Composite alloy bonding wire and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

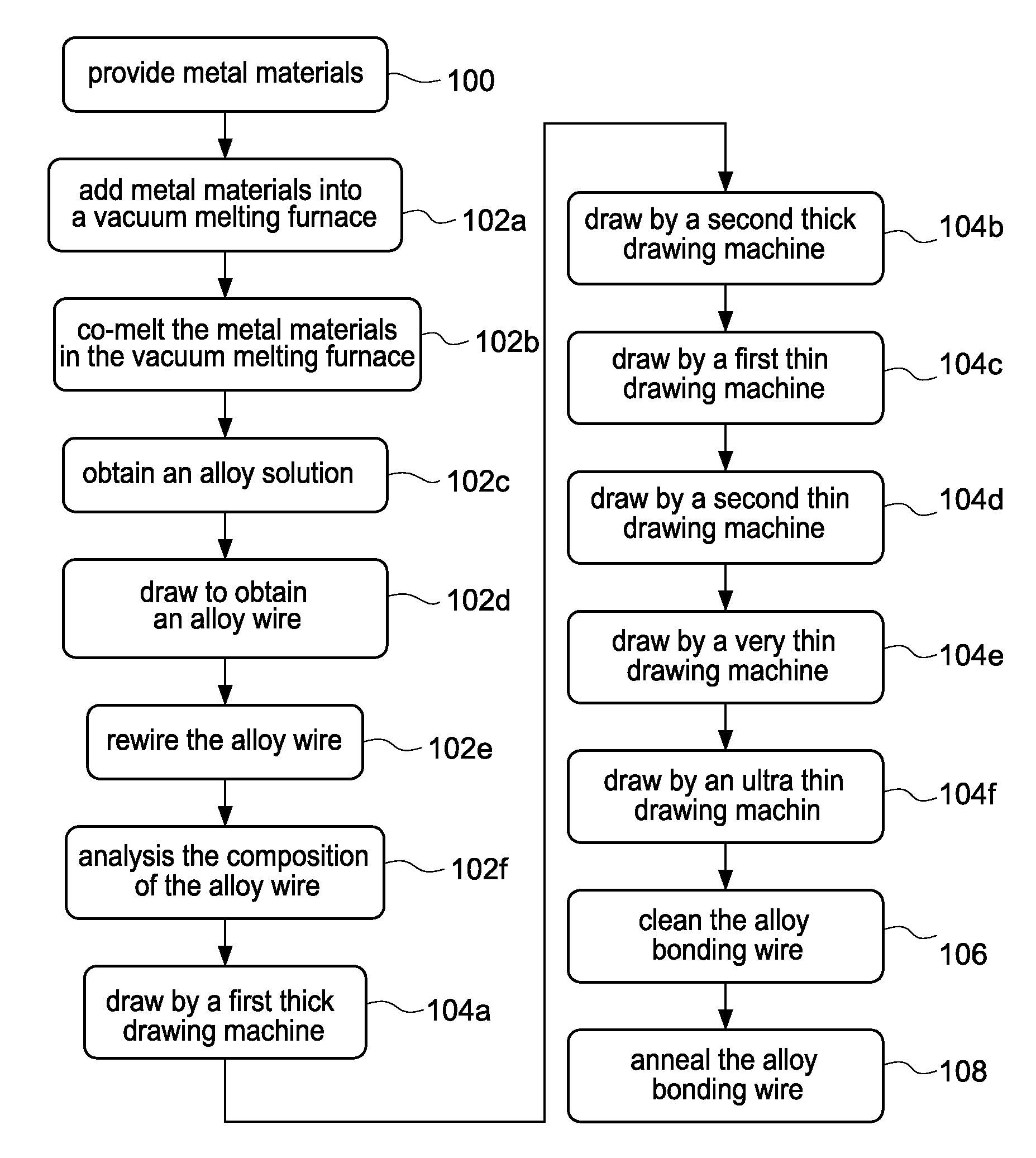

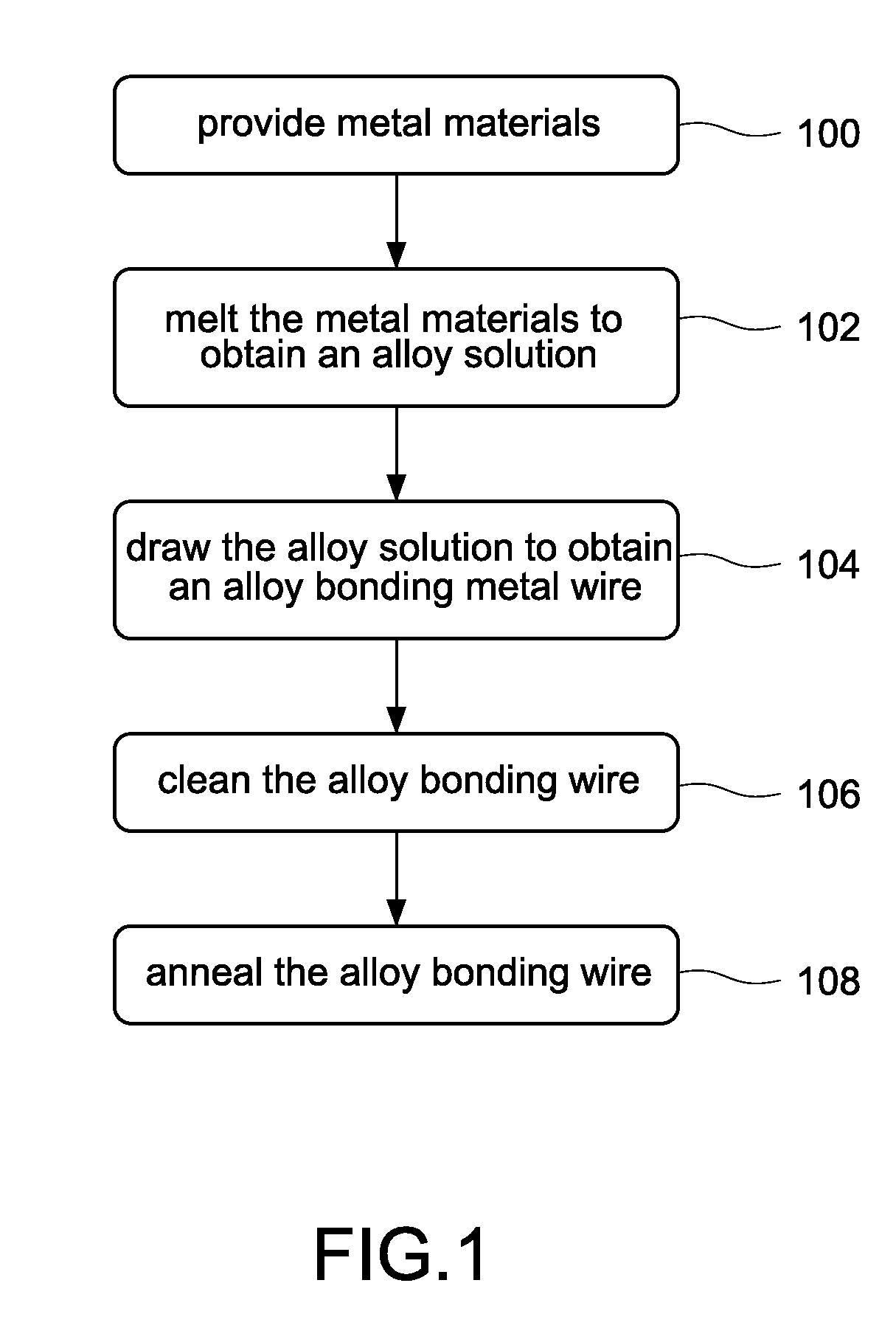

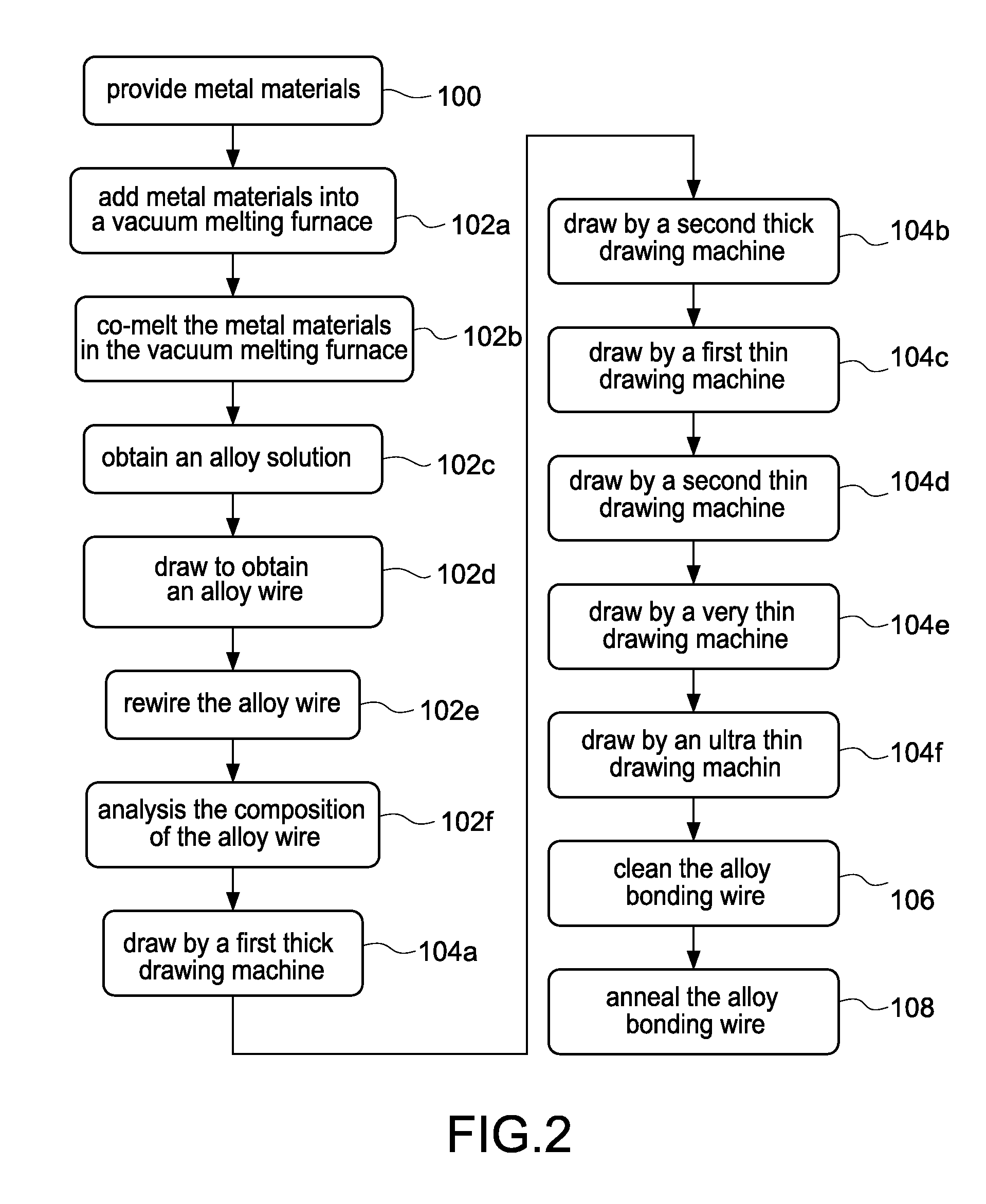

[0024]A primary material of Ag is provided and is melted in a vacuum melting furnace. Then, specific amount of a secondary metal material of Pd is added into the vacuum melting furnace, and is co-melted with the primary material in the vacuum melting furnace to obtain a Ag—Pd alloy solution. The Ag—Pd alloy solution consists of: 99.99 wt. % Ag and 0.001 wt. % Pd.

[0025]Continuous casting and drawing processes are performed on the Ag—Pd alloy solution to obtain a Ag—Pd alloy wire with a diameter of 4 mm. The Ag—Pd alloy wire is rewired by a reeling machine and then composition analysis is performed on the Ag—Pd alloy wire to check if the obtained composition meets the requirement.

[0026]A drawing process is performed on the Ag—Pd alloy wire; the obtained Ag—Pd alloy wire with a diameter of 4 mm is drawn by a first thick drawing machine to obtain a Ag—Pd alloy wire with a diameter of 3 mm. The Ag—Pd alloy wire with a diameter of 3 mm is drawn by a second thick drawing machine to obtain ...

embodiment 2

[0028]A primary material of Ag is provided and is melted in a vacuum melting furnace. Then, specific amount of a secondary metal material of Pd is added into the vacuum melting furnace, and is co-melted with the primary material in the vacuum melting furnace to obtain a Ag—Pd alloy solution. The Ag—Pd alloy solution consists of: 95.00 wt. % Ag and 5.00 wt. % Pd.

[0029]Continuous casting and drawing processes are performed on the Ag—Pd alloy solution to obtain a Ag—Pd alloy wire with a diameter of 6 mm. The Ag—Pd alloy wire is rewired by a reeling machine and then composition analysis is performed on the Ag—Pd alloy wire to check if the obtained composition meets the requirement.

[0030]A drawing process is performed on the Ag—Pd alloy wire; the obtained Ag—Pd alloy wire with a diameter of 6 mm is drawn by a first thick drawing machine to obtain a Ag—Pd alloy wire with a diameter of 3 mm. The Ag—Pd alloy wire with a diameter of 3 mm is drawn by a second thick drawing machine to obtain a...

embodiment 3

[0032]A primary material of Ag is provided and is melted in a vacuum melting furnace. Then, specific amount of a secondary metal material of Pd is added into the vacuum melting furnace, and is co-melted with the primary material in the vacuum melting furnace to obtain a Ag—Pd alloy solution. The Ag—Pd alloy solution consists of: 90.00 wt. % Ag and 10.00 wt. % Pd.

[0033]Continuous casting and drawing processes are performed on the Ag—Pd solution to obtain a Ag—Pd alloy wire with a diameter of 8 mm. The Ag—Pd alloy wire is rewired by a reeling machine and then composition analysis is performed on the Ag—Pd alloy wire to check if the obtained composition meets the requirement.

[0034]A drawing process is performed on the Ag—Pd alloy wire; the obtained Ag—Pd alloy wire with a diameter of 8 mm is drawn by a first thick drawing machine to obtain a Ag—Pd alloy wire with a diameter of 2 mm. The Ag—Pd alloy wire with a diameter of 2 mm is drawn by a second thick drawing machine to obtain a Ag—P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com