Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

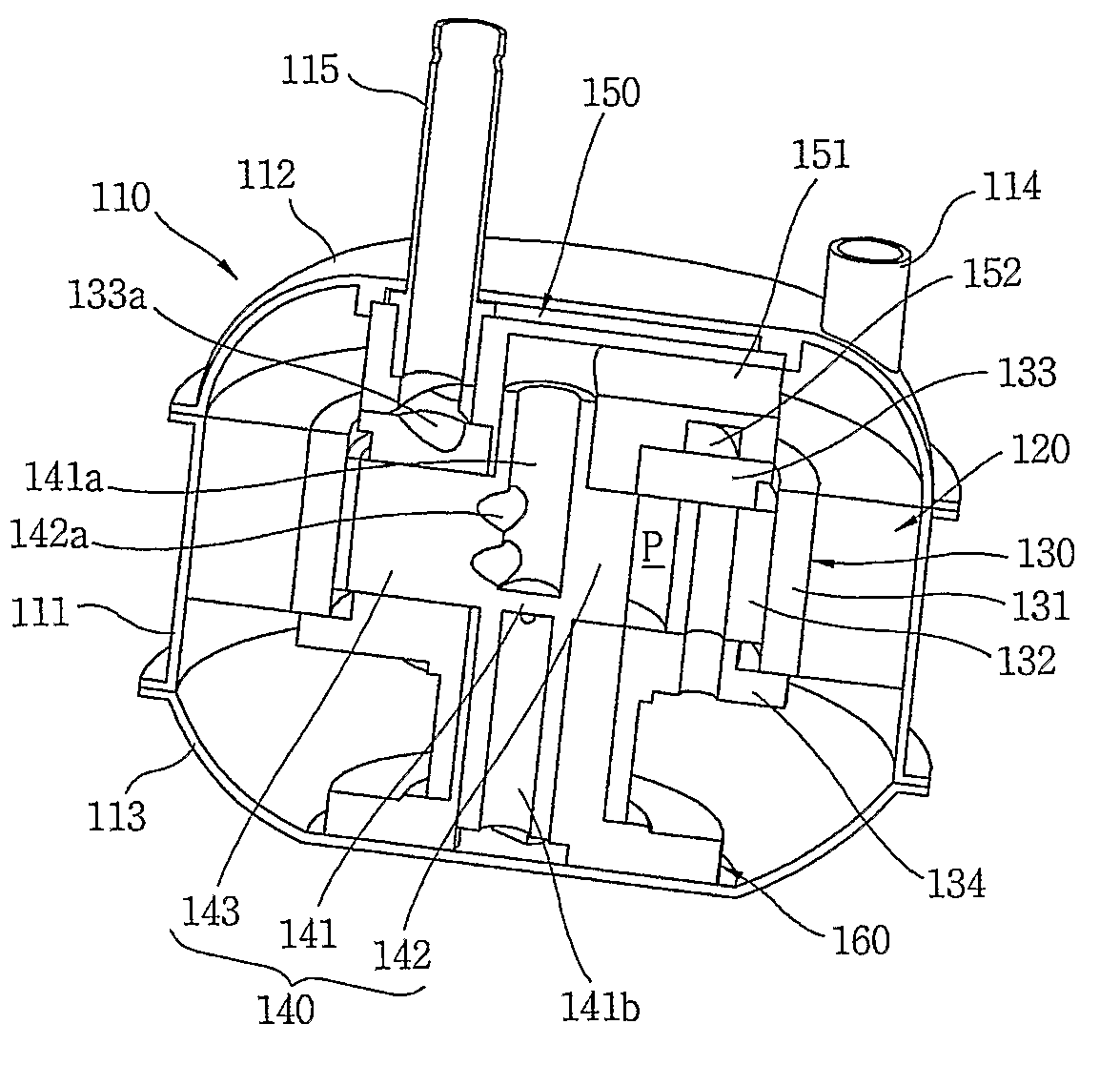

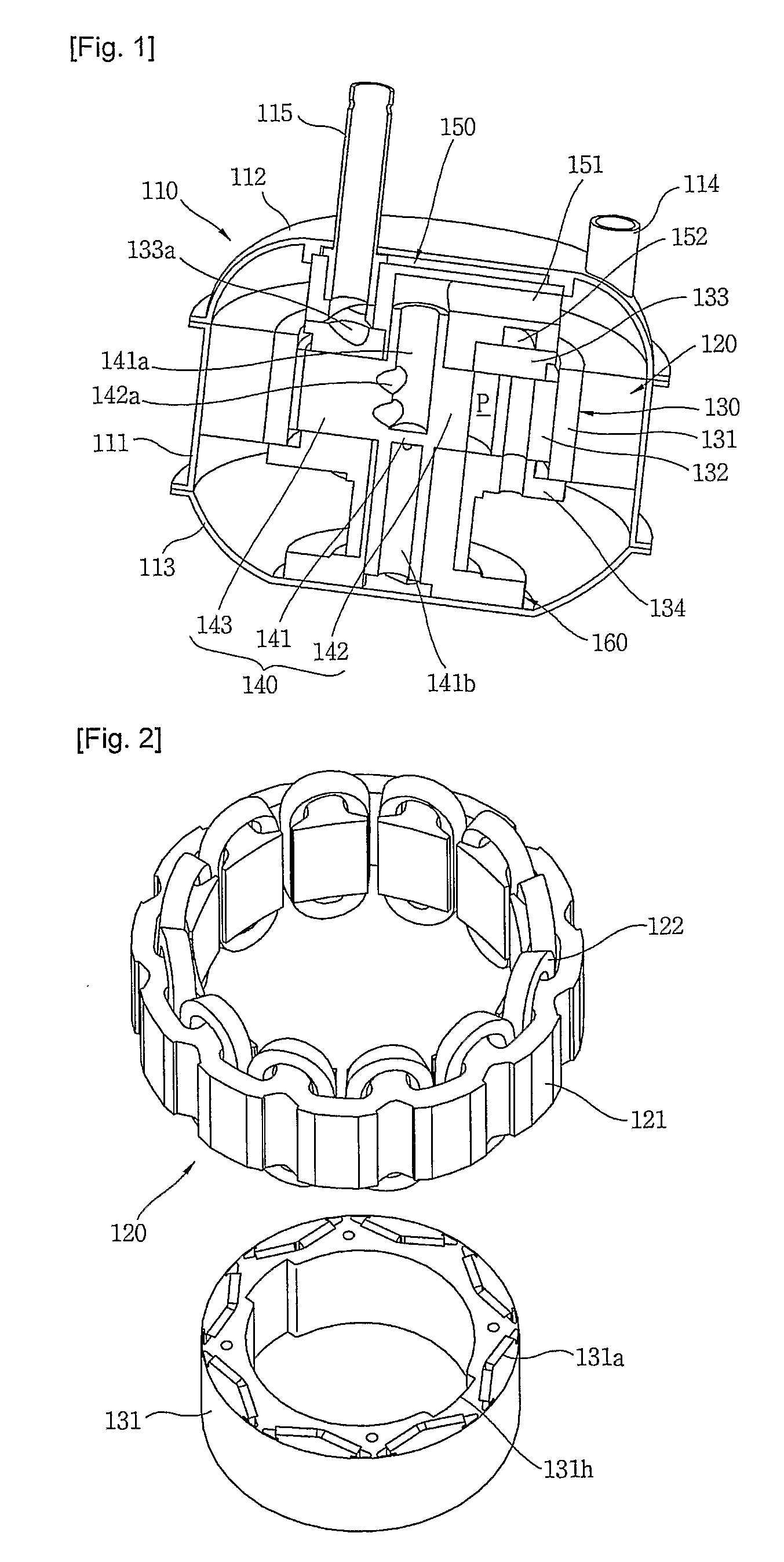

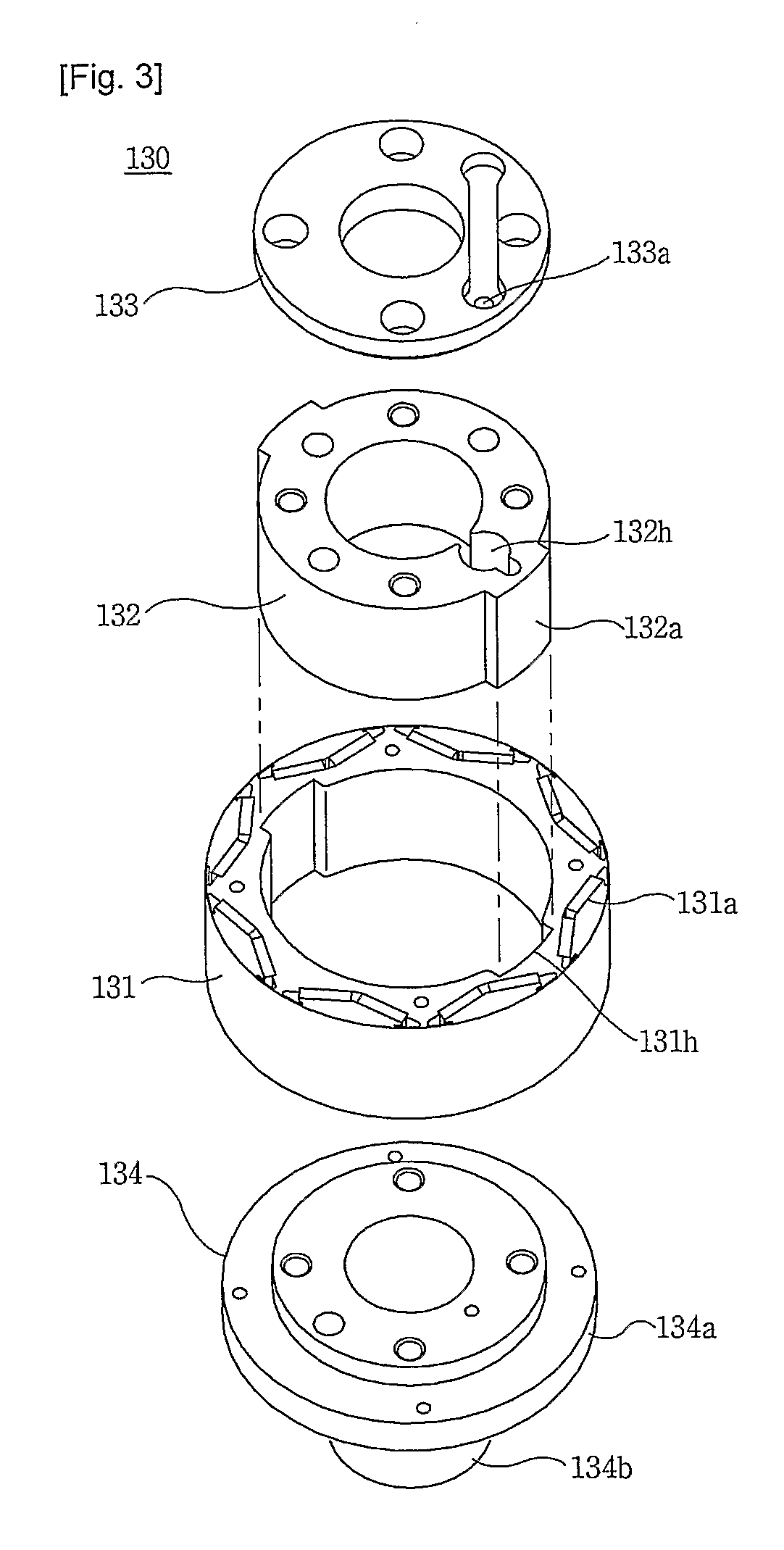

[0044]the compressor according to the present invention comprises, as shown in FIG. 1, a hermetically sealed container 110, a stator 120 installed inside the hermetically sealed container 110, a first rotary member 130 rotatably installed inside the stator 120 by a rotational electromagnetic field from the stator 120, a second rotary member 140 for compressing a refrigerant between the first and second rotary members 130 and 140 while rotating inside the first rotary member 130 upon receipt of a rotational force from the first rotary member 130, and first and second bearings 150 and 160 for rotatably supporting the first rotary member 130 and the second rotary member 140 on the inside of the hermetically sealed container 110. An electric motor part for providing electric power by an electrical action employs a kind of BLDC motor including a stator 120 and a first rotary member 130, and a compression mechanism part for compressing the refrigerant by a mechanical action includes a fir...

second embodiment

[0072]FIG. 12 is a side cross sectional view showing the compressor according to the present invention.

[0073]As shown in FIG. 12, the second embodiment of the compressor according to the present invention comprises a hermetically sealed container 210, a stator 220 installed inside the hermetically sealed container 210, a first rotary member 230 rotatably installed inside the stator 220 by interaction with the stator 220, a second rotary member 240 for compressing a refrigerant between the first and second rotary members while rotating inside the first rotary member upon receipt of a rotational force from the first rotary member 230, a muffler 250 for guiding the suction / discharge of the refrigerant to the compression space P between the first and second rotary members 230 and 240, and a bearing 260 for rotatably supporting the first rotary member 230 and the second rotary member 240 inside the hermetically sealed container 210 and a mechanical seal 270. In the second embodiment as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com