Epicyclic Gear System Having Two Arrays Of Pinions Mounted On Flexpins With Compensation For Carrier Distortion

a gear system and array technology, applied in the direction of gearing, toothed gearing, belt/chain/gearing, etc., can solve the problems of excessive wear of planet pinions and sun and ring gears, heavy loads tend to distort the carrier and its pins, and skew the axis,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

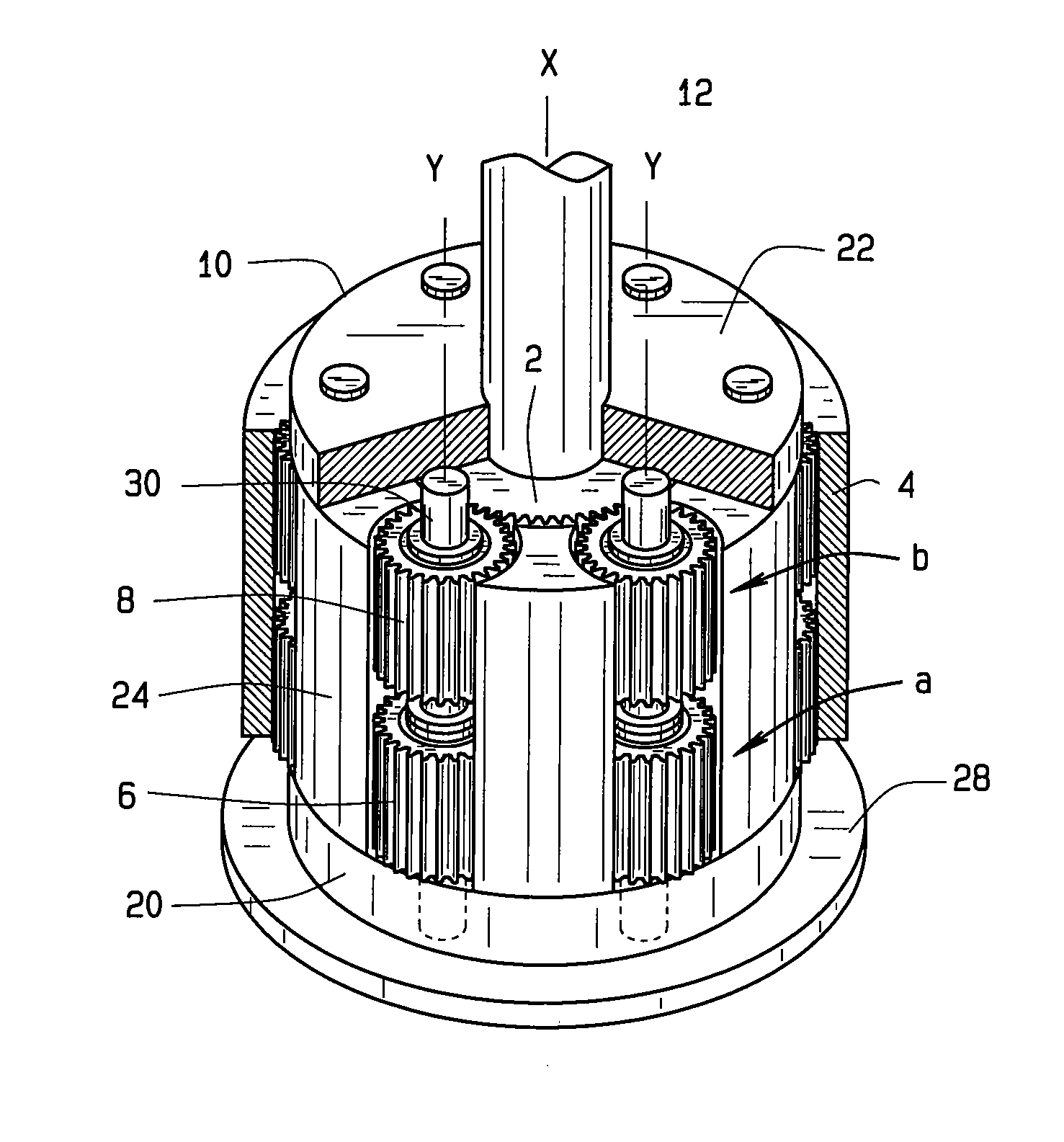

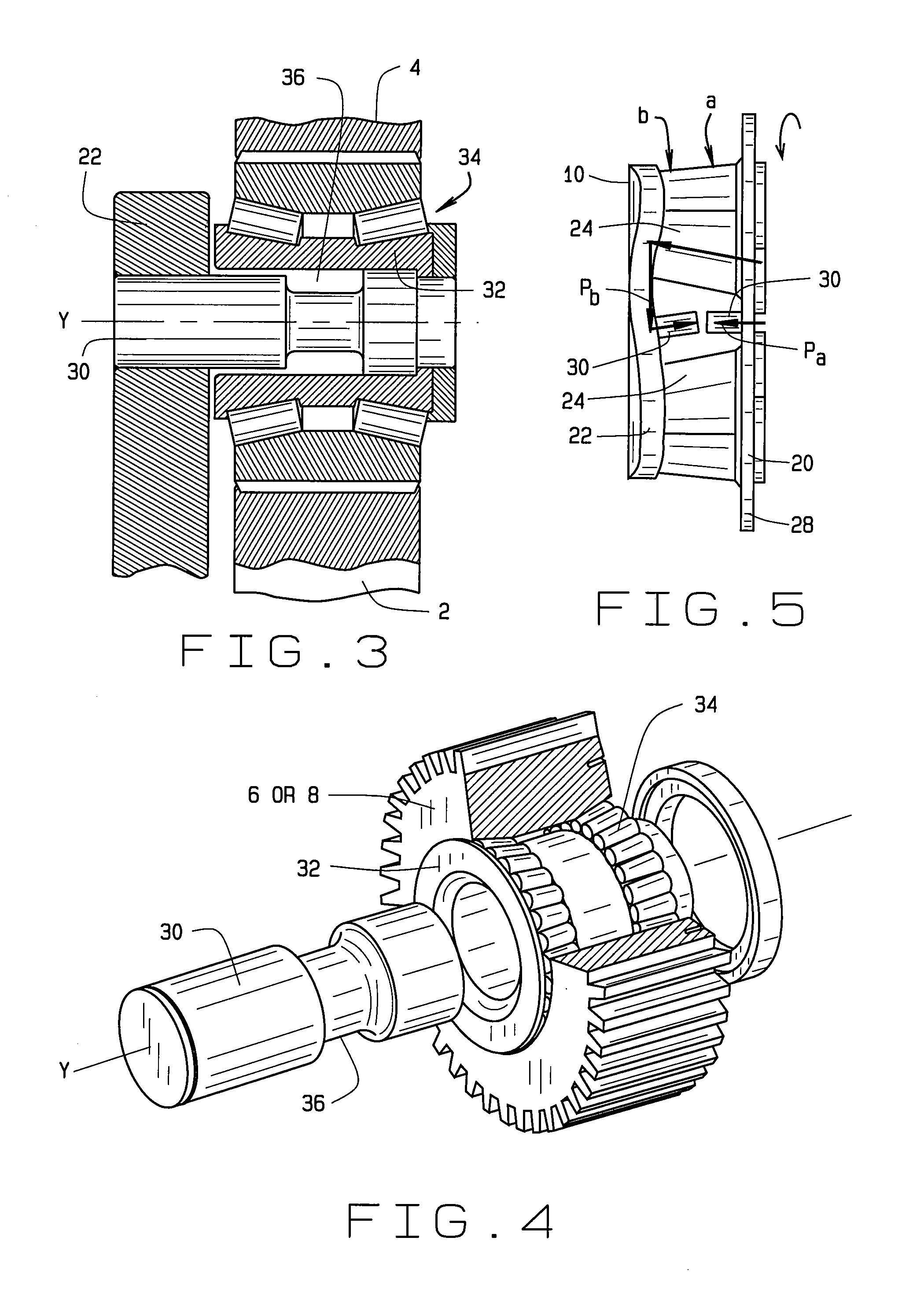

[0007]FIG. 1 is a perspective view, partially broken away and in section, of an epicyclic gear system having its planet pinions arranged in two arrays on flexpins and otherwise being constructed in accordance with and embodying the present invention;

[0008]FIG. 2 is another perspective view of the gear system, again partially broken away and in section;

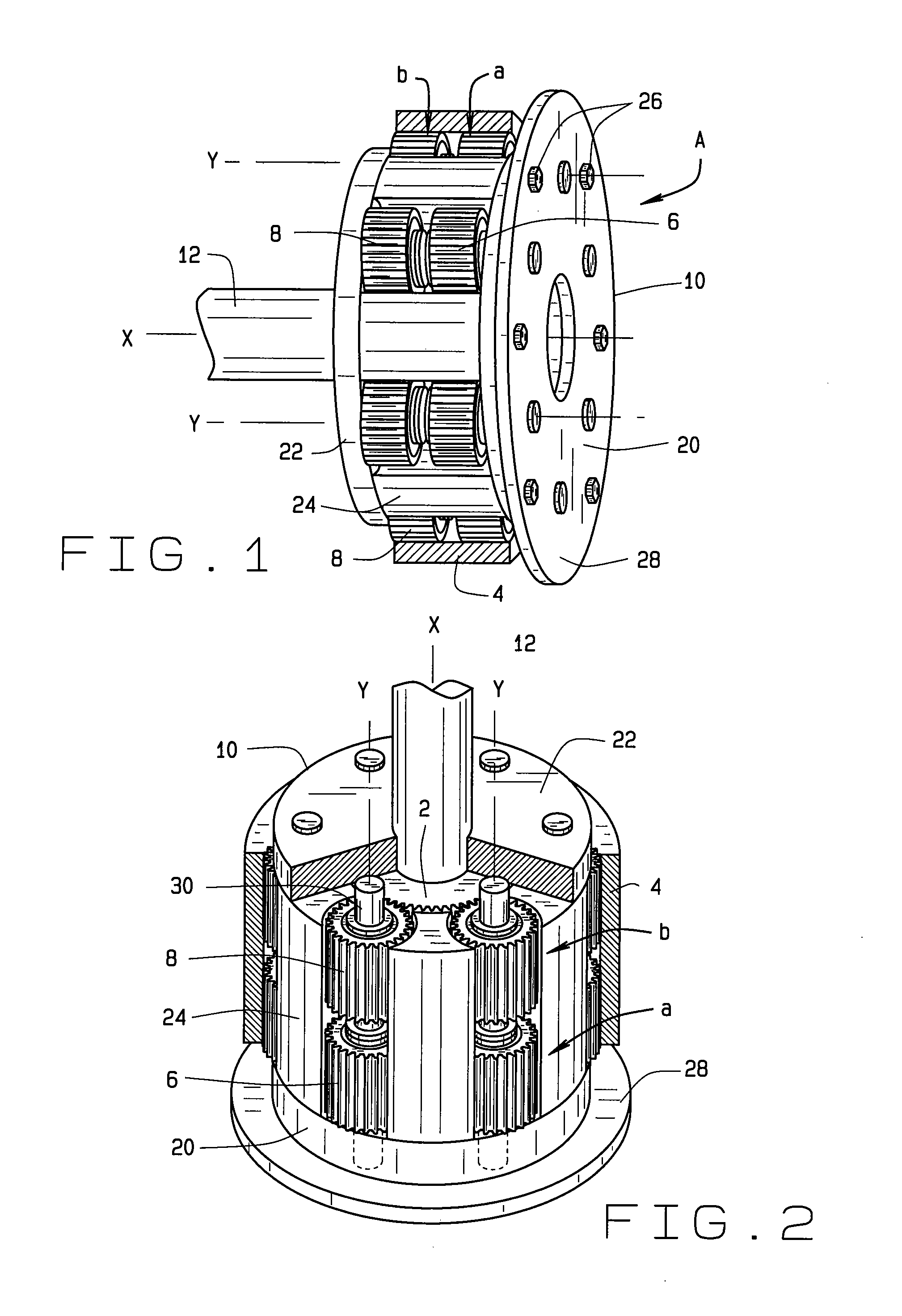

[0009]FIG. 3 is a partial sectional view showing one of the carrier walls and a flexpin on that wall;

[0010]FIG. 4 is an exploded perspective view of a flexpin, its sleeve, bearing and planet pinion, for either one of the arrays;

[0011]FIG. 5 is an elevational view of the carrier of the gear system, and showing load paths of uneven lengths and distortions, greatly exaggerated, caused by those uneven load paths;

[0012]FIGS. 6, 6A, and 6B are schematic views showing an angular offset between the flexpins of the two arrays to compensate for the distortion of the carrier and the resulting planet pinion and ring gear mesh;

[0013]FIG. 7 is a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com