Switchable Valve Lifter Having a Mis-Assembly Indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

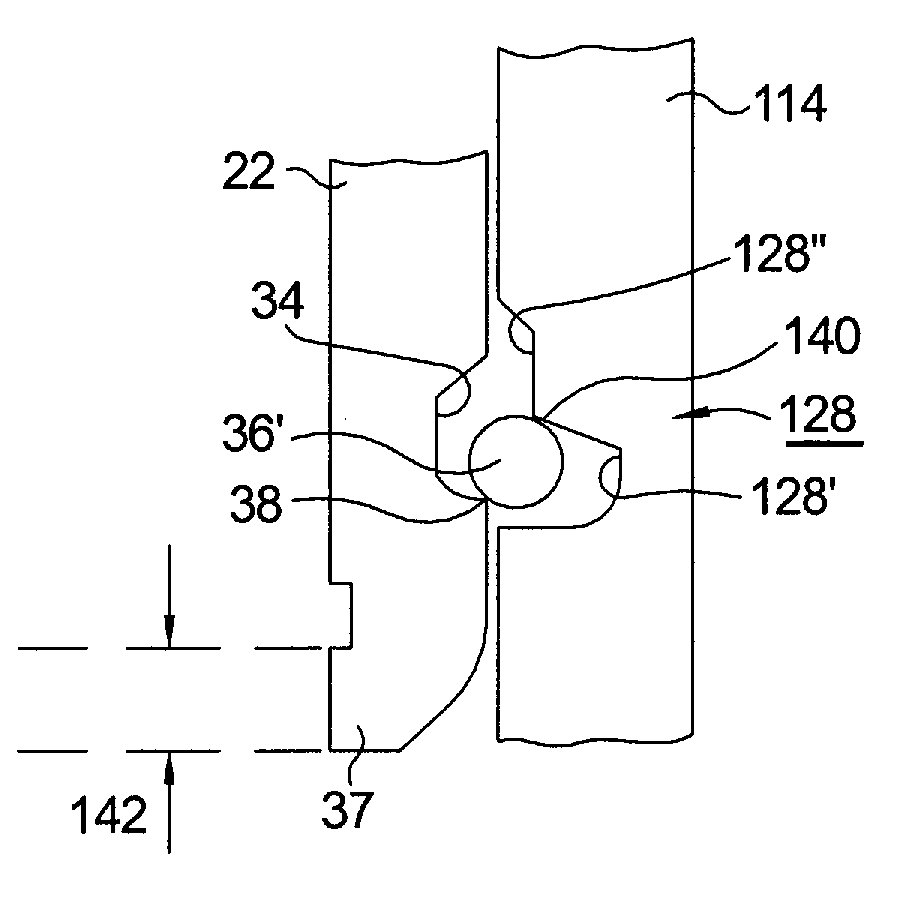

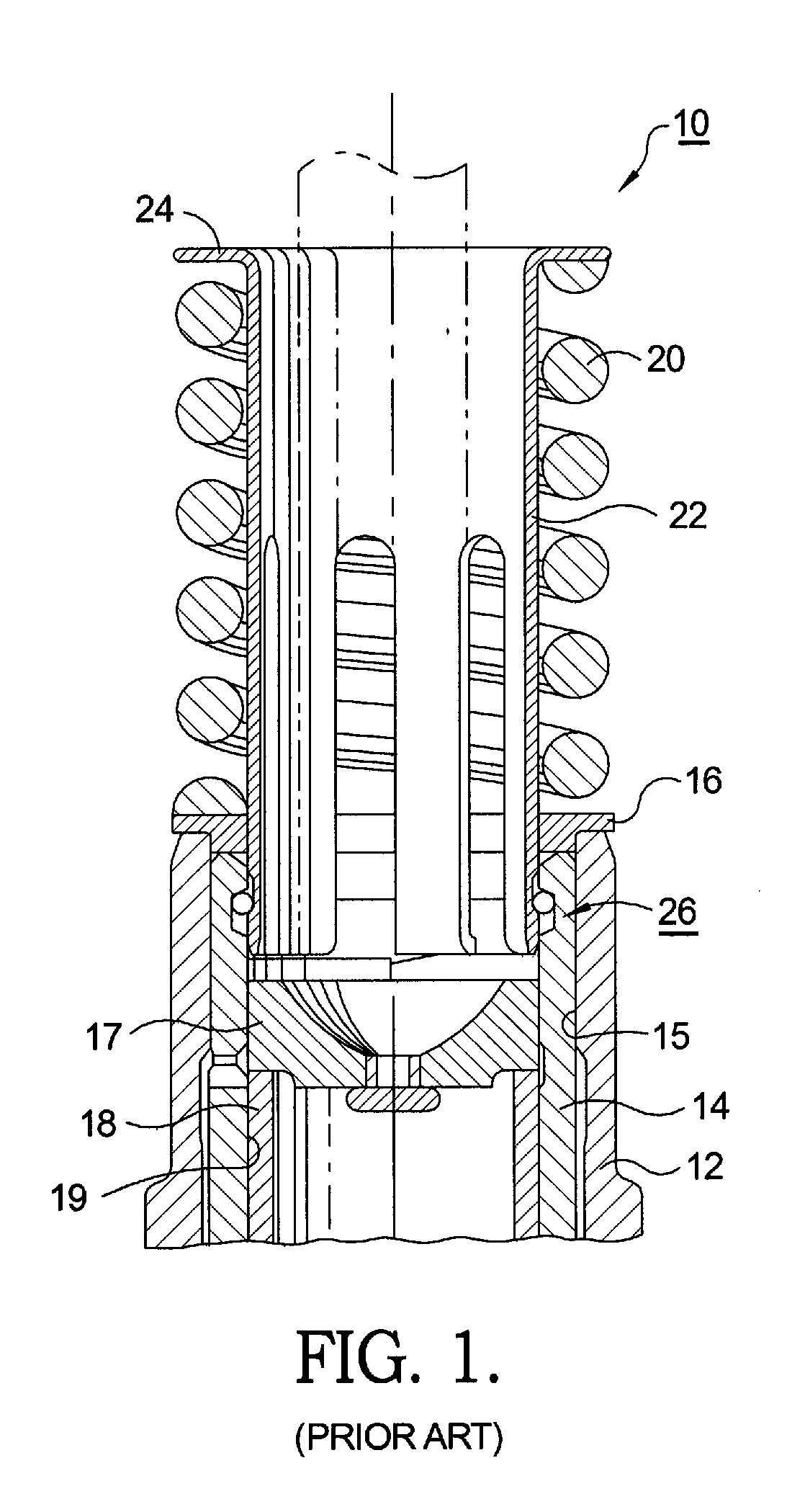

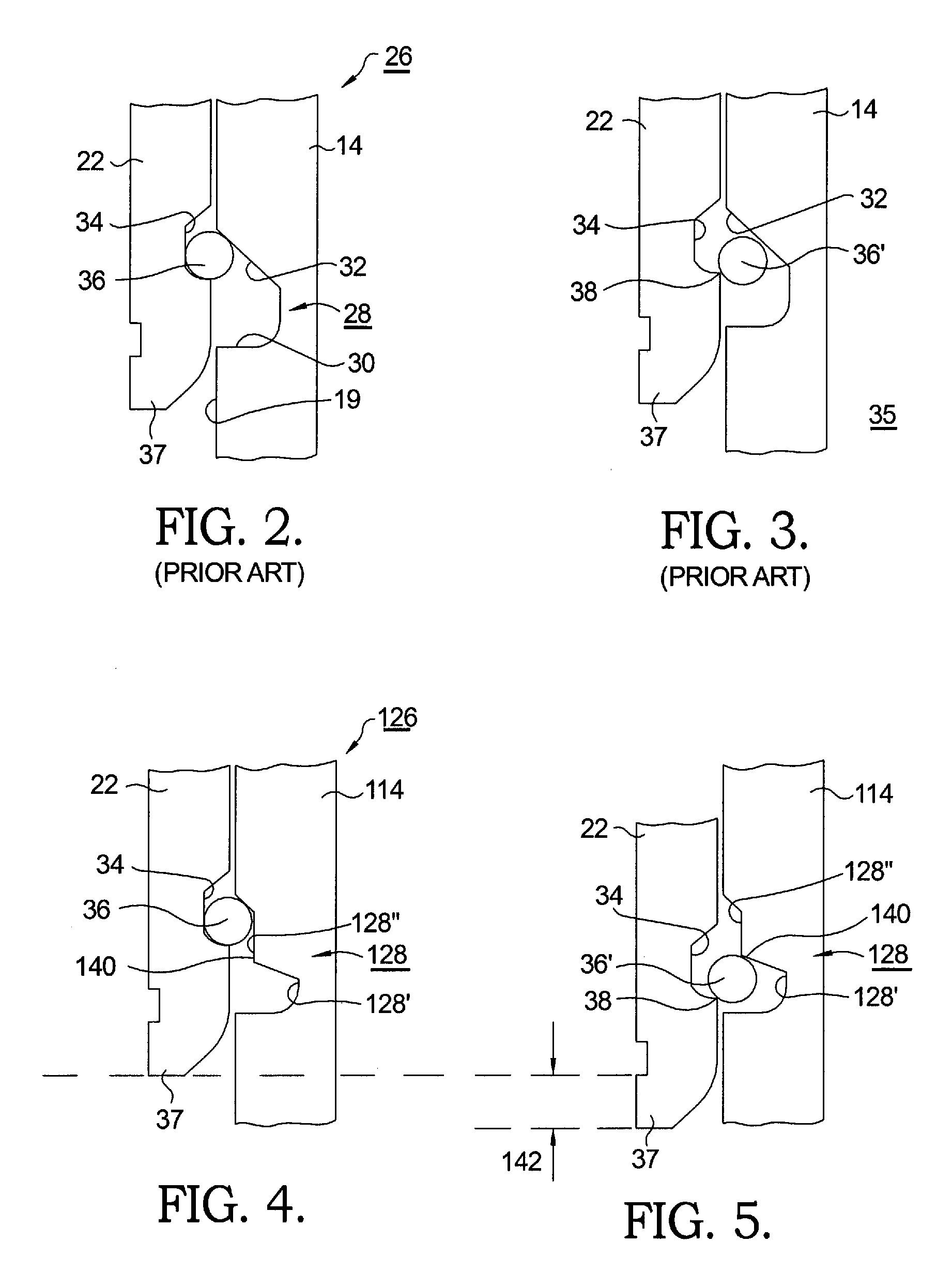

[0015]Referring to FIG. 1, a prior art SHVL 10 comprises a body 12. A pin housing 14 is slidably disposed in a first bore 15 in body 12 and retained therein by a spring seat 16 mounted on the end of body 12. A plunger 18 and pushrod seat 17 are slidably disposed within a second bore 19 in pin housing 14 for actuation by a conventional lash-adjustment mechanism (not appearing in the SHVL portion in FIG. 1). A lost-motion coil spring 20 is mounted on spring seat 16 and is captured by a spring tower 22 disposed within spring 20 and having a terminal flange 24. Spring tower 22 extends into second bore 19 and is captured therein by a tower-locking mechanism 26, the improvement of which is the object of the present invention.

[0016]Referring to FIG. 2, a correct prior art tower-locking mechanism 26 is shown. Pin housing 14 is provided with an ID annular groove 28 having a lower wall 30 orthogonal to second bore 19 and an upper wall 32 formed at an incline to second bore 19. Spring tower 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com