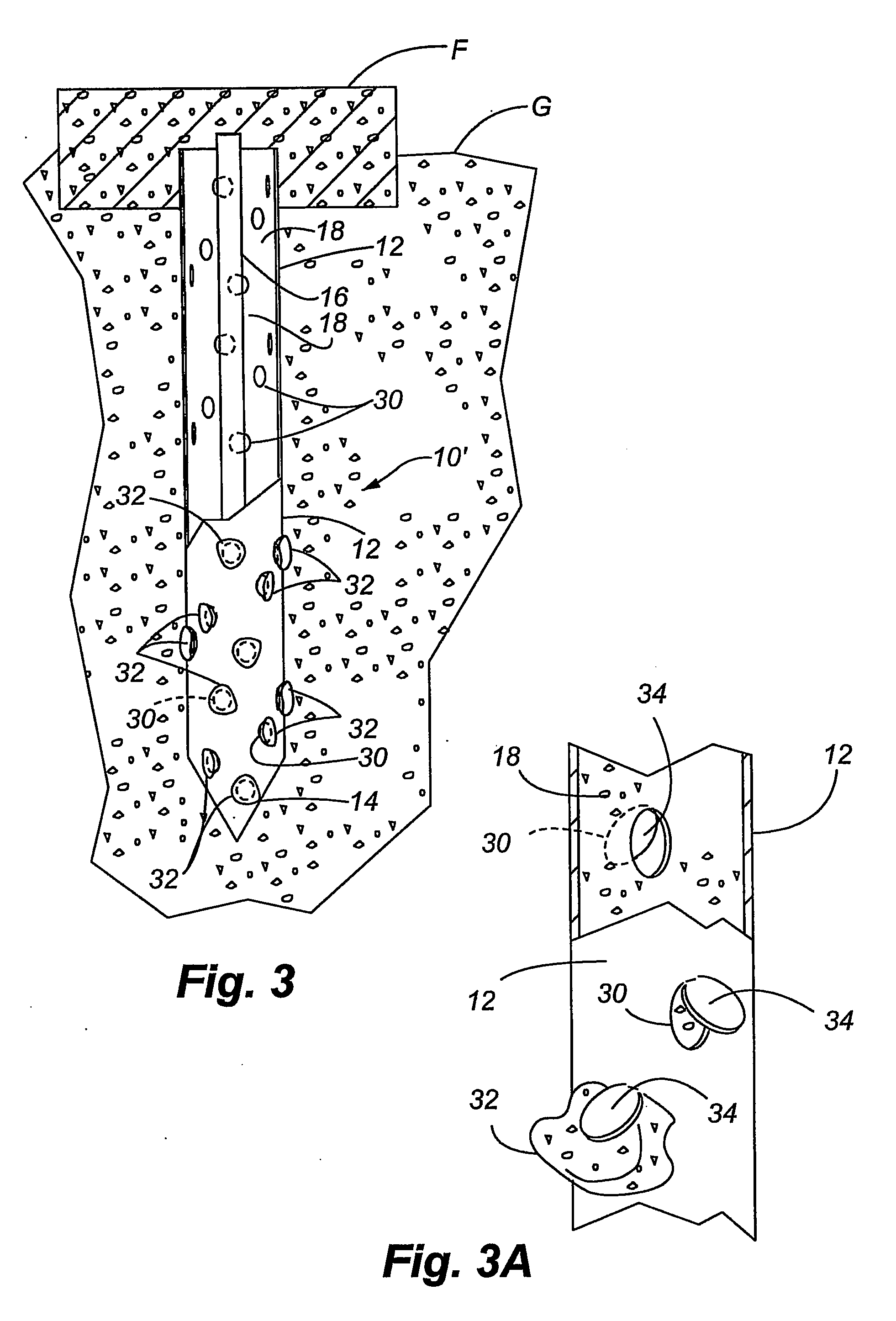

[0028]Referring to FIG. 1, the subsurface support 10 in a first embodiment of the present invention is shown installed in the ground G. The support device includes an outer member, preferably in the form of a steel or iron tube 12 having a selected length and diameter, and having an integral pointed tip 14. The tip 14 can be conical in shape that facilitates emplacement of the outer tube as by a launcher, as discussed below. After the outer tube is emplaced, the stabilizing mixture is placed in the interior chamber of the outer tube. Then, an inner support member that can be in the form of an epoxy coated steel rod or bar is then placed within the stabilizing mixture prior to hardening of the mixture. When the stabilizing mixture cures, the inner support member 16 can provide support to an overlying structure in compression, tension, and / or shear. Depending upon the design requirements of the particular structure to be built, a plurality of subsurface supports may be emplaced at des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com