Horizontal directional drilling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

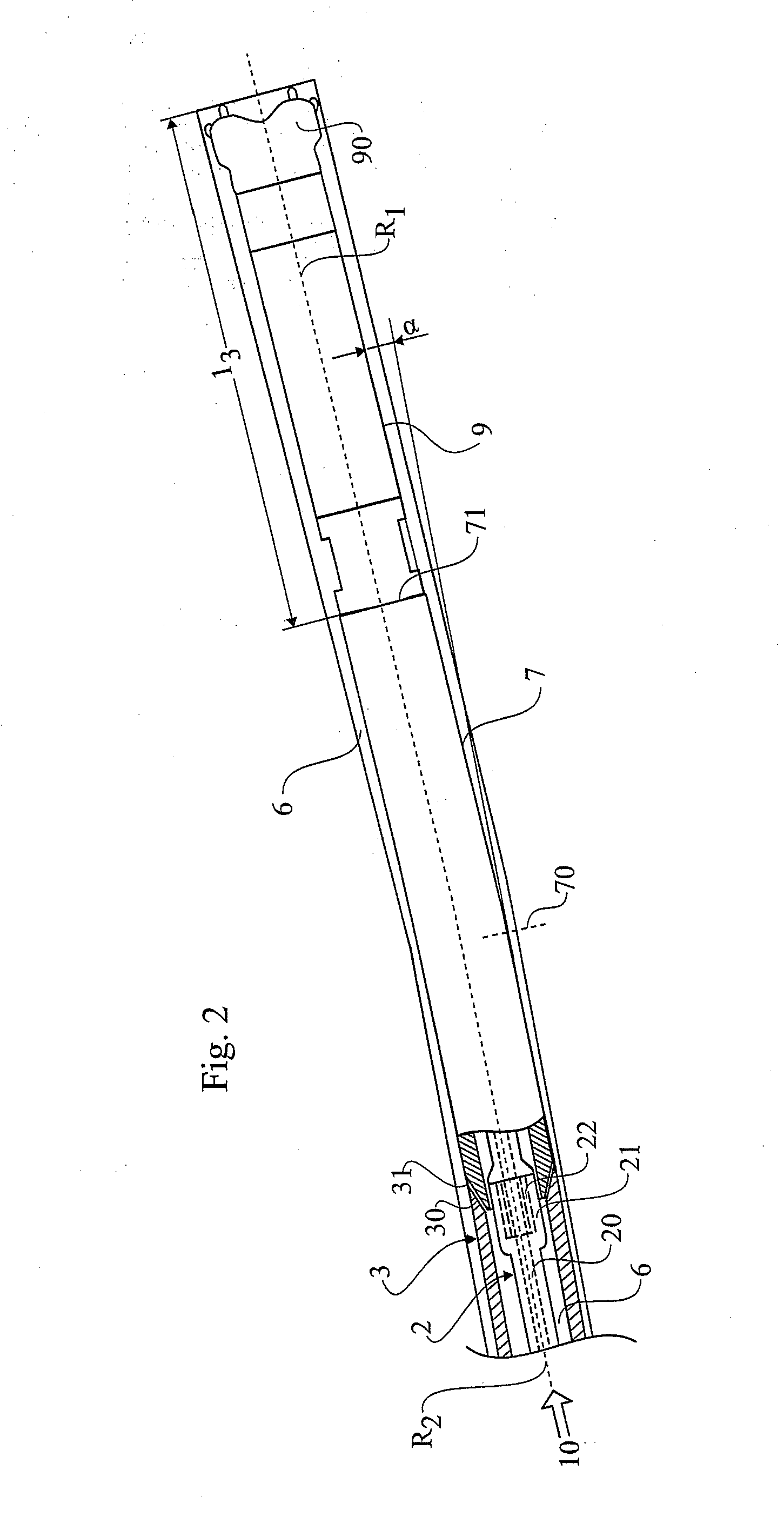

[0016]Various embodiments are described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that such embodiments may be practiced without these specific details.

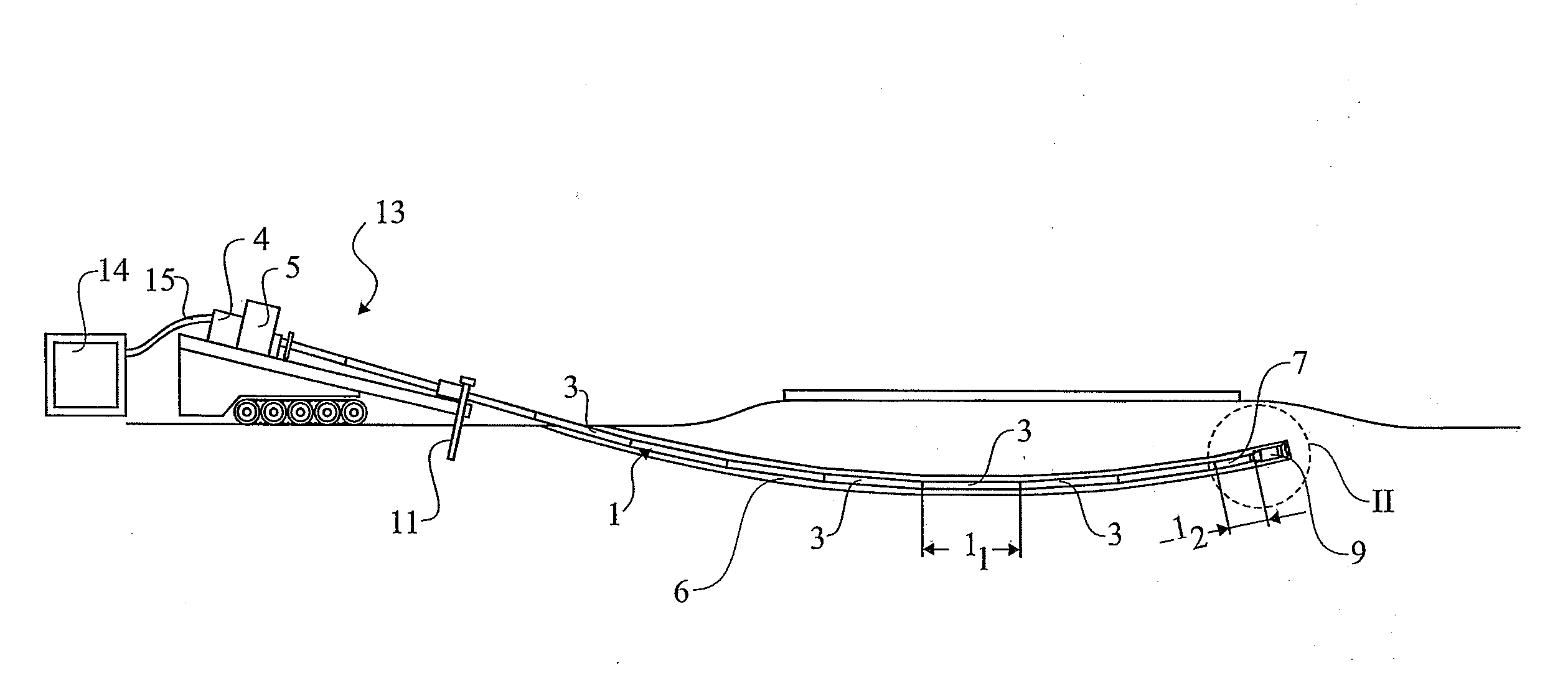

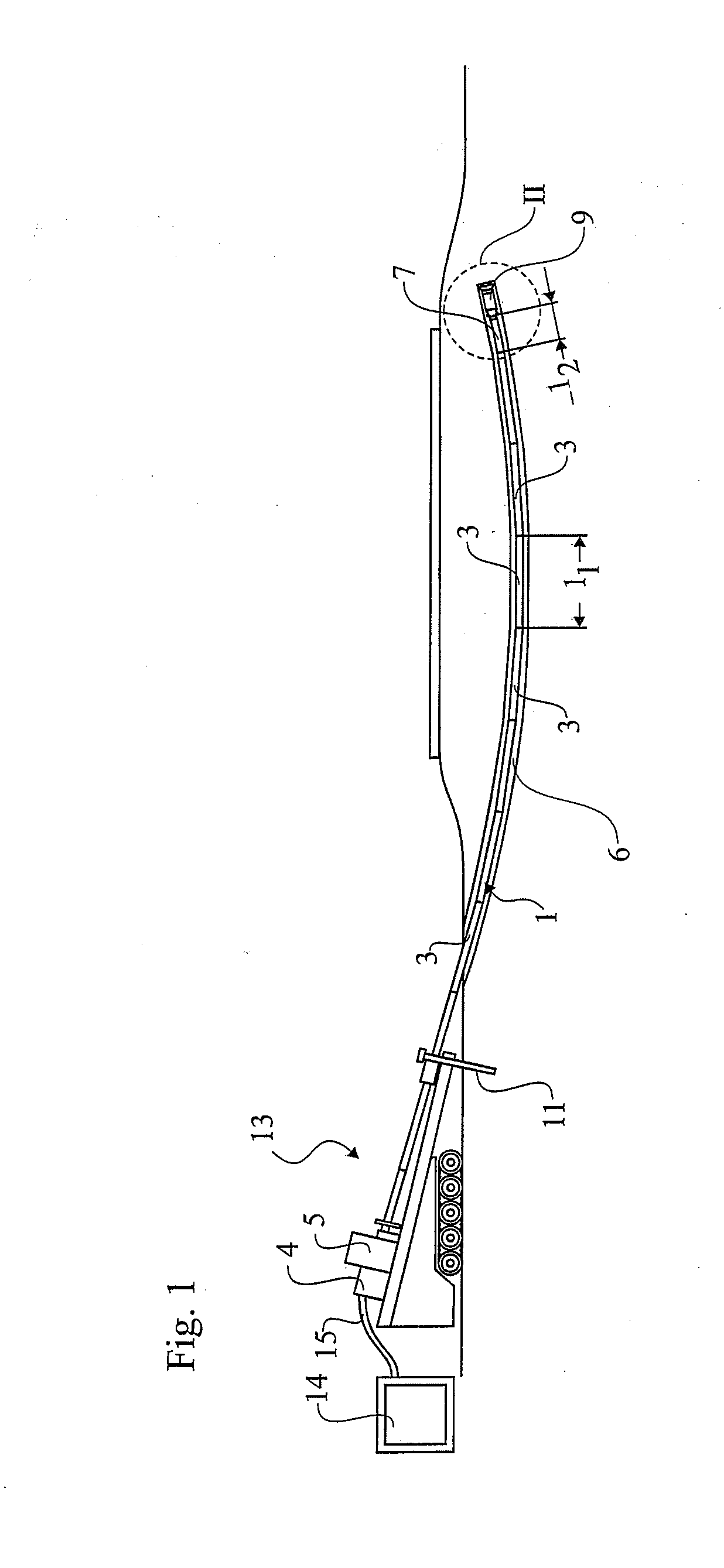

[0017]FIG. 1 illustrates a horizontal directional drilling system in accordance with an embodiment of the invention. The horizontal directional drilling system may be used to make a borehole 6, without disturbing an above ground structure. The horizontal directional drilling system comprises rotary drive systems 4, 5 on a moveable base 13, an earth anchor 11, a dual string 1 and equipment 14, 15 to supply pressurized fluid. The dual string 1, the rotary drive systems 4, 5 equipment 14, 15 to supply pressurized fluid are standard equipment known in the art.

[0018]In a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com