Method of producing an absorbent garment, and an absorbent garment produced according to the method

a technology of absorbent garments and seams, applied in the field of producing absorbent garments and absorbent garments according to the method, can solve the problems of seams and joins running parallel to the waist edge of the garment, affecting the quality of the garment, so as to reduce the risk of seams and joins, reduce welding times, and reduce the risk of seam breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

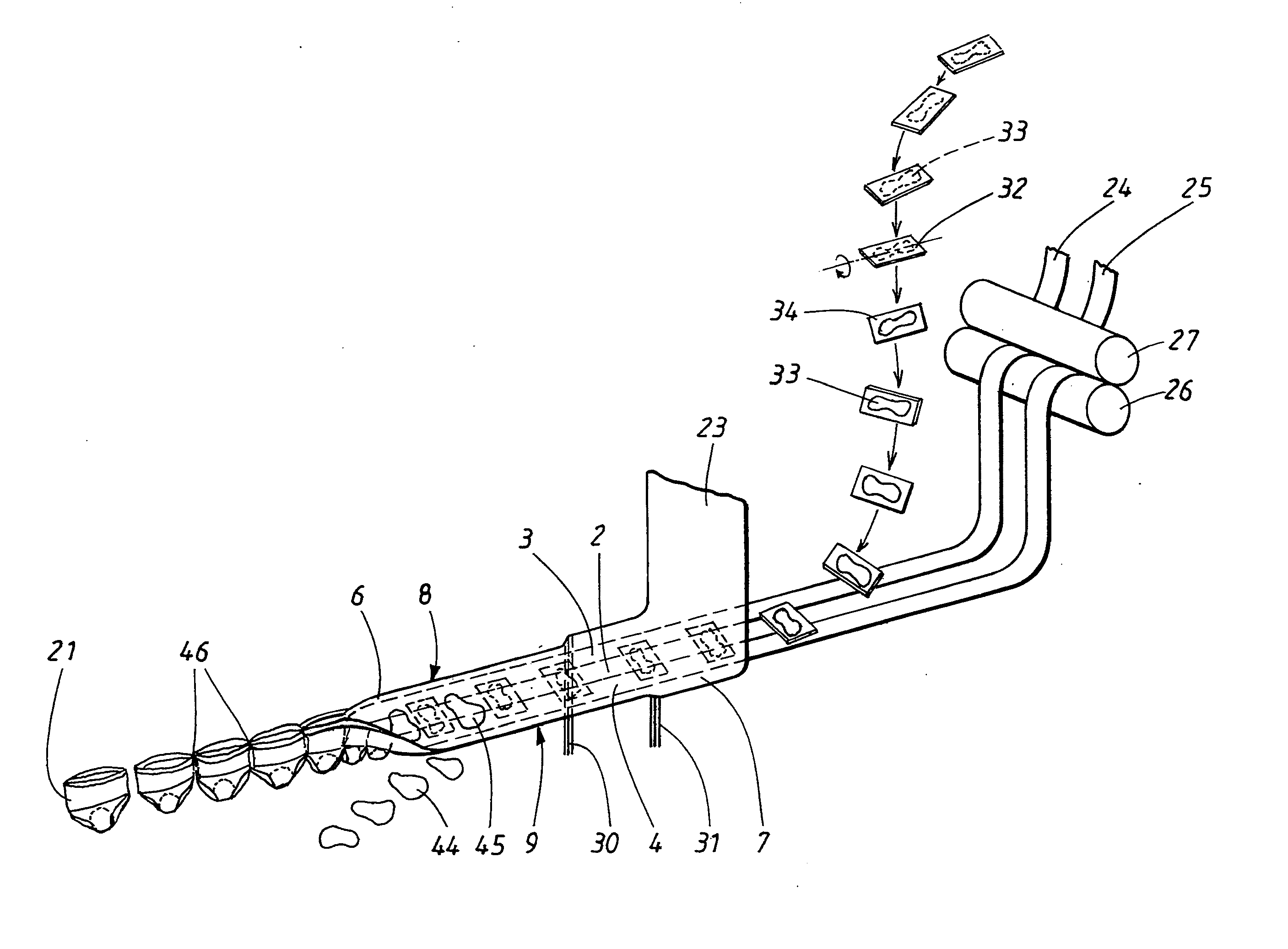

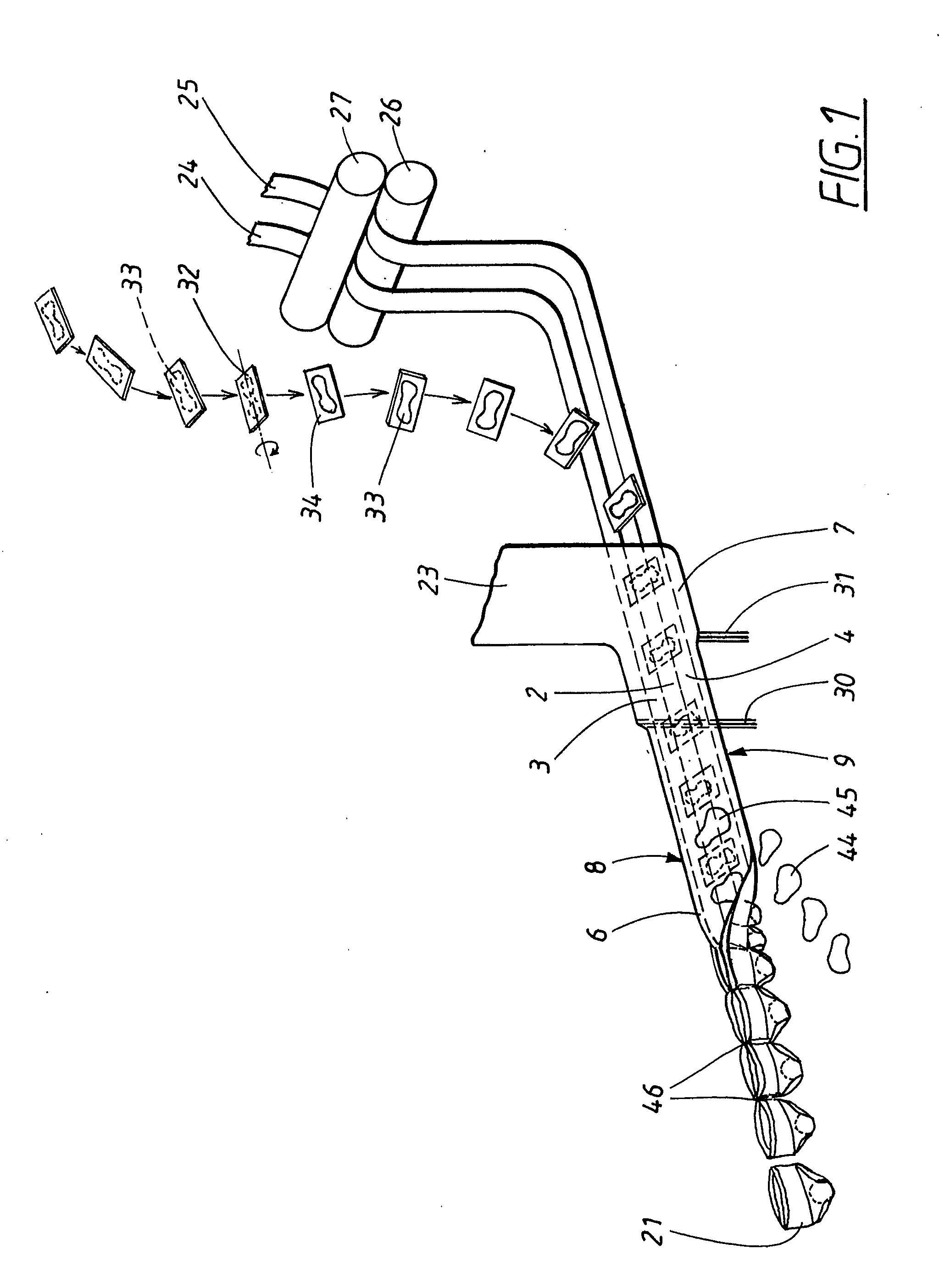

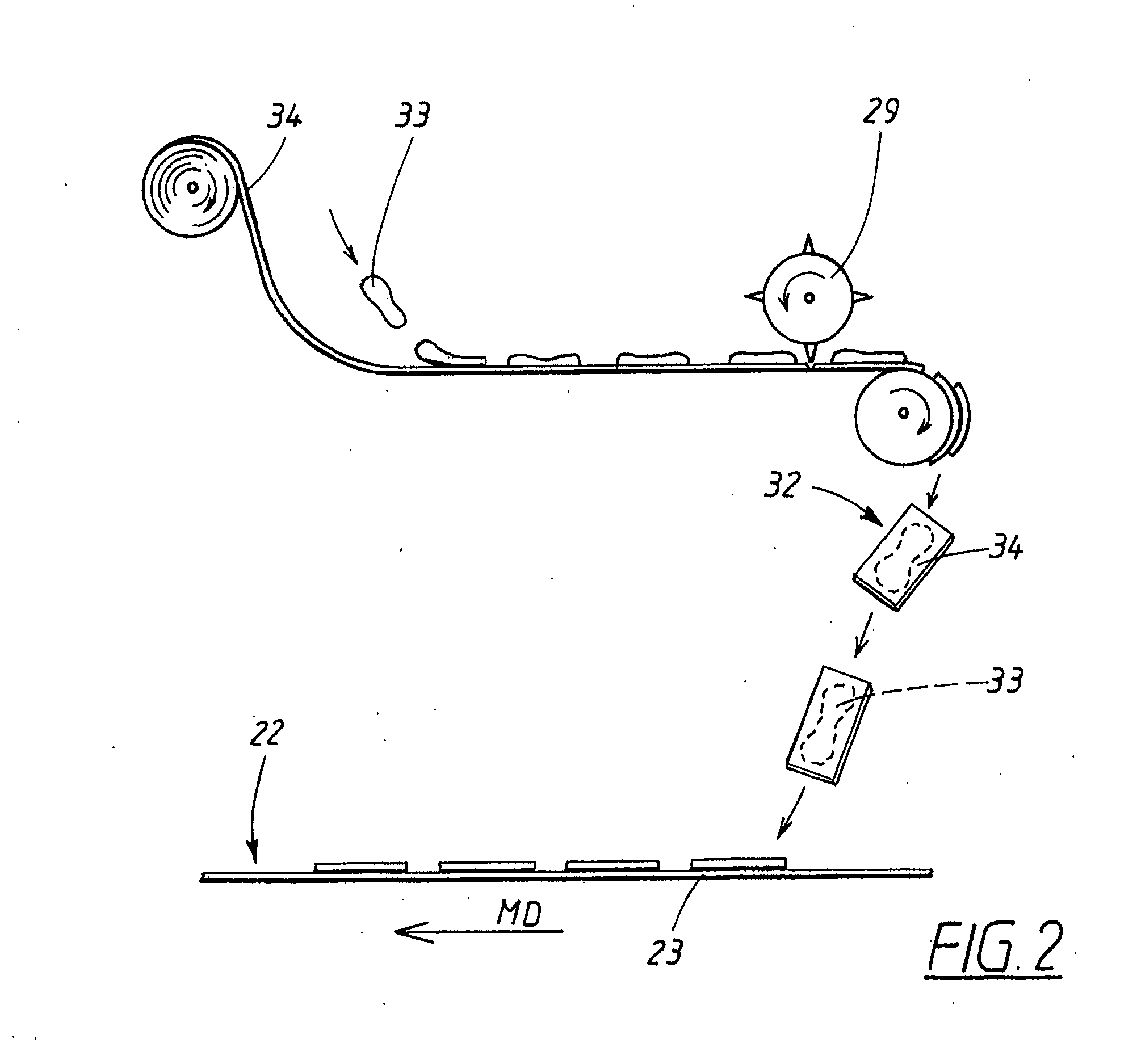

[0079]FIG. 1 shows a method for continuously producing absorbent garments, in particular pant-type diapers, although open-type diapers may be formed by the same general method. The method involves forming a continuous multi-component production web and cutting individual diapers from the production web.

[0080]In FIG. 1, a diaper chassis structure is formed from a compound production web 22, comprising a continuous base web 23 of liquid-permeable material and first and second elastic webs 24,25 and first and second waist elastic elements 30,31. The elastic webs 24,25 may be elastic films, elastic nonwoven webs or elastic laminates, as previously disclosed.

[0081]The production web 22 has an intermediate zone 2 extending in a travelling direction, the machine direction, MD and a first and a second lateral zone 3,4 on each side of the intermediate zone 2 each lateral zone including an edge zone 6,7 extending along an edge 8,9 of the production web 22. The edge zones are the parts of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com