Energy recovery apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In the exemplary embodiments that follow, individual characteristics, given in relation to specific examples, may actually be interchanged with other different characteristics that exist in other exemplary embodiments.

[0018]Moreover, it is noted that anything found to be already known during the patenting process is understood not to be claimed and to be the subject of a disclaimer.

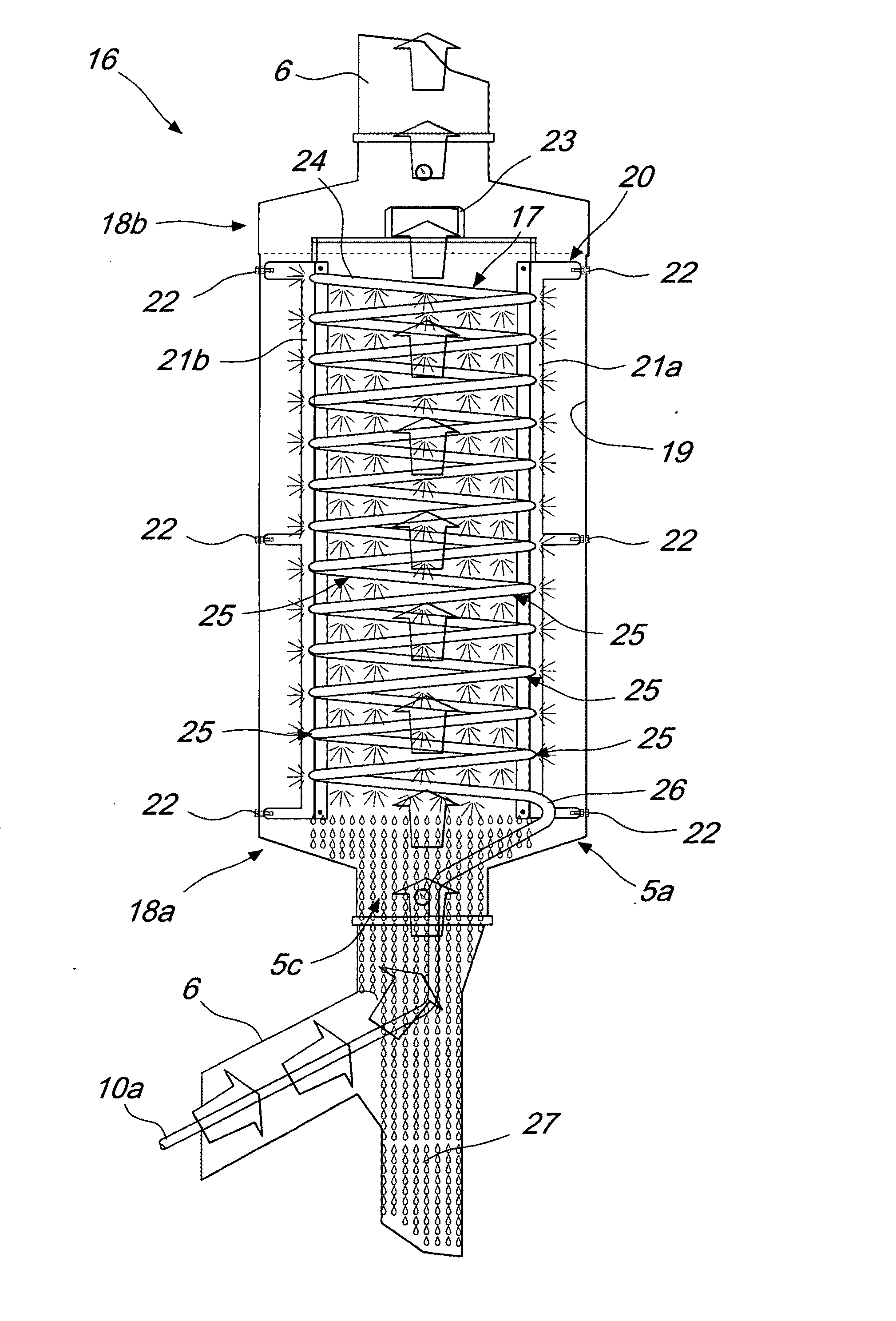

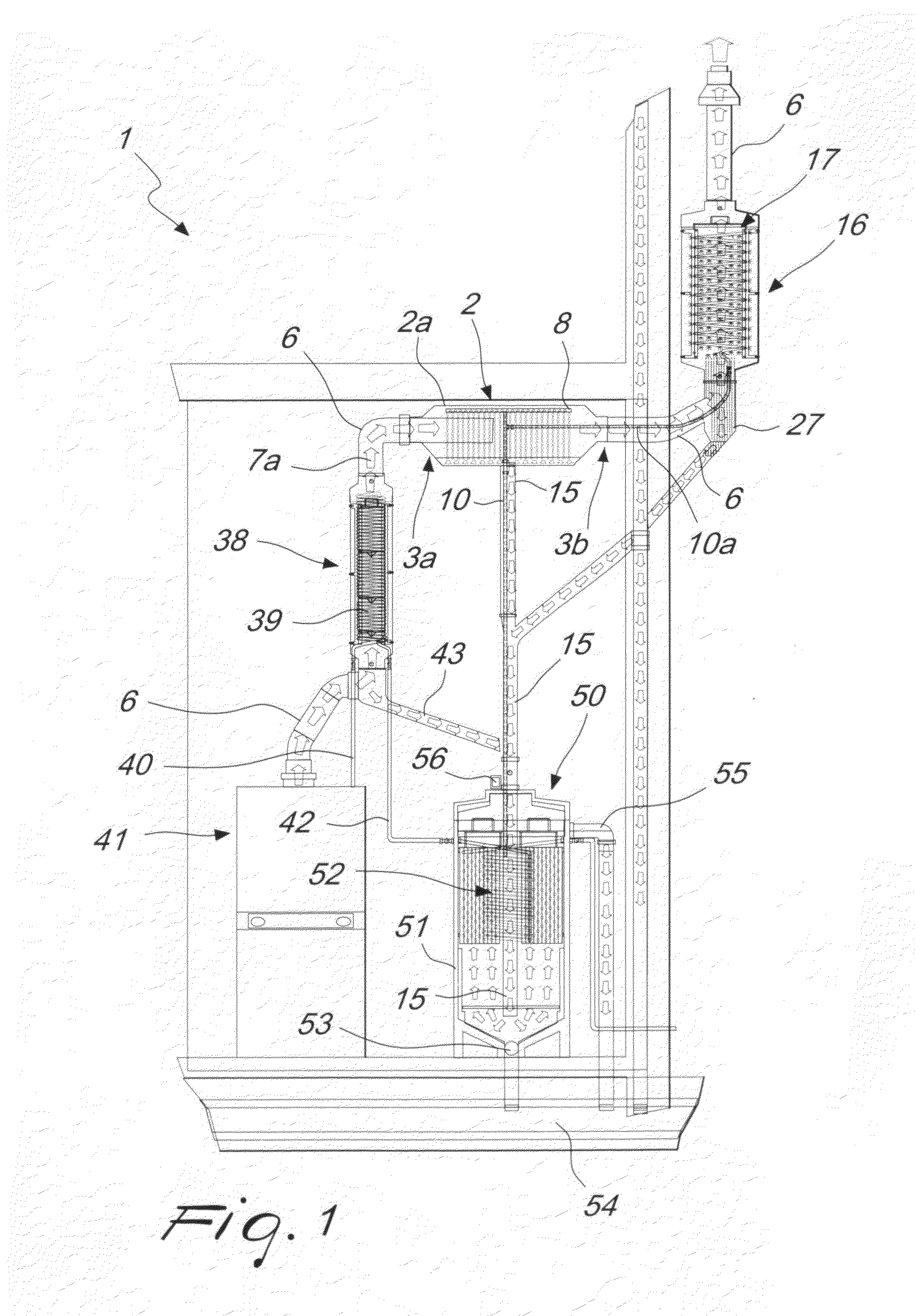

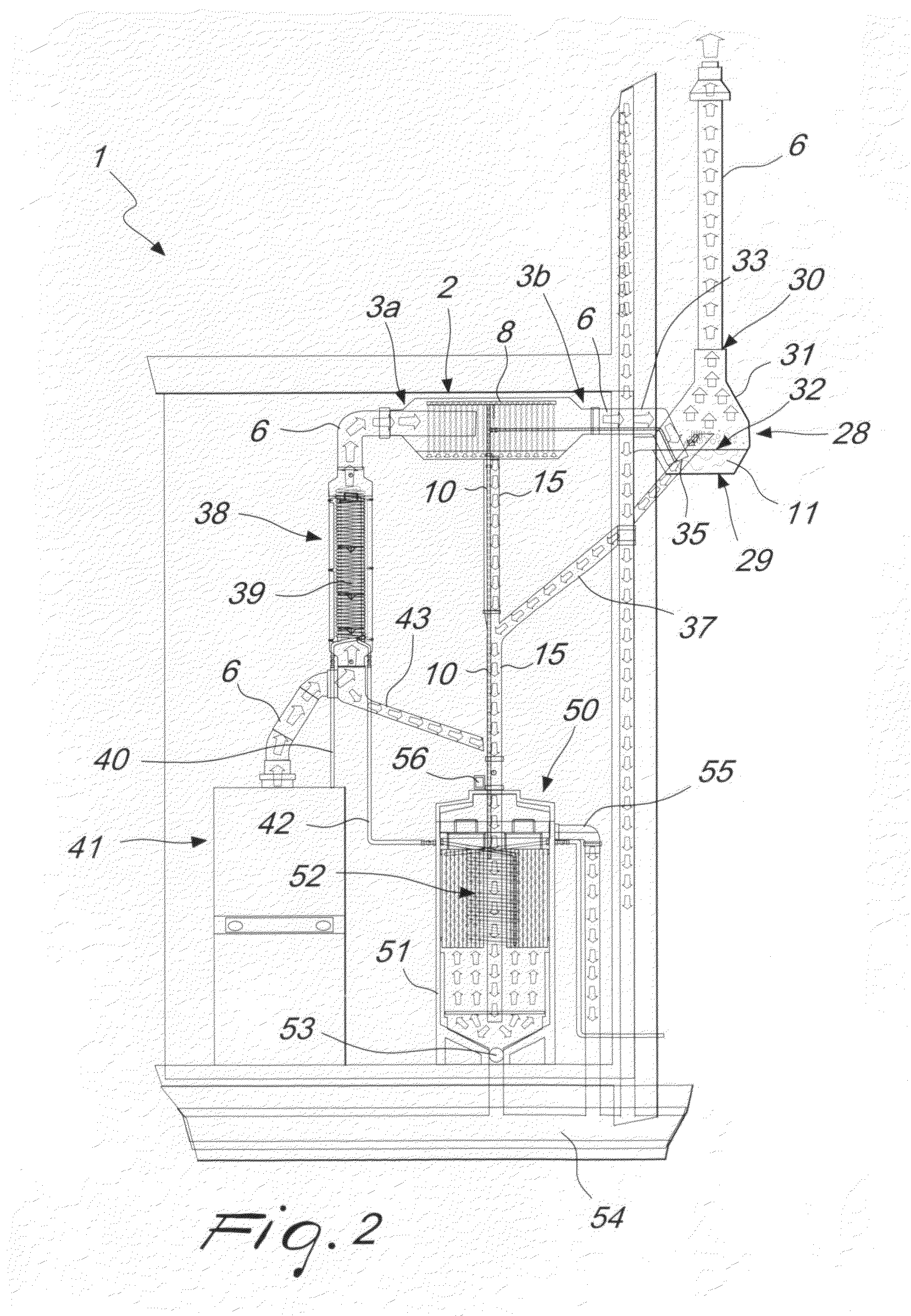

[0019]With reference to the figures, the reference numeral 1 designates an energy recovery apparatus, consisting of a first hollow tubular element 2, which is elongated and preferably has a substantially cylindrical cross-section with a preferably flat top 2a, which has, proximately to a first end 3a and a second end 3b, a preferably frustum-shaped tapering portion 4a, 4b for connection to a first opening and a second opening 5a, 5b that have a preferably circular cross-section, respectively for inflow and outflow.

[0020]The first and second openings 5a, 5b are connected at a portion of a flue or sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com