Conformable layer utilizing active material actuation

a technology of active material and conformable layer, applied in the field of conformable fabrics and coverings, can solve the problems of limited application range of wrap types, large cycle time, limited number of uses, etc., and achieve the effect of reducing wrinkles and other anomalies, increasing the superjacent area of engagement between layers, and smoothing the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

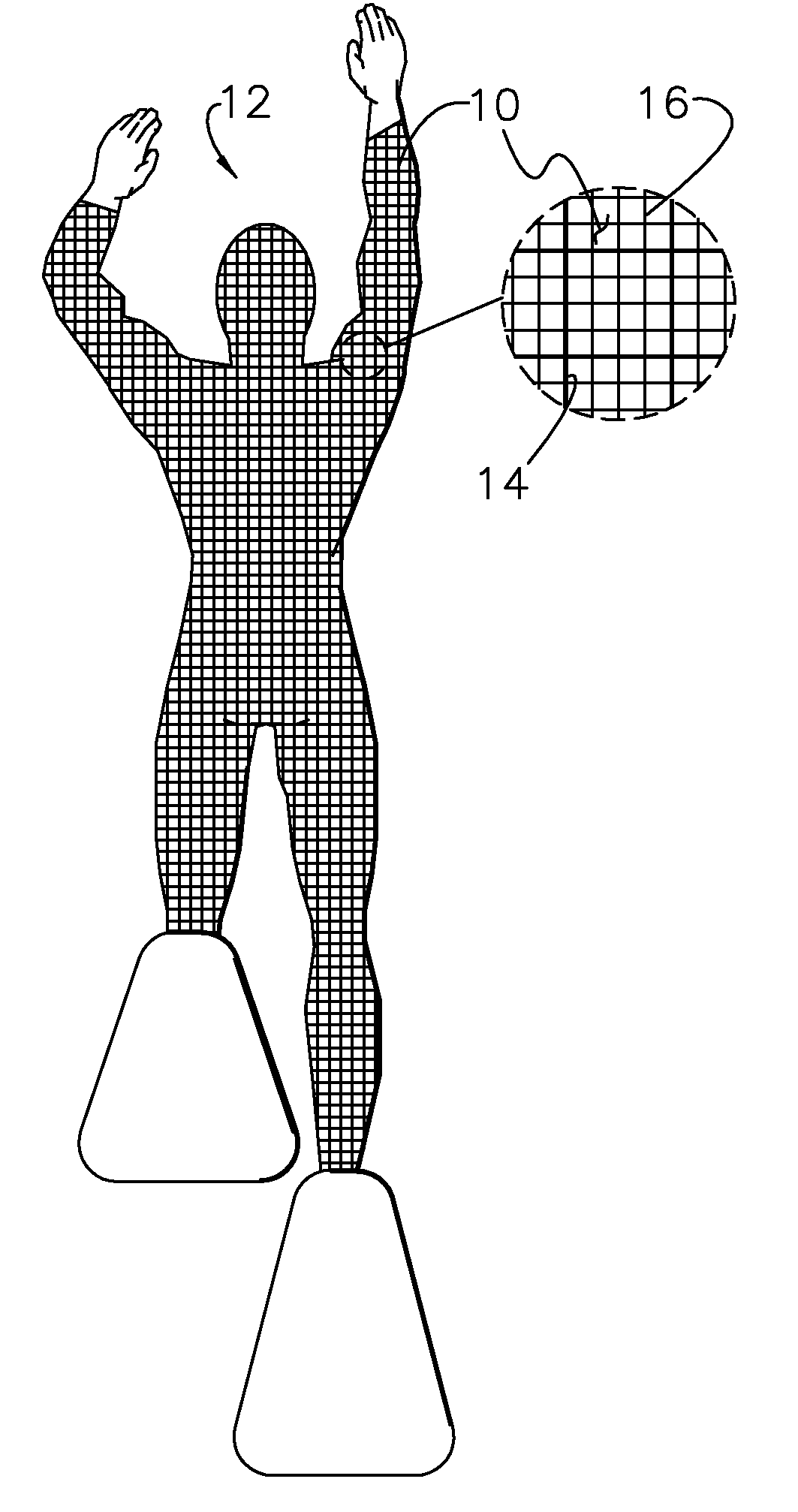

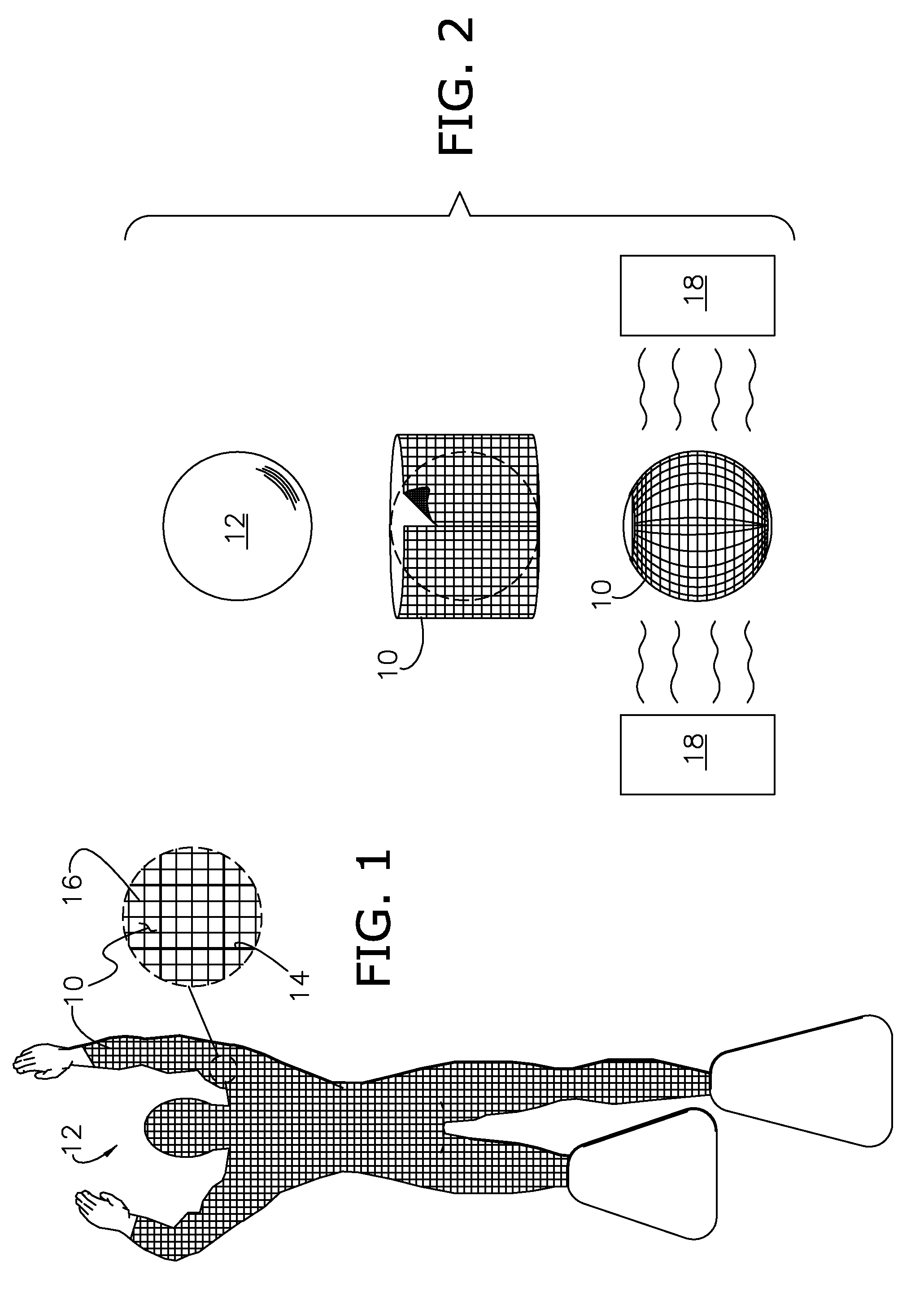

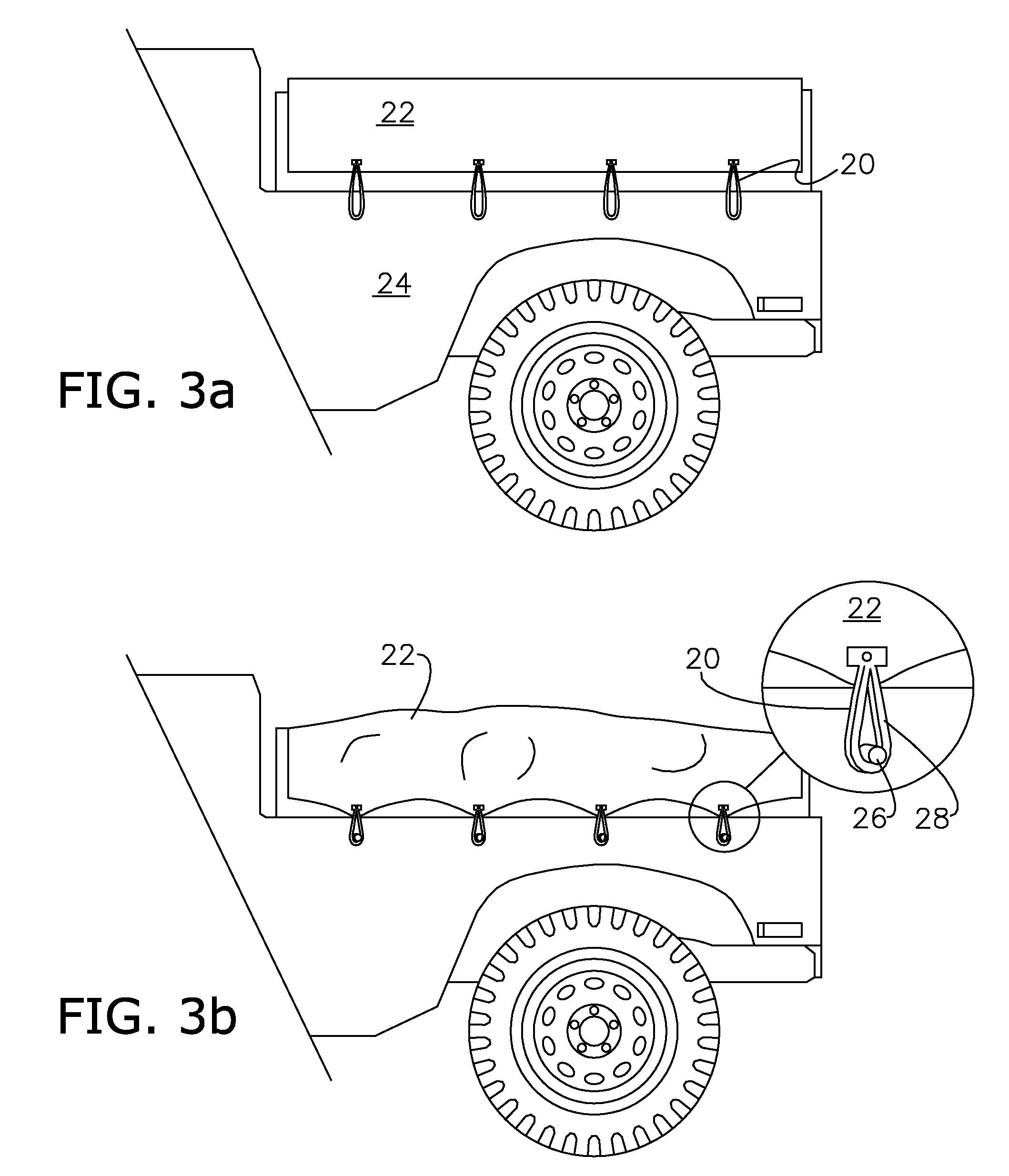

[0018]The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. The present invention may find utility in a wide range of applications; including, for example, in compositions of clothing and apparel (FIG. 1), as coverings for vehicles (FIGS. 3a,b), boats, and furniture, and as reusable shrinkage wrap (FIG. 2). That is to say, the invention is applicable wherever the advantages and benefits of using a selectively conformable fabric or covering is desired.

[0019]In general, the invention concerns a fabric, covering, sheath, film, or otherwise thin layer of conformable material configured to overlay the outer surface of an object or form a barrier between two adjacent spaces (collectively referred to herein as “protective layer”). The protective layer 10 employs active material actuation to facilitate application and / or improve function.

[0020]Suitable active materials for use with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com