Apparatus for energy transfer using converter and method of manufacturing same

a technology of converters and accessories, applied in the direction of electric energy management, dc-ac conversion without reversal, battery arrangement for several simultaneous batteries, etc., can solve the problems of adding cost and weight to the vehicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

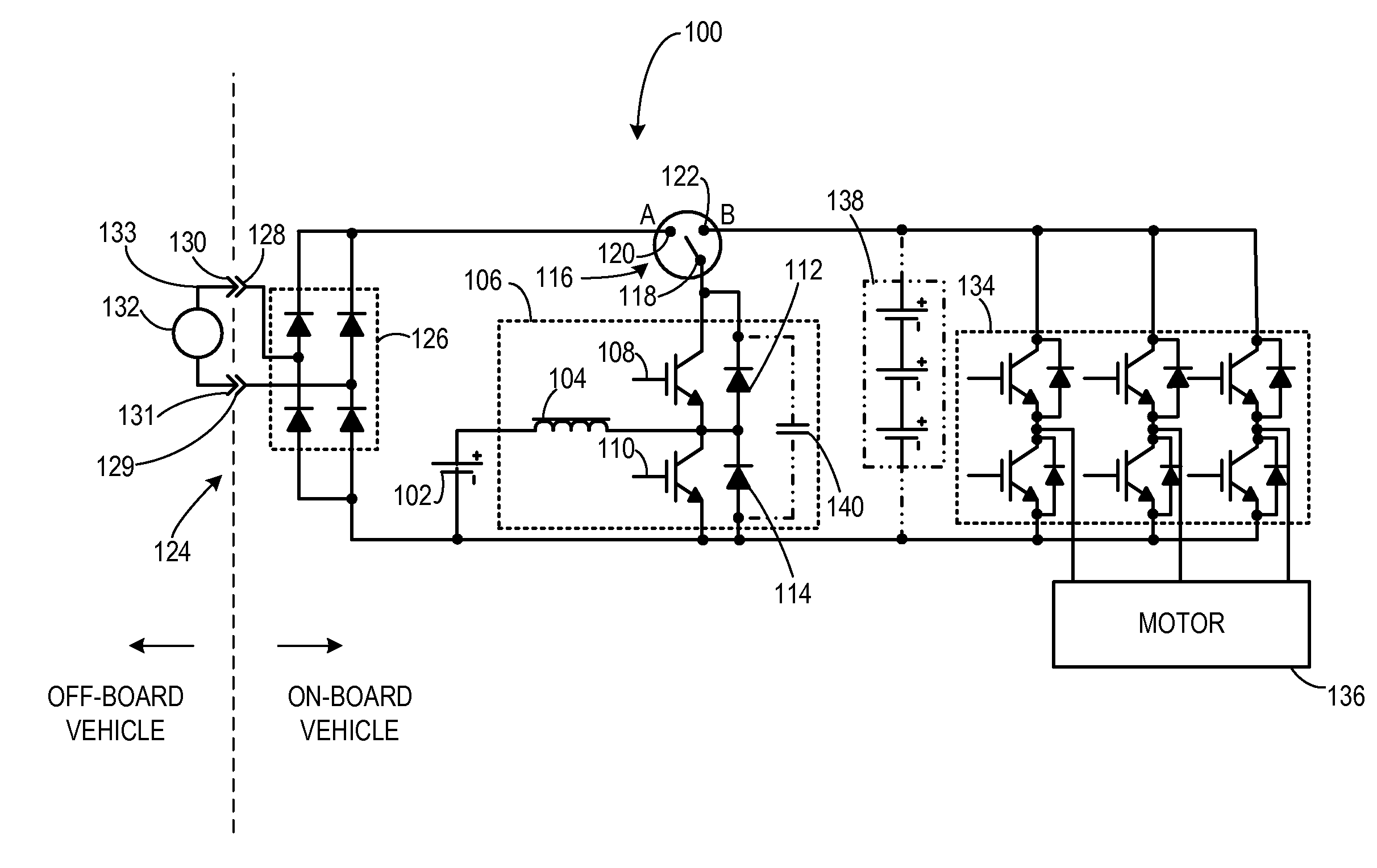

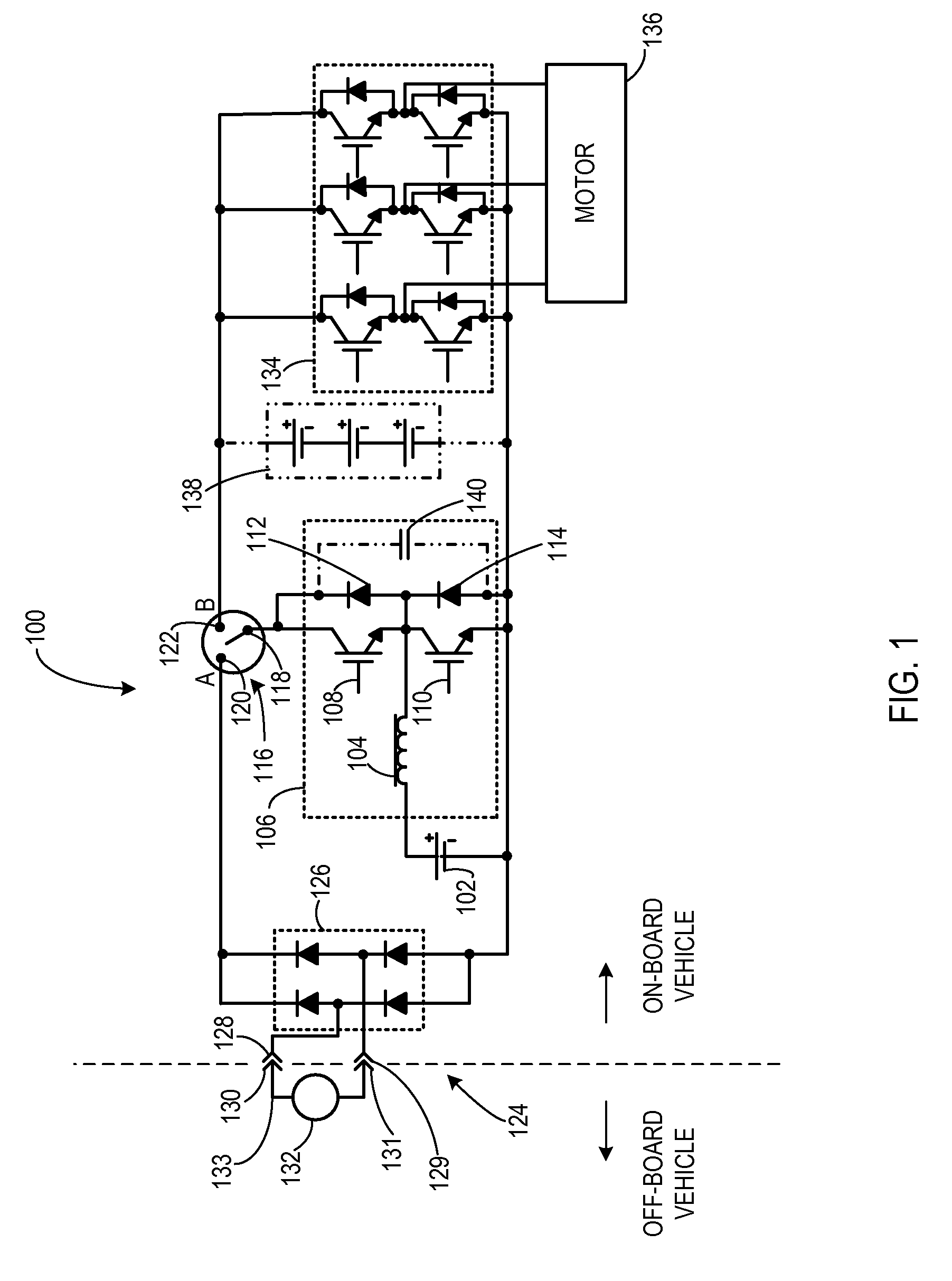

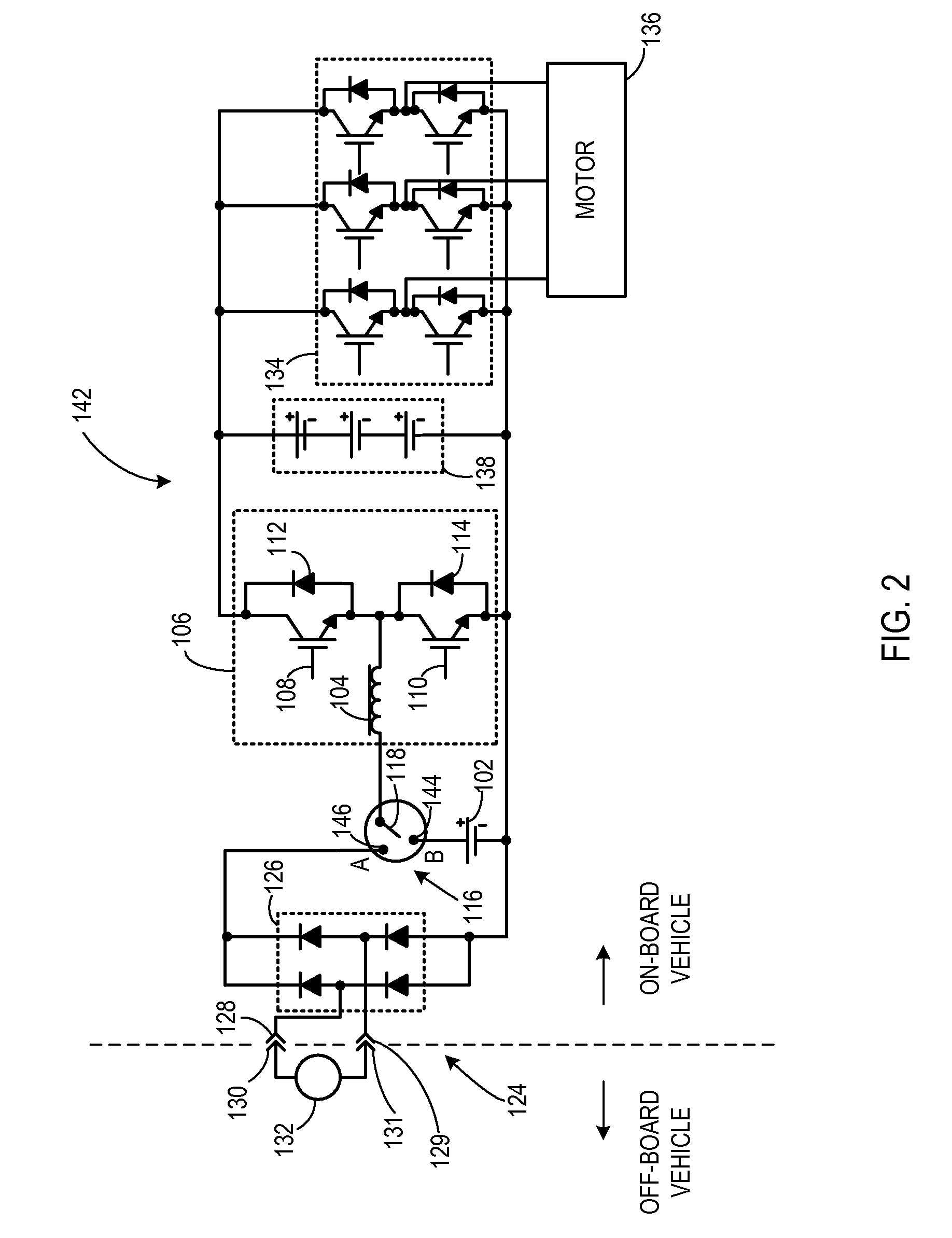

[0021]In an embodiment of the invention illustrated in FIG. 1, a traction system 100 usable in a vehicle, such as a plug-in electric or plug-in hybrid vehicle, or stationary electric drive system is shown. Traction system 100 includes a first energy storage device 102, which may be a battery, a fuel cell, an ultracapacitor, or the like, coupled to an inductor 104 of a bi-directional DC-to-DC voltage converter 106. Inductor 104 is coupled to a first transistor 108 and a second transistor 110 connected in series. Each of the transistors 108, 110 is coupled in anti-parallel with a first and second diode 112, 114, respectively. A coupling system 116 includes a switch 118, which may be, for example, a contactor, a relay, a semiconductor switch, or the like. Switch 118 has a first position 120 and a second position 122 that is coupled to first transistor 108. When switch 118 is in first position 120, bi-directional DC-to-DC voltage converter 106 is coupled to an input device 124, which in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| electrical energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com