Precast structure and method of construction

a precast structure and precast concrete technology, applied in the direction of construction, building repair, building material handling, etc., can solve the problems of high labor cost and high material cost of the anchoring system, and achieve the improvement of reduce labor and construction delays, and improve structural rigidity and damage toleran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

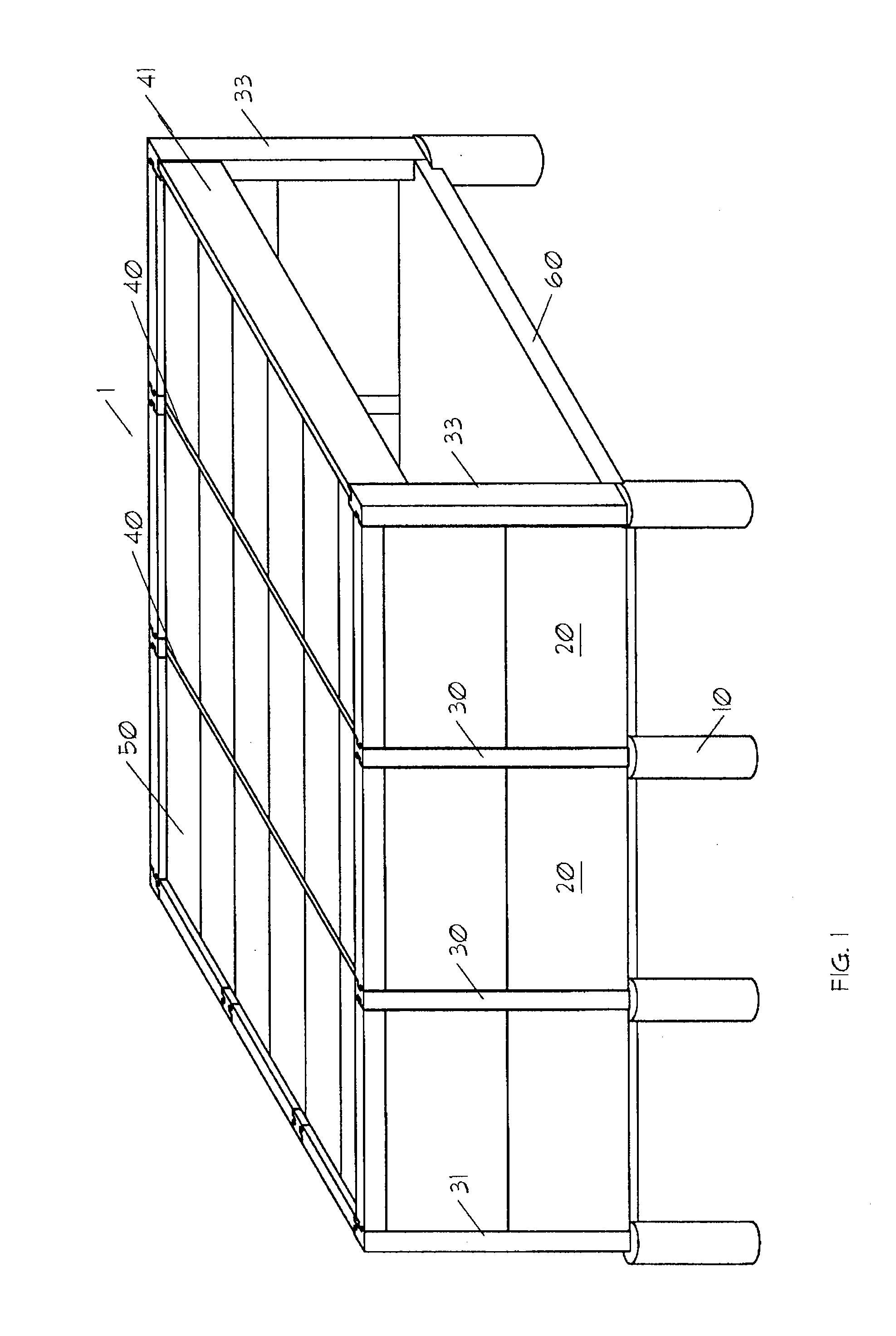

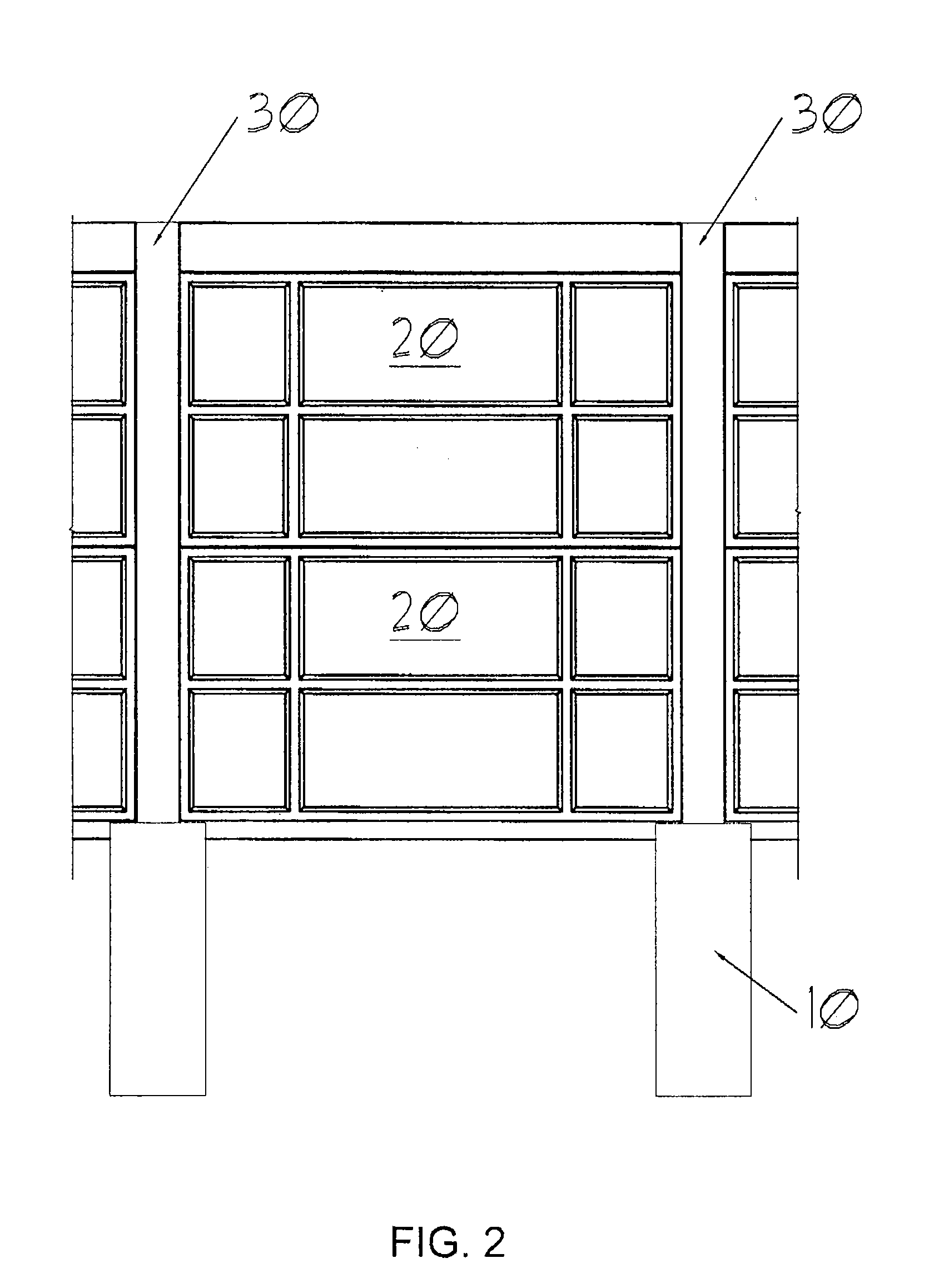

[0030]The examples described and drawings rendered are illustrative and are not to be read as limiting the scope of the invention as it is defined by the appended claims.

[0031]The following examples describe a precast structure and a method for construction of a precast structure, but the invention is not limited to the specific examples described. Instead, it should be understood that the features in the examples and the methods disclosed are merely illustrative. The claims that eventually issue should be interpreted in light of the specification, but the claims should not be limited by the description and drawings of the examples presented. The illustrations use the same illustration numbers to identify identical and similar features.

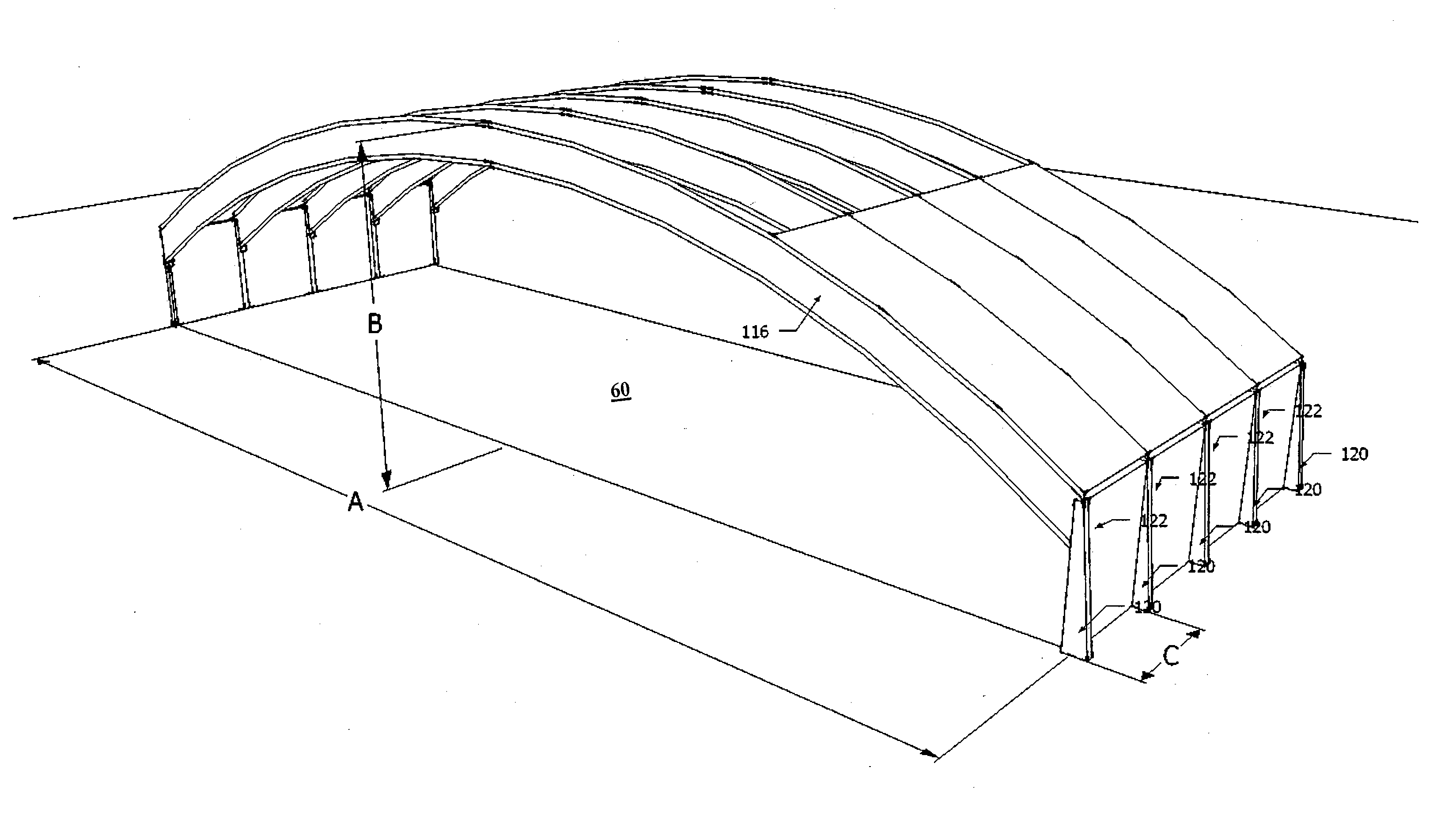

[0032]A method of construction for structures comprises erecting precast concrete posts in foundation footings, fitting a precast concrete panel between each pair of the posts, and pouring a slab. The slab is poured after the step of fitting each of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com