Solar thermal heating utilizing dynamic particle flow balancing

a technology of solar thermal heating and dynamic particle flow, applied in the safety of solar heat collectors, solar heat collector details, light and heating apparatus, etc., can solve the problems of high cost of solar thermal panels for home heat applications, many panels are required, and the use of thermal solar devices is not usually used to heat the house. to achieve the effect of reducing the cost of solar thermal panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

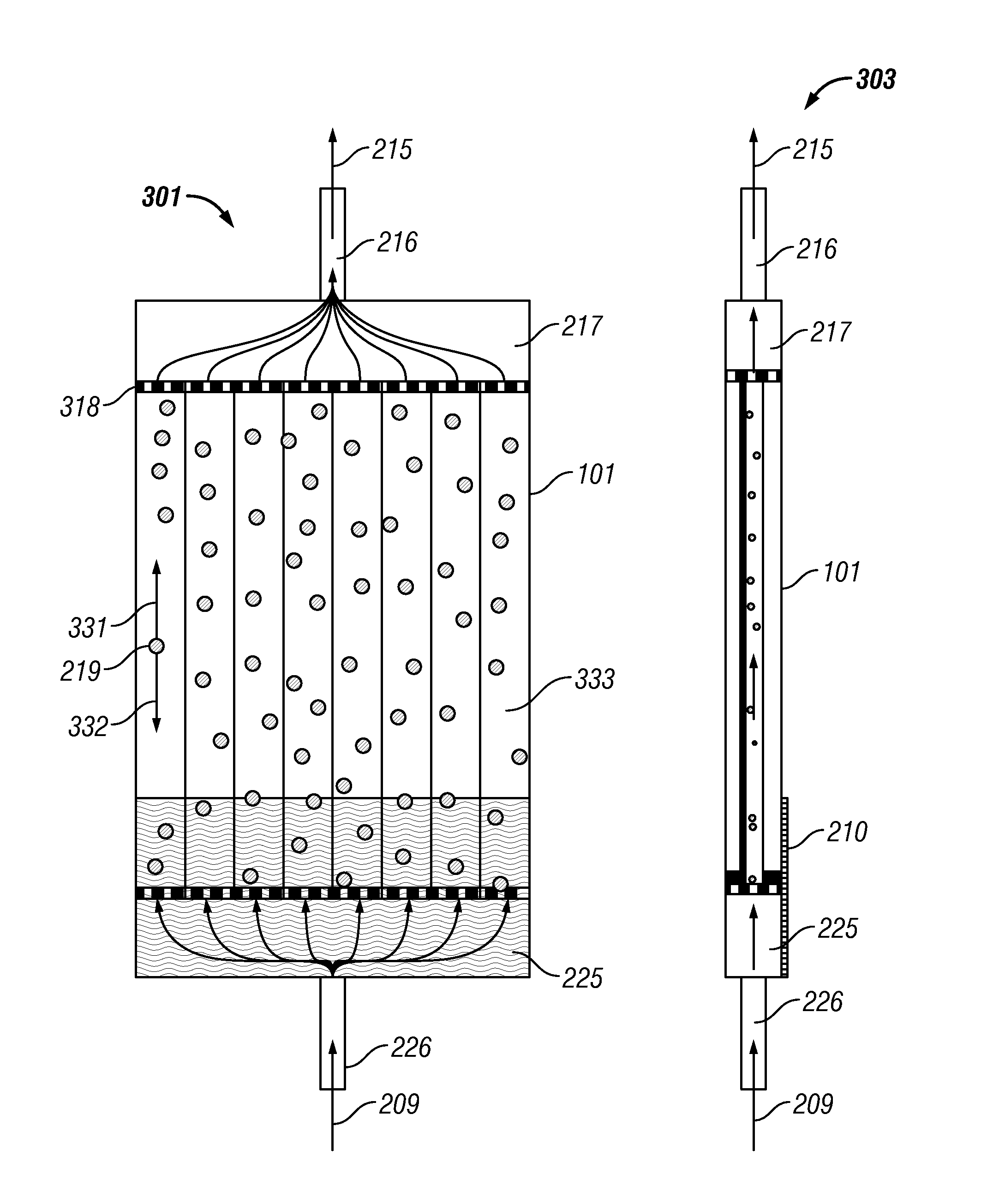

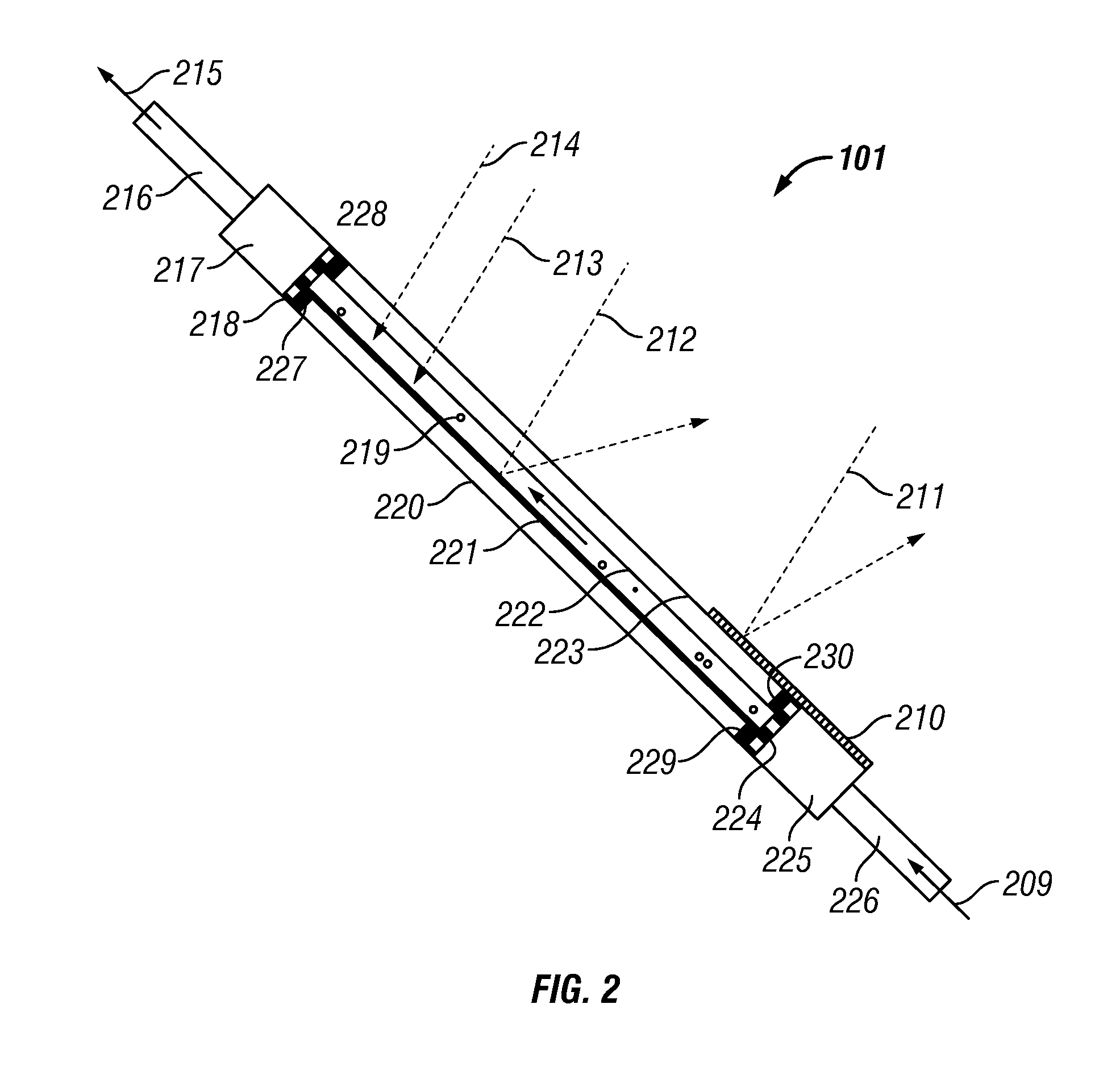

[0034]The particular values and configurations discussed in these non-limiting examples can be varied and are cited merely to illustrate an embodiment of the present invention and are not intended to limit the scope of the invention. Note that in FIGS. 1-6, identical or similar parts or elements are generally indicated by identical reference numerals.

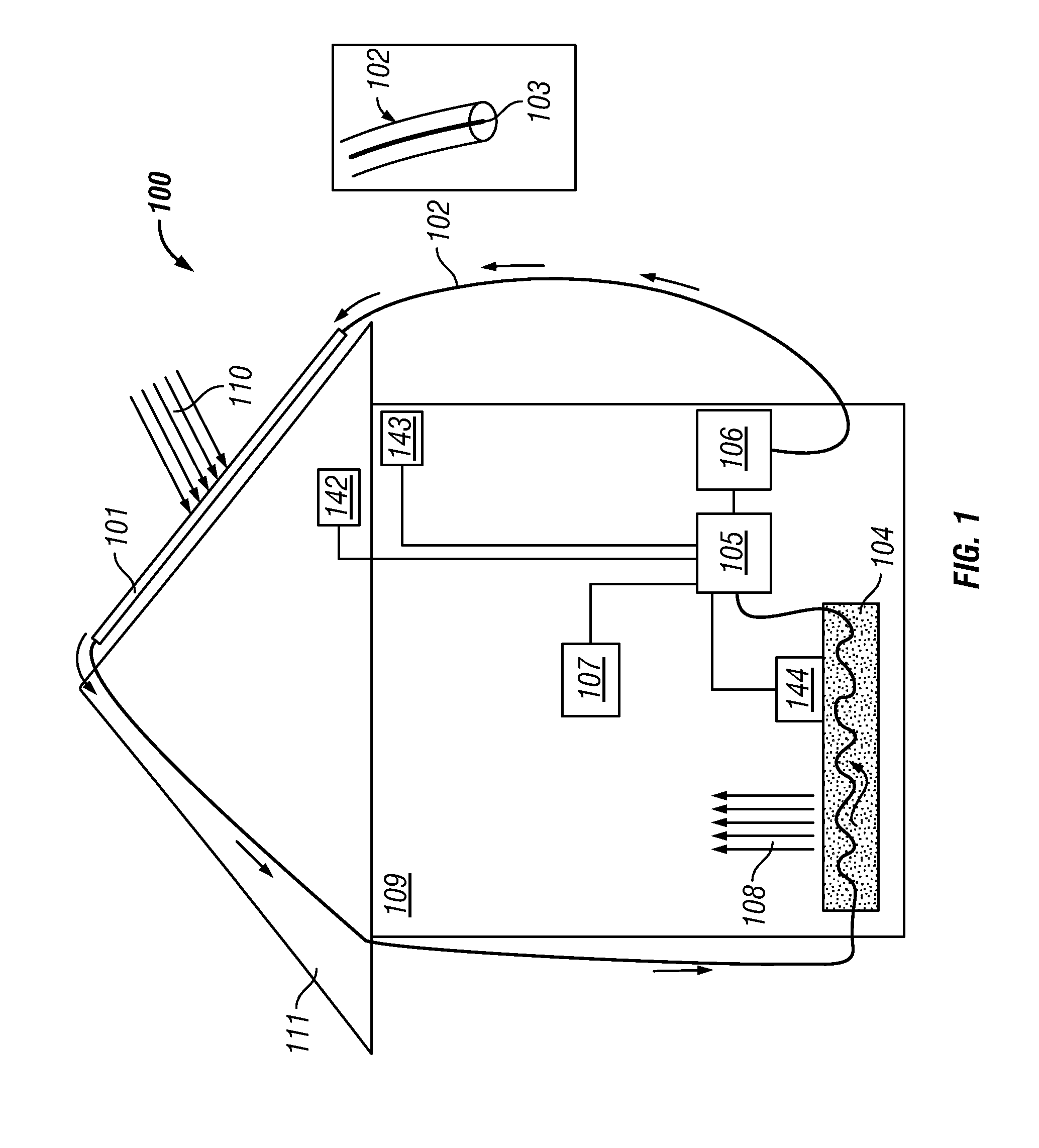

[0035]FIG. 1 illustrates a heating system 100, in accordance with an embodiment. In the configuration of system 100, a building 109 generally includes a roof 111 upon which a thermal solar panel 101 is located. Light (as indicated by arrows 110) impinges on the panel 101, where it is absorbed as heat by particles 219 suspended in a liquid that flows through the panel 101 in a direction against the force of gravity. Note that the particles 219 can be, for example, but not limited to silicon carbonate particles.

[0036]The liquid is circulated through a heat mass 104, through a controller 105, and finally through a circulation pump 106. A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com