Linear compressor

a compressor and linear technology, applied in the direction of machines/engines, positive displacement liquid engines, pumping, etc., can solve the problems of reducing the stability of linear compressors, unable to use mechanical springs, and affecting the operation of linear compressors, etc., to achieve stab operation, reduce noise and vibration, and simplify the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Hereinafter, a linear compressor according to the present invention will be described in detail with reference to the accompanying drawings.

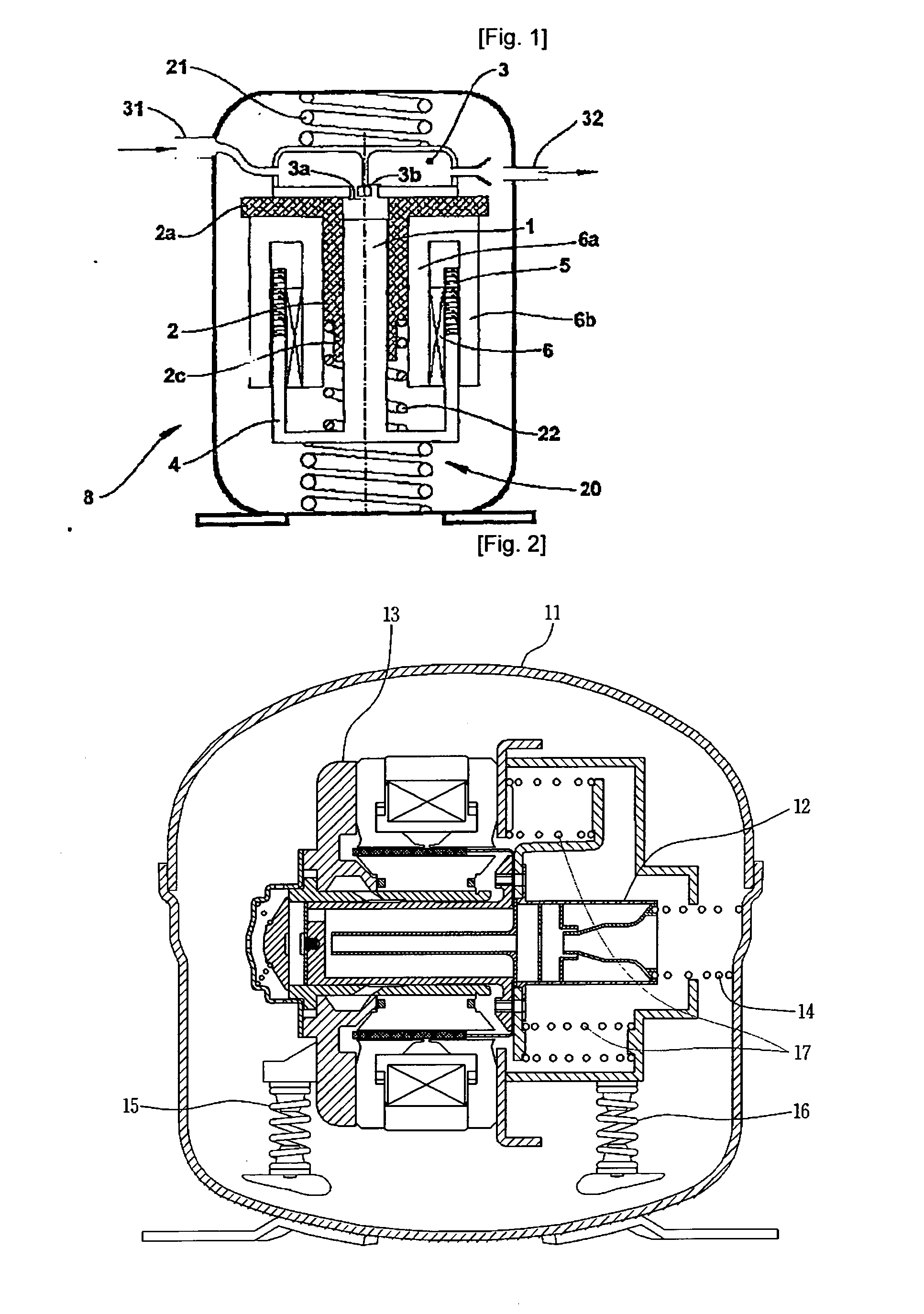

[0032]FIG. 3 is a schematic view illustrating a vibration system of a linear compressor according to an embodiment of the present invention.

[0033]The vibration system of the linear compressor includes a shell 11, a moving part 12, a stationary part 13, a first elastic body 14, second elastic bodies 15 and 16, and a third elastic body 17. Variables used to interpret the vibration system include a displacement xa of the moving part 12, a displacement xb of the stationary part 13, a mass Ma of the moving part 12, a mass Mb of the stationary part 13, an spring constant ka of the first elastic body 14, an spring constant 0.5·kb of each second elastic body 15 and 16, an spring constant kc of the third elastic body 17, motor parameters L, R, α and V, a motor output Fm, a force Fa applied to the moving part 12 by the first elastic body 14, a force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com