Image Display Device and Production Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

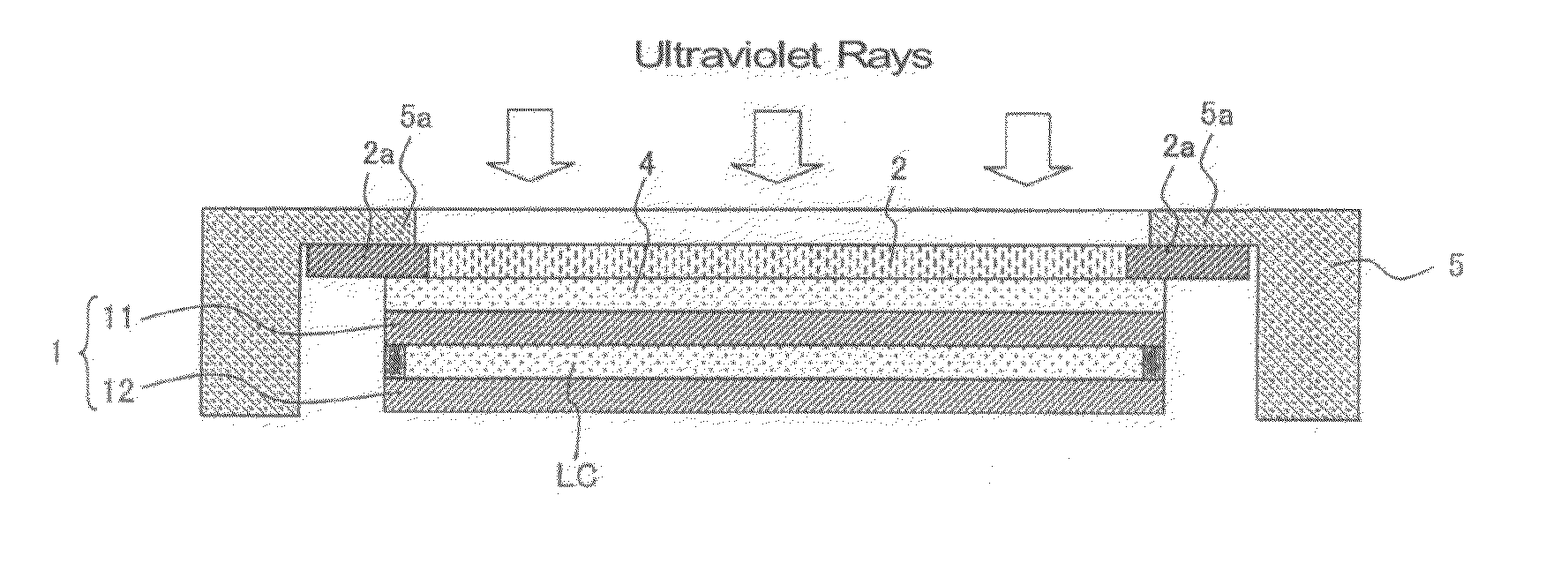

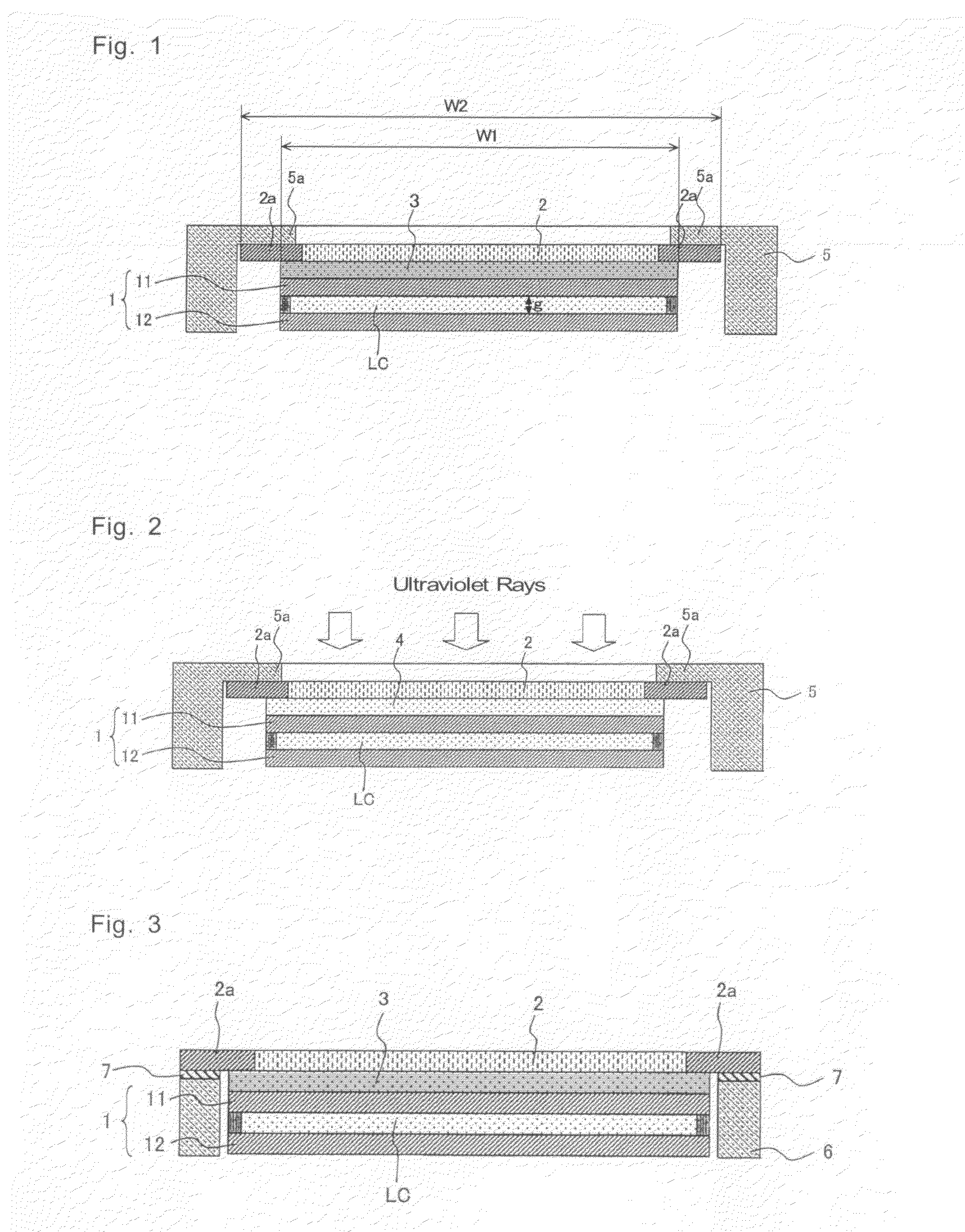

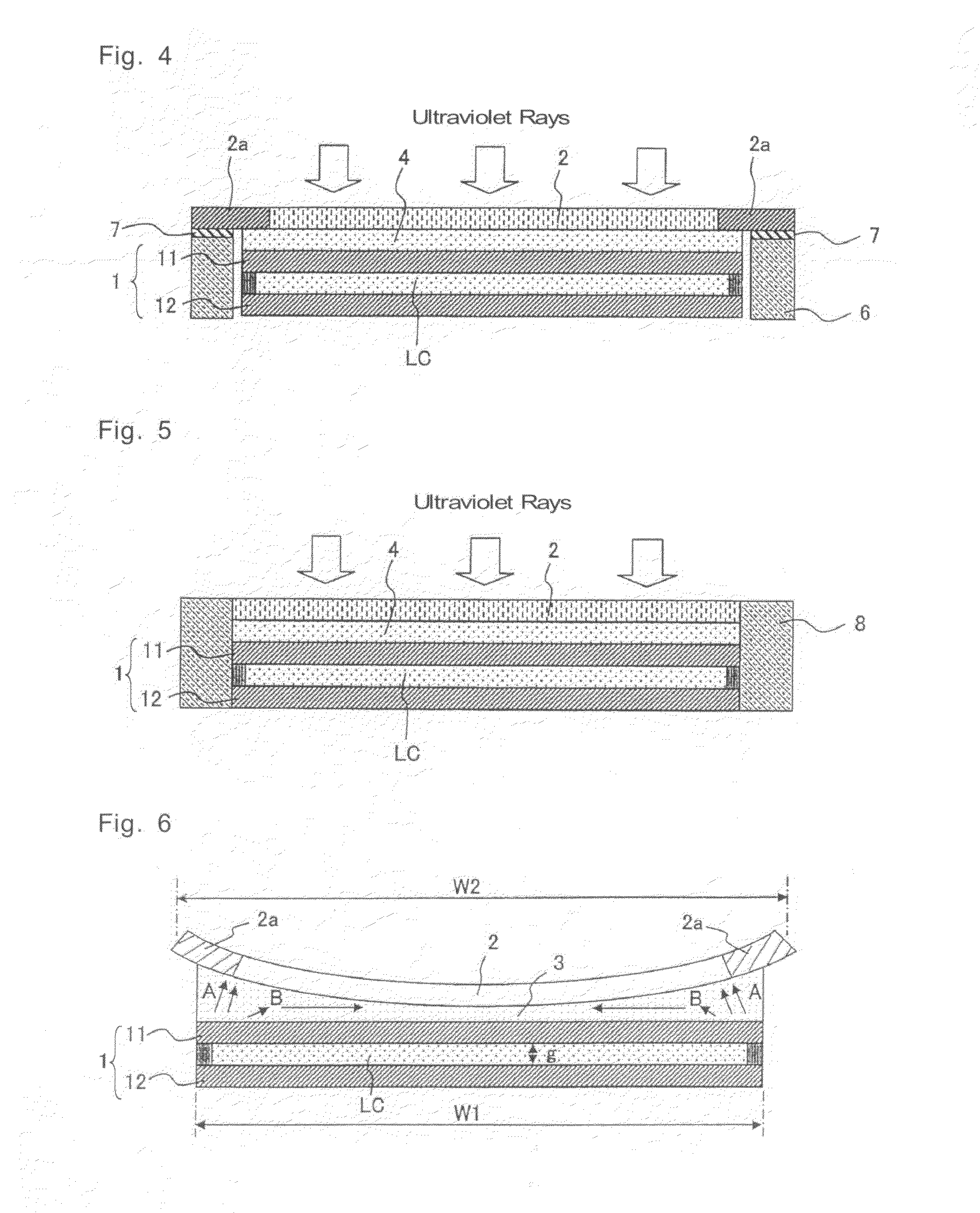

[0065]A protective panel was pasted on a liquid crystal display panel according to the method illustrated in FIG. 2 to produce a liquid crystal display device. The used protective panel was a transparent plastic panel formed from polymethyl methacrylate (PMMA). A case housing the liquid crystal display panel was used as a fixing jig. An upper face of a light shielding part formed on a peripheral edge of the protective panel was held and fixed with forming an eaves-shaped holding part on this case.

[0066]The resin composition to be arranged between the liquid crystal display panel and the protective panel was prepared by kneading in a kneader 70 parts by weight of an ester compound formed from a maleic anhydride adduct of a polyisoprene polymer and 2-hydroxyethyl methacrylate, 30 parts by weight of dicyclopentenyl oxyethyl methacrylate, 10 parts by weight of 2-hydroxybutyl methacrylate, 30 parts by weight of a hydrogenated terpene resin, 140 parts by weight of a butadiene polymer, 4 p...

example 2

[0072]A liquid crystal display device was produced in the same manner as in Example 1, except that the resin composition to be arranged between the liquid crystal display panel and the protective panel was changed as follows. In the present example too, a liquid crystal display device could be obtained which had hardly any warping of the protective panel, no display unevenness, and excellent outdoor visibility and impact resistance.

[0073]More specifically, the resin composition in the present example was prepared by kneading in a kneader 100 parts by weight of an ester compound formed from a maleic anhydride adduct of a polyisoprene polymer and 2-hydroxyethyl methacrylate, 30 parts by weight of dicyclopentenyl oxyethyl methacrylate, 10 parts by weight of 2-hydroxybutyl methacrylate, 30 parts by weight of a hydrogenated terpene resin, 210 parts by weight of a butadiene polymer, 7 parts by weight of a photopolymerization initiator, and 1.5 parts by weight of a visible region photopoly...

example 3

[0075]A liquid crystal display device was produced in the same manner as in Example 1, except that the resin composition to be arranged between the liquid crystal display panel and the protective panel was changed as follows. In the present example too, a liquid crystal display device could be obtained which had hardly any warping of the protective panel, no display unevenness, and excellent outdoor visibility and impact resistance.

[0076]More specifically, the resin composition in the present example was prepared by kneading in a kneader 70 parts by weight of an ester compound formed from a maleic anhydride adduct of a polyisoprene polymer and 2-hydroxyethyl methacrylate (trade name: UC-203, manufactured by Kuraray Co., Ltd.), 30 parts by weight of dicyclopentenyl oxyethyl methacrylate (trade name: FA512M, manufactured by Hitachi Chemical Co., Ltd.), 10 parts by weight of 2-hydroxybutyl methacrylate (trade name: Light Ester HOB, manufactured by Kyoeisha Chemical Co., Ltd.), 30 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com