Displacement diffuser with heat/cool changeover

a diffuser and heat/cool technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of reducing the overall relative ventilation efficiency, sharp drop in ventilation efficiency, and high concentration of contaminants near these sources, so as to maximize comfort in both heating and cooling modes, and consume minimal usable floor space. , the effect of easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

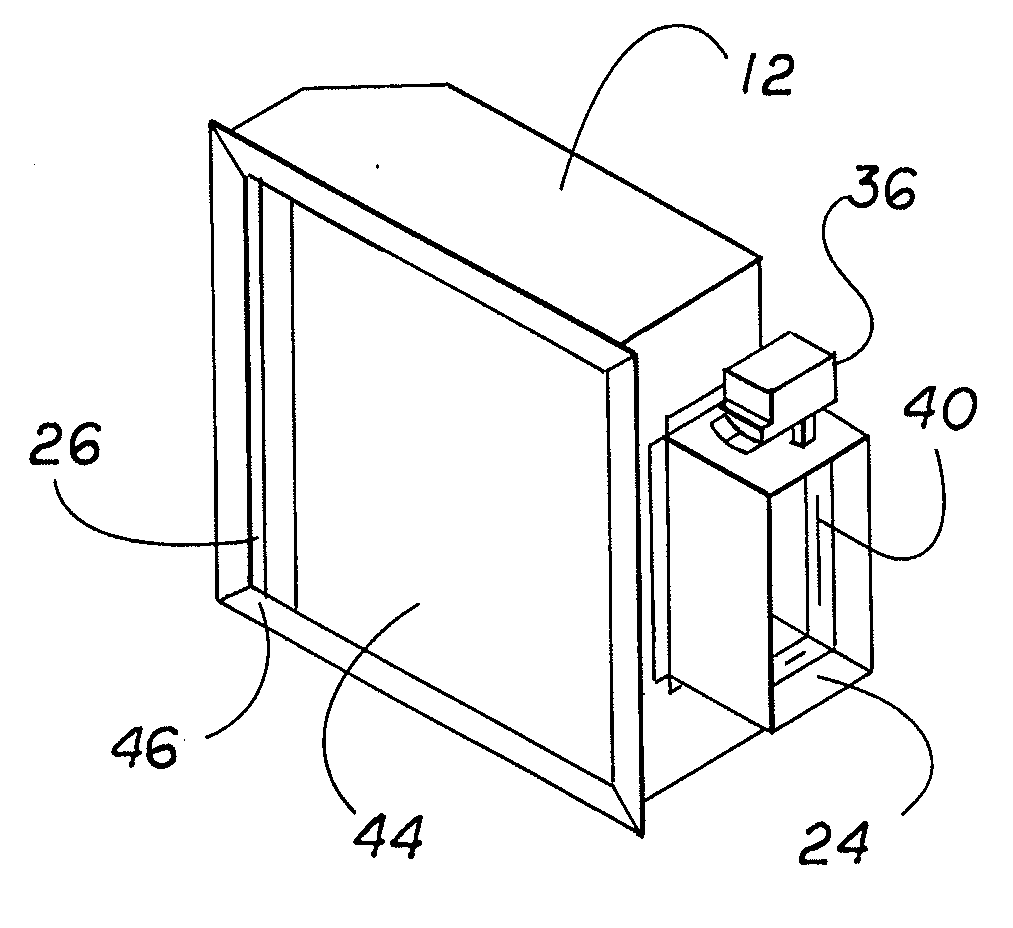

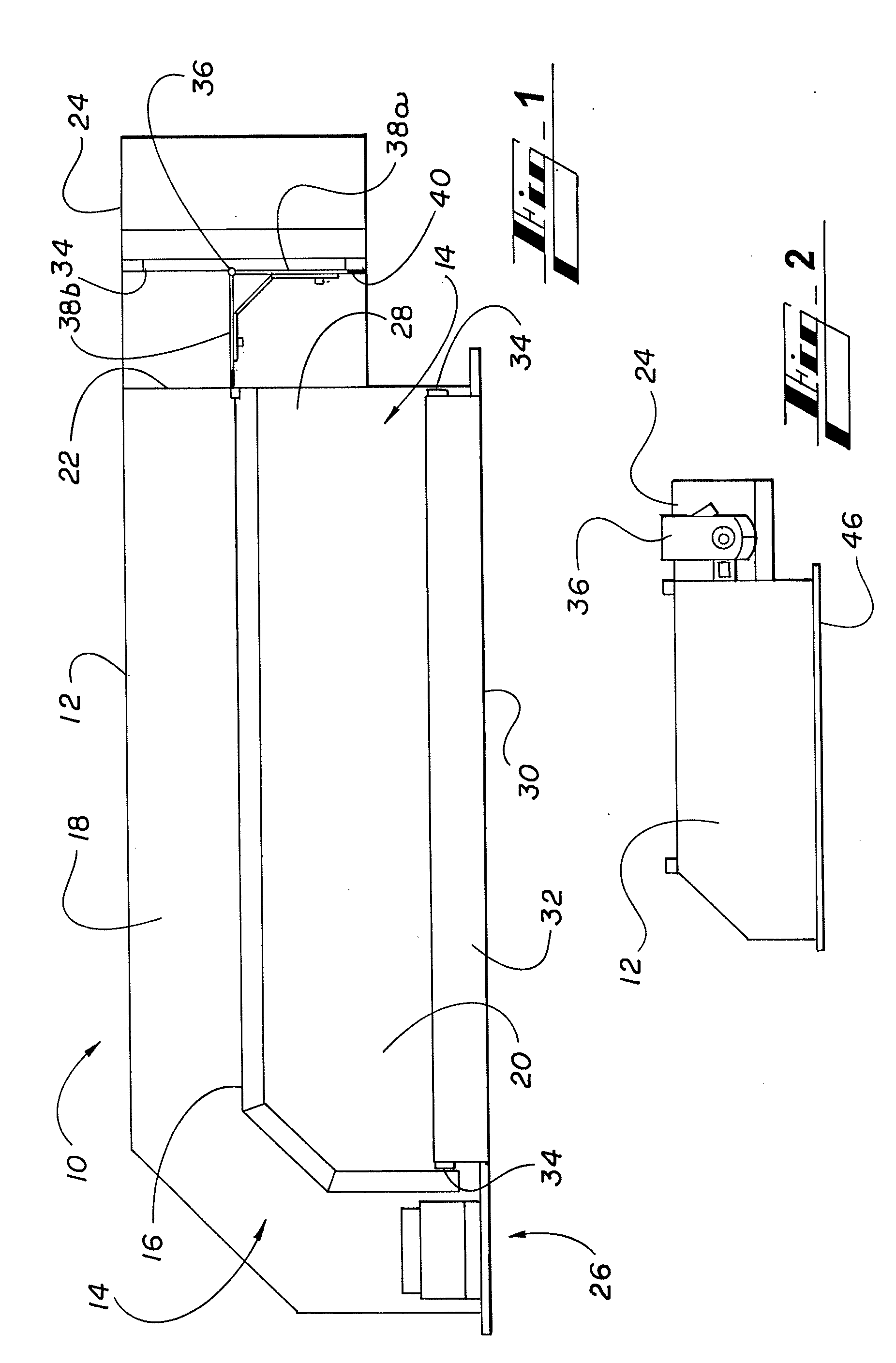

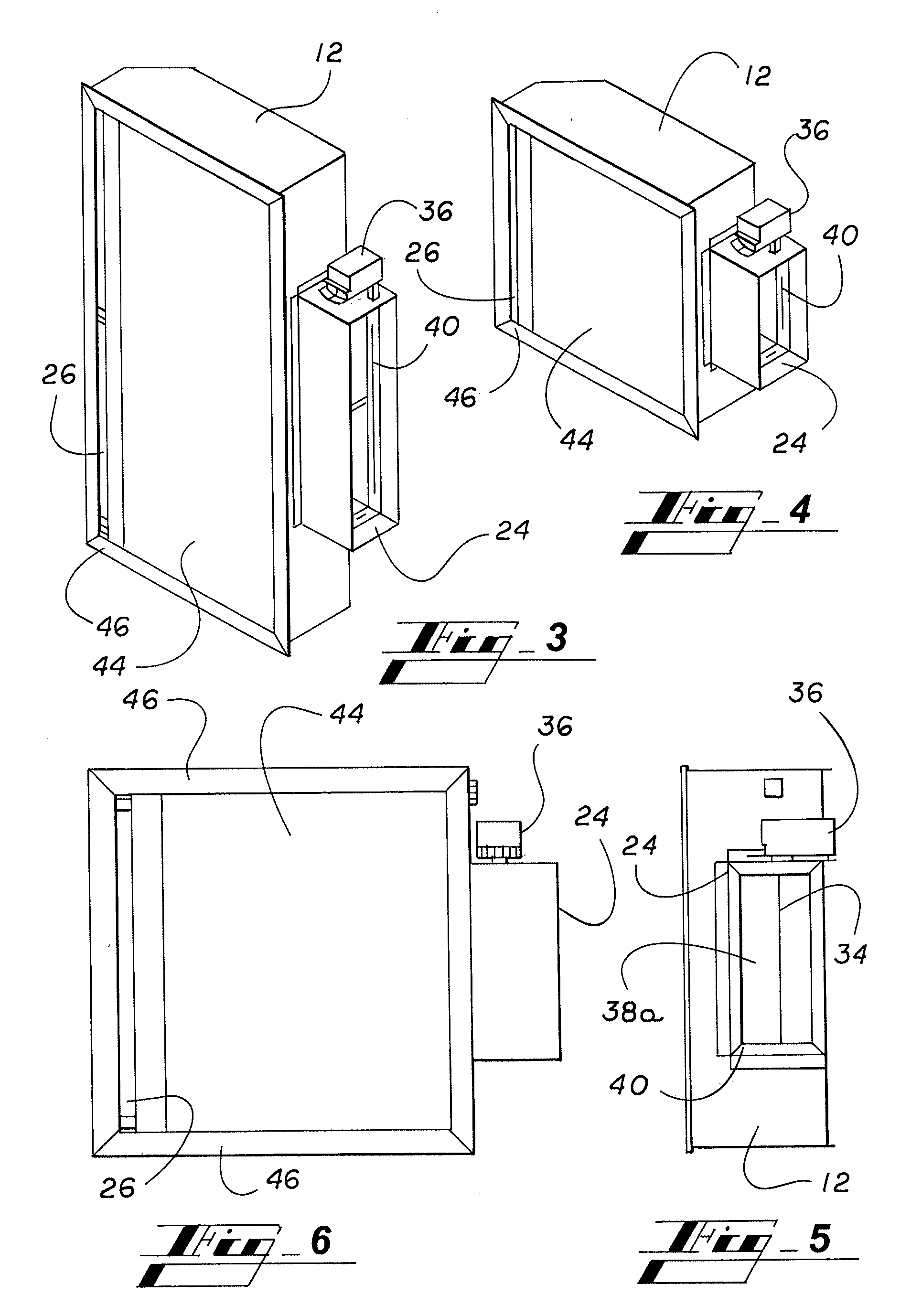

[0035]Illustrative embodiments of a device according to the present invention are shown in FIGS. 1 through 6. FIG. 1 cross-sectional side view of an embodiment of the displacement diffuser with a heating and cooling function in accordance with the present invention. FIG. 2 is a side elevation view of an embodiments of the displacement diffuser with a heating and cooling function in accordance with the present invention showing the exterior of the diffuser of FIG. 1, and detailing the control mechanism. FIGS. 3 and 4 are corner perspective views of the bottom and sides of two embodiments in different dimensions of a displacement diffuser with a heating and cooling function in accordance with the present invention in which an internal gasket can be seen in the duct housing. FIG. 5 is a side view of an embodiment of the displacement diffuser with a heating and cooling function in accordance with the present invention from an end of the diffuser containing the duct housing, the pivoting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com