Apparatus and method of superconducting magnet cooling

a superconducting magnet and cooling apparatus technology, applied in the direction of superconducting magnets/coils, instruments, sustainable manufacturing/processing, etc., can solve the problems of high cost of superconducting magnets for the provision of helium cryogen, unfavorable use of superconducting magnets, and inability to meet the requirements of superconducting magnets. , to achieve the effect of reducing the amount of cryogen needed, simplifying the design of super

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

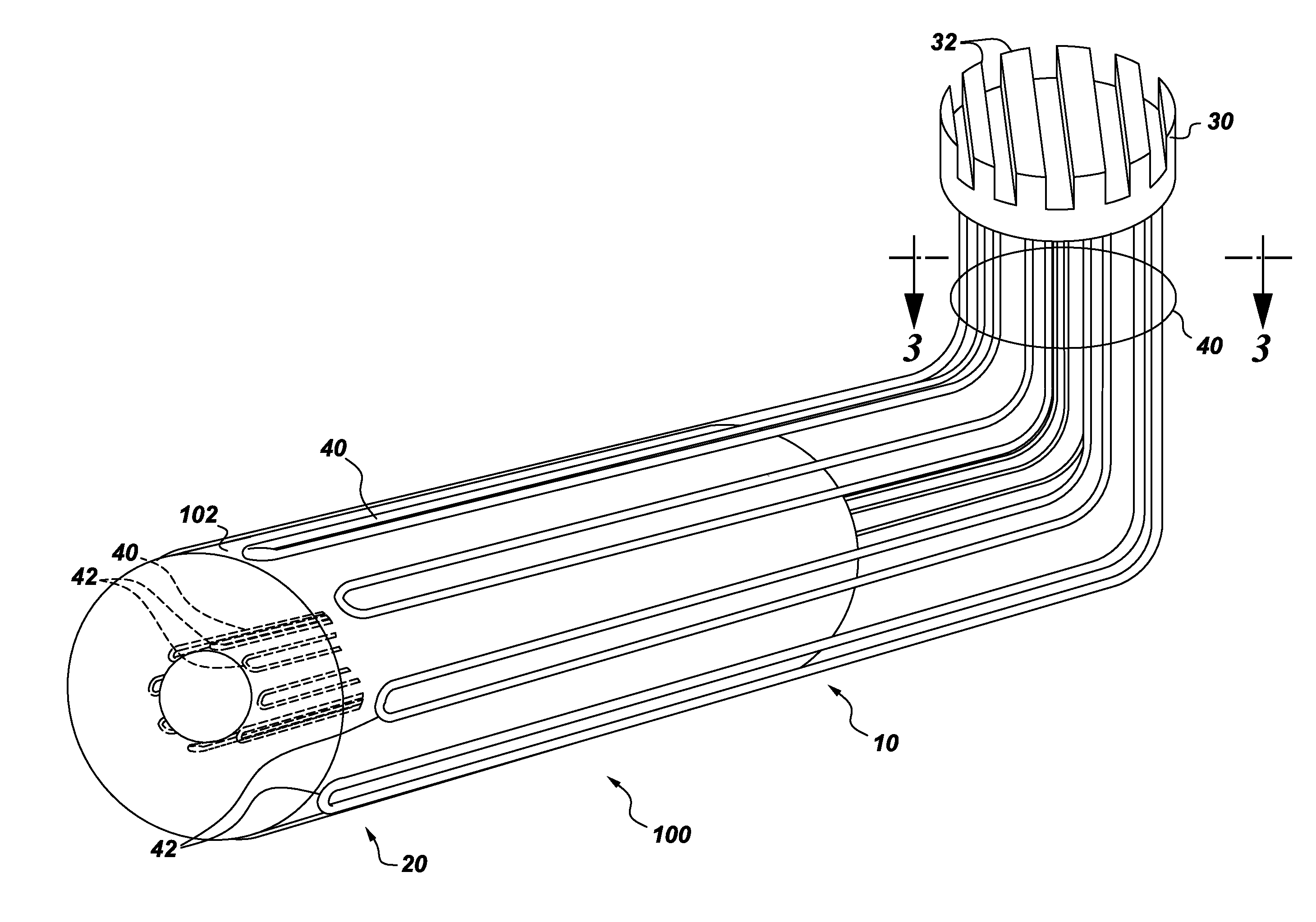

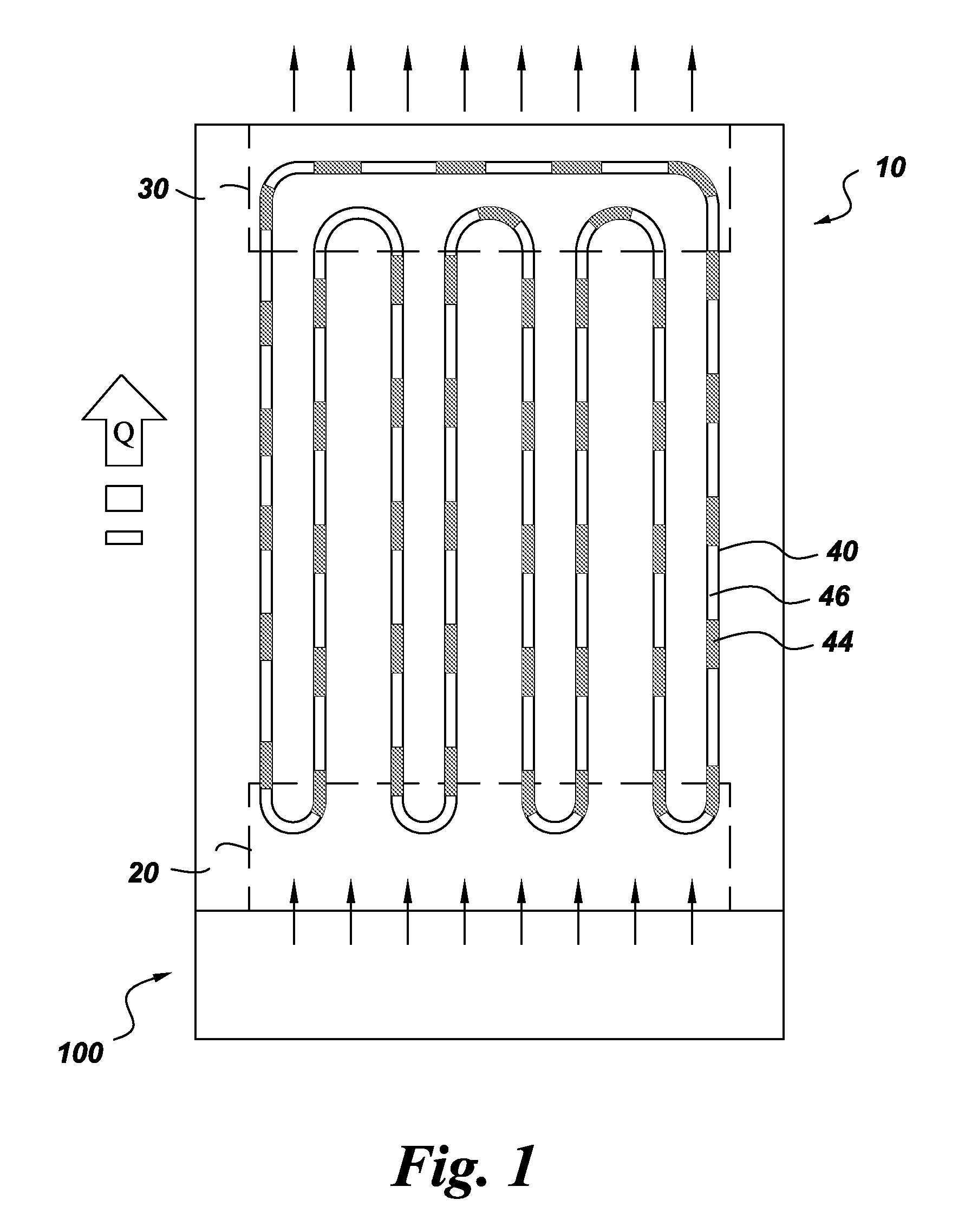

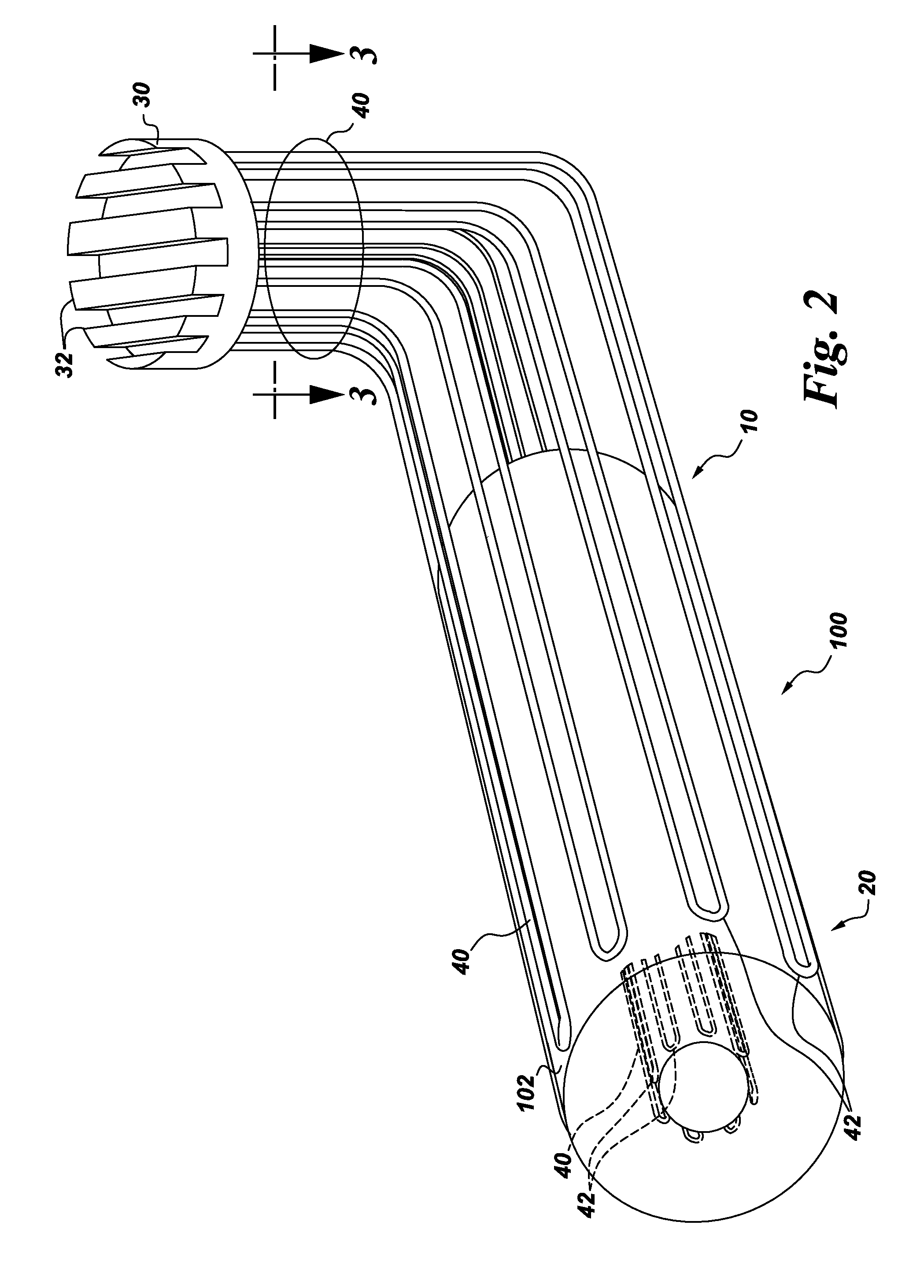

[0017]Aspects of the present invention have been shown to offer advantages over previous methodologies of cooling superconducting magnets. The apparatus and method require no mechanical moving parts (e.g., no pumps, no external pressure fed supply system, no refrigeration “coldbox” for cryogen supply, no helium can-fed flow, etc.) in cooling a superconducting magnet. The cooling method is orientation-independent, which aids in the design and ultimate physical volume and footprint of the superconducting magnet assembly. Design integration of tubing into the existing superconducting magnet geometry is simplified. Further, any hot spots that may arise can immediately be cured by the pulsating slug flow provided by the pulsating heat pipe employed in aspects of the present invention. The design offers other advantages in that it does not require costly helium bath cooling, nor is any cryogen lost during a quench. The proposed capillary tubing can withstand high pressures of several 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com