Heat exchanger with improved condensate removal

a heat exchanger and condensate technology, which is applied in the field of heat exchangers for cooling air, can solve the problems of increasing air side pressure, adverse effects on the overall performance of the refrigerant vapor compression system, and not always draining quickly of condensate on the heat exchange tube and associated fins, etc., and achieves the effect of facilitating condensate drainag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

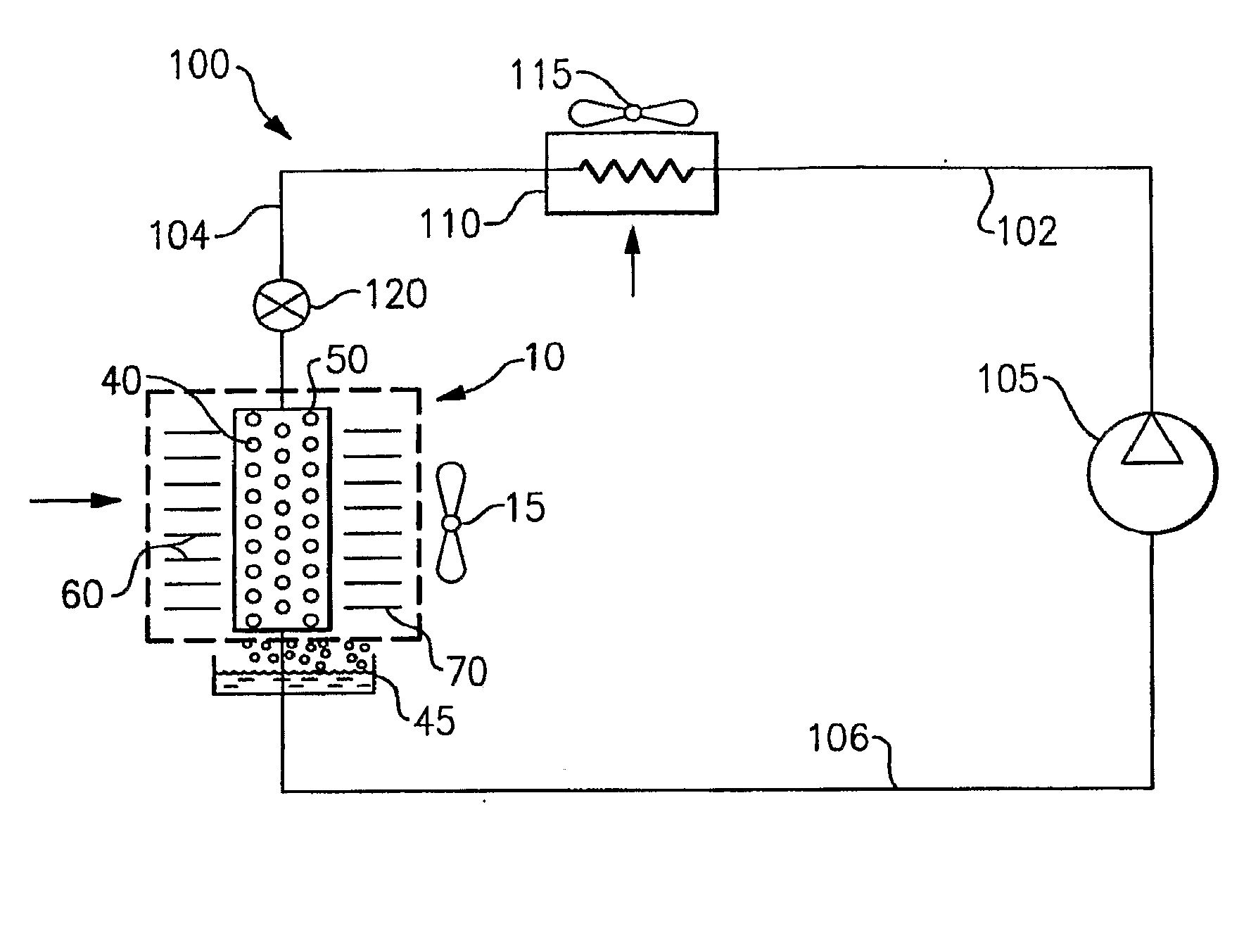

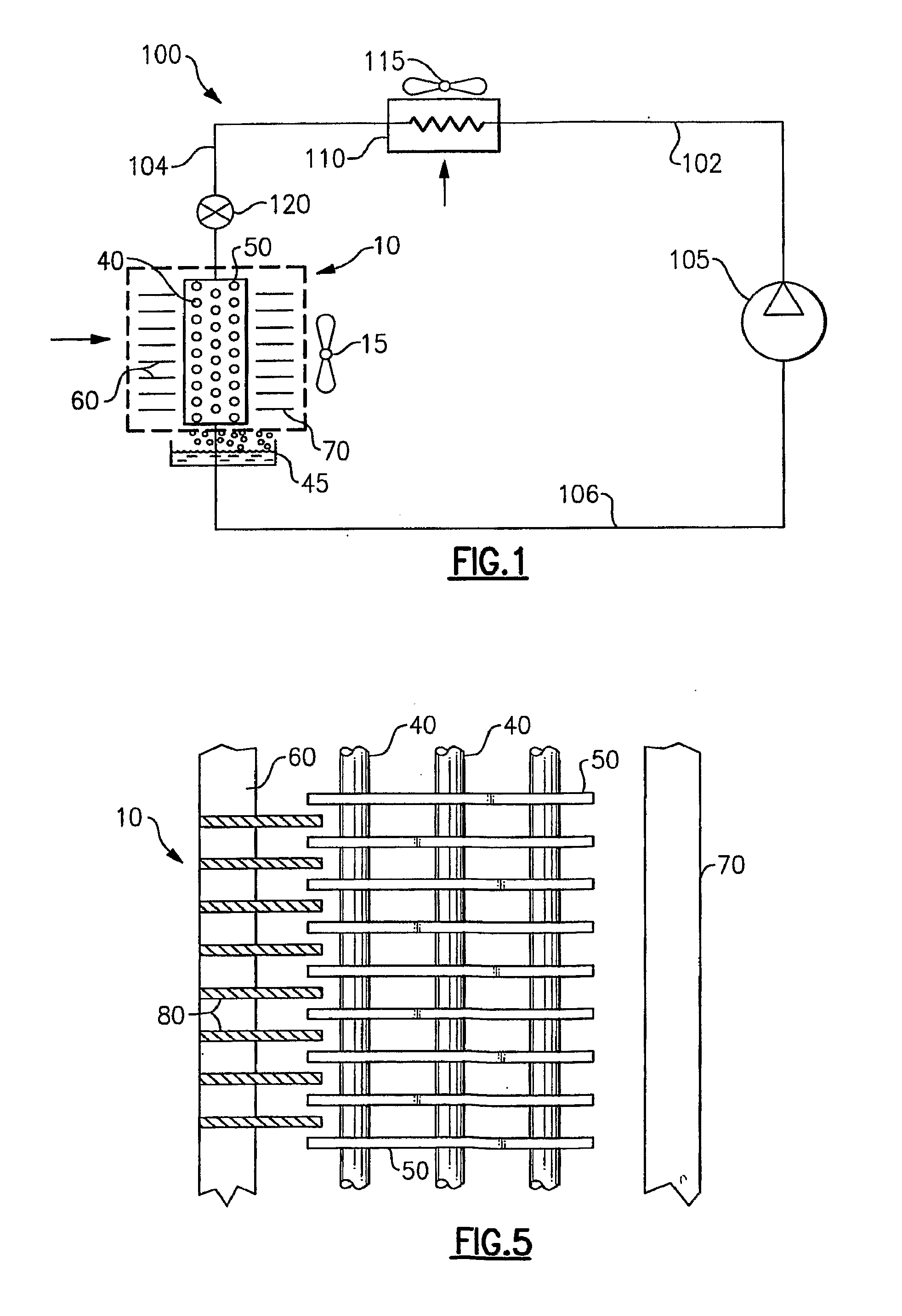

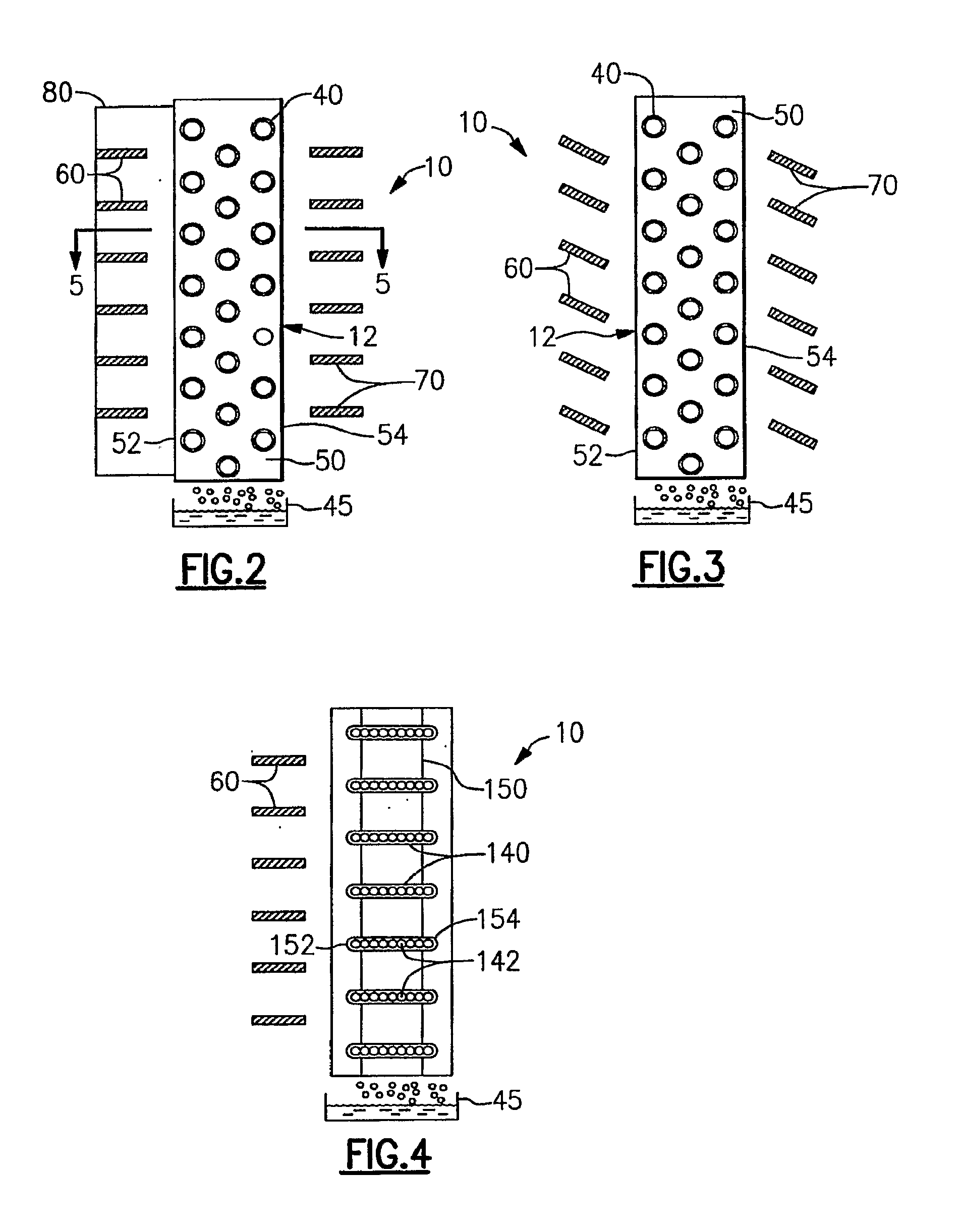

[0021]The heat exchanger of the invention will be described herein in use as an evaporator, in connection with a simplified air conditioning cycle refrigerant vapor compression system 100, as depicted schematically in FIG. 1. Although the exemplary refrigerant vapor compression cycle illustrated in FIG. 1 is a simplified air conditioning cycle, it is to be understood that the heat exchanger of the invention may be employed in refrigerant vapor compression systems of various designs, including, without limitation, heat pump cycles, economized cycles, cycles with tandem components such as compressors and heat exchangers, chiller cycles, cycles with reheat and many other cycles including various options and features. Also, it has to be recognized that although the blow-off phenomenon is described in connection to evaporators of refrigerant systems operating in a vapor compression cycle, cooling heat exchangers of air handling equipment, utilizing cold water or glycol solutions to cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com