Thermal module and manufacturing method thereof

a technology of thermal modules and manufacturing methods, applied in indirect heat exchangers, lighting and heating apparatuses, laminated elements, etc., can solve the problems of time-consuming and complex, and the heat dissipation capability of thermal modules is thus greatly reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0021]FIG. 6 shows a thermal module 300 according to a The thermal module is similar to the previous first thermal module 100. The thermal module 300 includes a substrate 32 and a plurality of heat pipes 36. The substrate 32 forms a bottom surface 322 and a top surface 324 opposite to the bottom surface 322. The thermal module 300 differs from the first thermal module 100 in that a plurality of fins 34 are integrally formed on the top surface 324 of the substrate 32, and a shape of the heat pipes 36 is different from the heat pipes 16 of the first thermal module 100. The heat pipes 36 of the thermal module 300 each are U-shaped, including an evaporating section 362 and a condensing section 362 parallel to the evaporating section 362. The evaporating section 362 is integrally embedded in the substrate 32, while the condensing section 364 extends through and thermally connects with the fins 34. The evaporating section 362 of each of the heat pipes 36 forms a planar contacting surface...

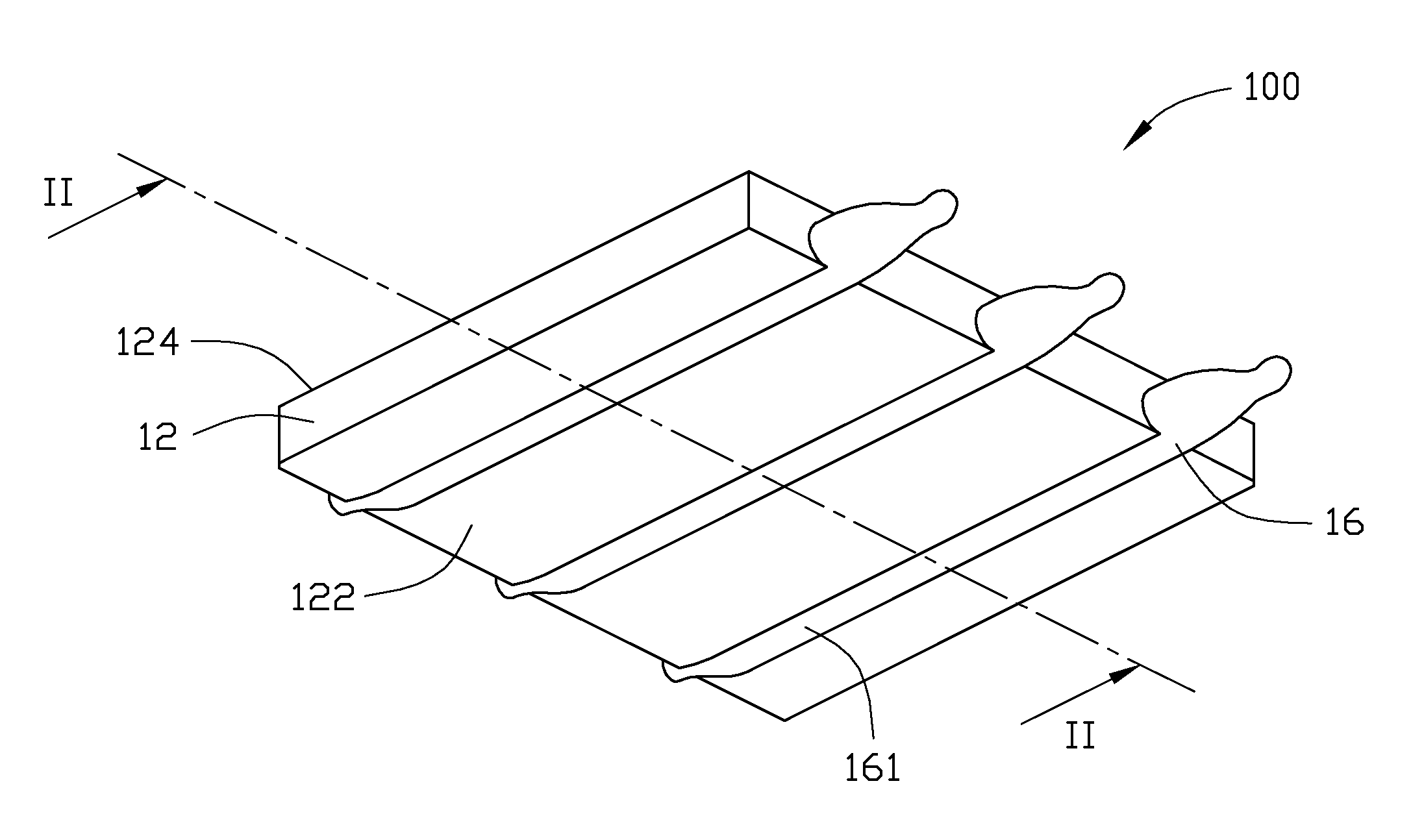

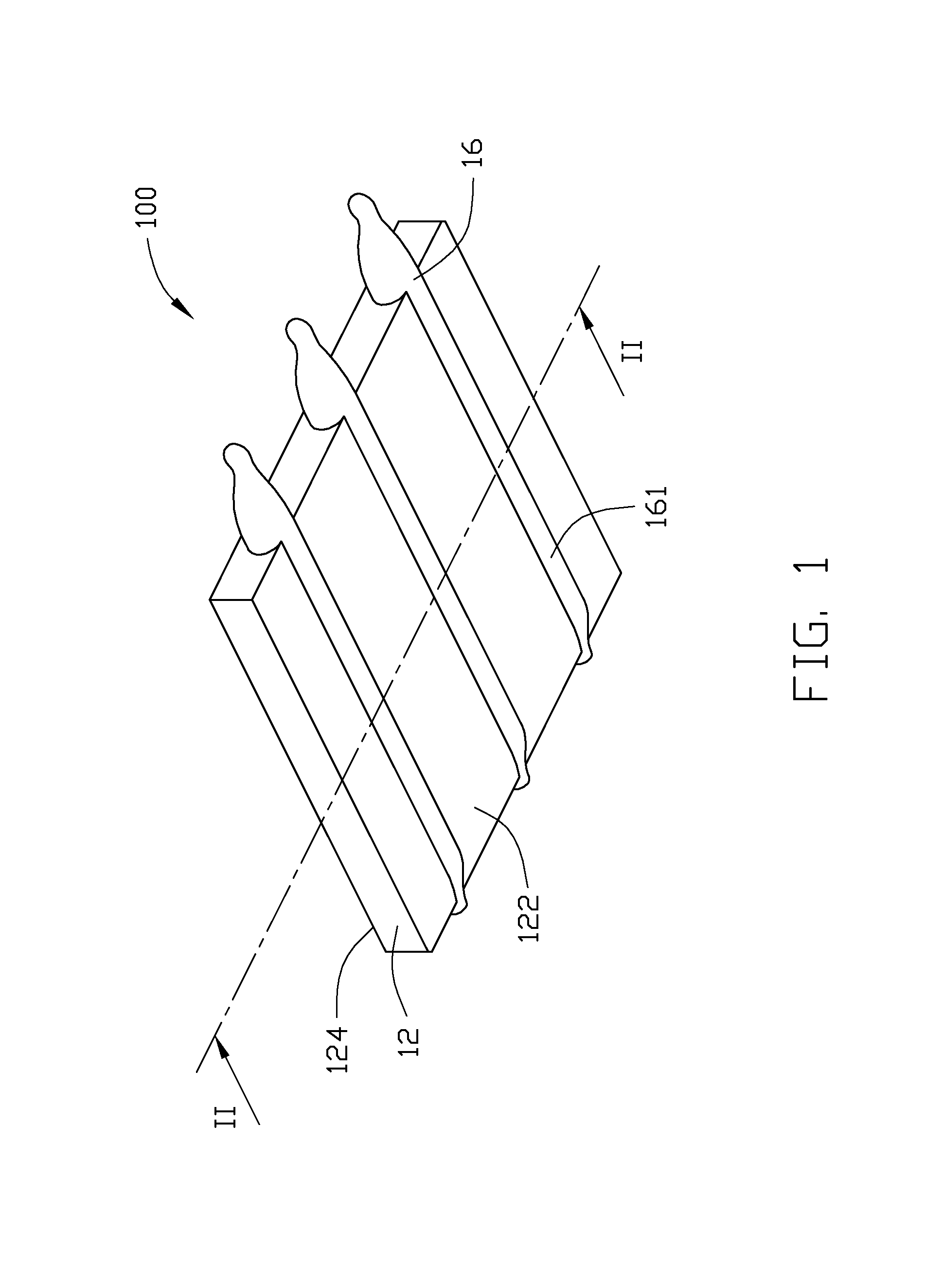

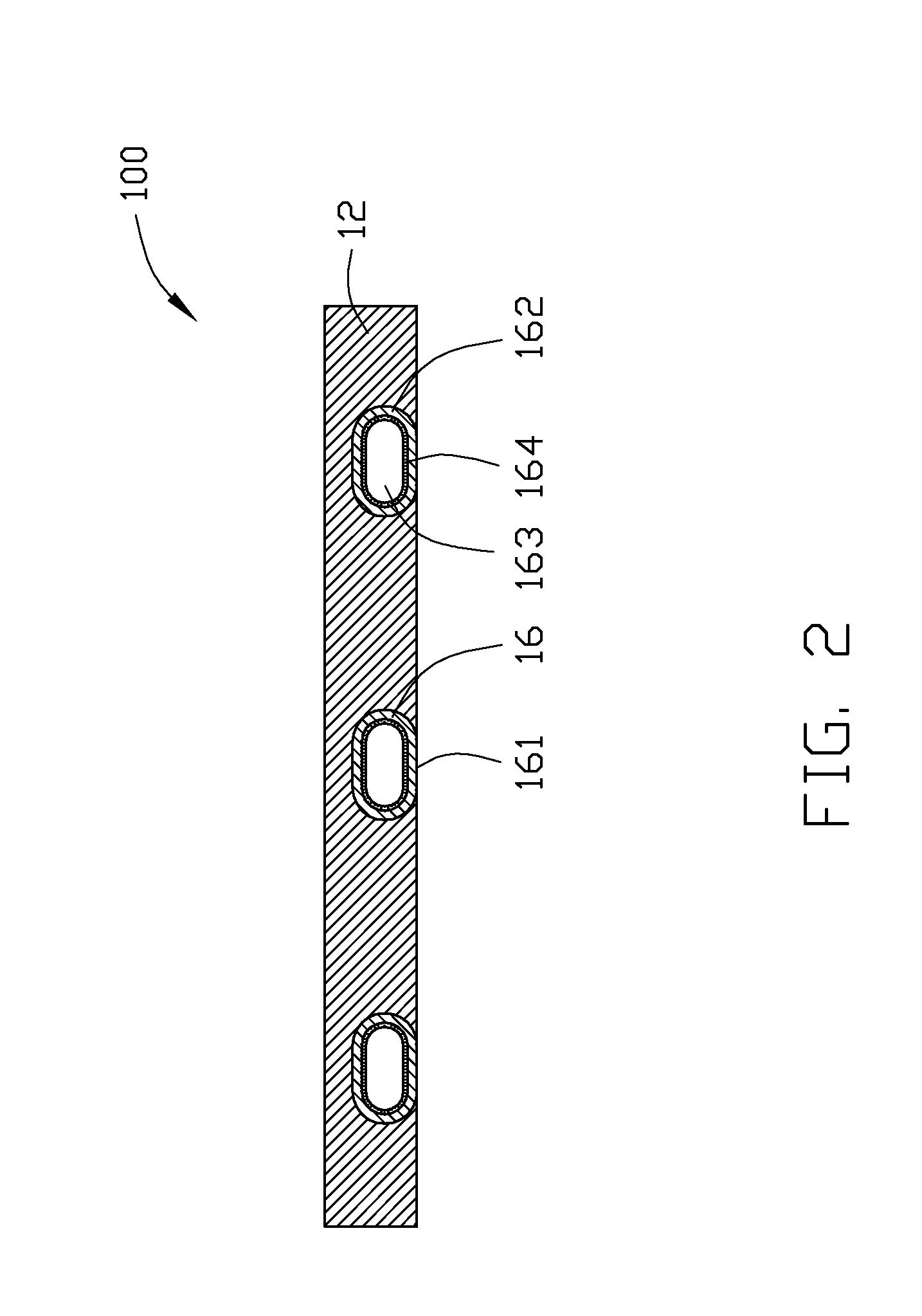

first embodiment

[0022]A method of manufacturing the thermal module 300 is similar to the method of manufacturing the previous thermal module 100 of the When the thermal module 300 is manufactured, a plurality of tubes each with a wick structure attached to an inner surface thereof are firstly provided. Each of the tubes is flat in cross section and U-shaped in profile. Each tube includes a first section used for forming the evaporating section 362 of the heat pipe 36 and a second section used for forming the condensing section 364 of the heat pipe 36. One end of each of the tubes is open and the other end of each of the tubes is sealed. Secondly, the tubes are placed into a mold which is applied for forming the substrate 32 and the fins 34. Thirdly, a molten metal is injected into the mold to simultaneously form the substrate 32 and the fins 34 wherein the first sections of the tubes are integrally embedded in the substrate 32 and the second sections of the tubes integrally extend through the fins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com