Hydraulic Oilfield Lift Pump

a technology of hydraulic oilfield and lift pump, which is applied in the direction of piston pump, fluid removal, borehole/well accessories, etc., can solve the problem of low effective electric rate, and achieve the effect of reducing system stress and reducing large load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

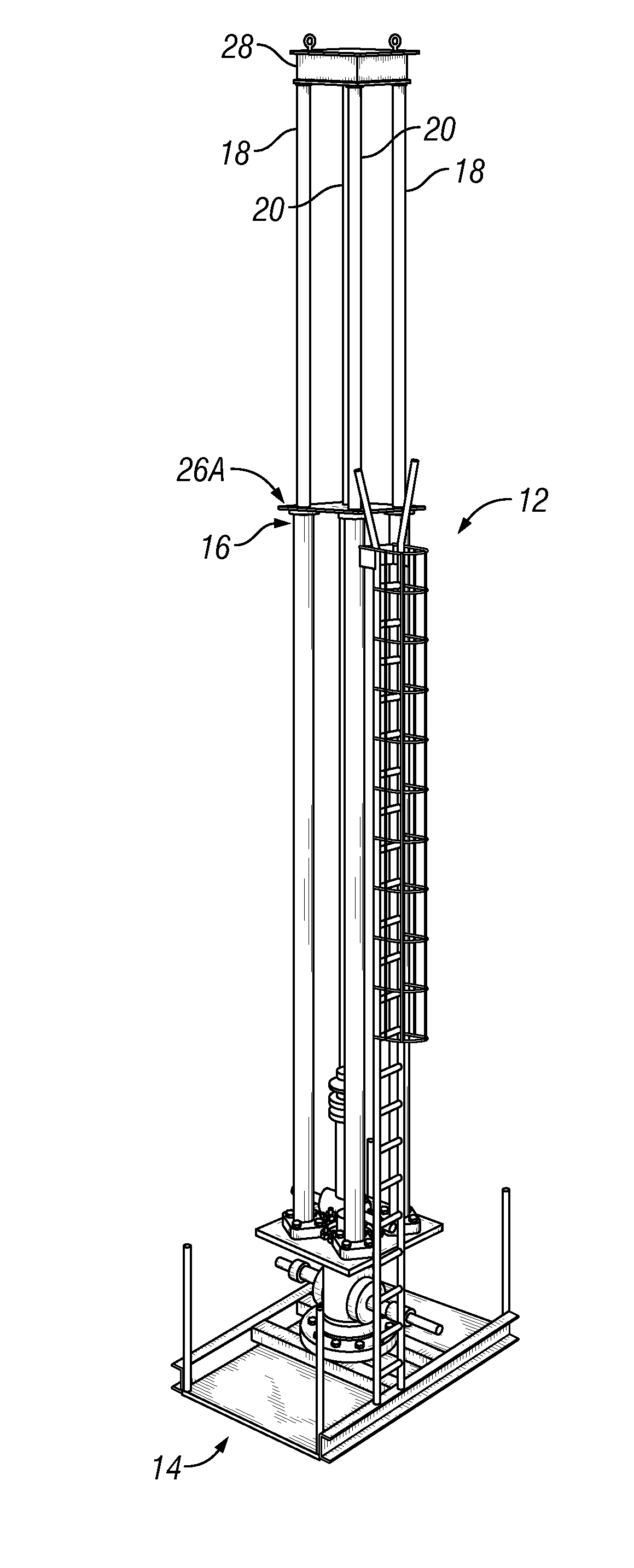

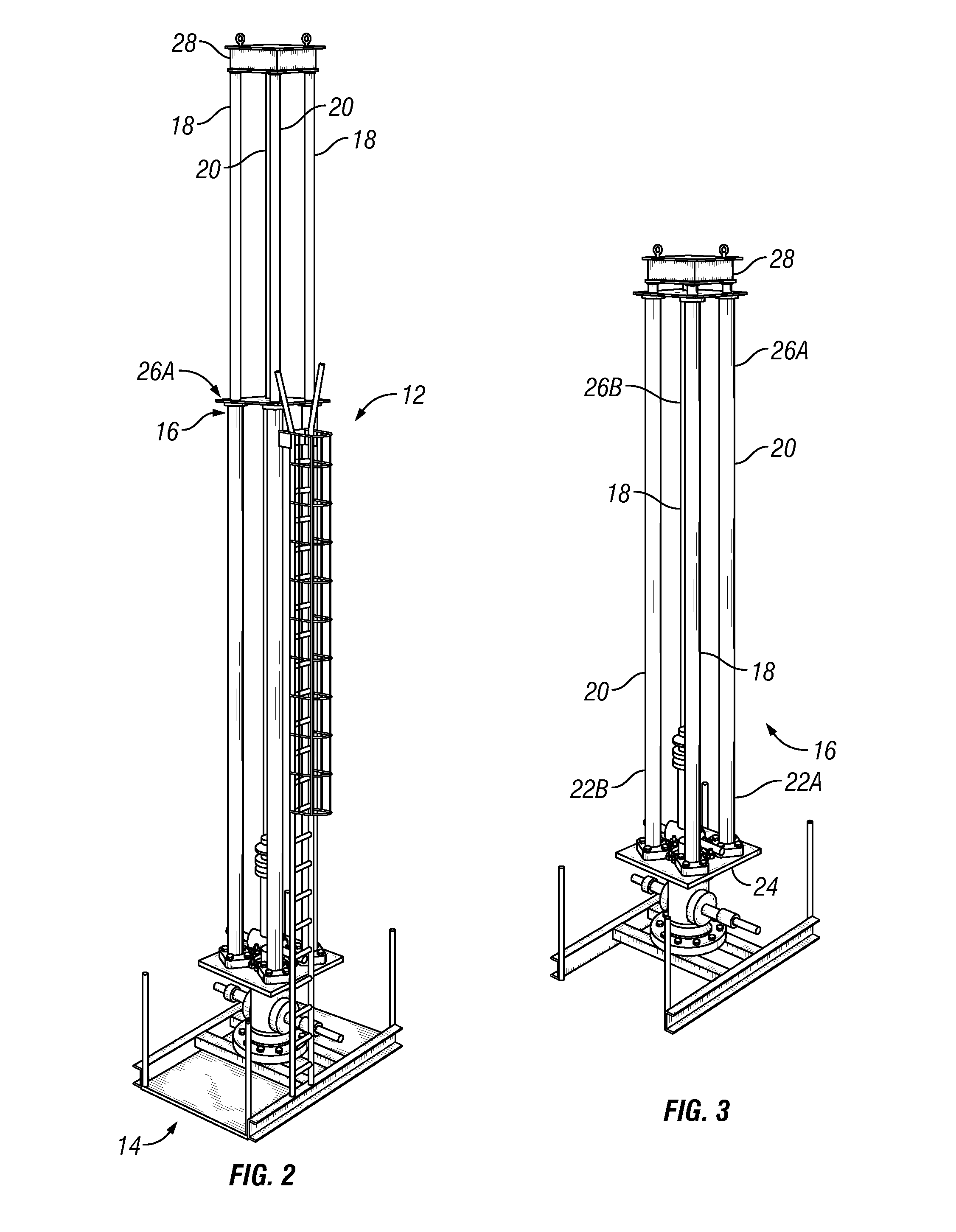

[0022]Referring now to FIGS. 2 and 3; the hydraulically driven surface oil well pumping unit 12 of the present invention comprises a base portion 14, including a hydraulic power unit (not shown) and a mast portion 16 comprising a pair of single acting hydraulic cylinders 18 and a pair of double acting hydraulic cylinders 20. FIG. 2 shows the hydraulic cylinders 18, 20 of the hydraulically driven oil field pumping unit 12 fully extended, and FIG. 3 shows the mast portion 16 separated from the rest of the oilfield pumping unit 12 of FIG. 2 with the hydraulic cylinders 18, 20 fully retracted. The new oil well pumping unit 12 of the present invention is useful in reciprocating a “load” in the wellbore; particularly a load which is substantially higher as the load is being raised, than when the load is being lowered—as is typically the case when pumping oil in an oil well.

[0023]The cap ends 22a and 22b of the hydraulic cylinders 18, 20 are shown mounted to a common rigid base plate 24. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com