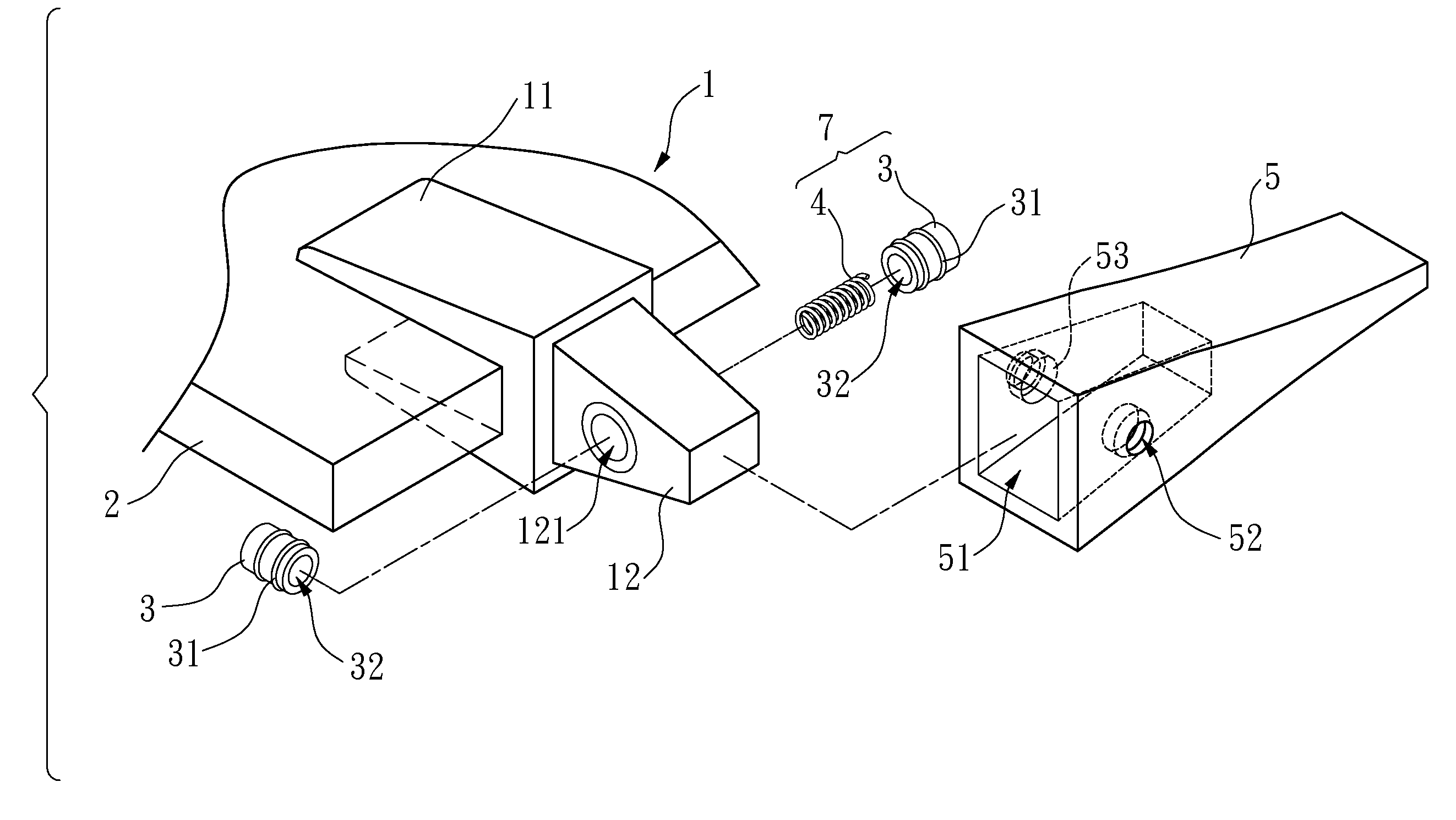

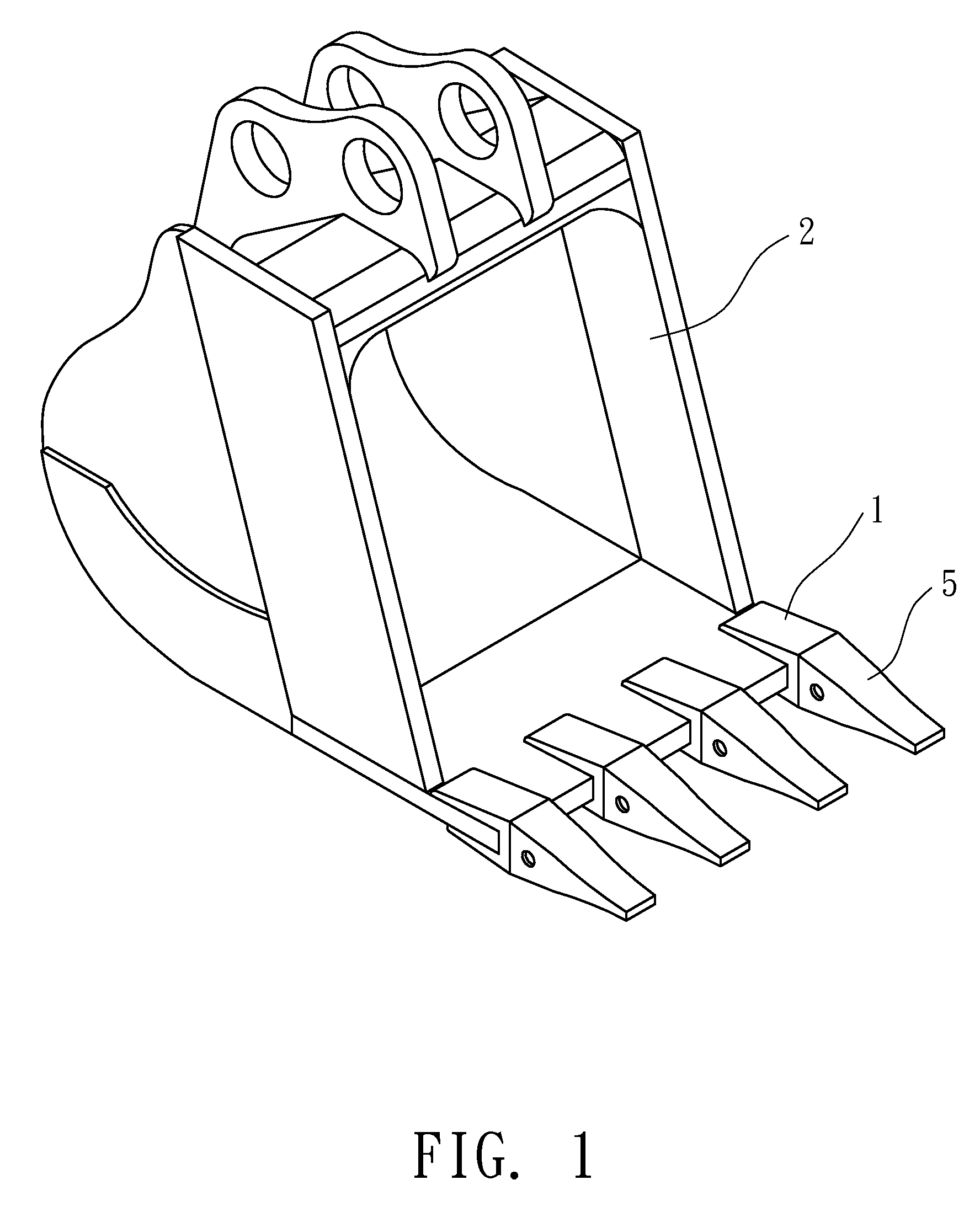

Replacement and urging device for the bucket teeth of an engineering construction machine

a technology of engineering construction machine and urging device, which is applied in the direction of soil shifting machine/dredger, construction, etc., can solve the problems of clogging the pin, increasing the difficulty of replacement, and inconvenience in replacement, and achieve the effect of quick removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fourth embodiment

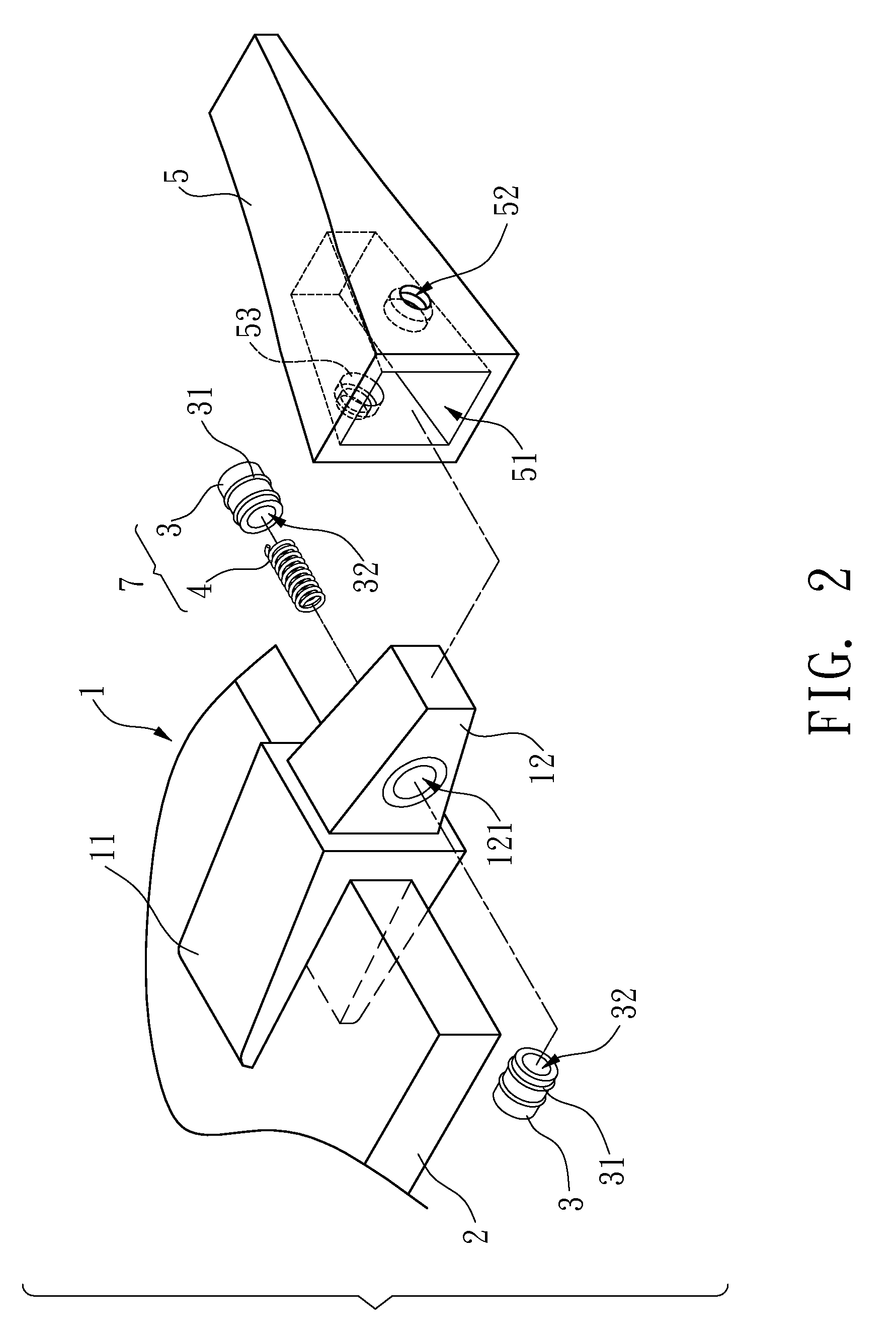

[0056]Please refer to FIG. 8 for the invention. The bucket teeth 5 has an inner guiding angle 55 on the side that the second through holes 52 open towards the slot 51. The end of each of the stopping posts 3 protruding from the first through hole 121 has an outer guiding angle 33 towards the fixing part 11. The outer guiding angle 33 attaches the bucket teeth 5 to the inner guiding angle 55 of the second through hole 52. The depth of the outer guiding angle 33 is smaller than the inner guiding angle 55. This keeps a gap so that the adaptor 1 and the bucket teeth 5 do not have collisions.

[0057]FIG. 9 shows that the outer guiding angle 33 of the two stopping posts 33 initially urges against the inner guiding angle 55 of the bucket teeth 5 when the bucket teeth 5 is mounted on the adaptor f. As shown in the drawing, the adaptor 1 and the bucket teeth 5 are urged by the two stopping posts 3. Therefore, there is no sliding gap.

[0058]However, as shown in FIGS. 10 to 12, when the bucket te...

fifth embodiment

[0061]Please refer to FIG. 13 for the invention. Each of the stopping posts 4 protrudes from one end of the first, through hole 121. The other side of the outer guiding angle 33 has another corresponding outer guiding angle 33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com