Armor protection against explosively-formed projectiles

a technology of explosively formed projectiles and armor, applied in reactive armour, protective equipment, weapons, etc., can solve the problems of heavy vehicles, excessive bulky vehicles, and difficult to defeat ieds, and achieve the effect of saving weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

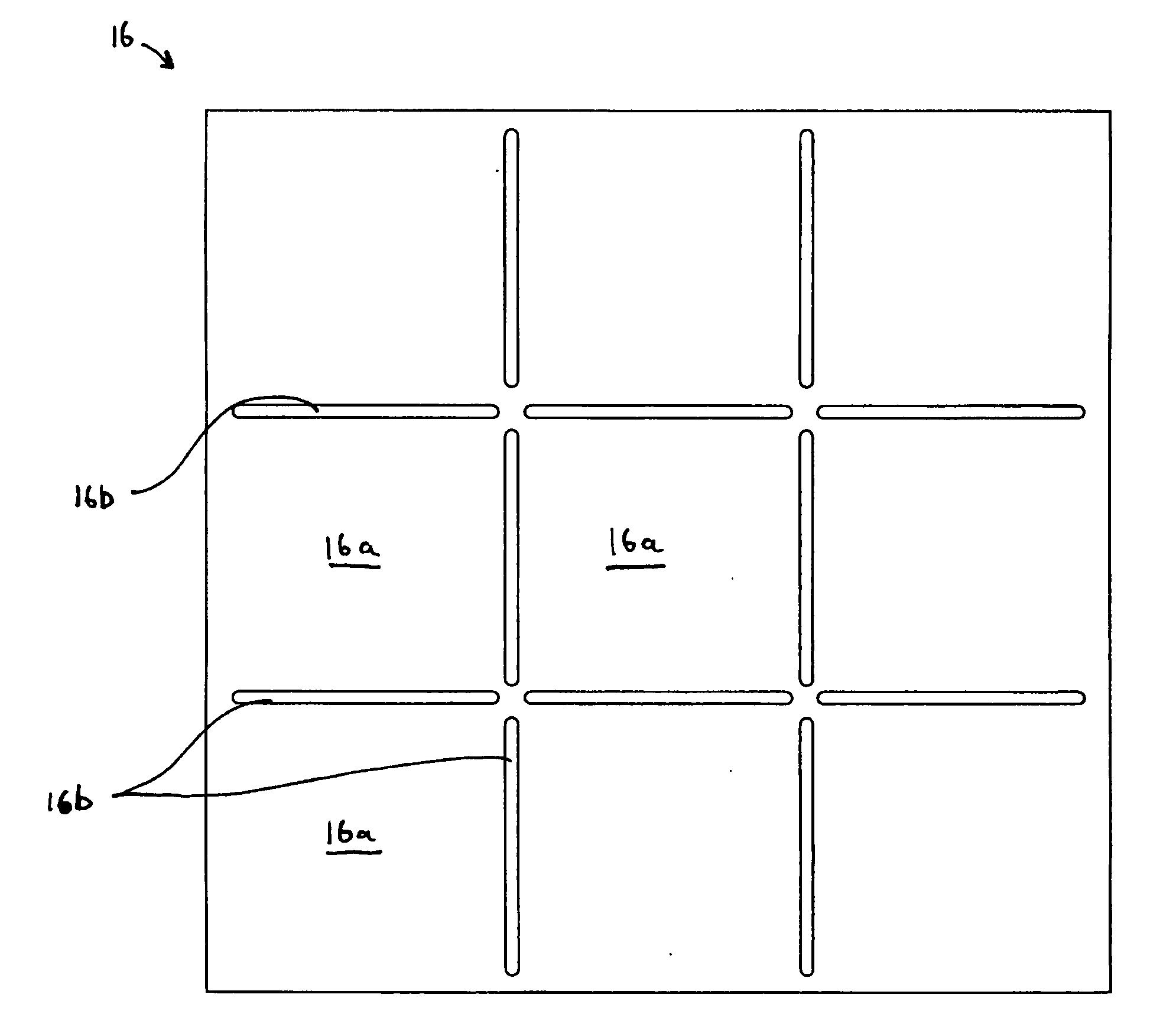

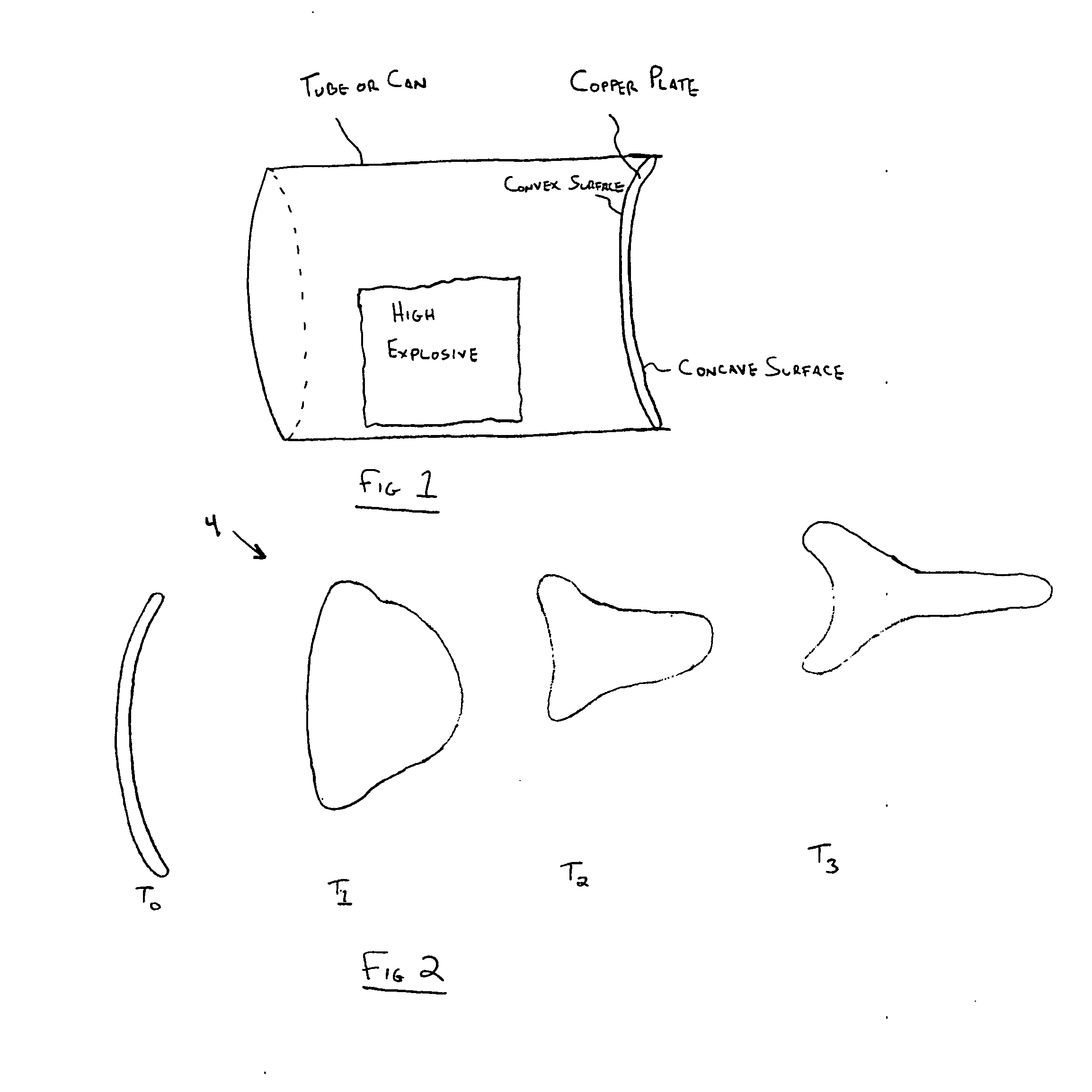

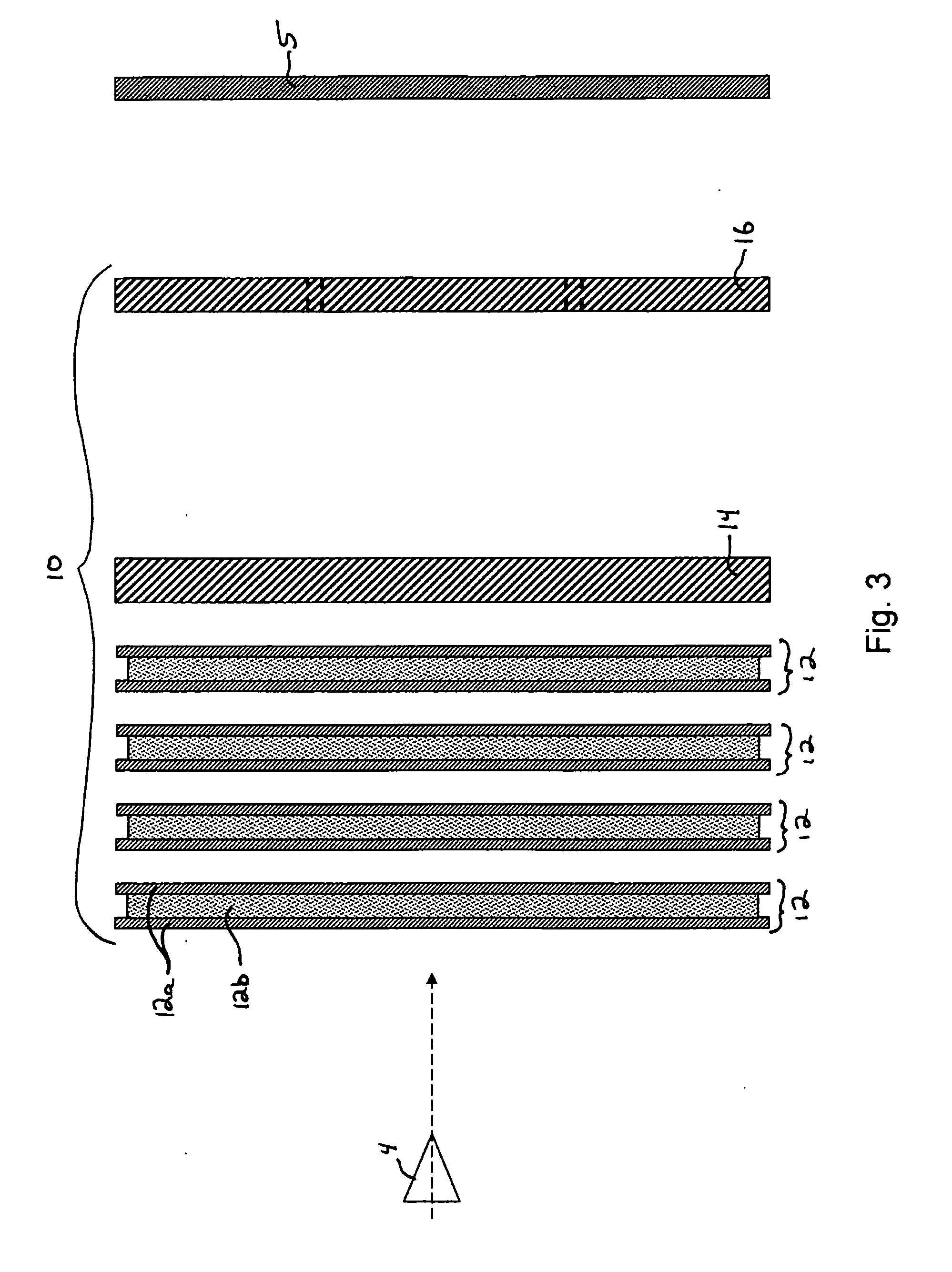

[0053]An armor architecture consisting of 7 layers of laminate non-reactive panels 12 each consisting of two ⅛″ aluminum plates (12a) sandwiching a ¼″ LDPE (low density polyethylene sheet) (12b) arranged in a zig-zag manner (shown in FIG. 6b), followed by a flyer plate 16 consisting of ⅜″ RHA, which all together weighed approximately 47 (+ / −2) pounds per square foot, has been shown to defeat an EFP threat provided in the form of 460 grams of copper propelled from an EFP device by 7.5 lbs. of C4 high explosive when the armor was placed with the flyer plate 16 spaced at 4.5 feet from a ⅜-inch thick RHA panel to simulate the skin (body panel 5) of a typical armored military vehicle. High speed photography was used determine that the velocity of the EFP was in the range of 2.2 to 2.6 km / sec. In testing with these parameters, the ⅜-inch thick RHA skin exhibited no perforation and only a small indentation less than ⅛ inch deep. As a comparison, the identical threat penetrated approximatel...

example 2

[0054]An armor arrangement was constructed as follows: five laminate non-reactive panels 12 were constructed in such a way that each panel 12 consisted of two ⅛″ aluminum plates (Alloy 6061) (12a) with a ¼″ polyethylene sheet (12b) in intimate contact. The panels 12 were spaced approximately ½″ apart and were oriented at roughly an 11-degree angle with respect to the horizontal plane of the following armor plate consisting of a ⅜″ RHA plate (14) and ½″ fiberglass composite (˜70 vol % E-Glass). A gap of about 1.5″ between the RHA plate and the composite. A flyer plate made of ⅜″ RHA was disposed behind the armor plate and spaced at 2″ from the vehicle skin to be protected. The overall area density of this arrangement was about 58 lbs / ft2. The EFP threat was identical to Example 1. Projectile was aimed at zero obliquity with respect to the armor plate and the flyer plate. The vehicle skin consisted of ⅜″RHA plate as an outer layer, 2″ fiberglass composite in the middle and ¼″ RHA plat...

example 3

[0055]An armor architecture according to Example 2 was constructed except only four panels (12) were used instead of five. As a result, the areal density of this armor arrangement was reduced to about 53 lbs / ft2. The EFP threat was identical to Example 1. After the test, the outer skin of the vehicle was damaged or punctured, the 2″ fiberglass panels showed cracking, and there was no damage to vehicle's interior plate. As compared to an RHA armor panel alone, weight savings was about 62%. As seen in this and the above Examples, there is a relationship between the areal density of the armor architecture and the acceptable level of damage to the vehicle skin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com