Method for reducing the H2S content of an H2S-containing subterranean formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In the discussion of the Figures, numerous valves, heat exchangers, and the like required to achieve the process flows shown have not been shown in the interest of simplicity since such equipment is well known to those skilled in the art.

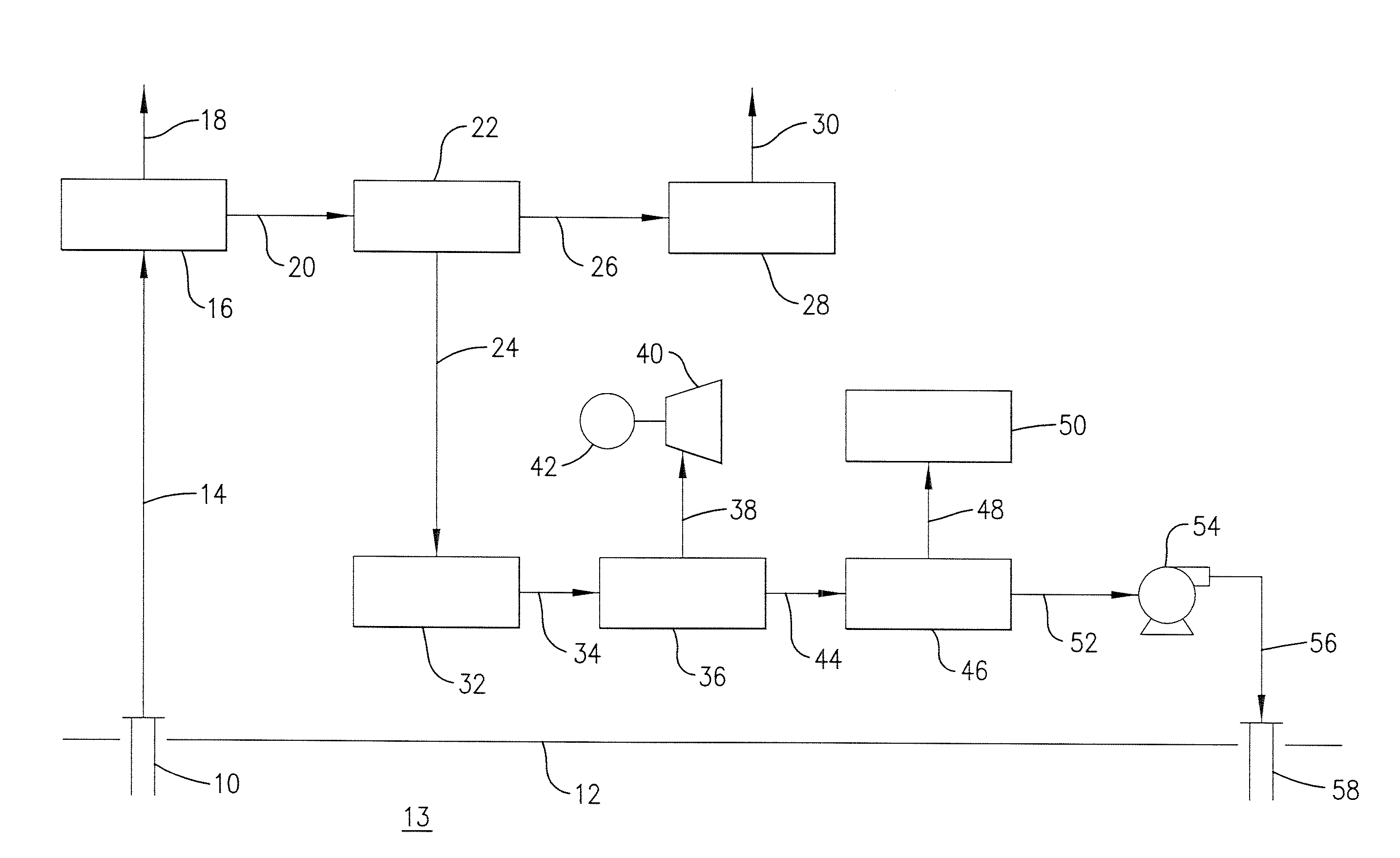

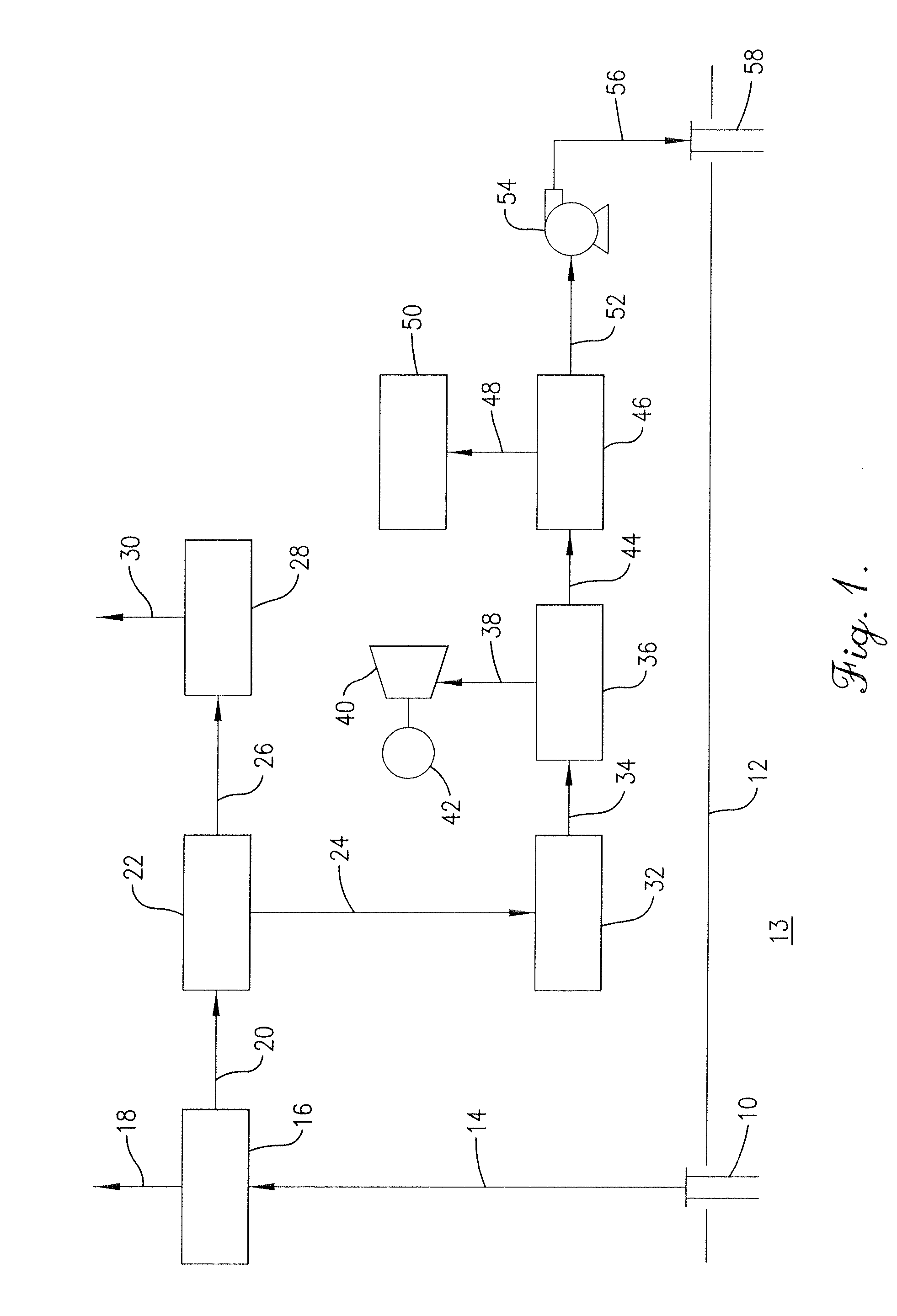

[0018]in FIG. 1 a representative process is shown for the production of SO2 for injection into a subterranean formation containing H2S. In the process shown schematically in FIG. 1, a production well 10 is shown extending from an earth surface 12 into a subterranean formation 13 containing H2S and producing gas. Sour gas is recovered through a line 14 and passed to a gas treatment facility 16 where the H2S is removed, along with other materials such as carbon dioxide, condensable gases and the like, as known to those skilled in the art. The sweet gas is then passed through a line 18 as a product to a pipeline or the like. The H2S is recovered through a line 20 and passed to a Claus sulfur recovery unit 22. Such units, as well known to those sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com