Drill guide with angle verification

a technology of angle verification and drill guide, which is applied in the field of angle verification, can solve the problems of bone deformation, difficult to drill the pilot hole at the correct angle, and surgeons often had difficulty eyeing the correct angl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

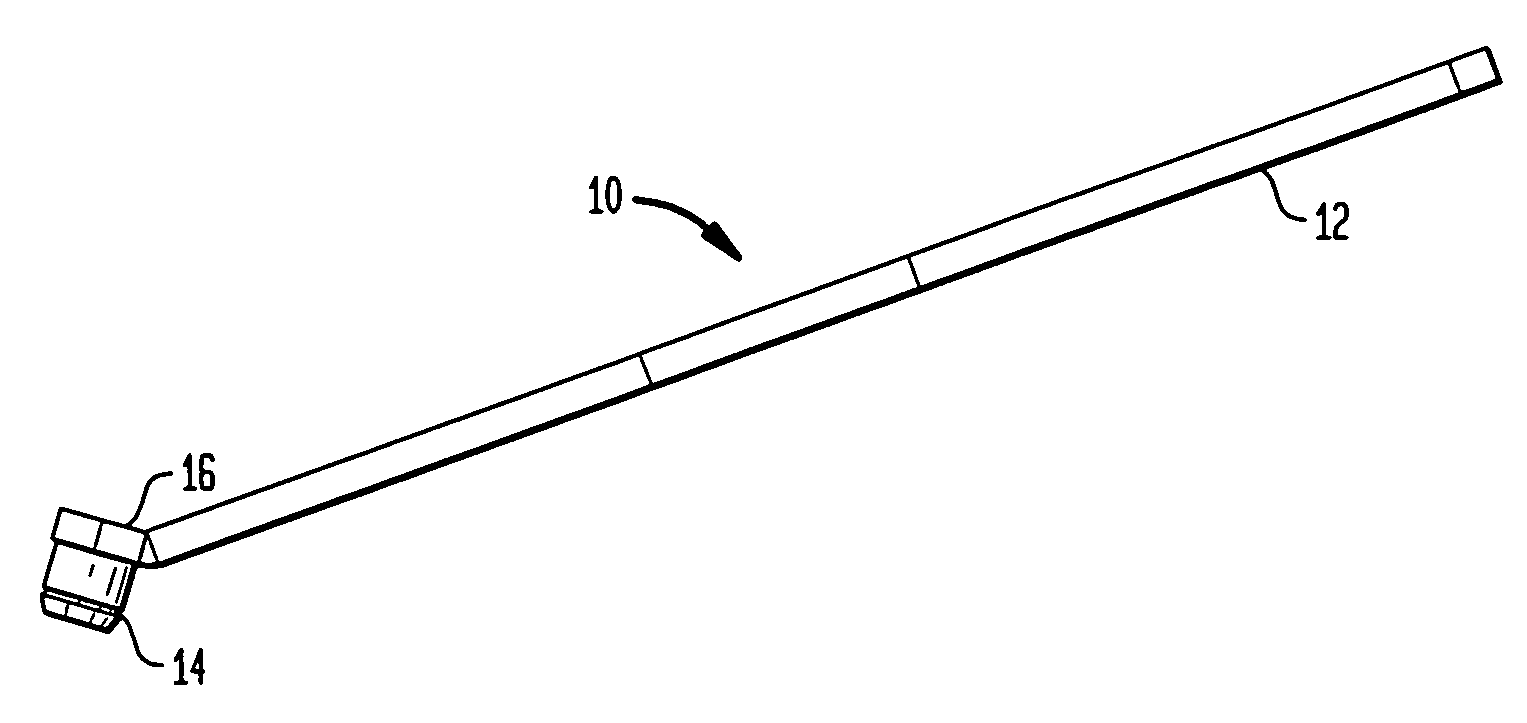

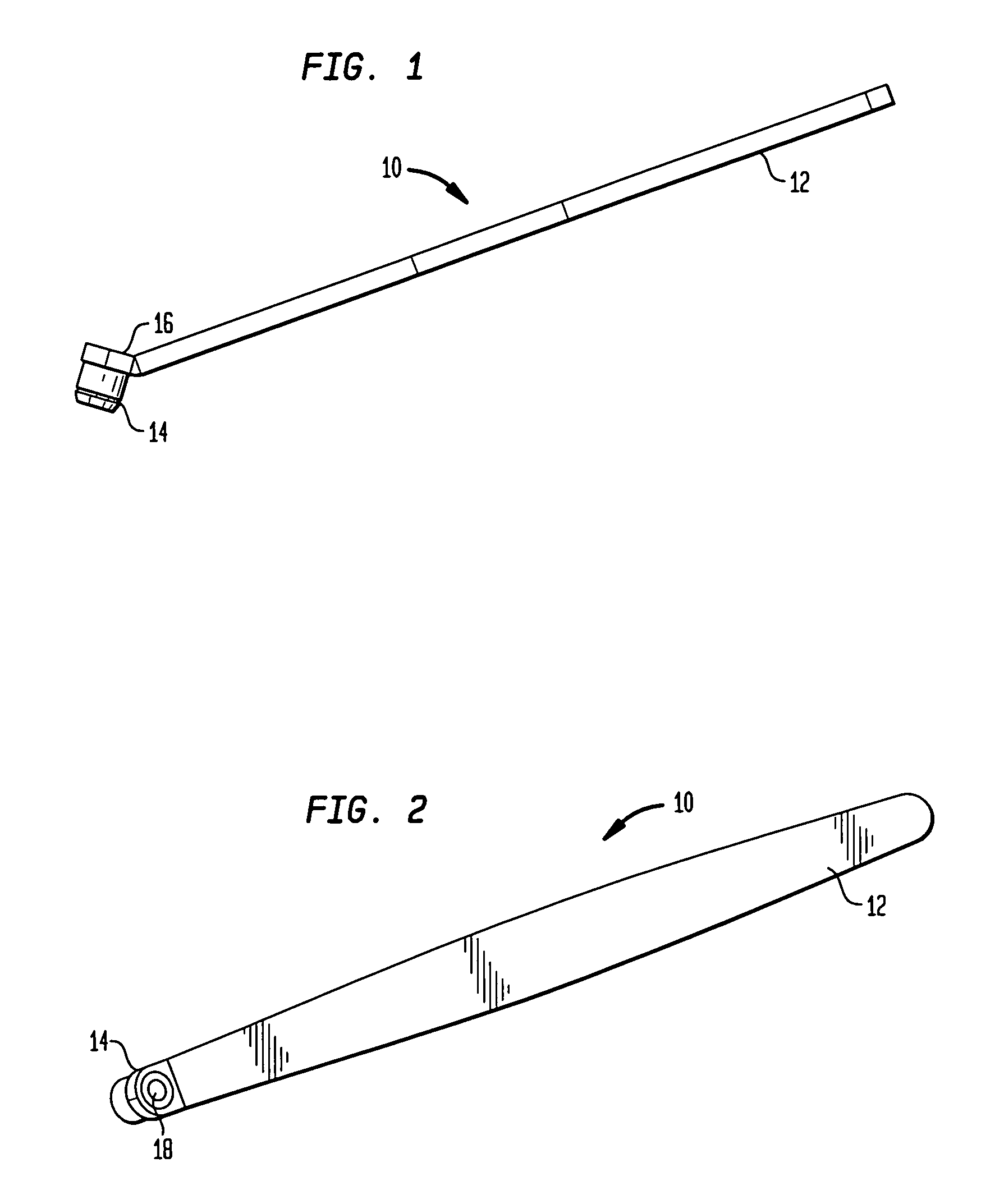

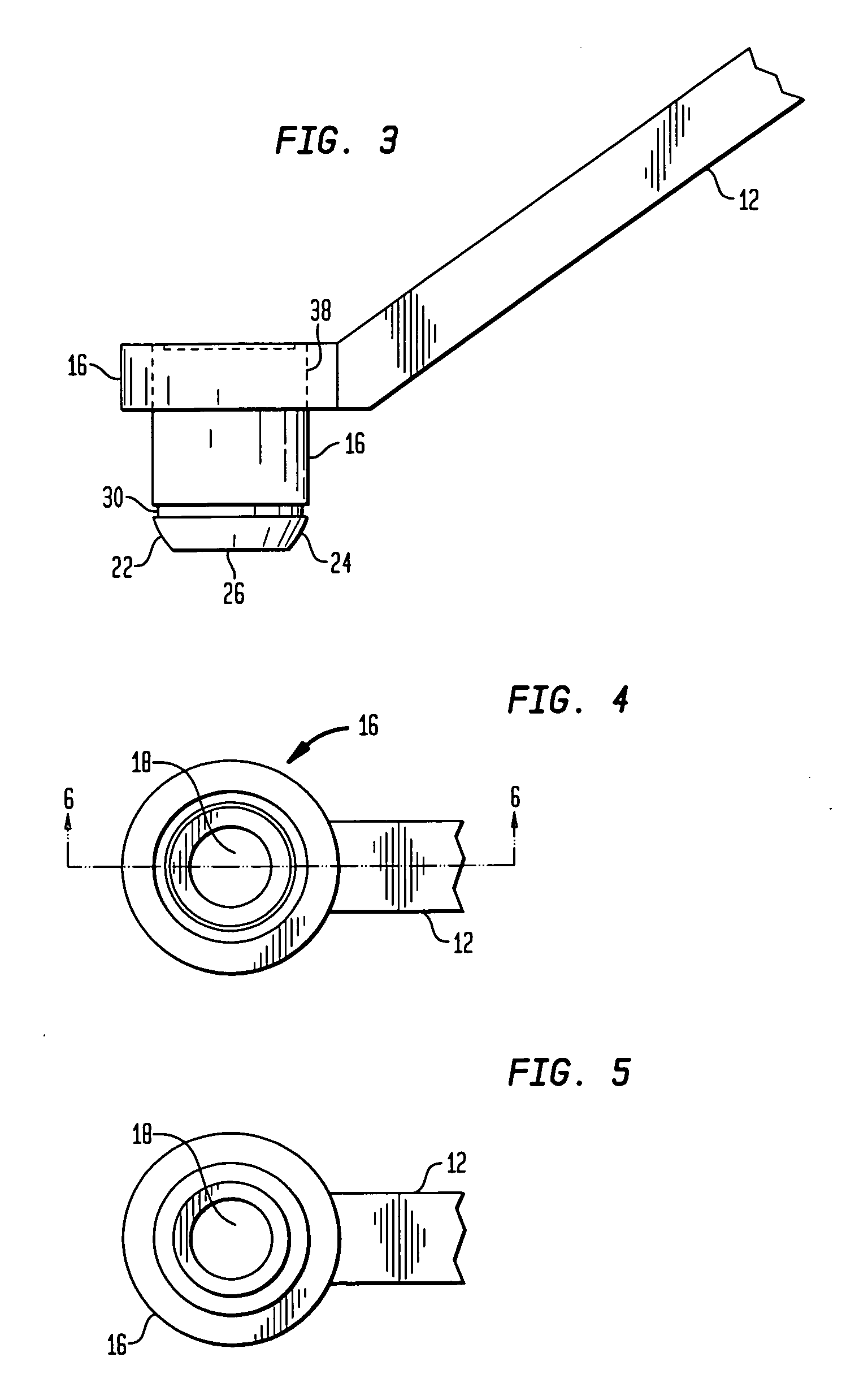

[0026]Referring to FIG. 1, there is shown an isometric view of the instrument of the present invention generally denoted as 10. Instrument 10 includes a handle portion 12 and a leading or distal end 14 which includes a drill guide element 16 as can be seen in FIGS. 2, 4 and 5. Drill guide element 16 includes a guide bore 18. Guide bore 18 is adapted to receive a drill bit 20 such as shown in FIG. 9.

[0027]Referring to FIG. 3, the drill guide element 16 has a leading end 22 which, in the preferred embodiment is cylindrical and includes a part-spherical convex contact surface 24 for engaging a part-spherical concave surface 28 surrounding a plate bore as shown in FIGS. 8 and 9. In the preferred embodiment, the element 16 includes a marking ring or line 30 which can be etched or laser marked or even being a groove of a reduced diameter in a predetermined axial location along the axial direction of element 16. The spacing of marking 30 with regard to end 26 of element 16 is determined by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com