Gravity-assisted drain valve for restricting intake of mildew spores

a gravity-assisted, drain valve technology, applied in water installations, thin material processing, construction, etc., can solve the problems of disadvantaged drain stoppers, backflow prevention devices drain traps that do not protect the habited environment, so as to limit the entry of unhealthy particulates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

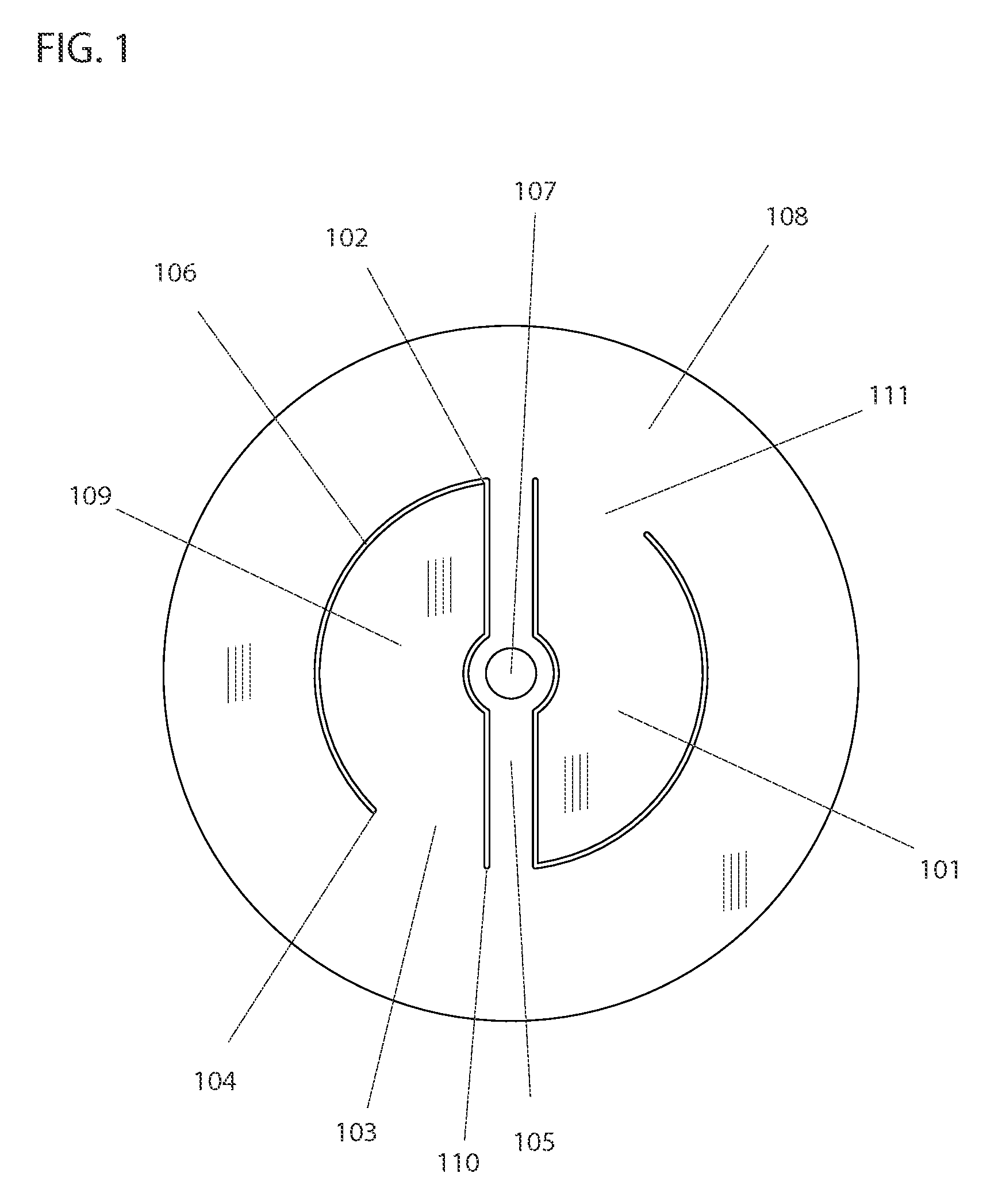

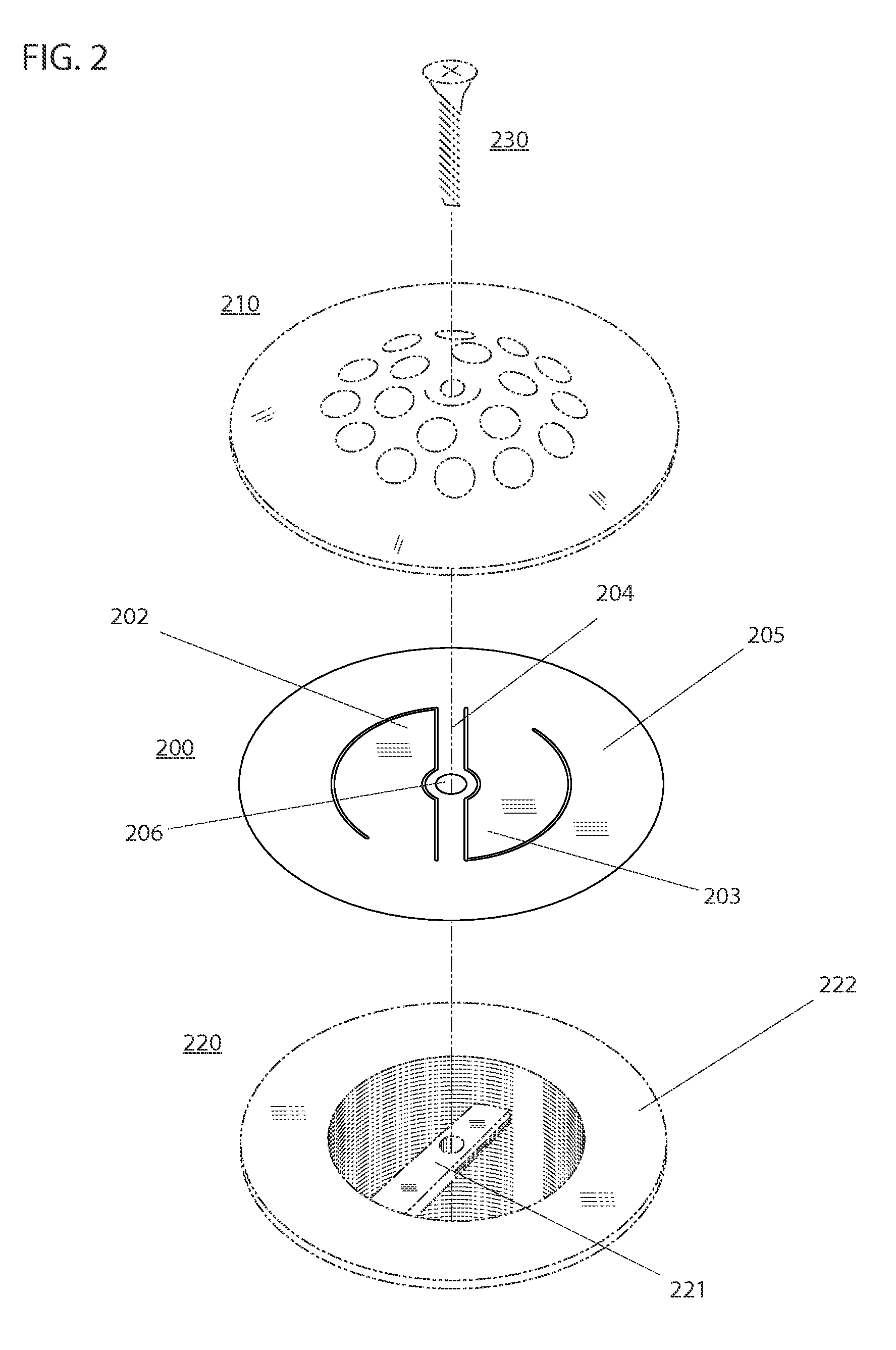

[0032]The need arises for a drain valve that limits the intake of odious particulates such as mildew spores into the habited environment while allowing for the normal drainage of fluids such as bathtub drainwater. The need further arises for such a valve that is easy to manufacture, disposable and easily replaced as a do-it-yourself project by an untrained homeowner with no plumbing experience and minimal tools. The need arises for such an intake restrictor valve to be substantially flat so as to fit beneath a conventional shower / bath drain strainer, to have a method for opening and closing that does not interfere with the drain shoe walls, the drain crosshair, the drain strainer and the centered drain strainer bolt.

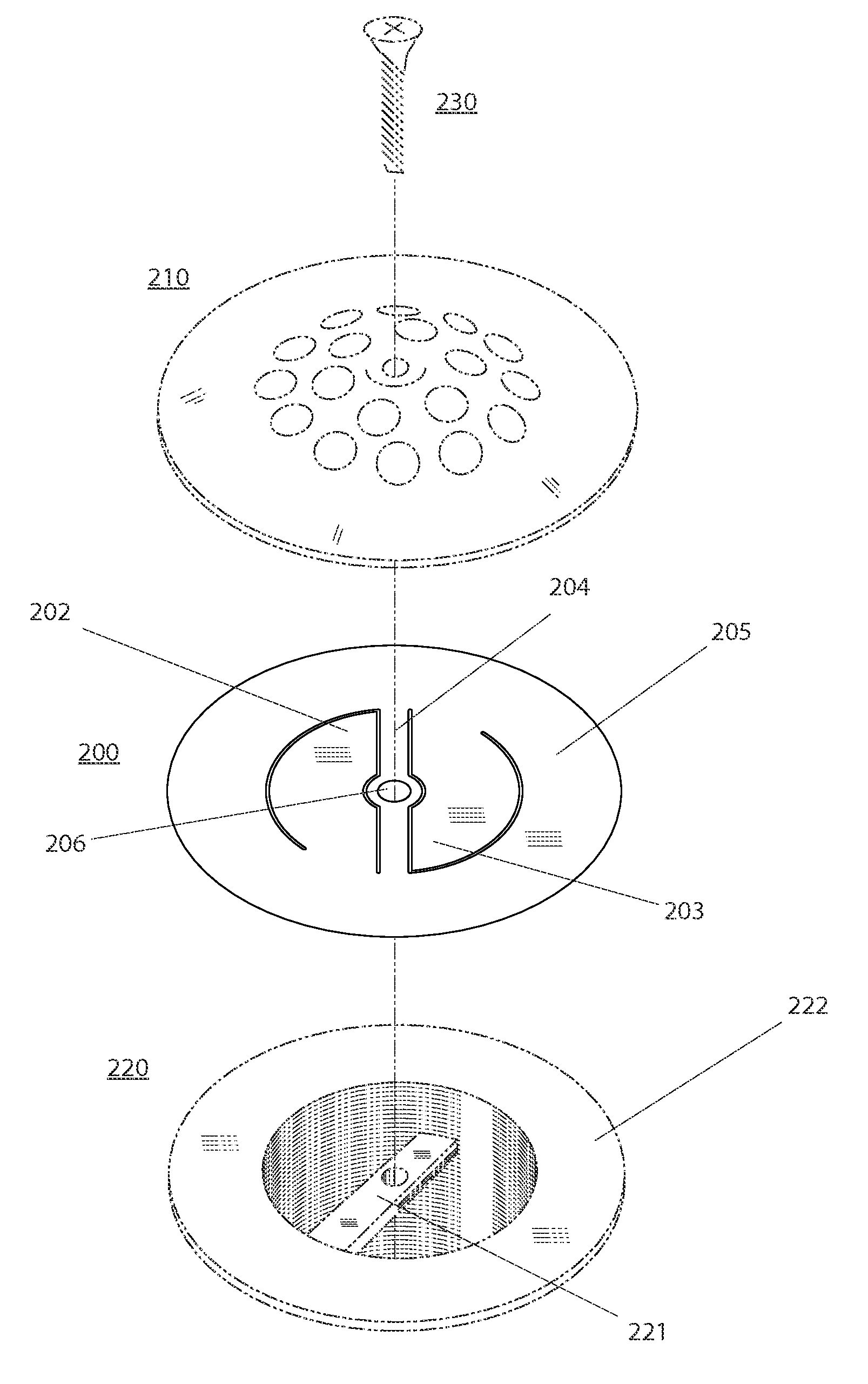

[0033]The valve of FIG. 1 is a substantially flat disc and has a Perimeter Lip that is substantially circular and encompasses the valve. The valve has two Drain Leaves 101 and 109. Brace 105 exists across the perimeter, with Brace Hole 107 at its center. Gap 106 exists b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com