Heat pipe, exhaust heat recoverer provided therewith

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

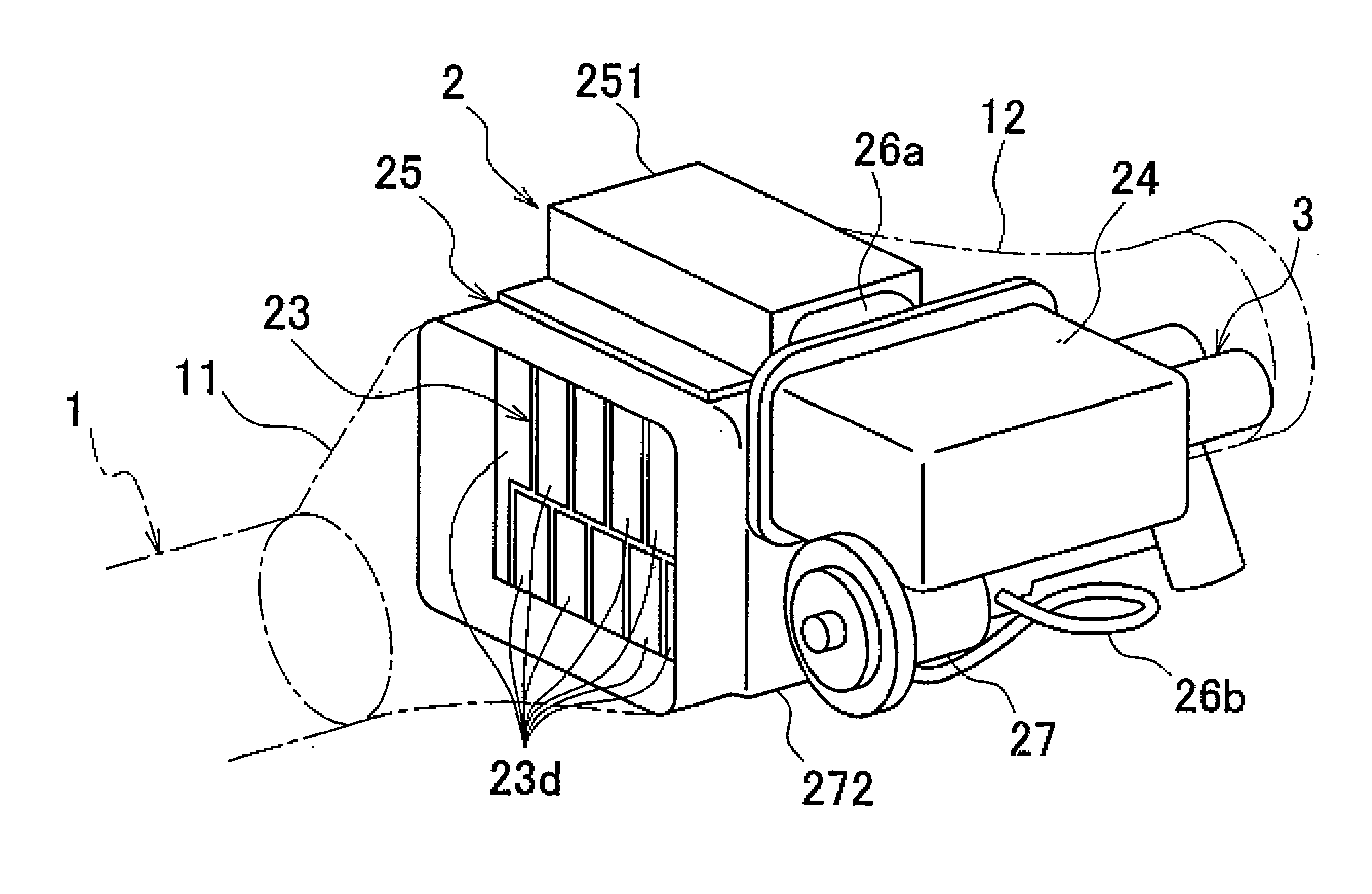

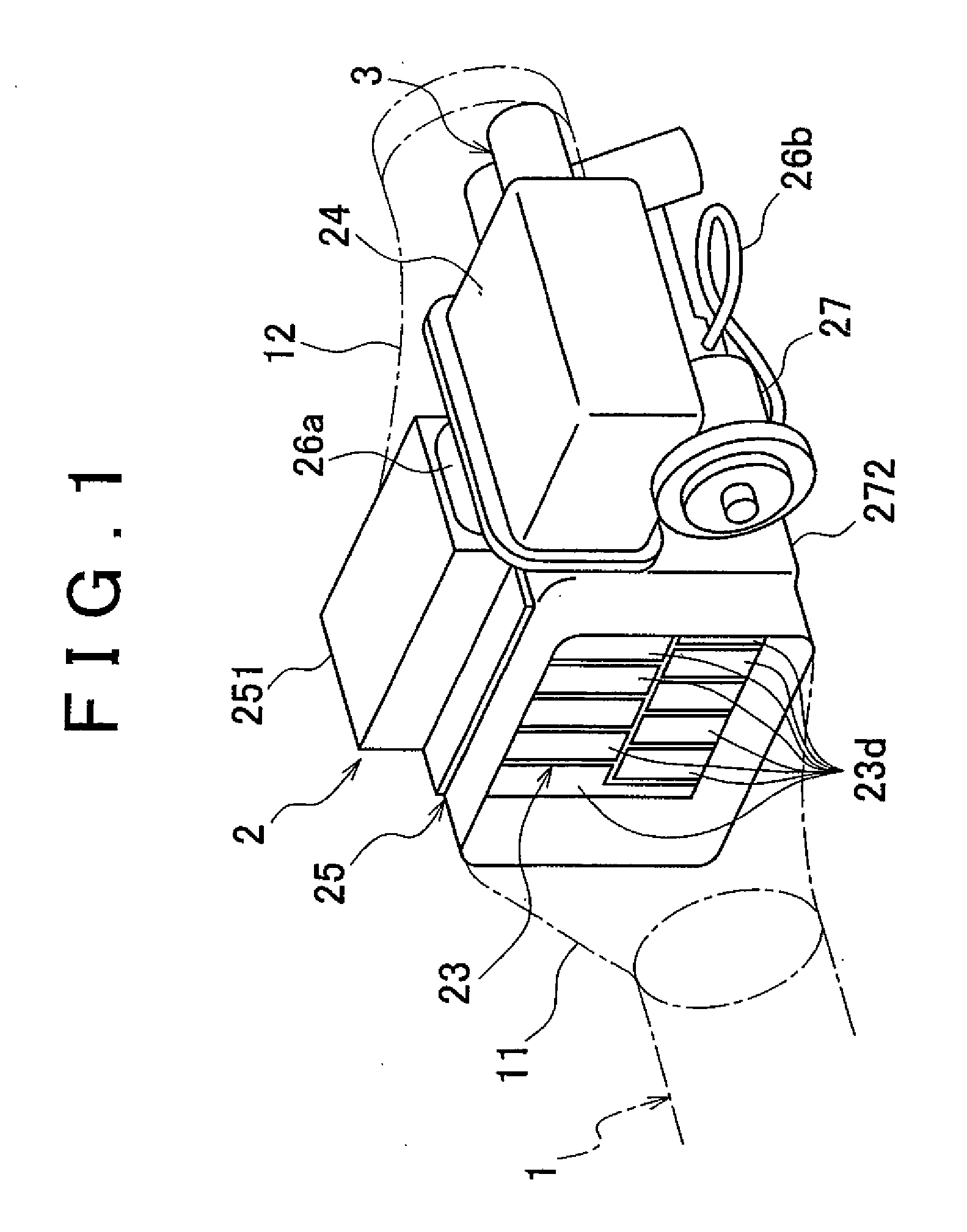

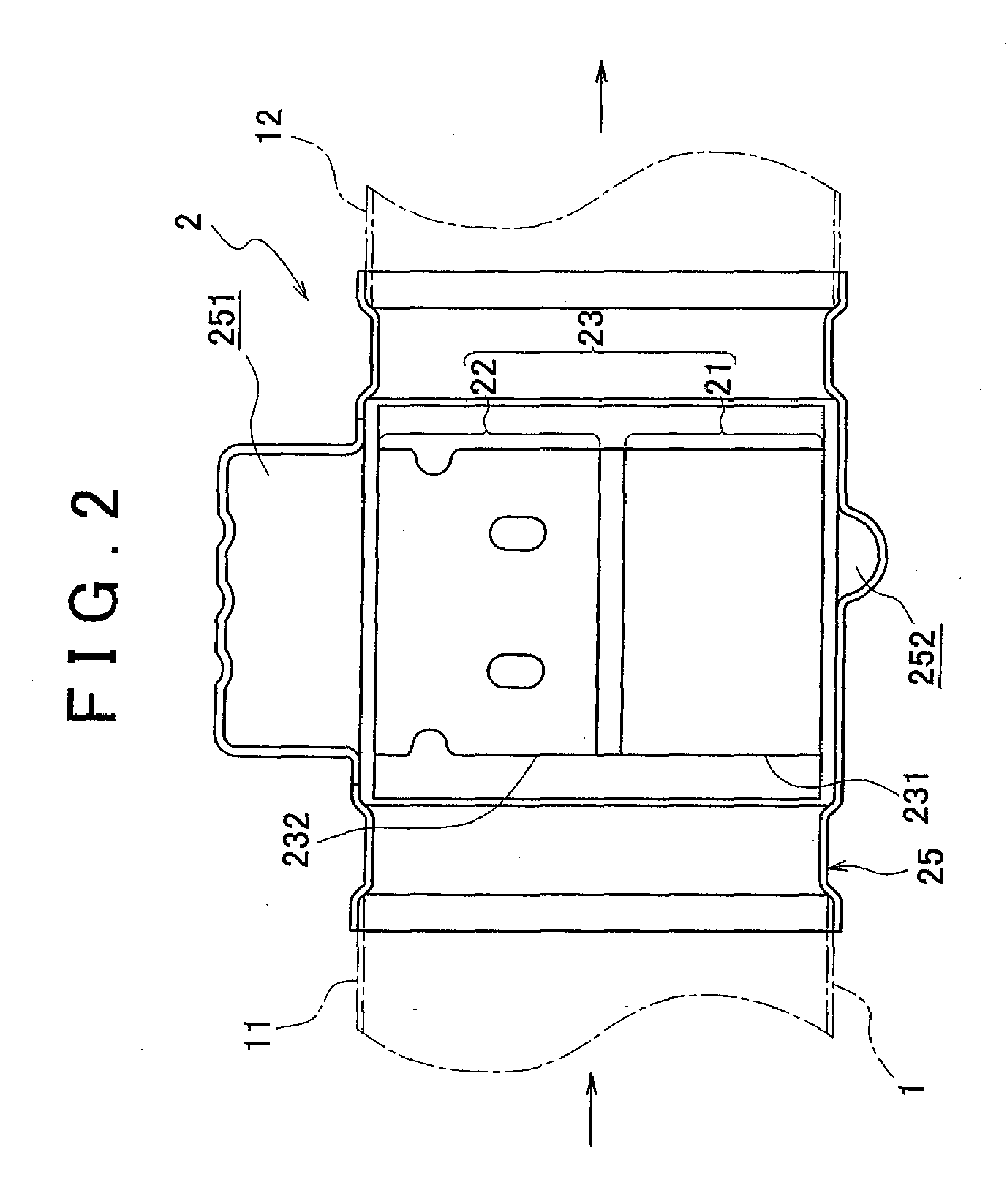

first embodiment

[0039]Thus, in the above-mentioned first embodiment, the heat pipe 23 causes the flow rate of pure water flowing through each of the heating unit side heat pipe portions 23a to be retarded in the merging portion 23c on the side of the evaporation unit 22 by the flow rate retardation means 4 provided with the merging portion 23c that merges pure water respectively heated by the seven heating unit side heat pipe portions 23a on the side of the heating unit 21 to the side of the evaporation unit 22. This is carried out to retard the flow rate of pure water merged from each of the heating unit side heat pipe portions 23a by retaining in the merging portion 23c having a large flow path cross-sectional area by causing pure water heated by each heating unit side heat pipe portion 23a to merge into the merging portion 23c on the side of the evaporation unit 22. Moreover, since the flow path cross-sectional area of the merging portion 23c is provided to be larger than the flow path cross-sec...

second embodiment

[0042]Next, an explanation is provided of the invention based on FIG. 4.

[0043]A different configuration is employed for the heat pipe in this second embodiment. Furthermore, other constituents with the exception of the heat pipe are the same as in the case of the above-mentioned first embodiment, like reference numerals are used to indicate like constituents, and a detailed explanation thereof is omitted.

[0044]Namely, in this second embodiment, a heat pipe 28 allows the flow of a working fluid in the form of pure water there through, and is housed within the evaporation side case 25 in the shape of a rectangular frame. A central portion of the evaporation side case 25 in which this heat pipe 28 is located is arranged so as to face an inside of the exhaust pipe 1. The heat pipe 28 is provided with a plurality of heating unit side heat pipe portions 28a on the side of the heating unit 21 (bottom of FIG. 4) that heats pure water with heat of exhaust gas, and a plurality of evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com