Tubular-member flange coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

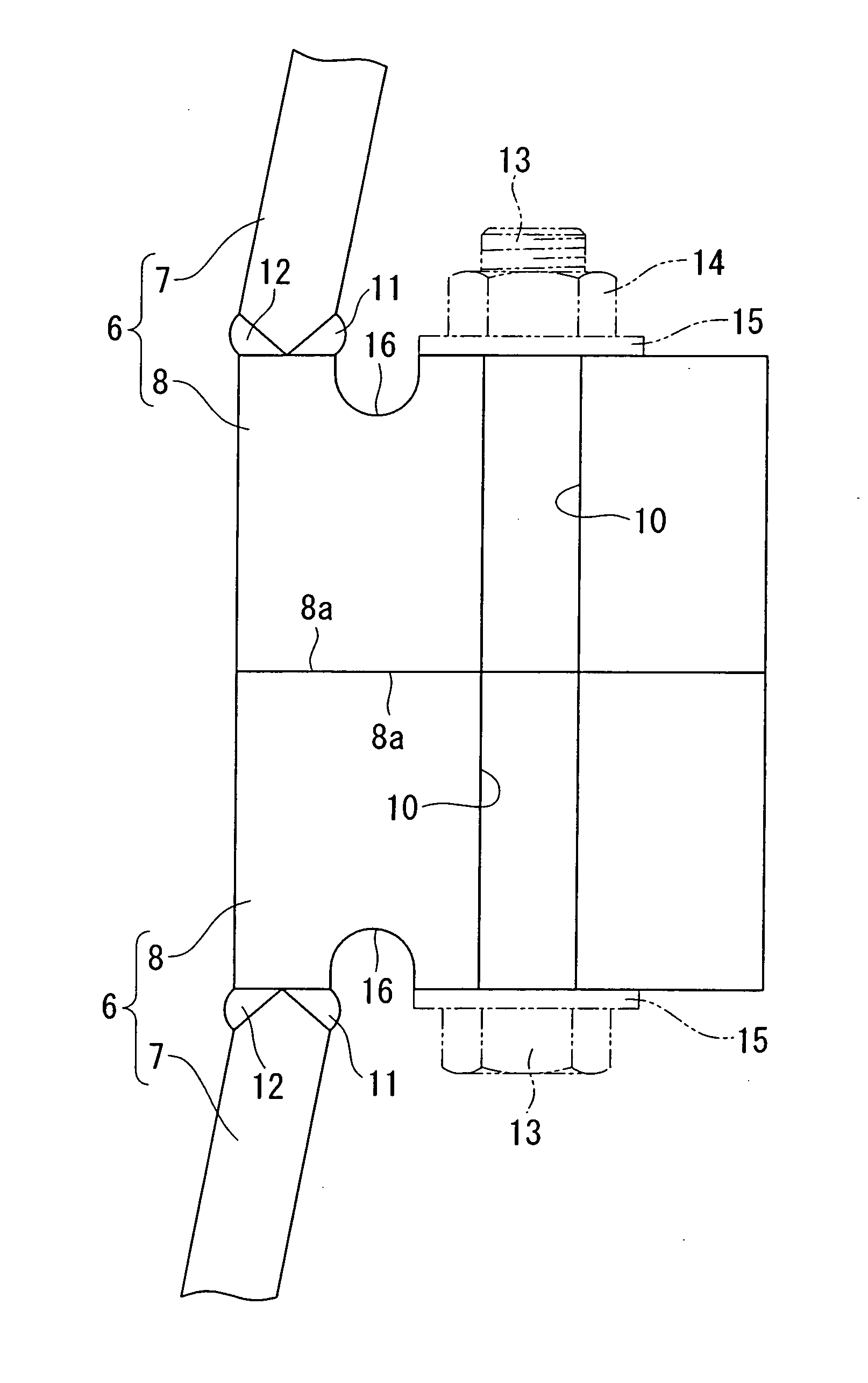

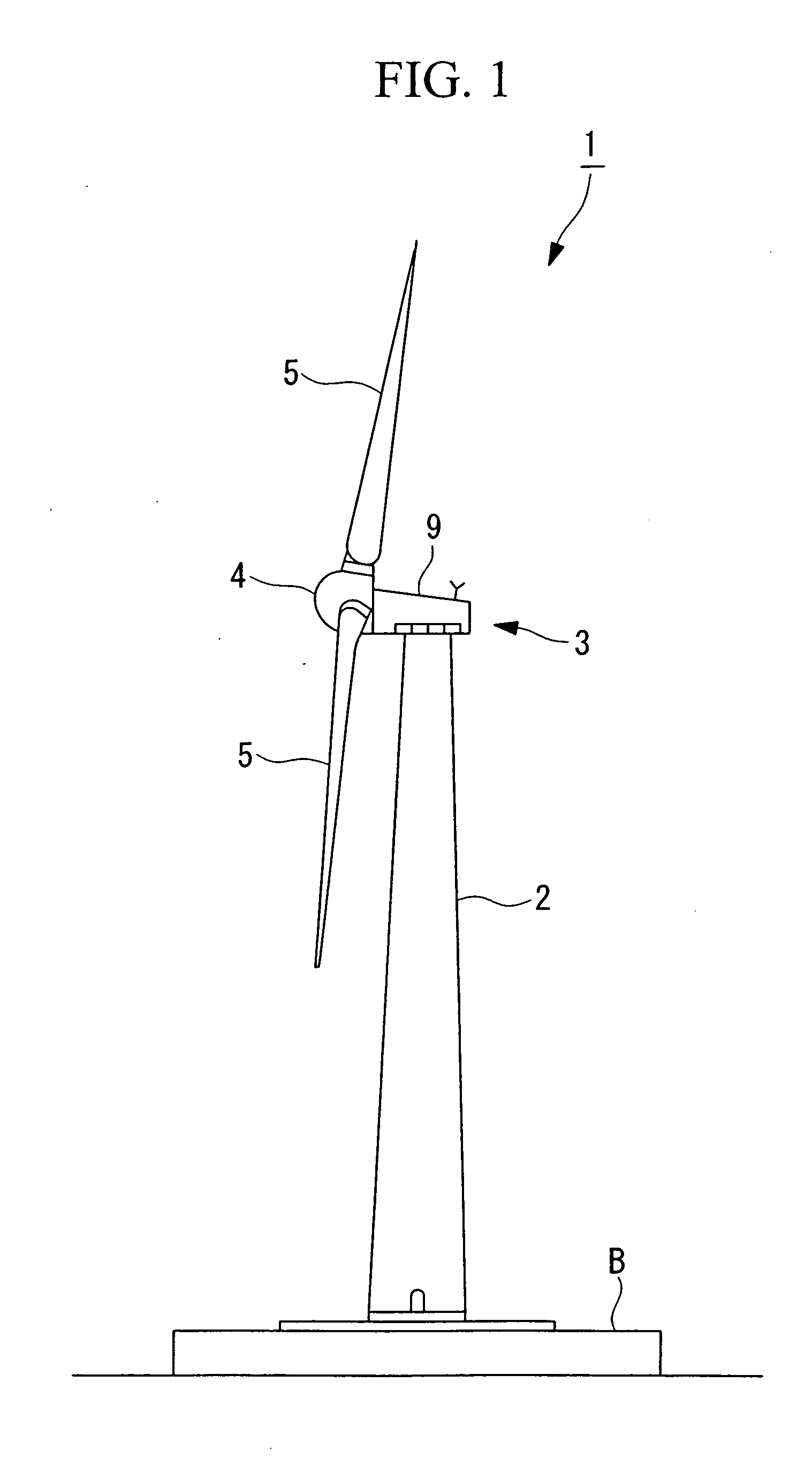

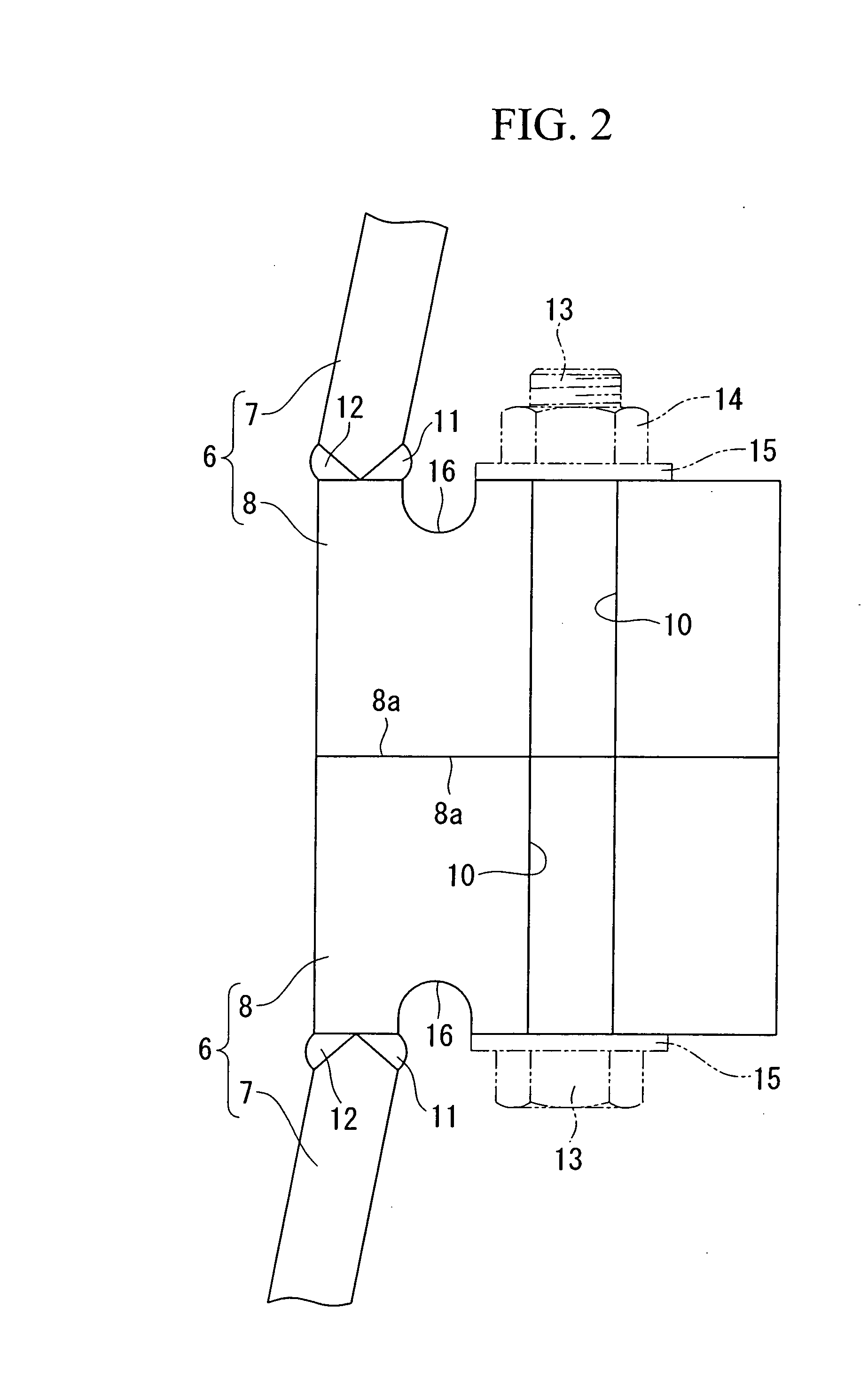

[0033]A ring-shaped-member flange coupling (hereinafter, “flange coupling”) according to an embodiment of the present invention will be described below with reference to FIGS. 1 and 2.

[0034]FIG. 1 is a side view of a wind turbine for wind turbine generator having flange couplings according to this embodiment, and FIG. 2 is a longitudinal sectional view of a relevant part in FIG. 1.

[0035]As shown in FIG. 1, the wind turbine for wind turbine generator 1 includes a support tower (also referred to as “tower”) 2 installed upright on a foundation B, a nacelle 3 mounted on the top of the support tower 2, and a rotor head 4 mounted to the nacelle 3 so as to be rotatable about a substantially horizontal axis.

[0036]A plurality of (for example, three) wind turbine rotor blades 5 are radially attached around the rotation axis of the rotor head 4. Thus, the force of the wind blowing in the rotation axis direction of the rotor head 4 against the wind turbine rotor blades 5 is converted into motiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com