Patents

Literature

33results about How to "Difference in speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

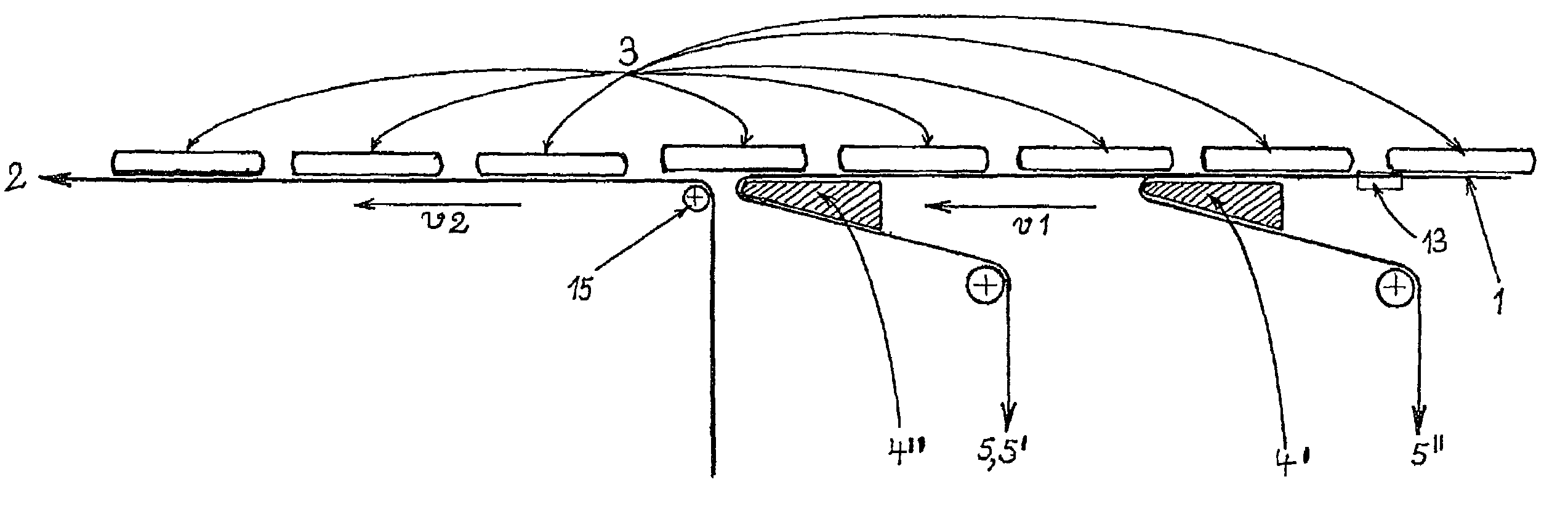

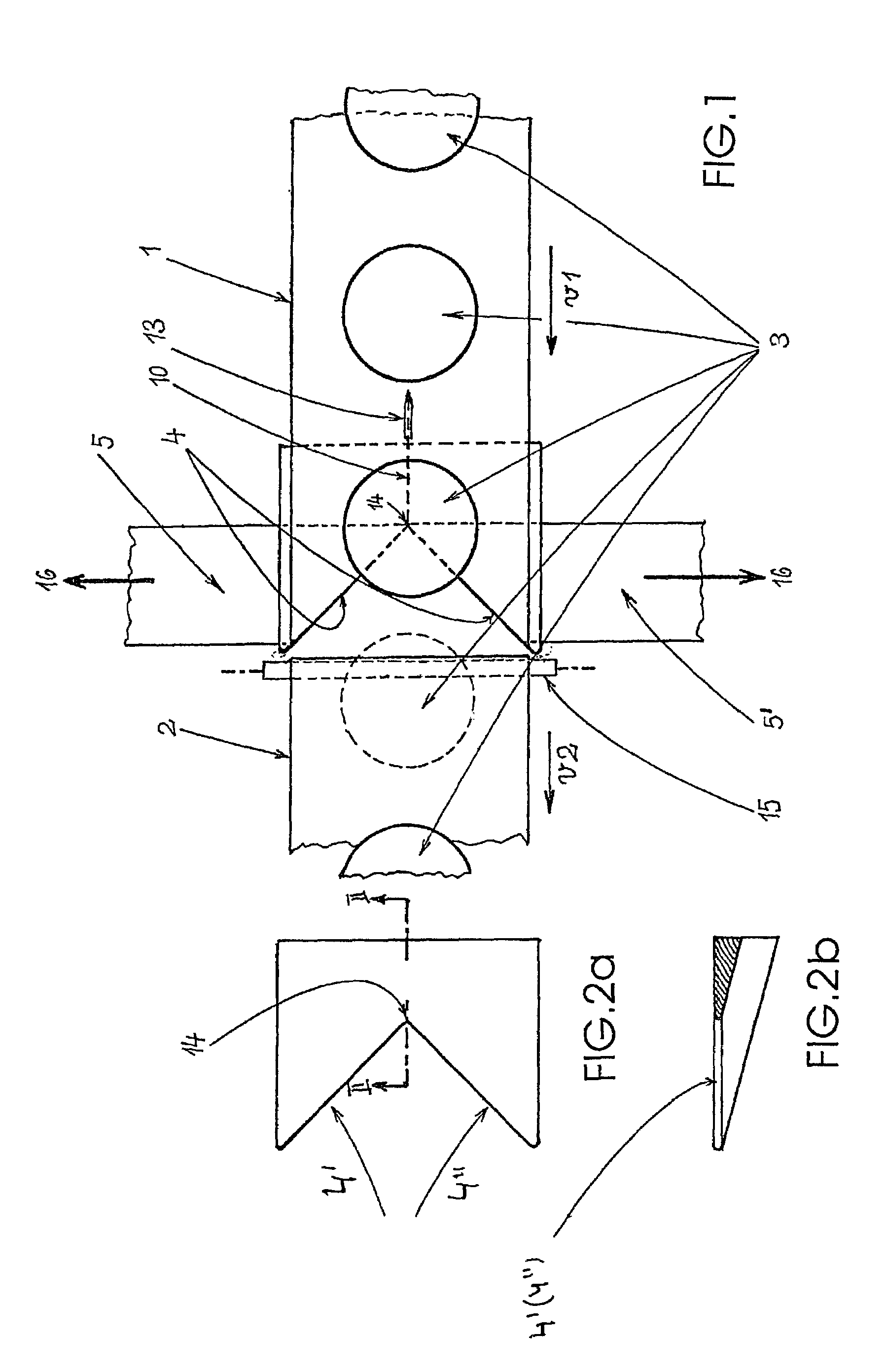

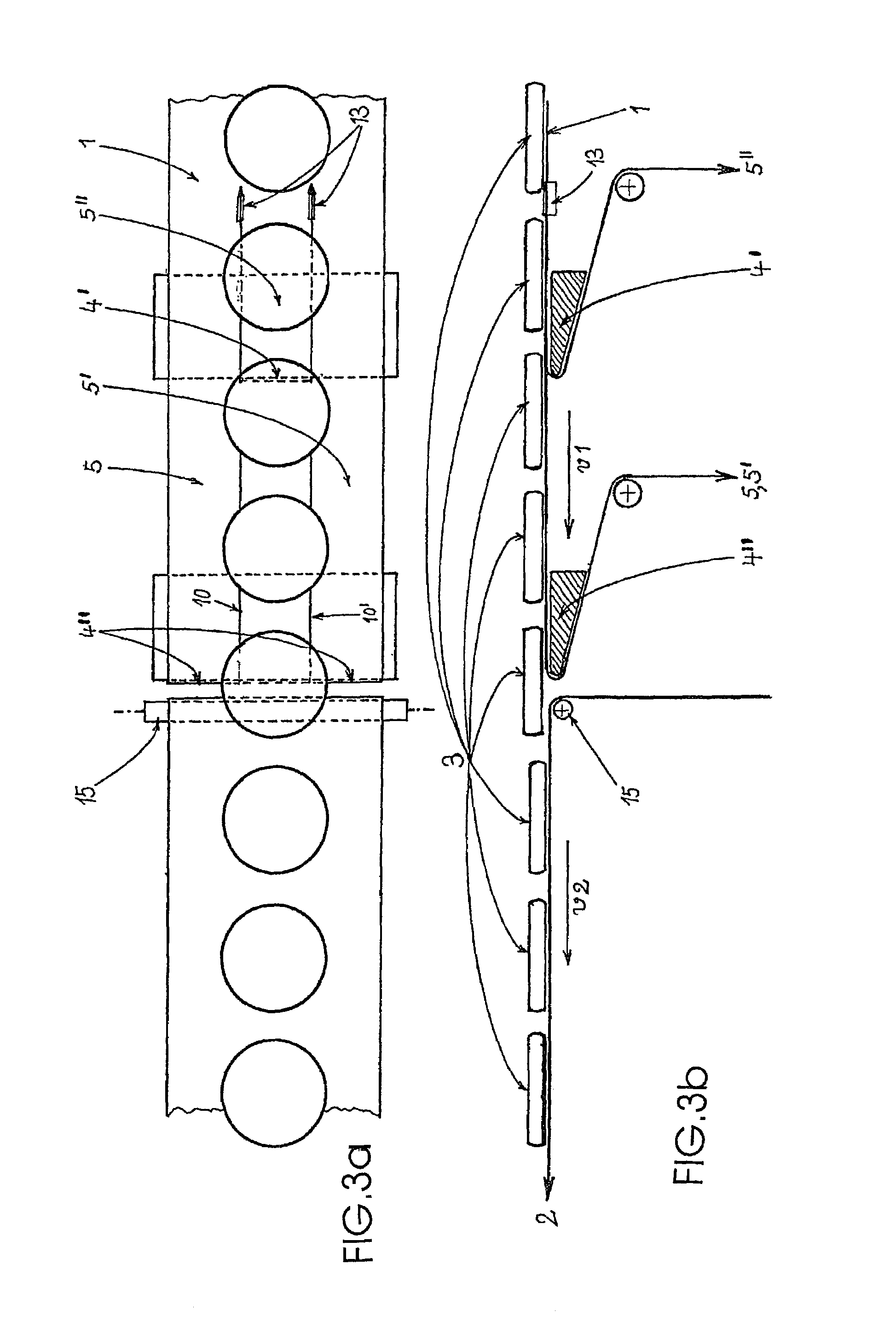

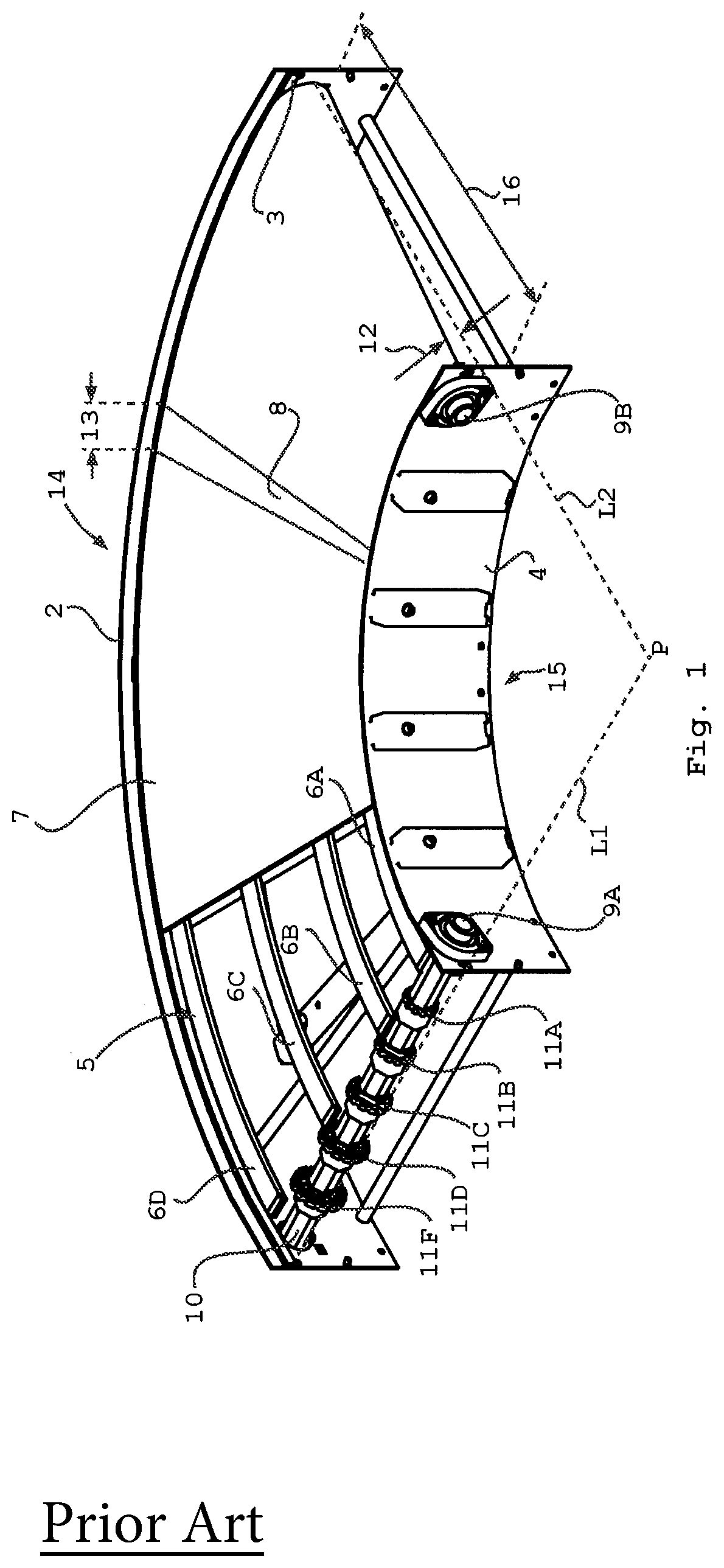

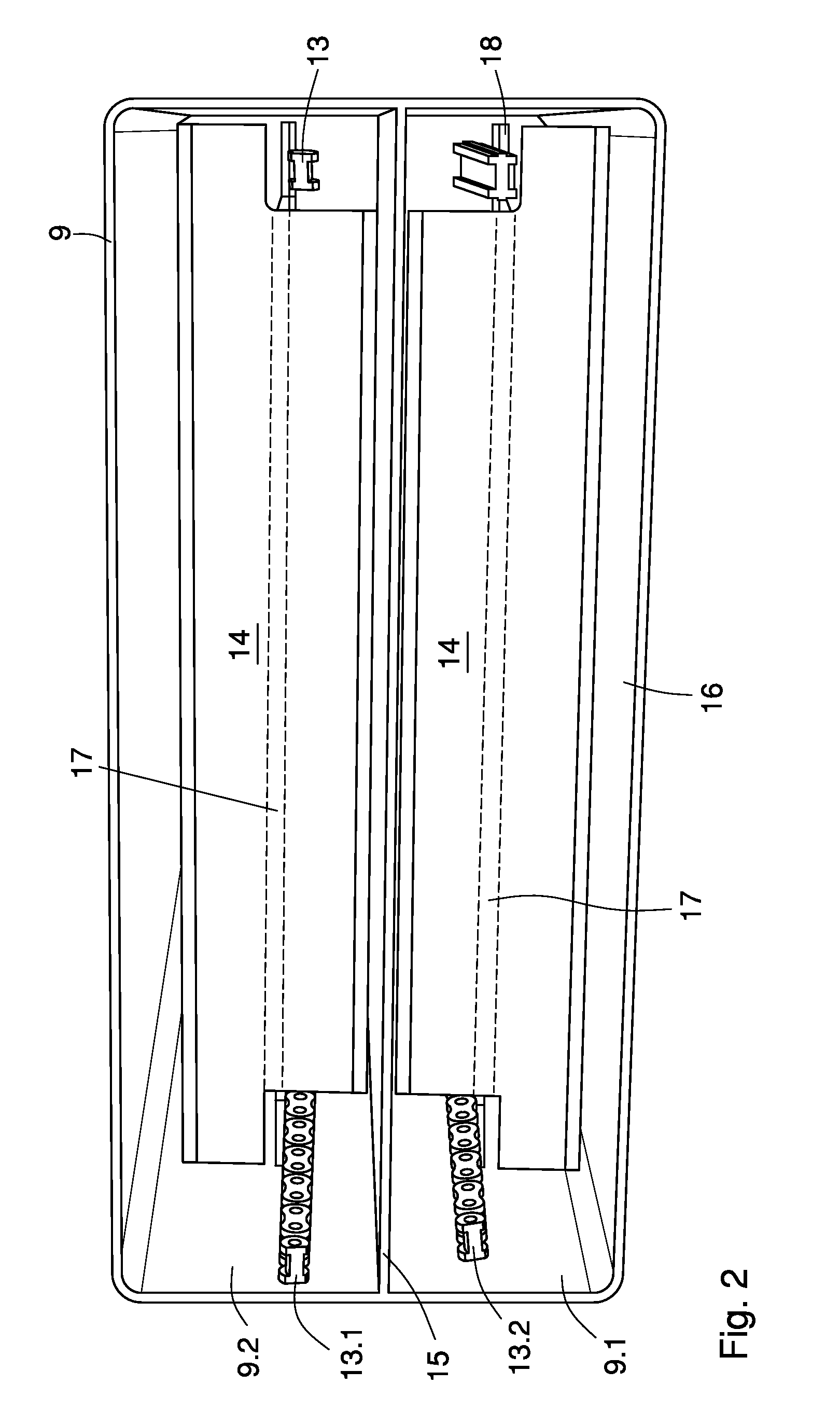

Method and device for dispensing adhesive laminate segments

InactiveUS7029549B1Increase distanceDifference in speedPaper/cardboard articlesDecorative surface effectsPressure sensitiveBiomedical engineering

A process for dispensing pressure-sensitive adhesive laminates (3) or laminate sections from a movable primary (1) onto a movable secondary carrier band (2), the laminates (3), upon deflection of the primary band (1) around a dispenser edge (4), being detached and dispensed onto the secondary band (2), is characterized in that the primary band (1) is provided with at least one separation line or predetermined breaking line, thus subdividing it into at least two strips (5, 5′), and that the strips are individually drawn from separate sections (4′, 4″) of the dispenser edge (4).

Owner:LTS LOHMANN THERAPIE-SYST AG

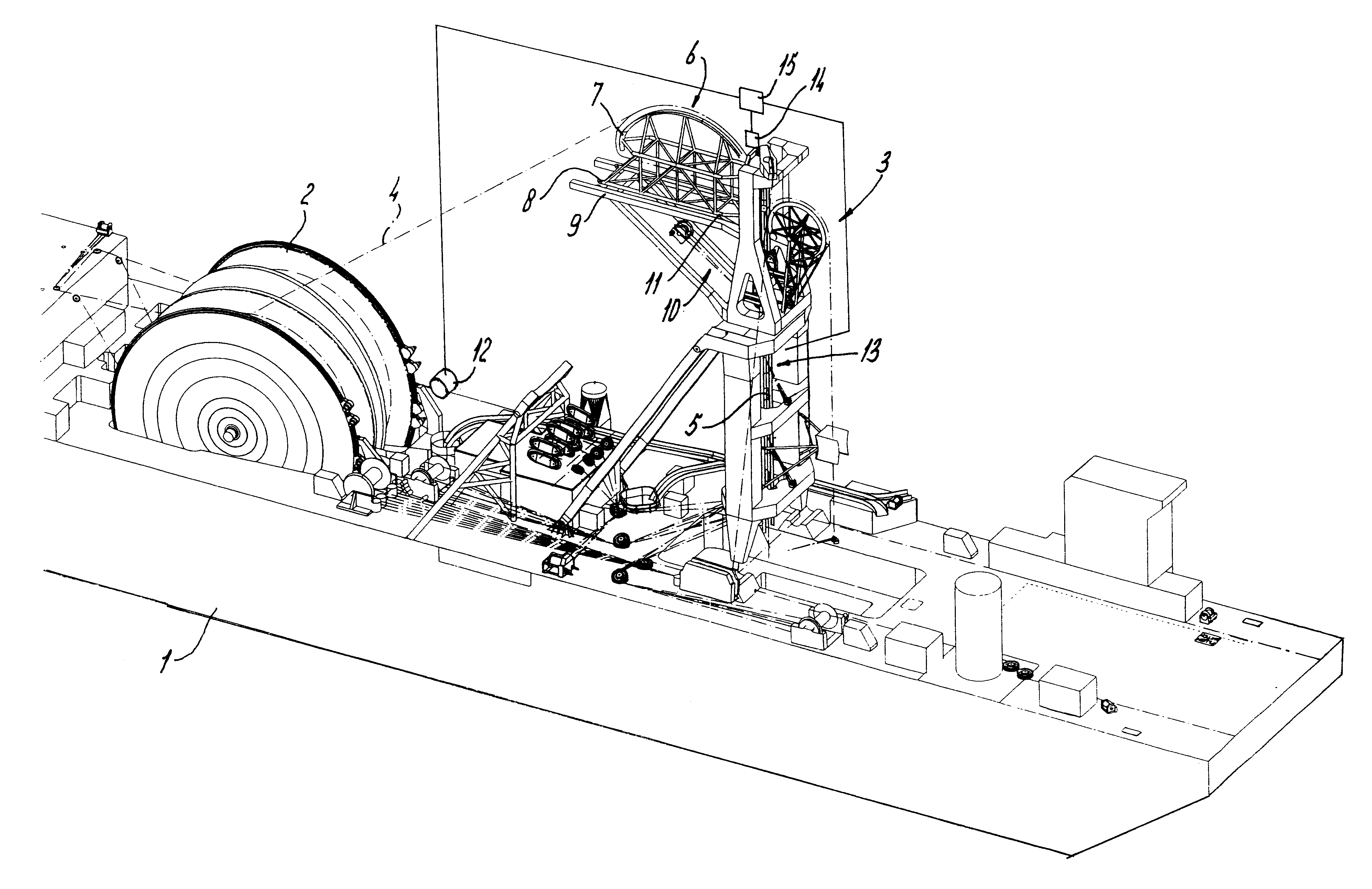

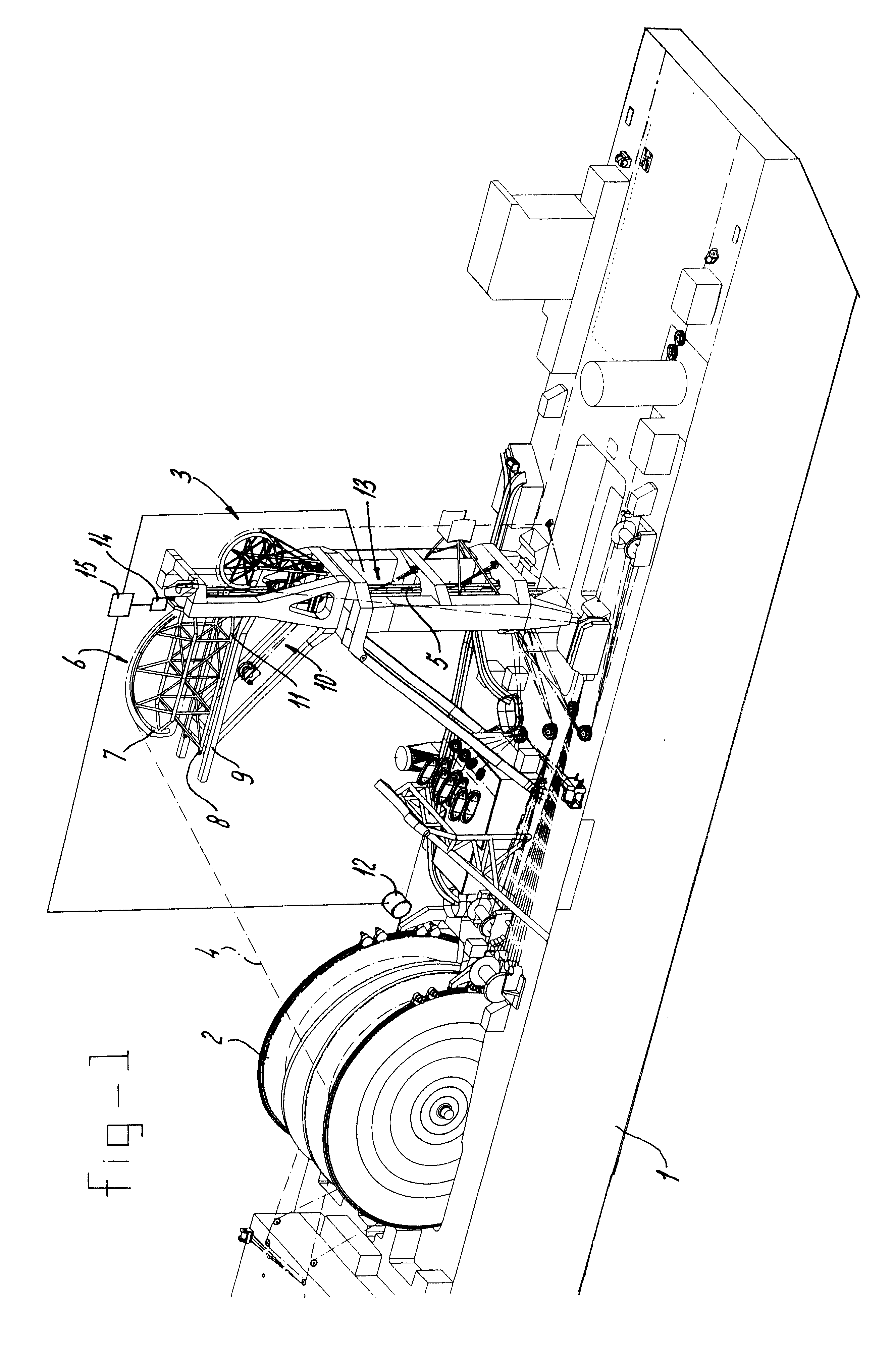

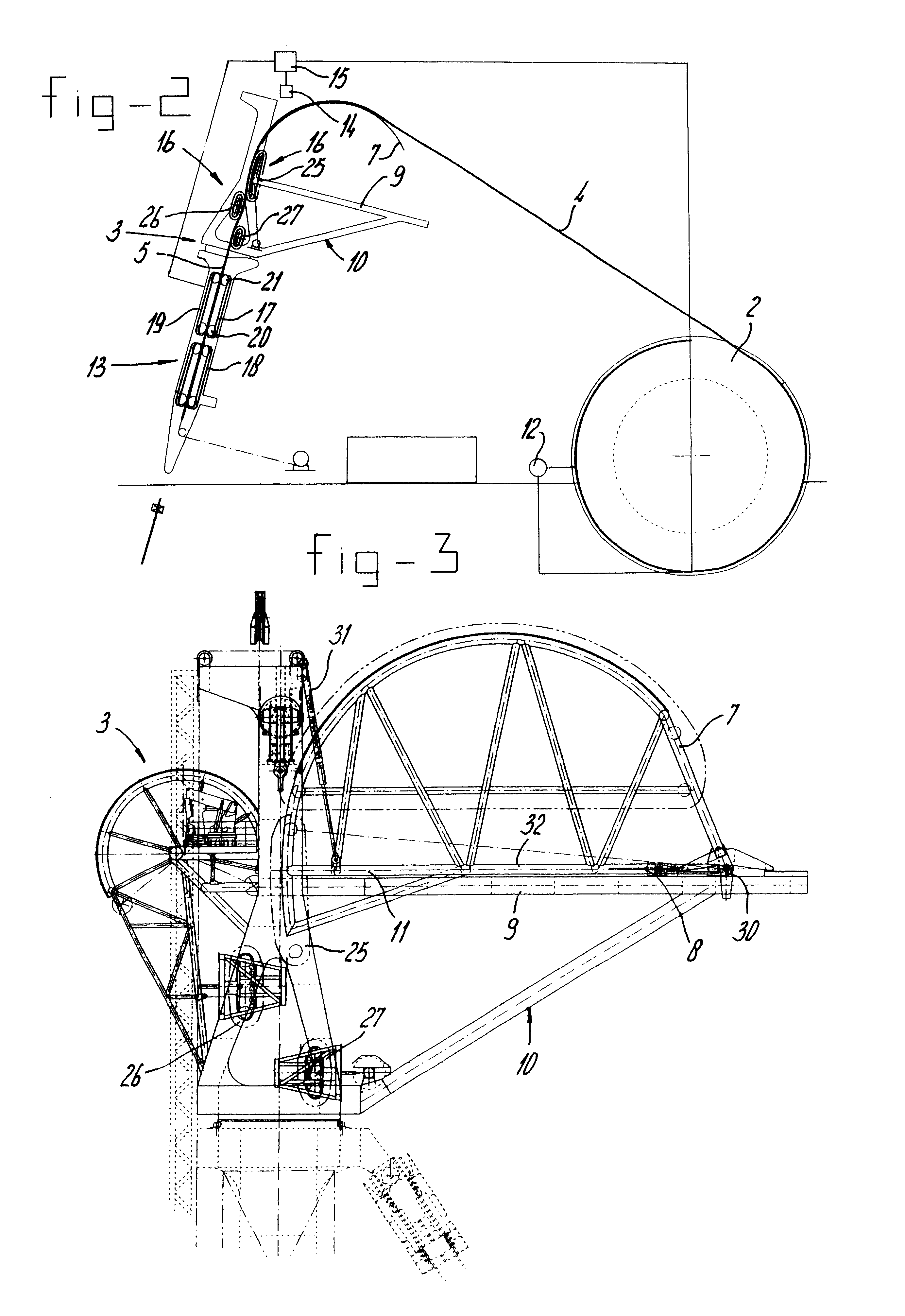

Pipe lay system with tension compensator

InactiveUS6761506B2Maintain tensionConstant tensionPipe laying and repairFilament handlingLength variationConductor Coil

A pipe lay vessel with a reel for carrying a length of pipe and first drive part for controlling rotation of the reel. A substantially vertical guide structure includes at its upper end a deflection member for deflecting the pipe from a first trajectory extending between the reel and the guide structure to a second, substantially vertical trajectory. A clamping member carries the vertical pipe section and has second drive for feeding the pipe along the vertical trajectory. A movable tension compensator (7) is provided at the first pipe trajectory for lengthening or shortening the first pipe trajectory to maintain a substantially constant tension of the pipe along the first trajectory during unwinding of the reel. By displacing the tension compensator, the first pipe trajectory can be lengthened or shortened to compensate for variations in speed due to non-uniform winding of the pipe and varying diameter of the spooled pipe and to compensate for sagging of the pipe due to its own weight and length variations upon unspooling in view of occuring plasticity and partial straightening of the pipe.

Owner:SINGLE BUOY MOORINGS INC

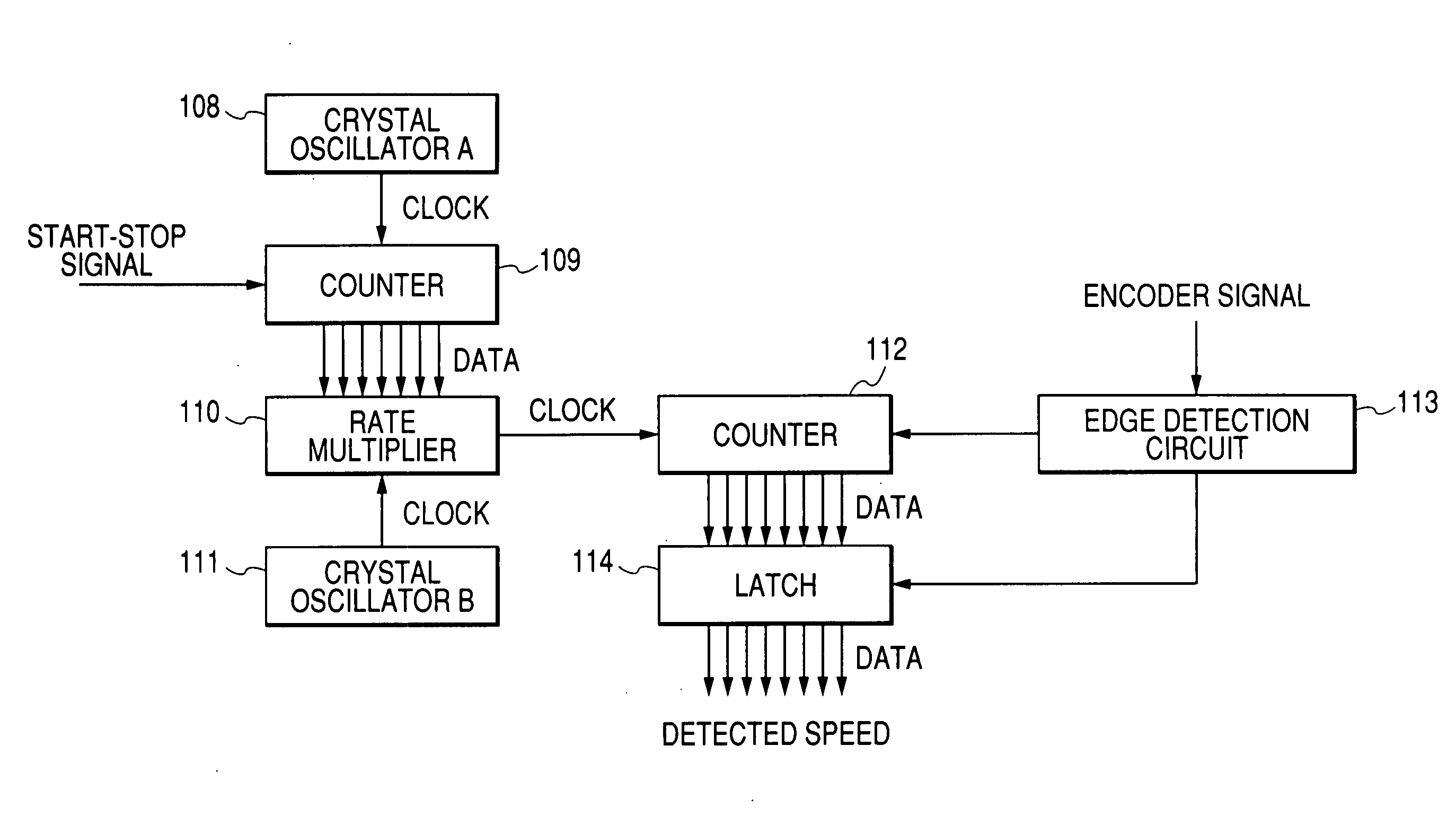

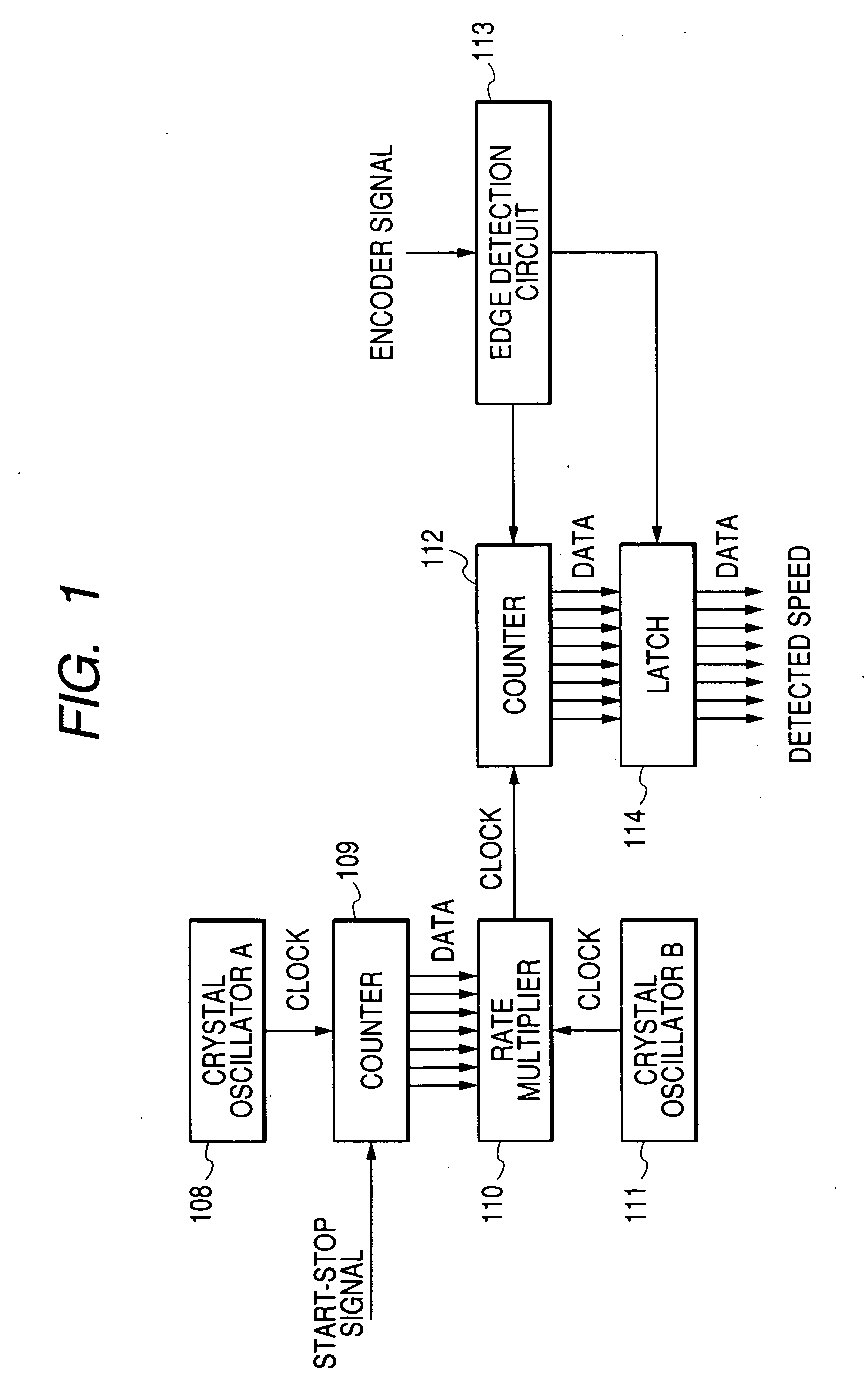

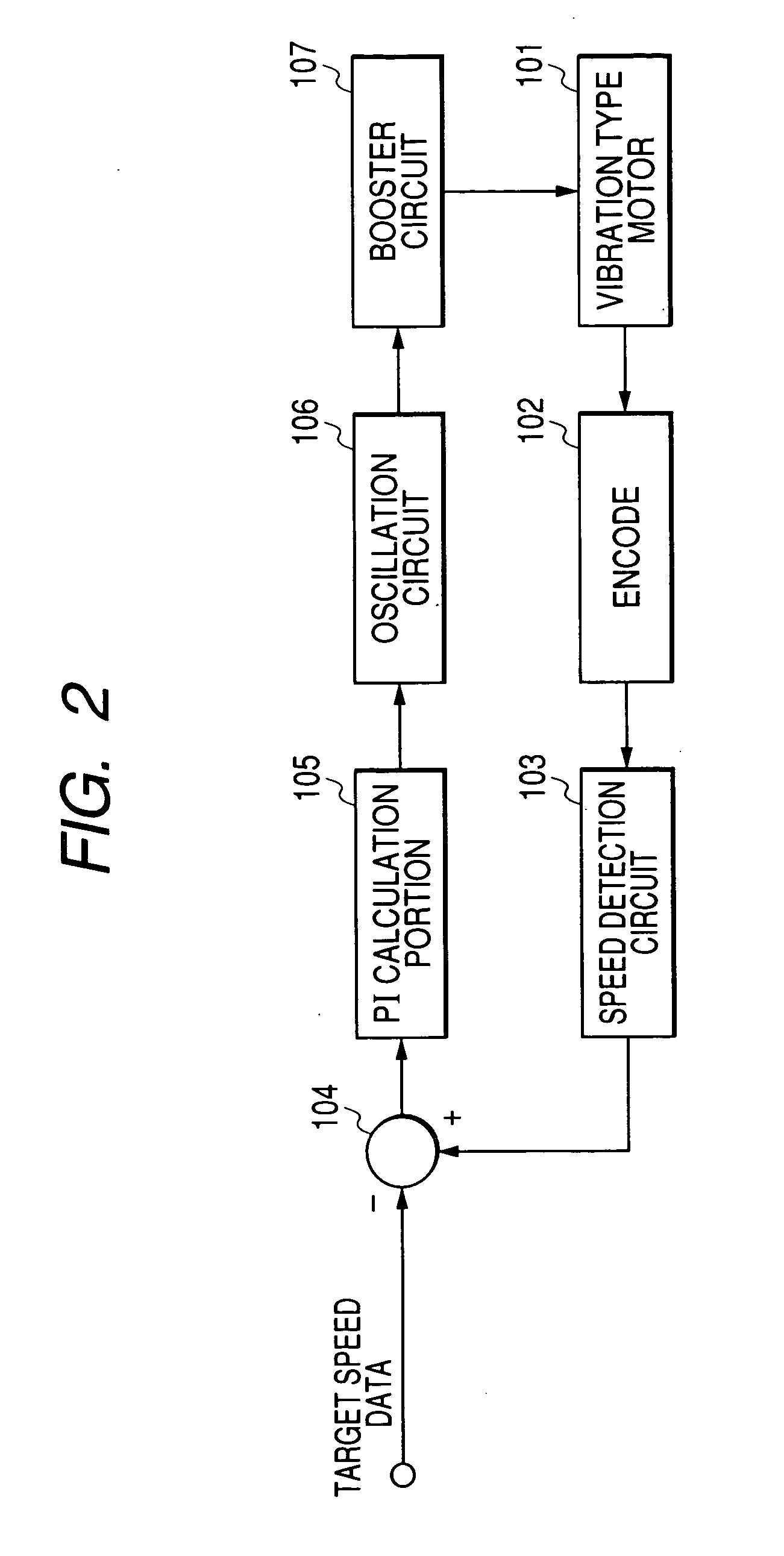

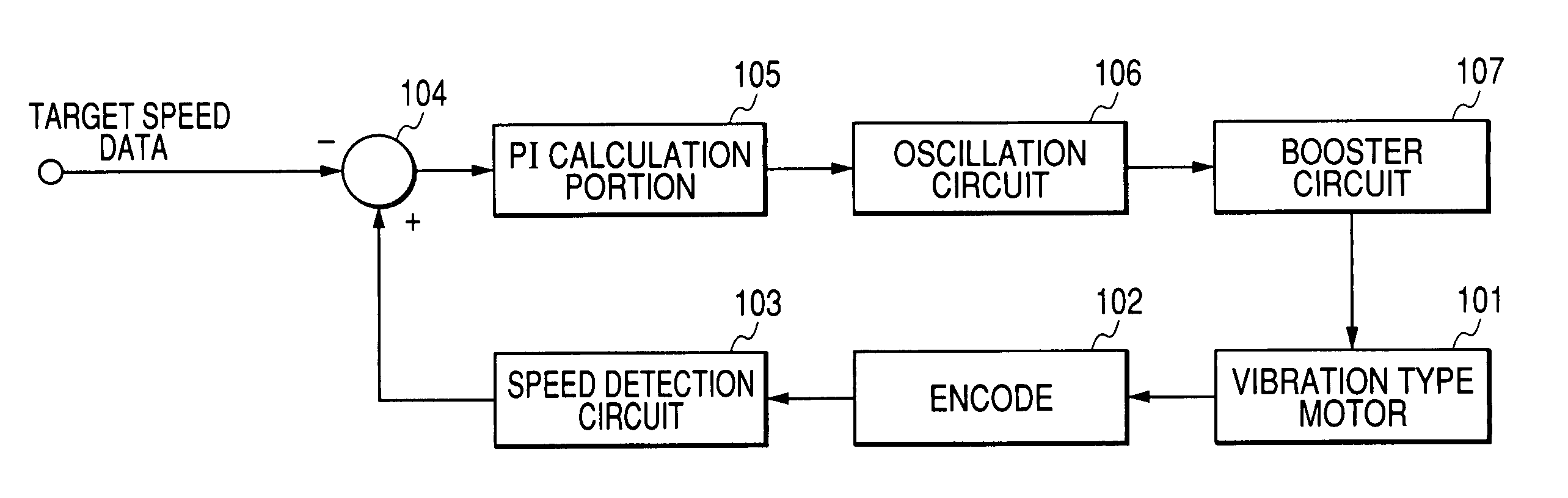

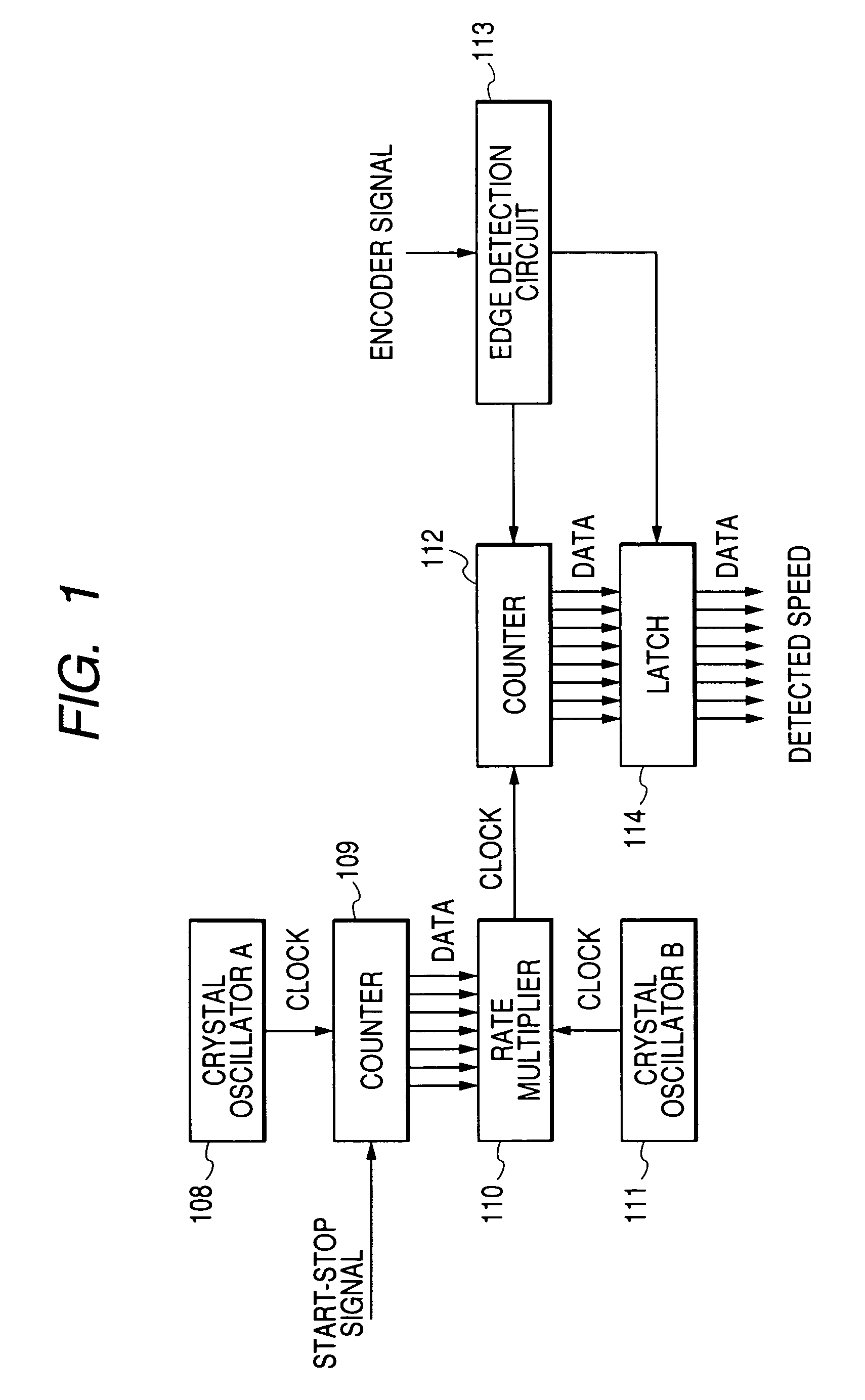

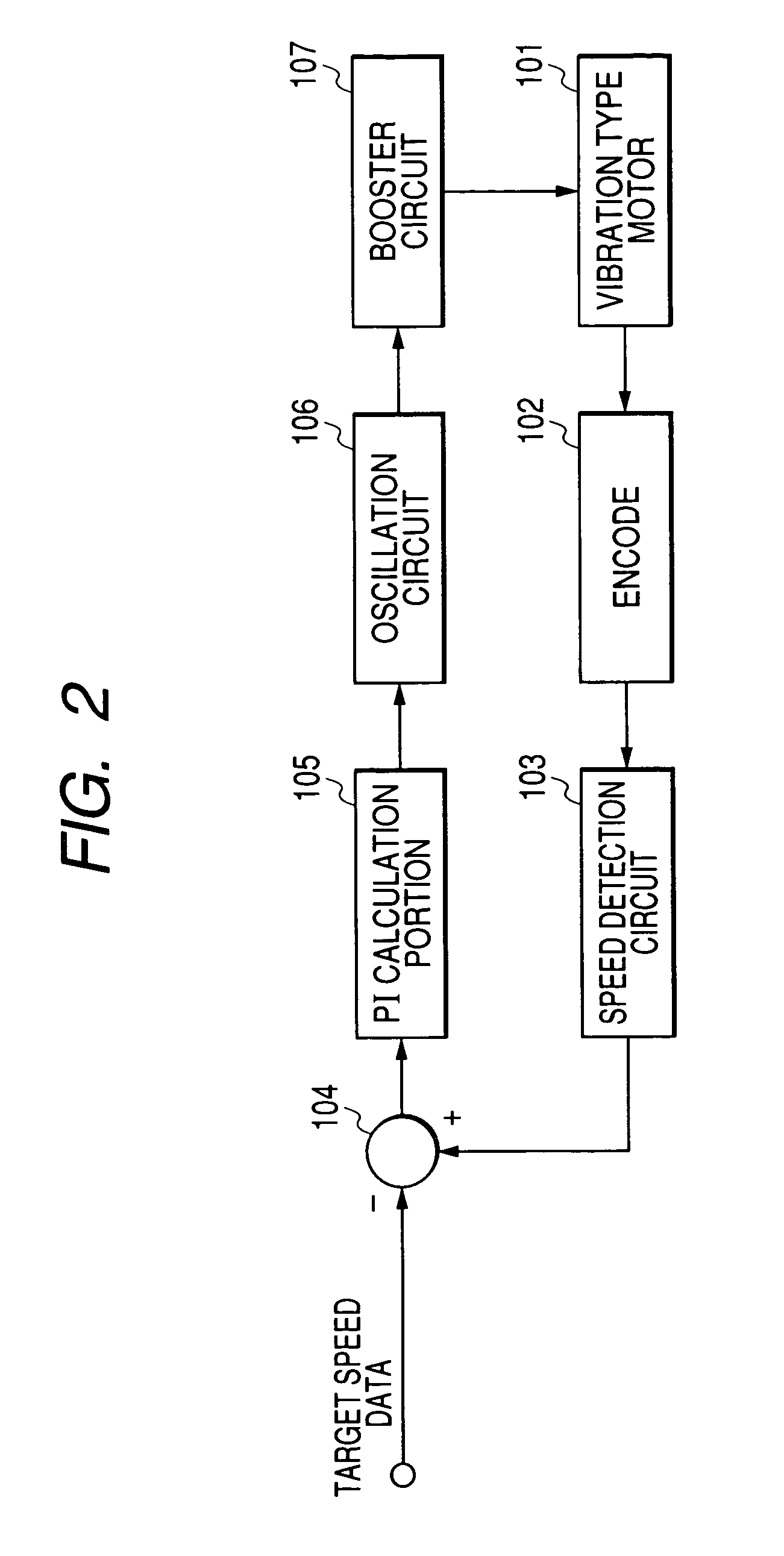

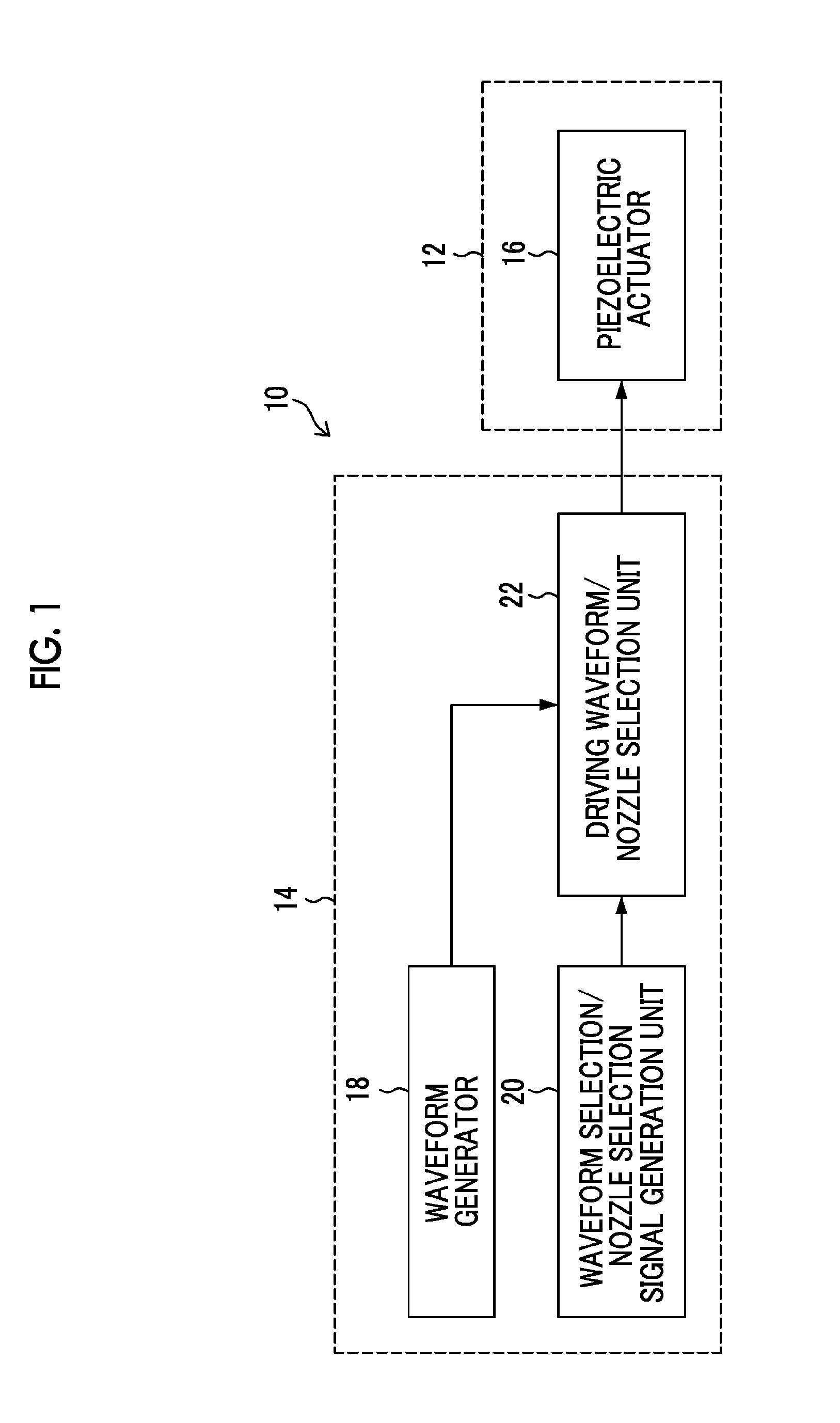

Vibration type actuator drive controller and method of controlling drive speed of vibration type actuator

InactiveUS20050046363A1Guaranteed uptimeReduce drive frequencyMotor/generator/converter stoppersDC motor speed/torque controlResonanceActuator

This disclosure relates to a technique for smoothly carrying out an acceleration operation and a deceleration operation for a vibration type actuator to prevent a situation where in starting the vibration type actuator, a drive frequency is reduced to become lower than a resonance frequency to stop the vibration type actuator. A first counter performs up-count from a first value to a second value larger than the first value at predetermined time intervals in accelerating the vibration type actuator. A rate multiplier outputs a clock signal having a frequency corresponding to the count value. A second counter measures a period of a pulse signal, the period being adapted to change in correspondence to a drive speed of the vibration type actuator, by counting the clock pulses. The drive speed of the vibration type actuator is controlled such that the measured pulse period becomes a predetermined target value.

Owner:CANON KK

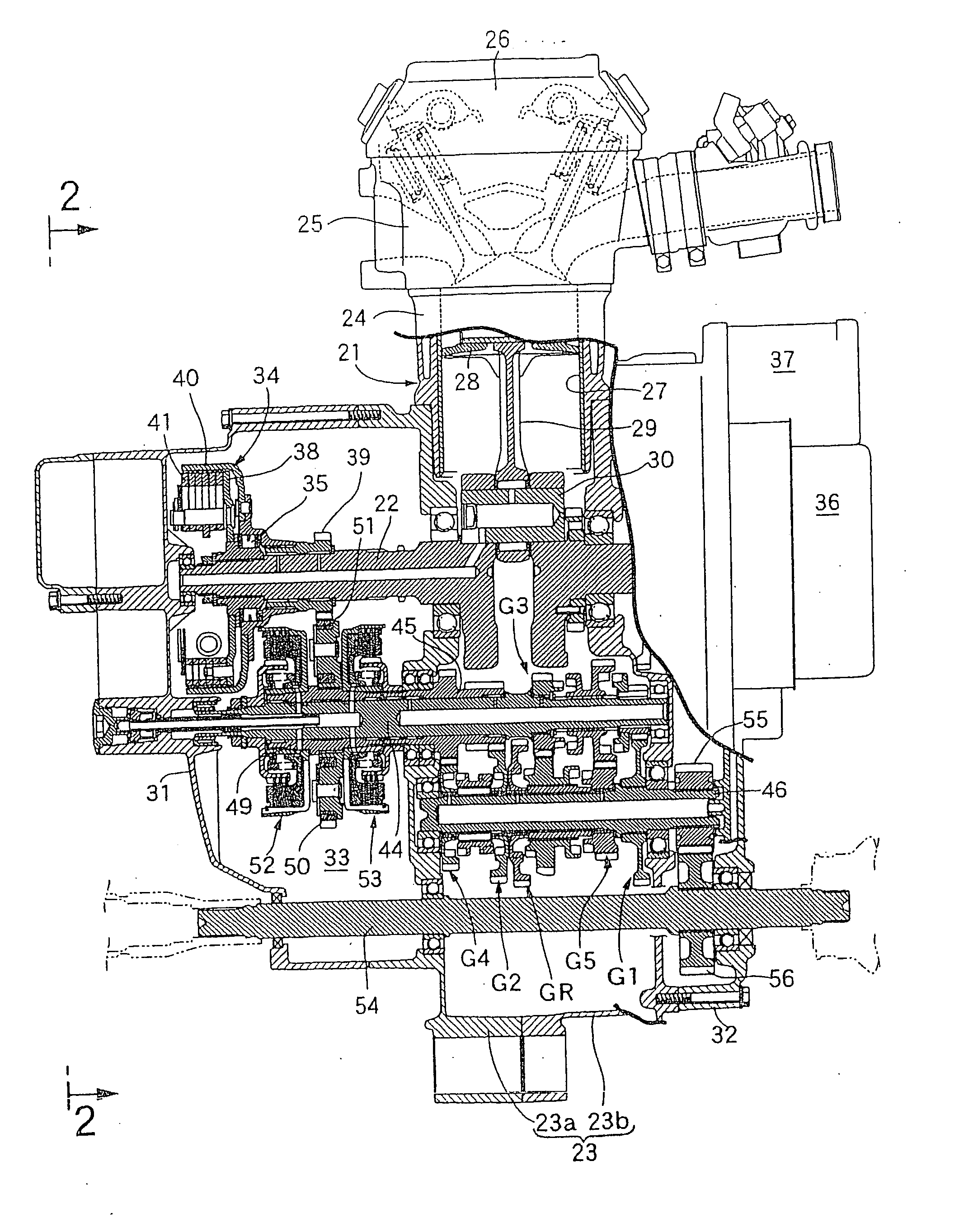

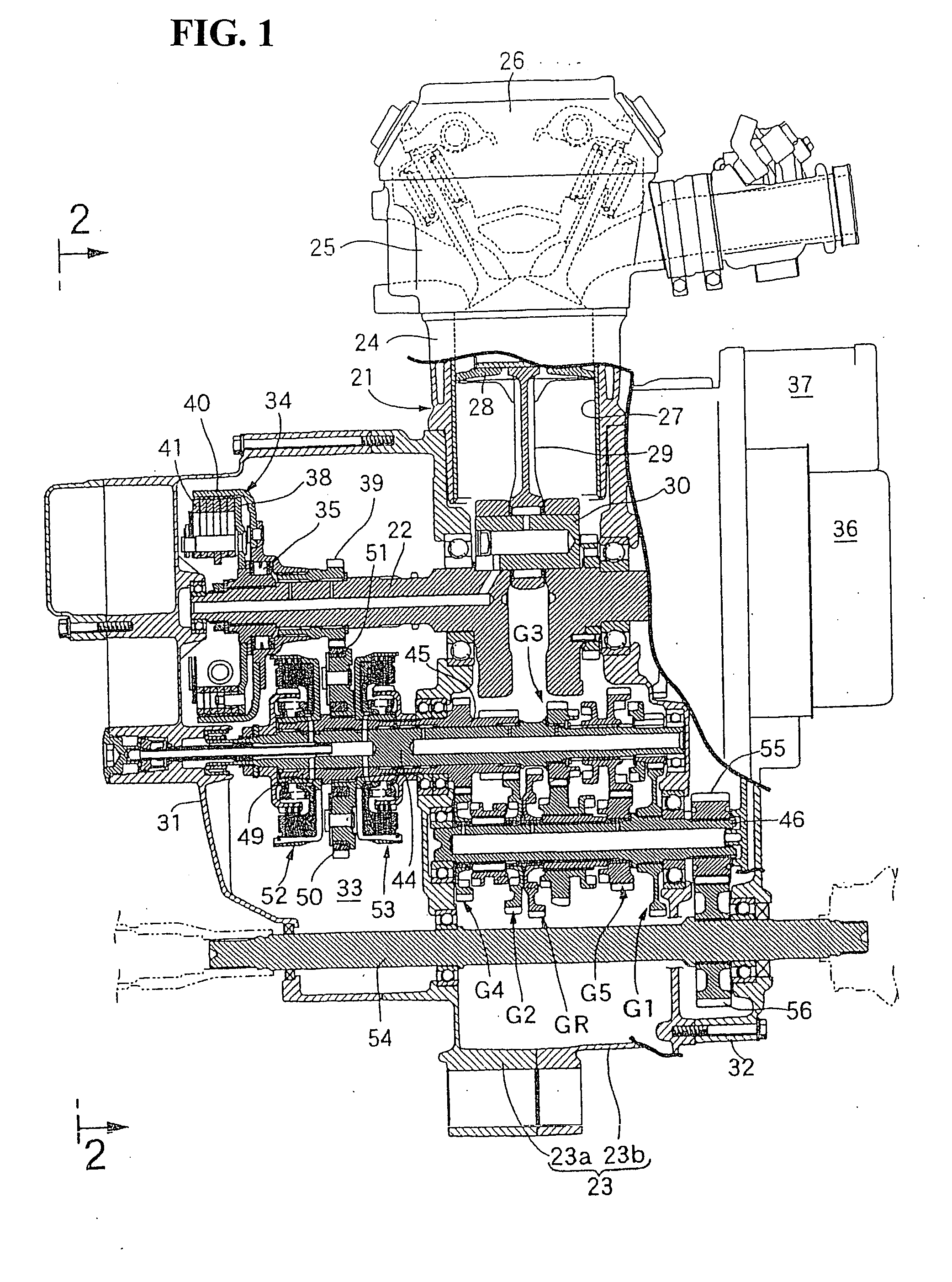

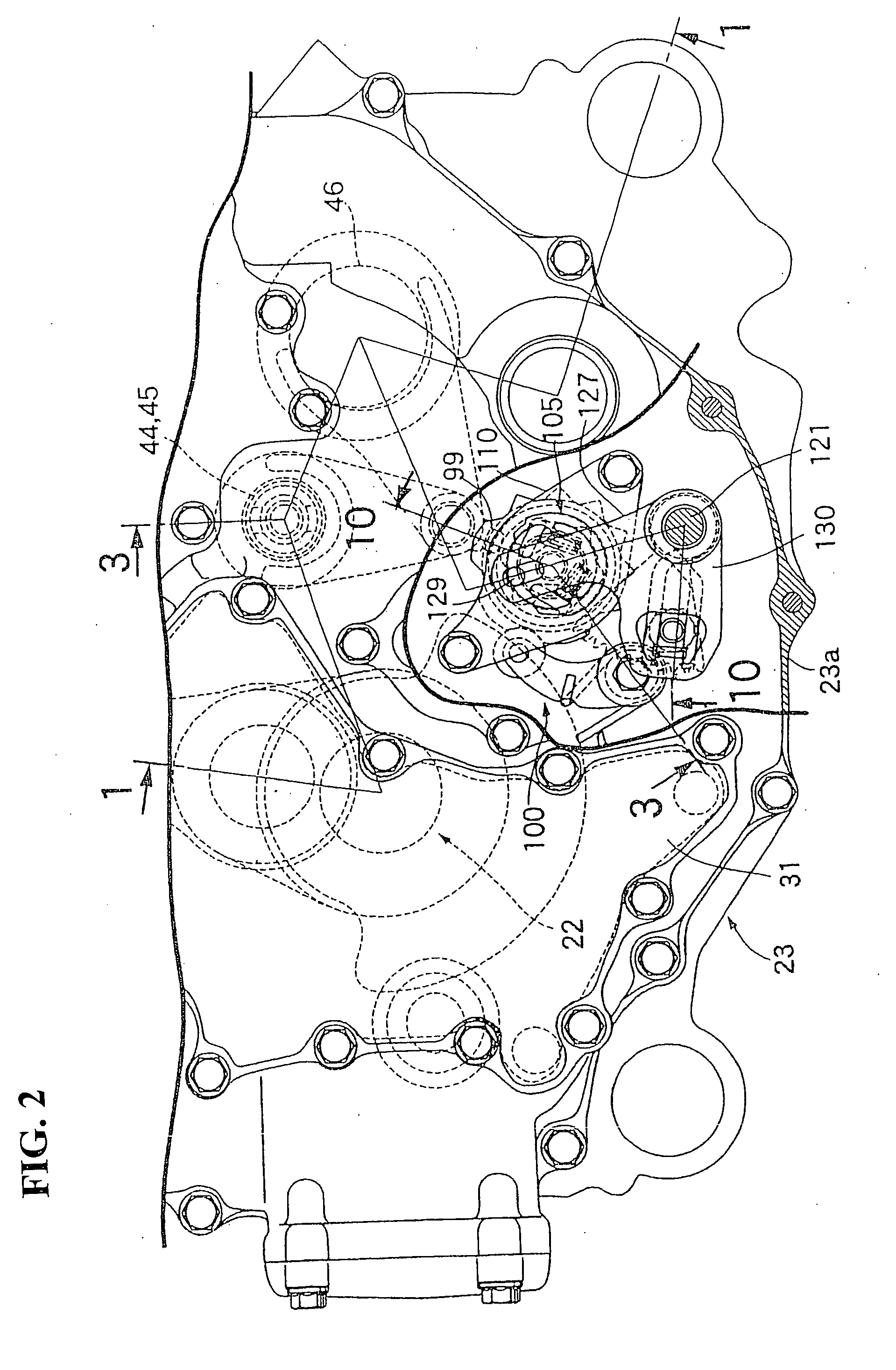

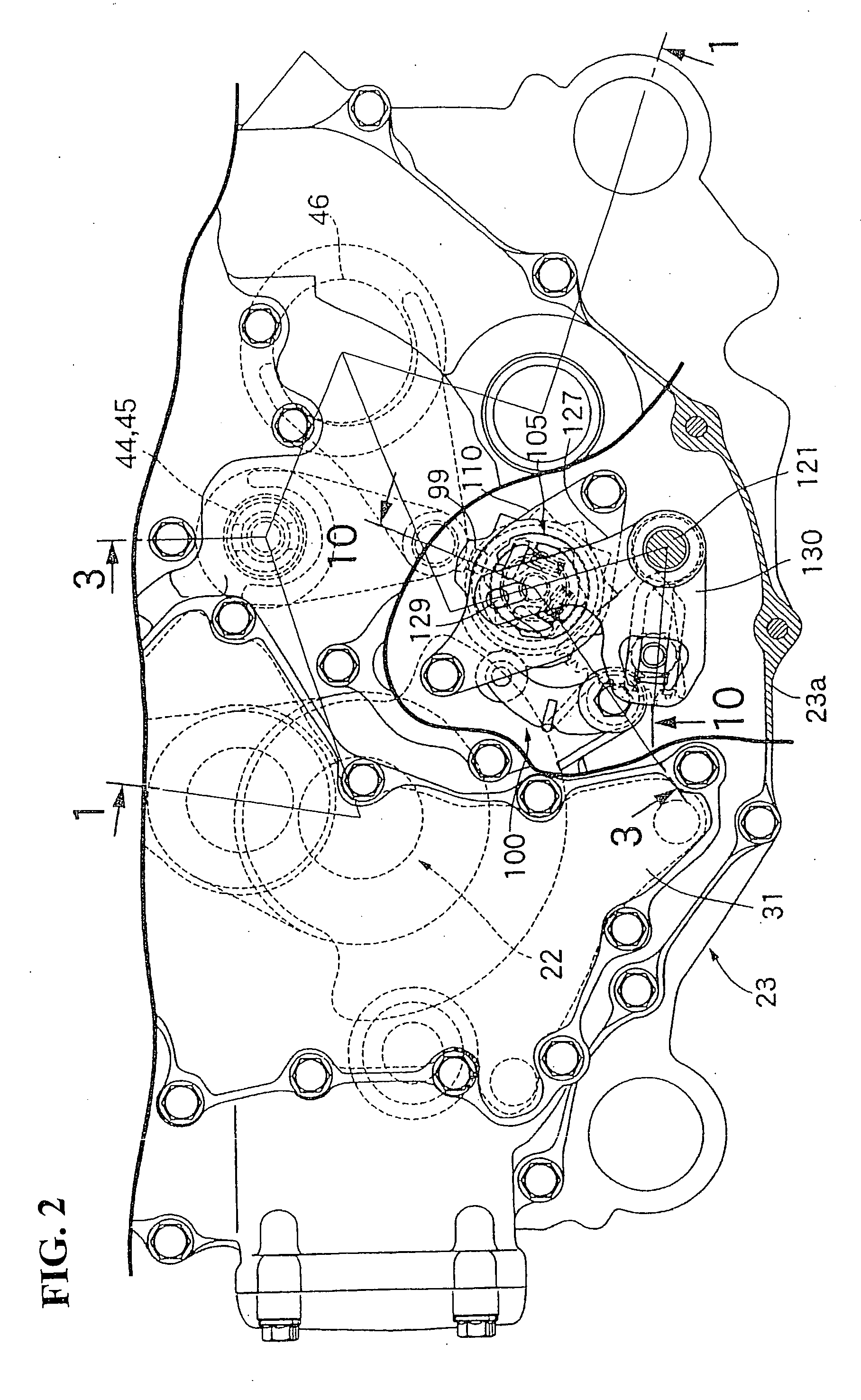

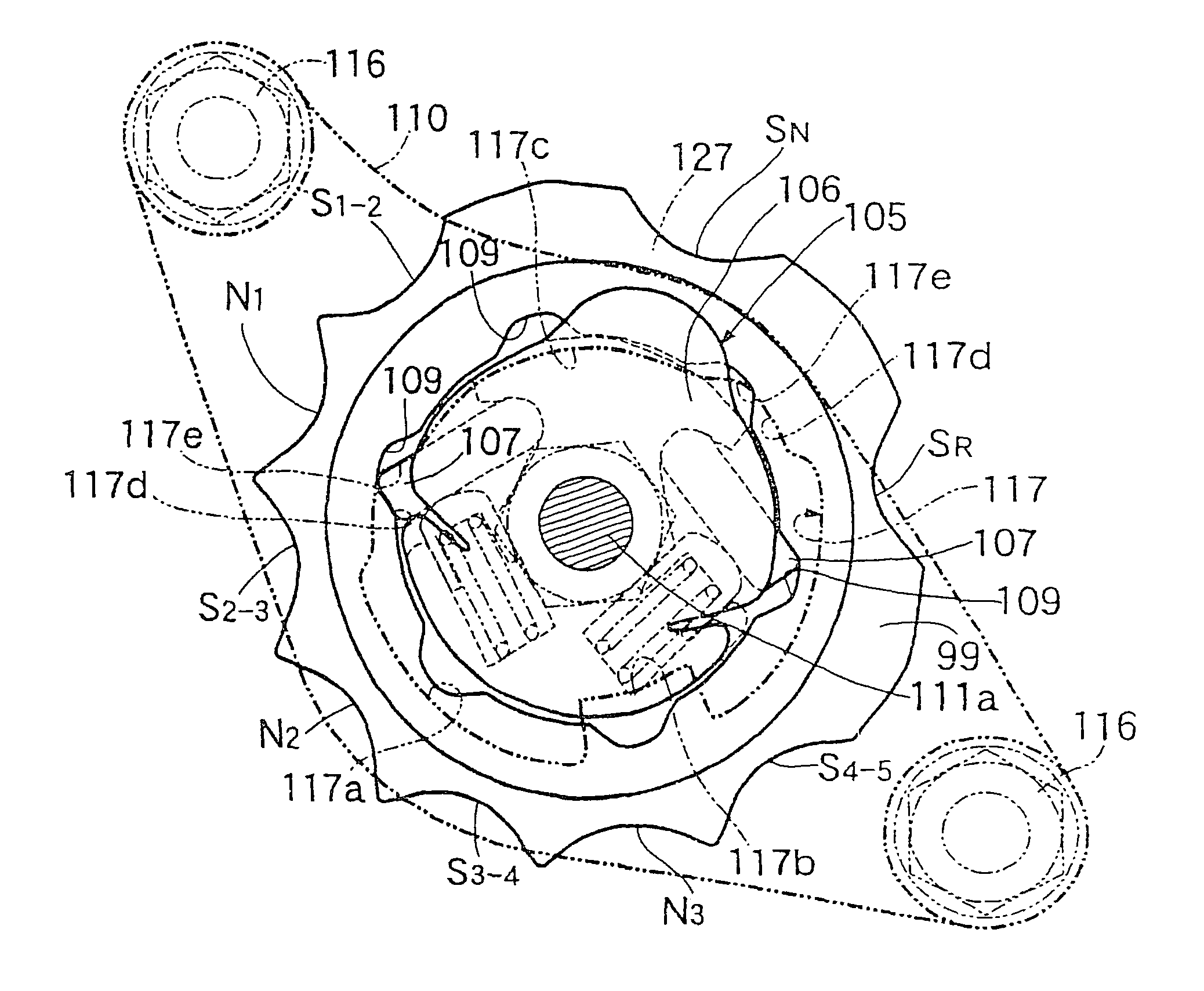

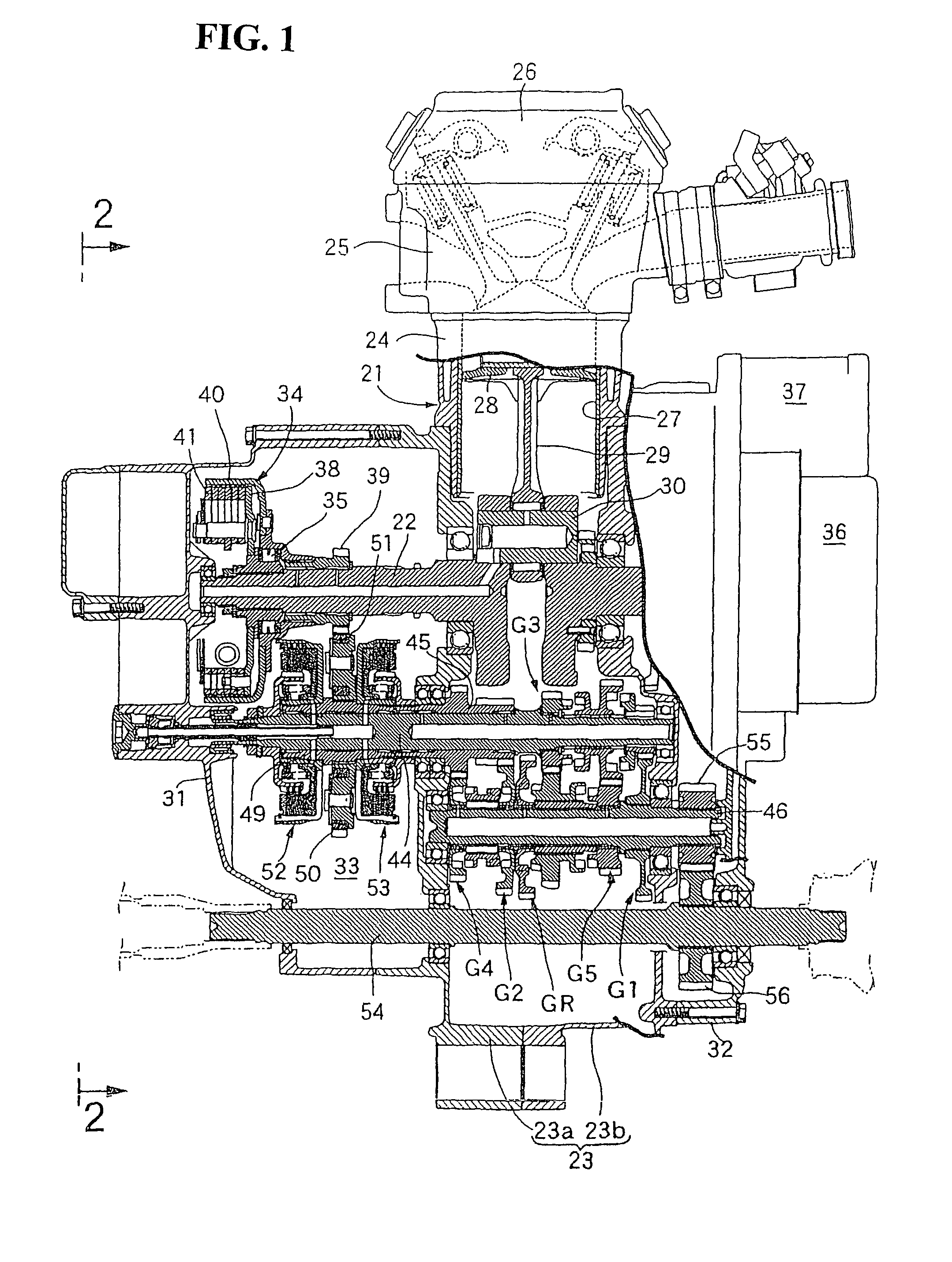

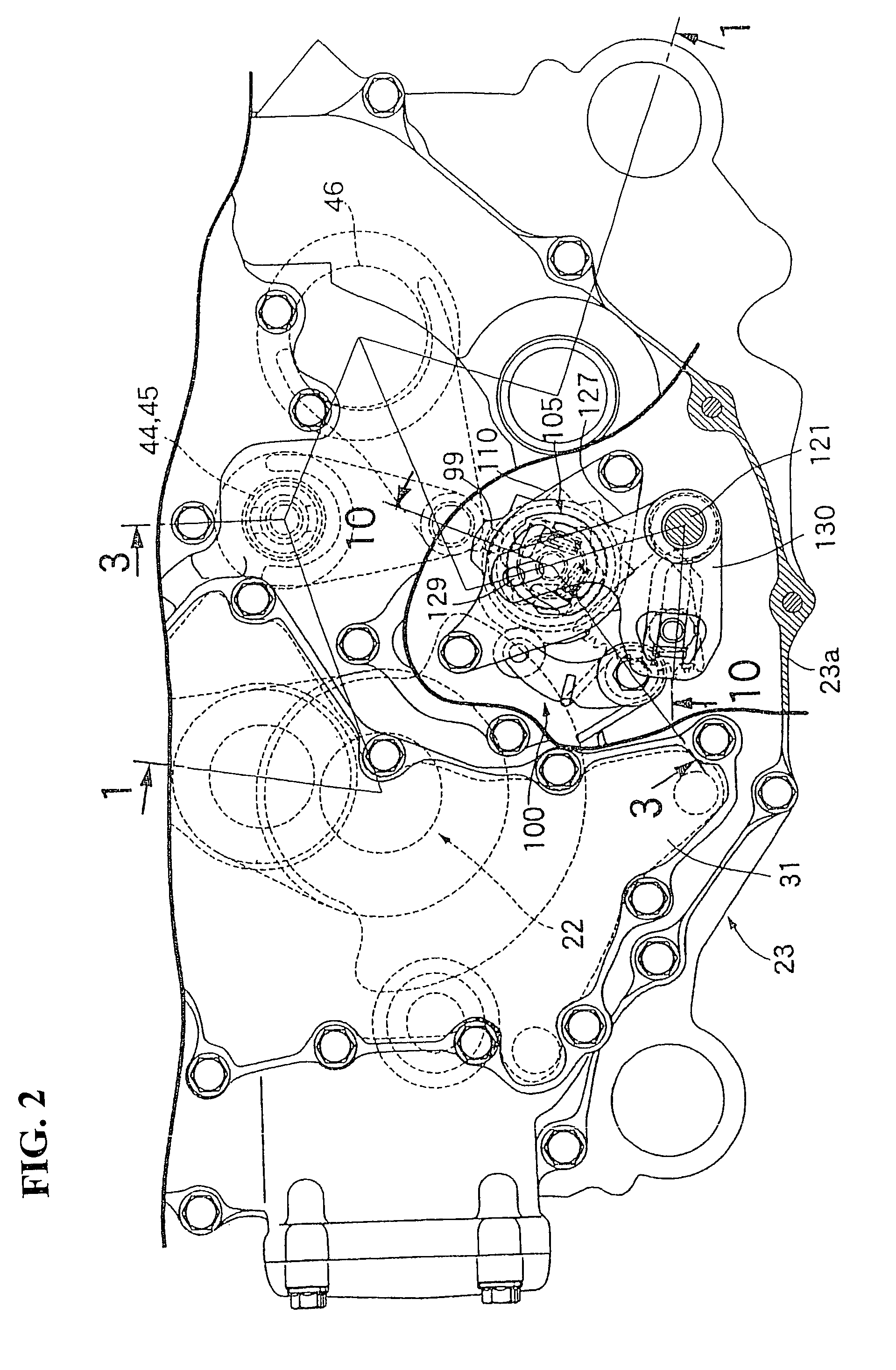

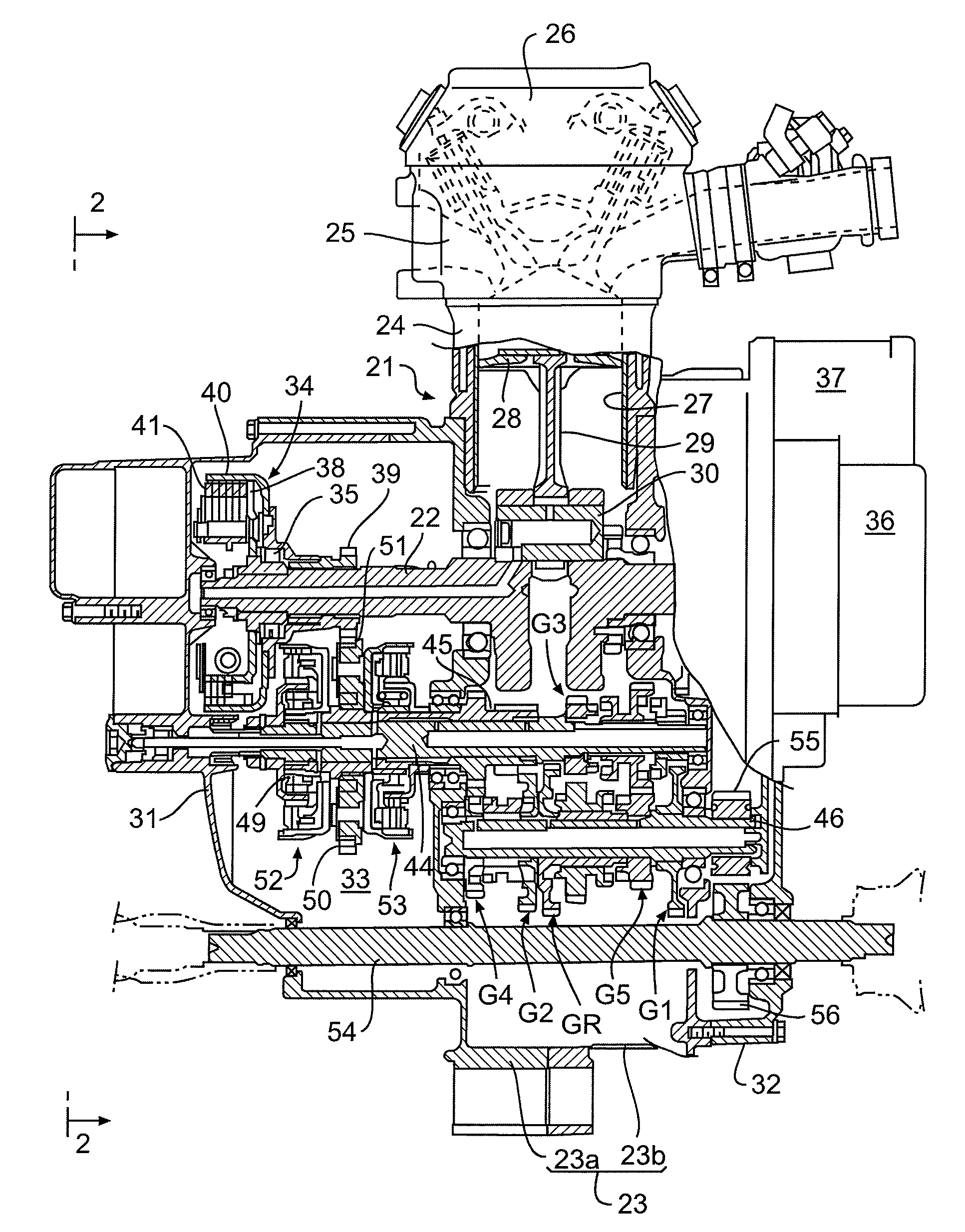

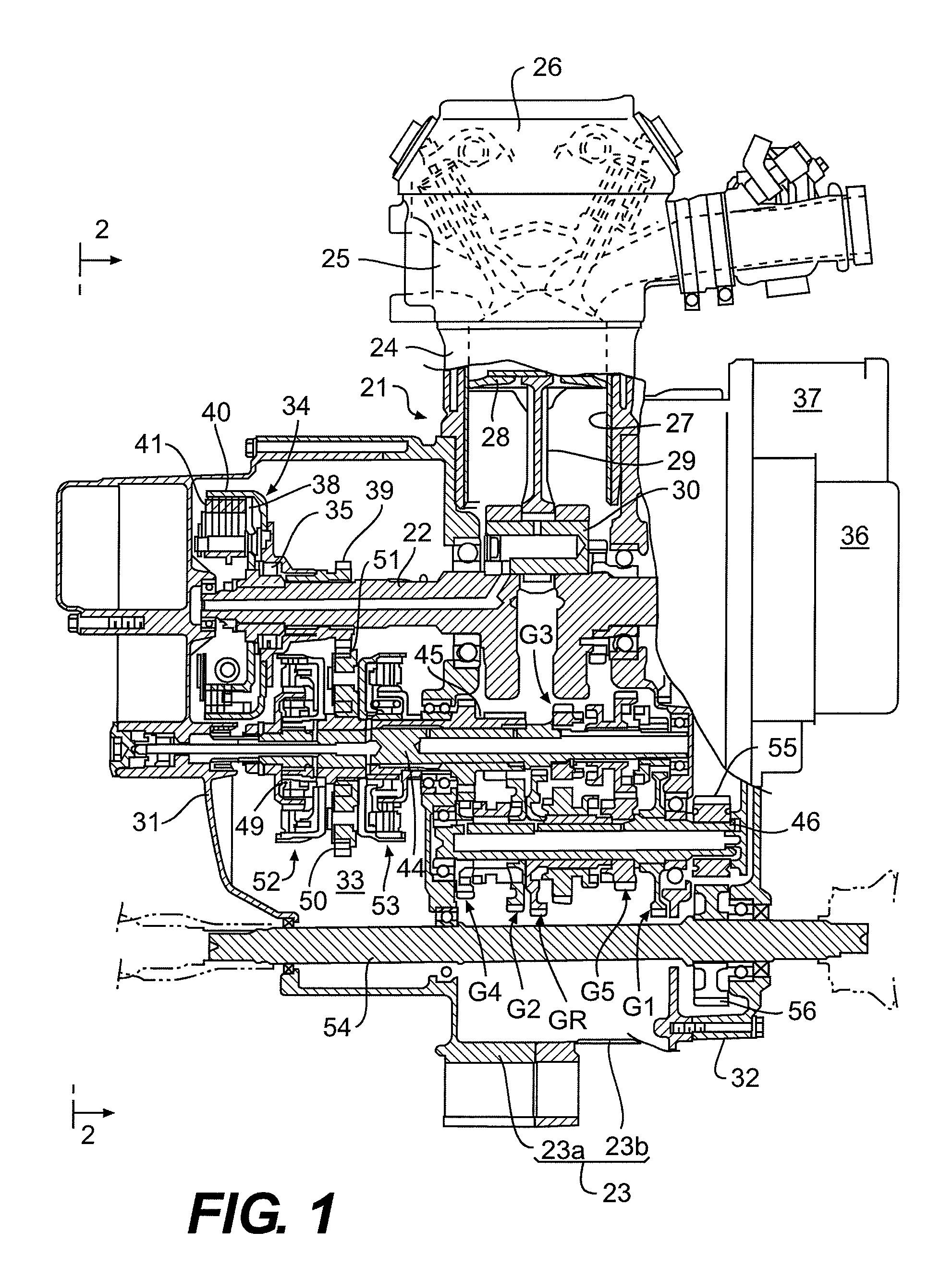

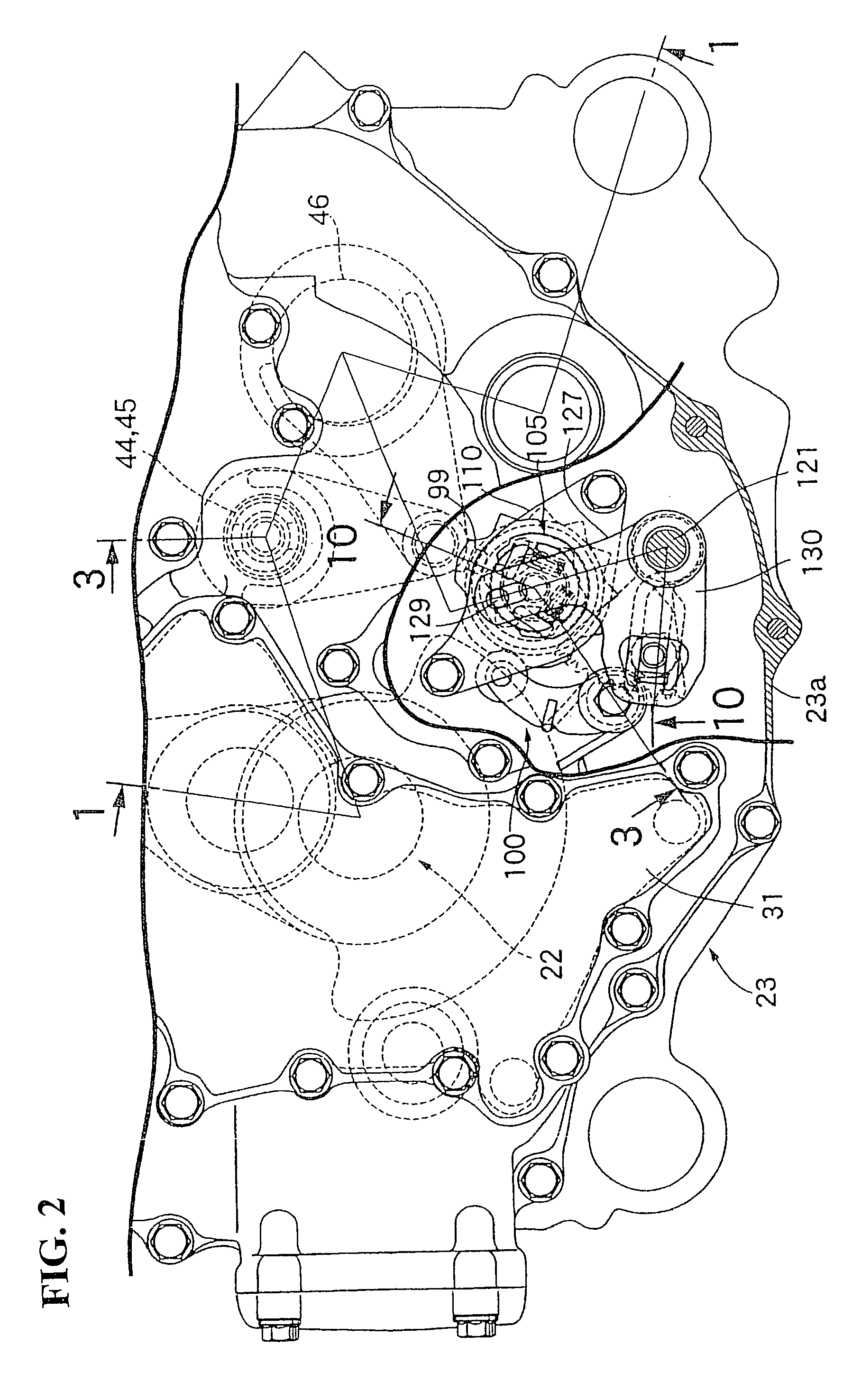

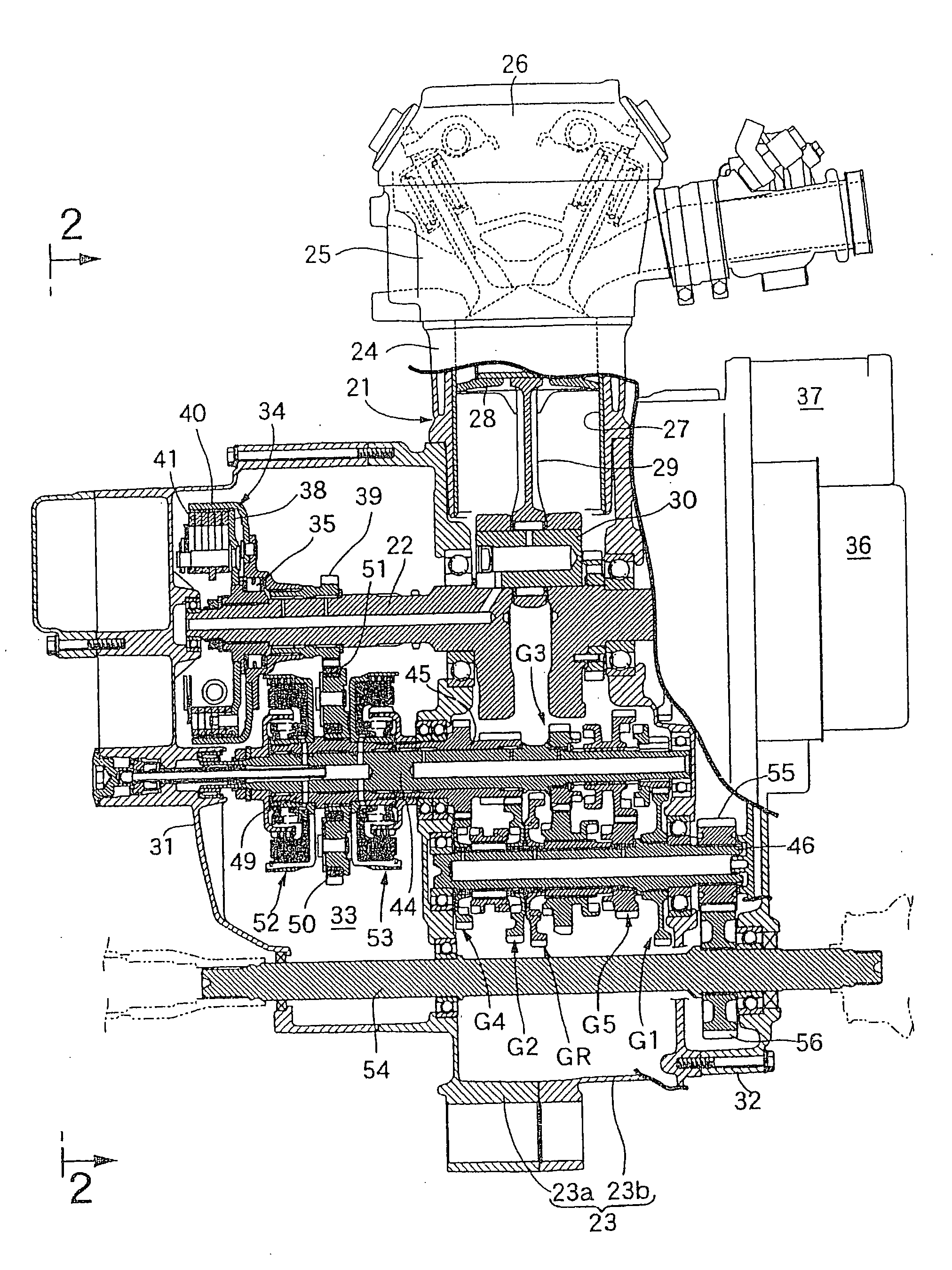

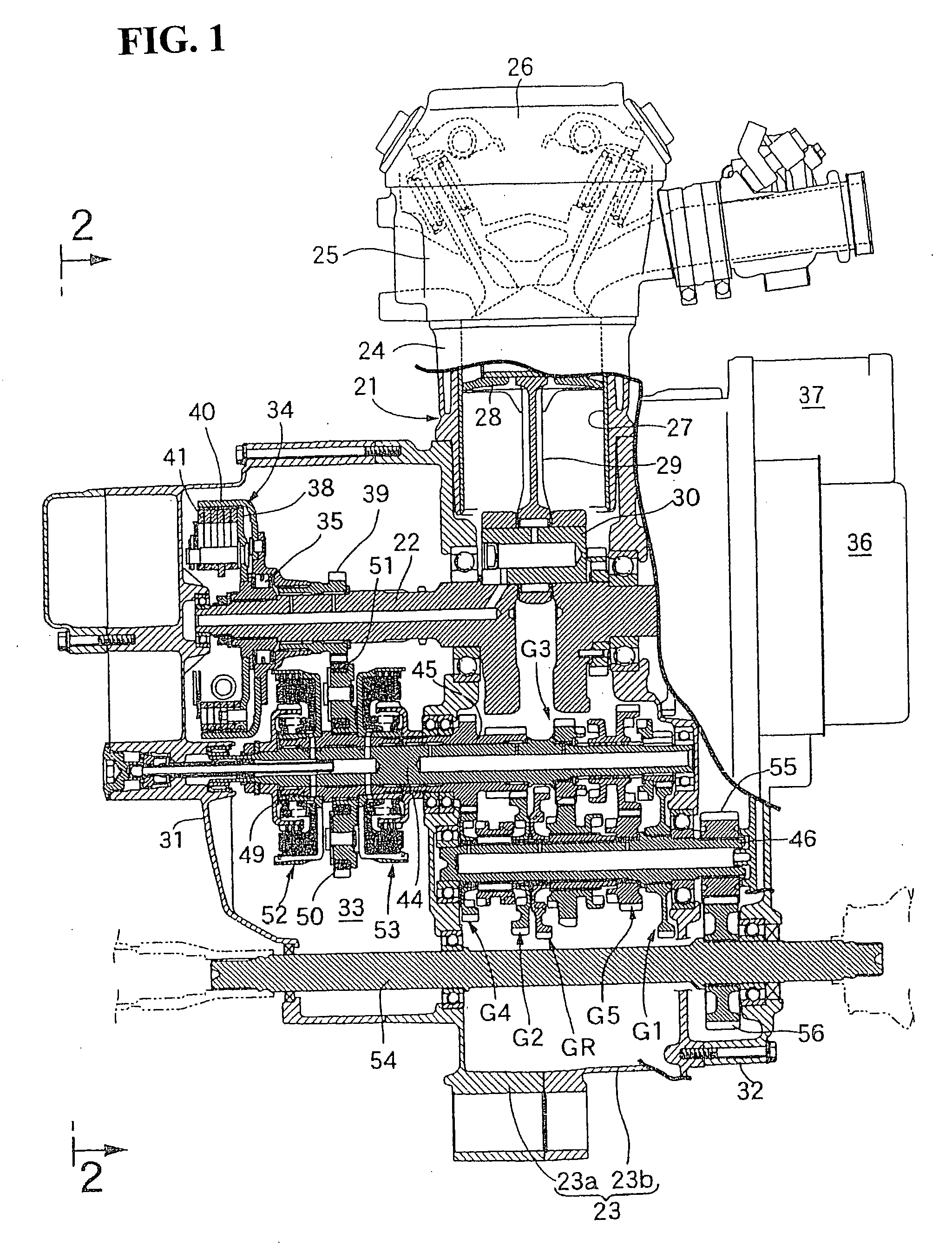

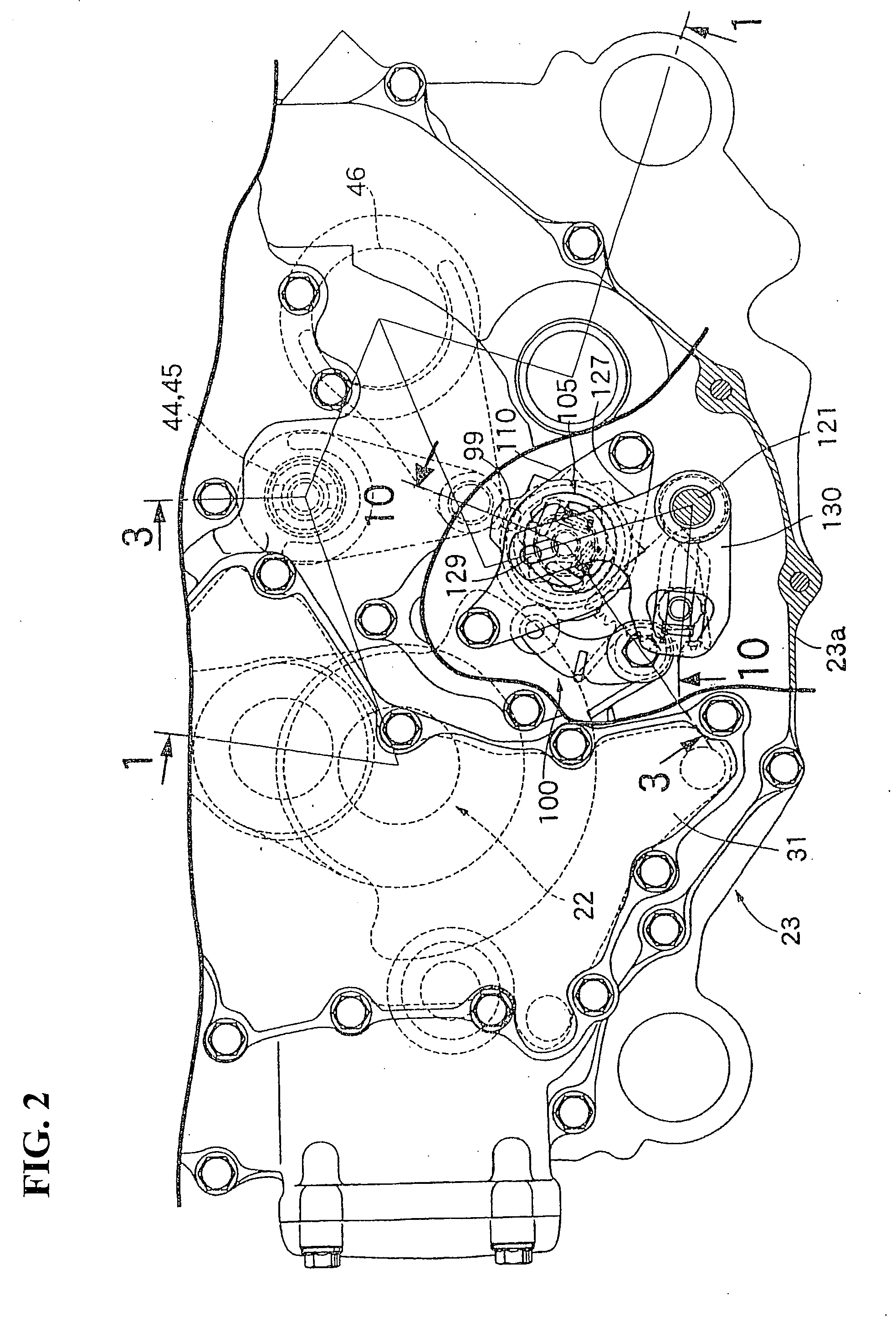

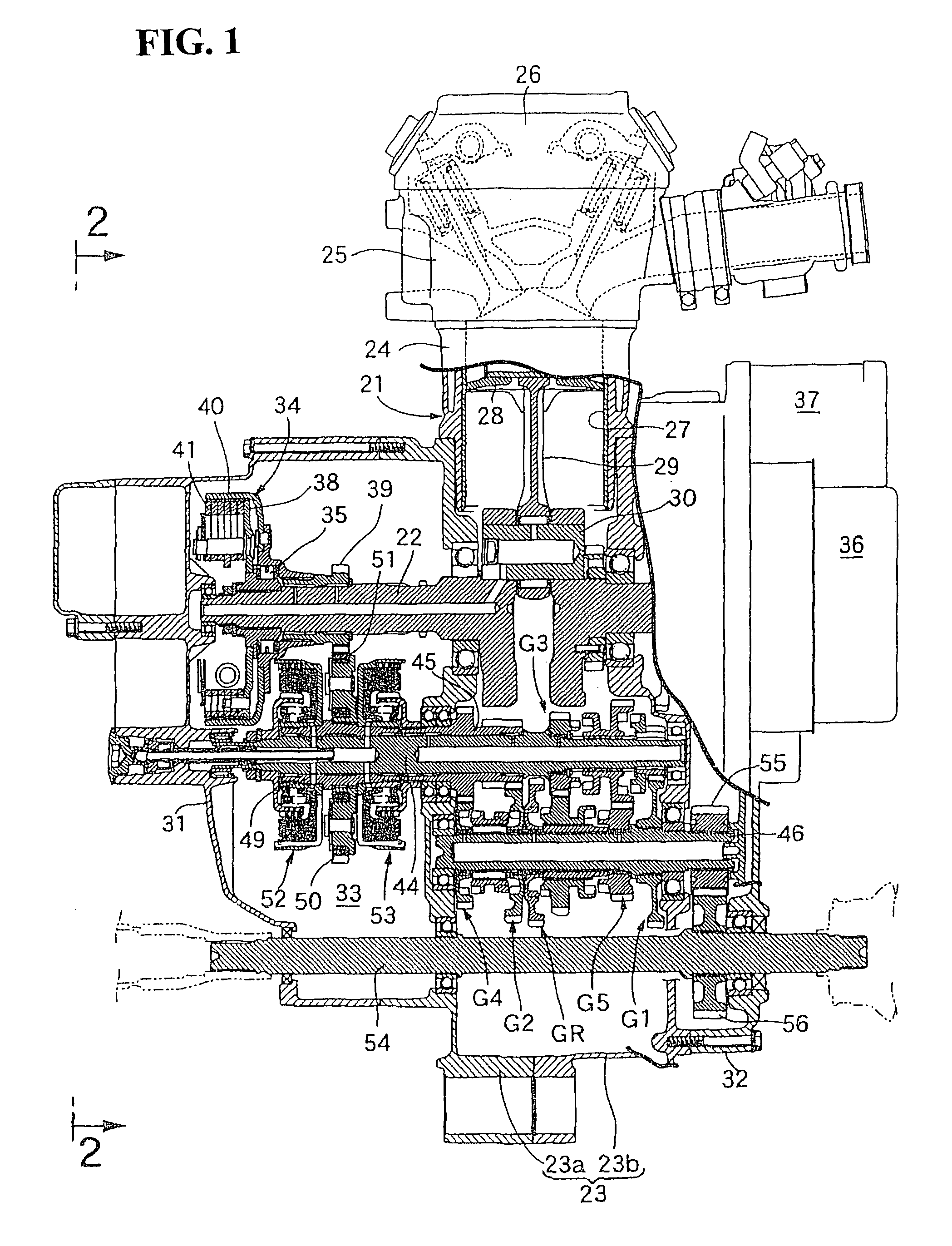

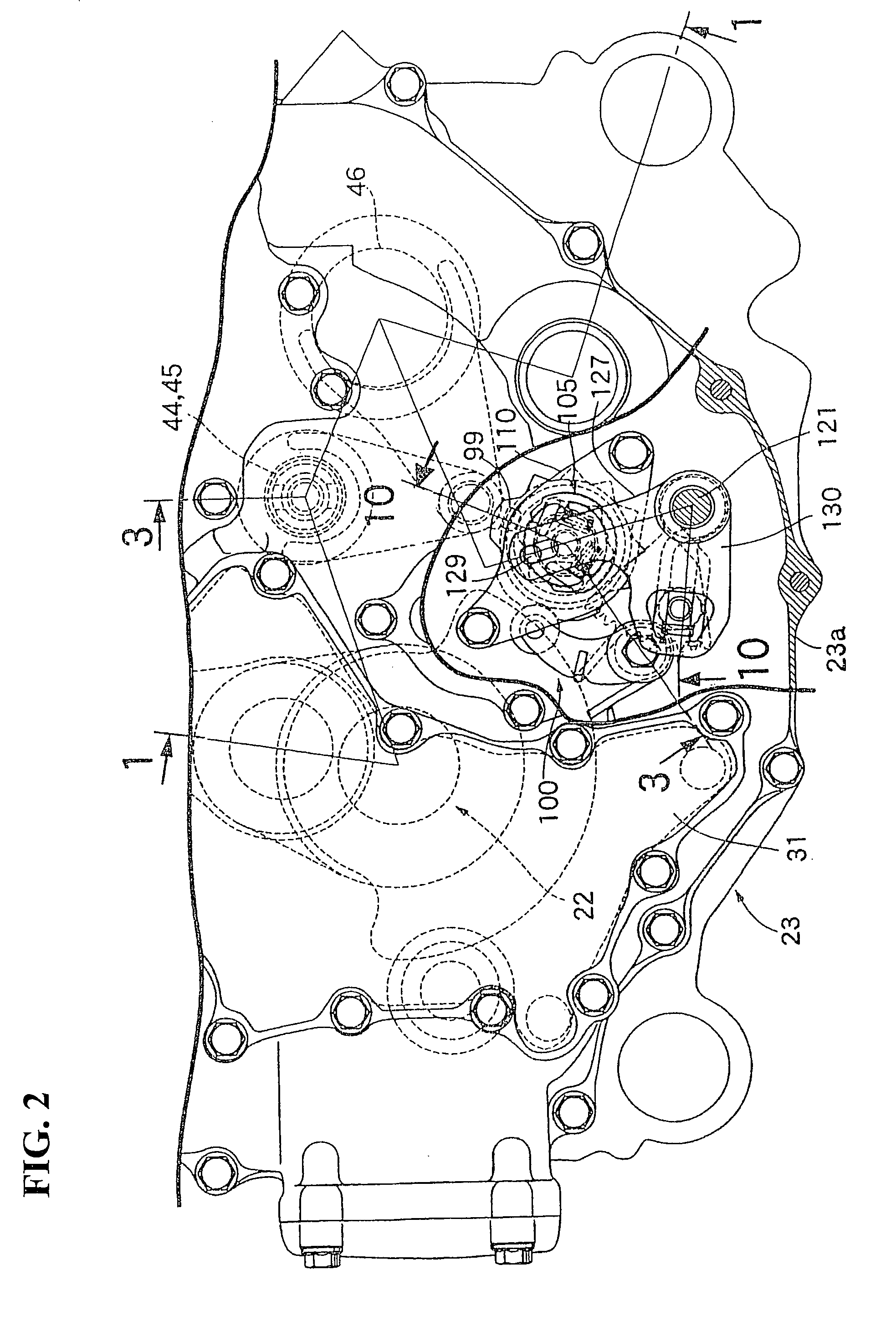

Vehicular transmission

A vehicular transmission includes a shift drum center with a plurality of gear train establishment notches disposed, equally spaced apart from each other, on the outer periphery thereof. The gear train establishment notches establish a specific gear train selected from among a plurality of gear trains by selectively engaging a drum stopper arm therein. The shift drum center further includes half neutral notches to be engaged with the drum stopper arm. The half neutral notches are disposed on the outer periphery of the shift drum center and at a central portion between each pair of the gear train establishment notches, respectively. The resulting configuration effectively suppresses an engagement noise during changing of a gear position through a sliding motion of a shifter.

Owner:HONDA MOTOR CO LTD

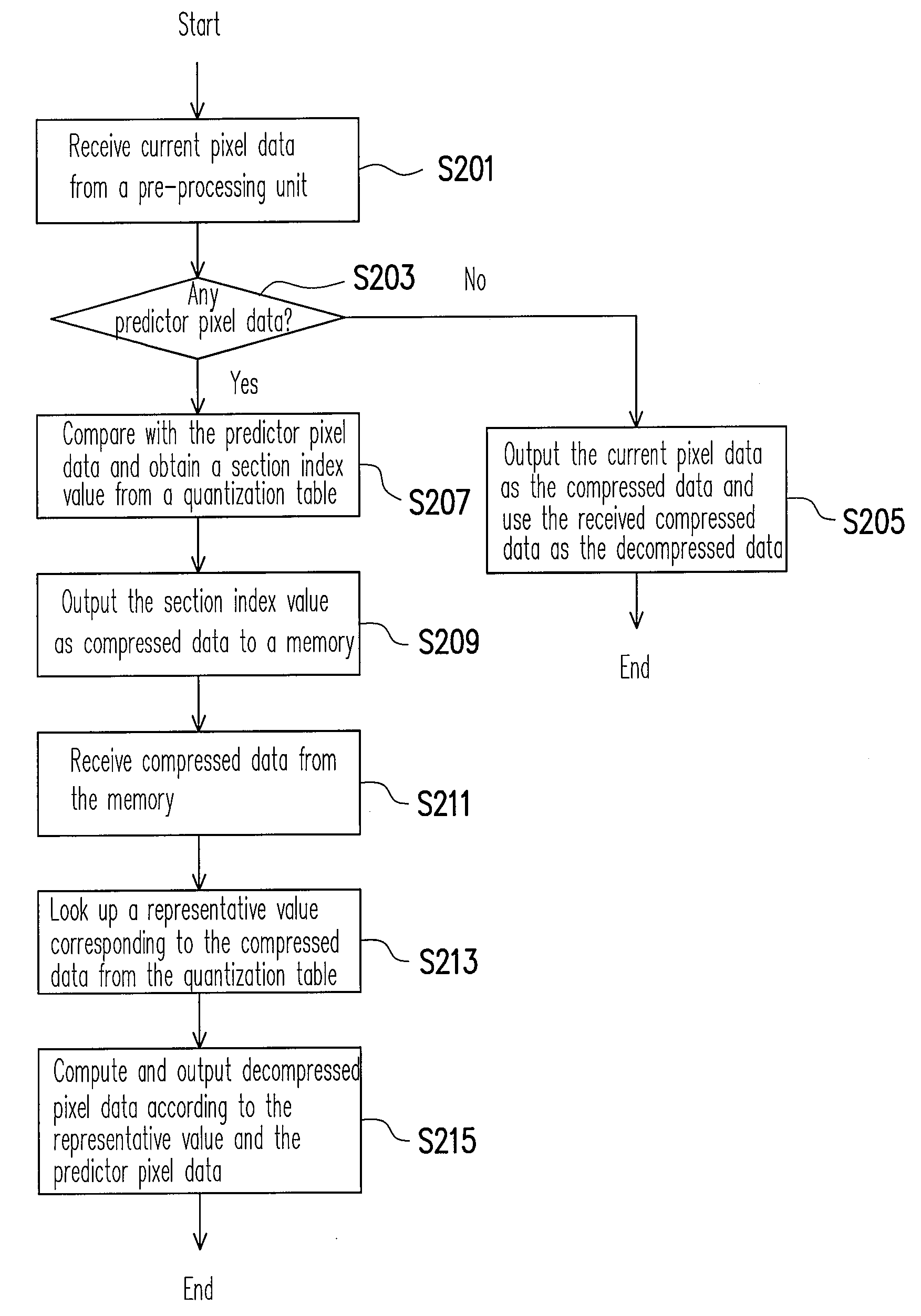

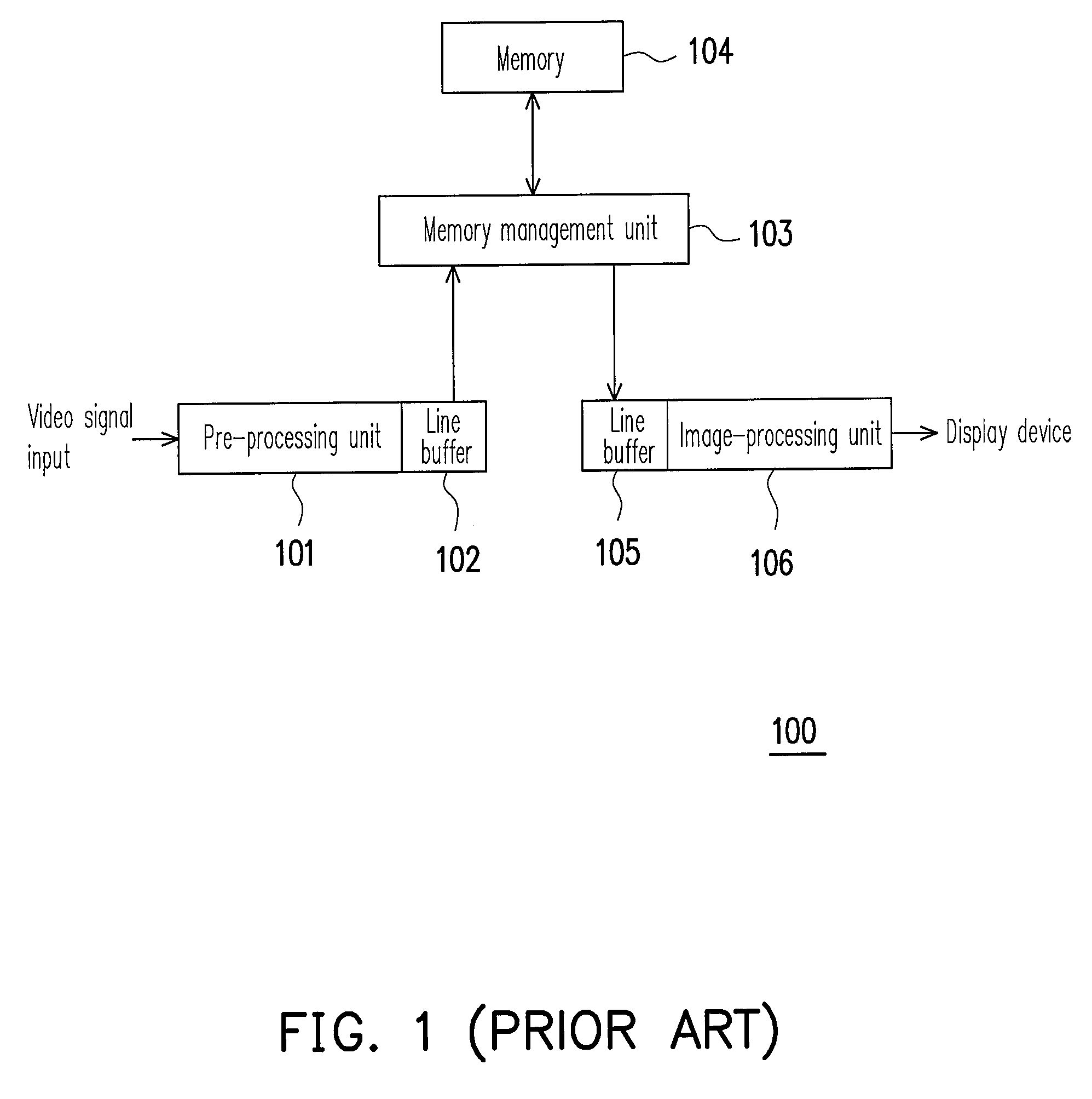

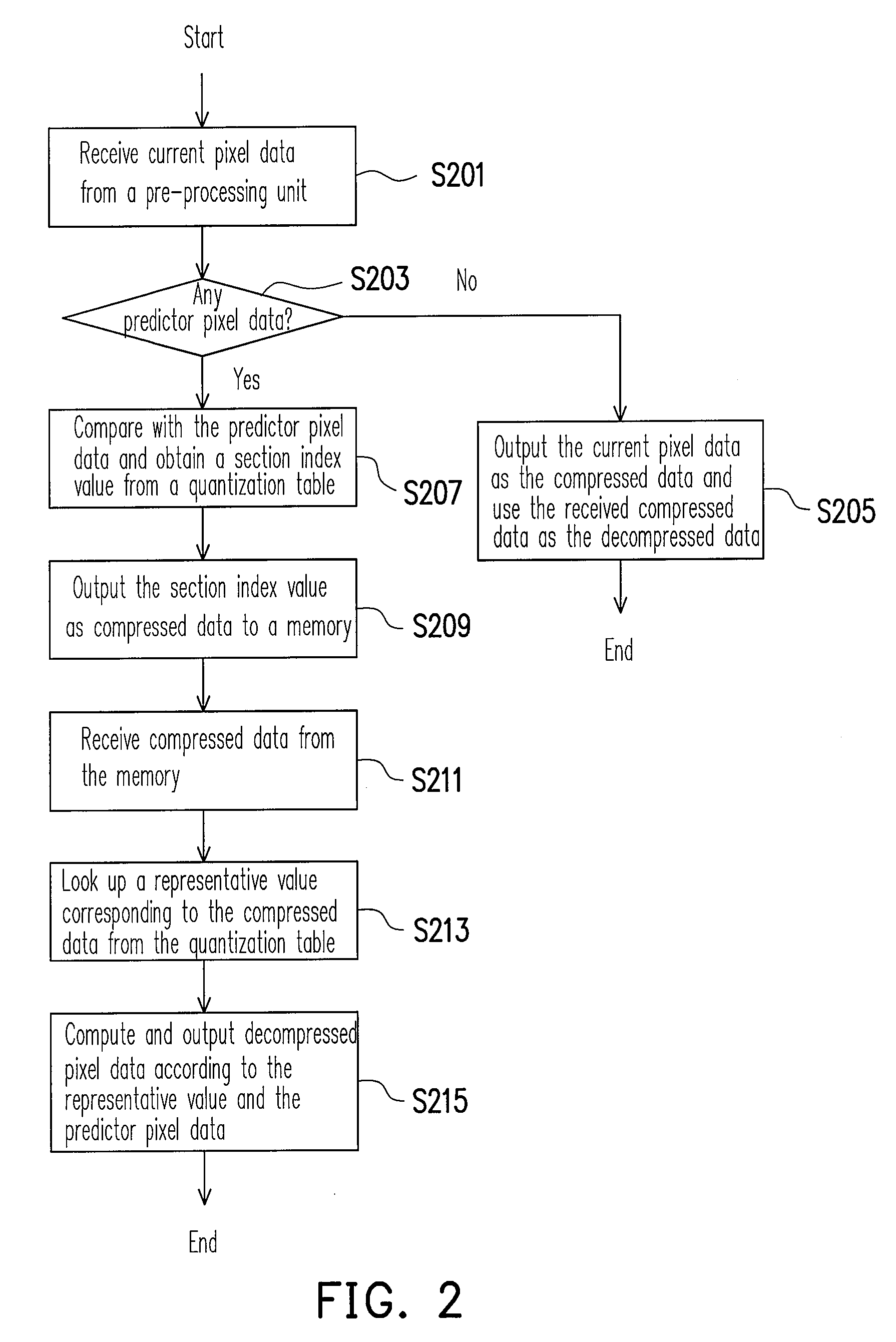

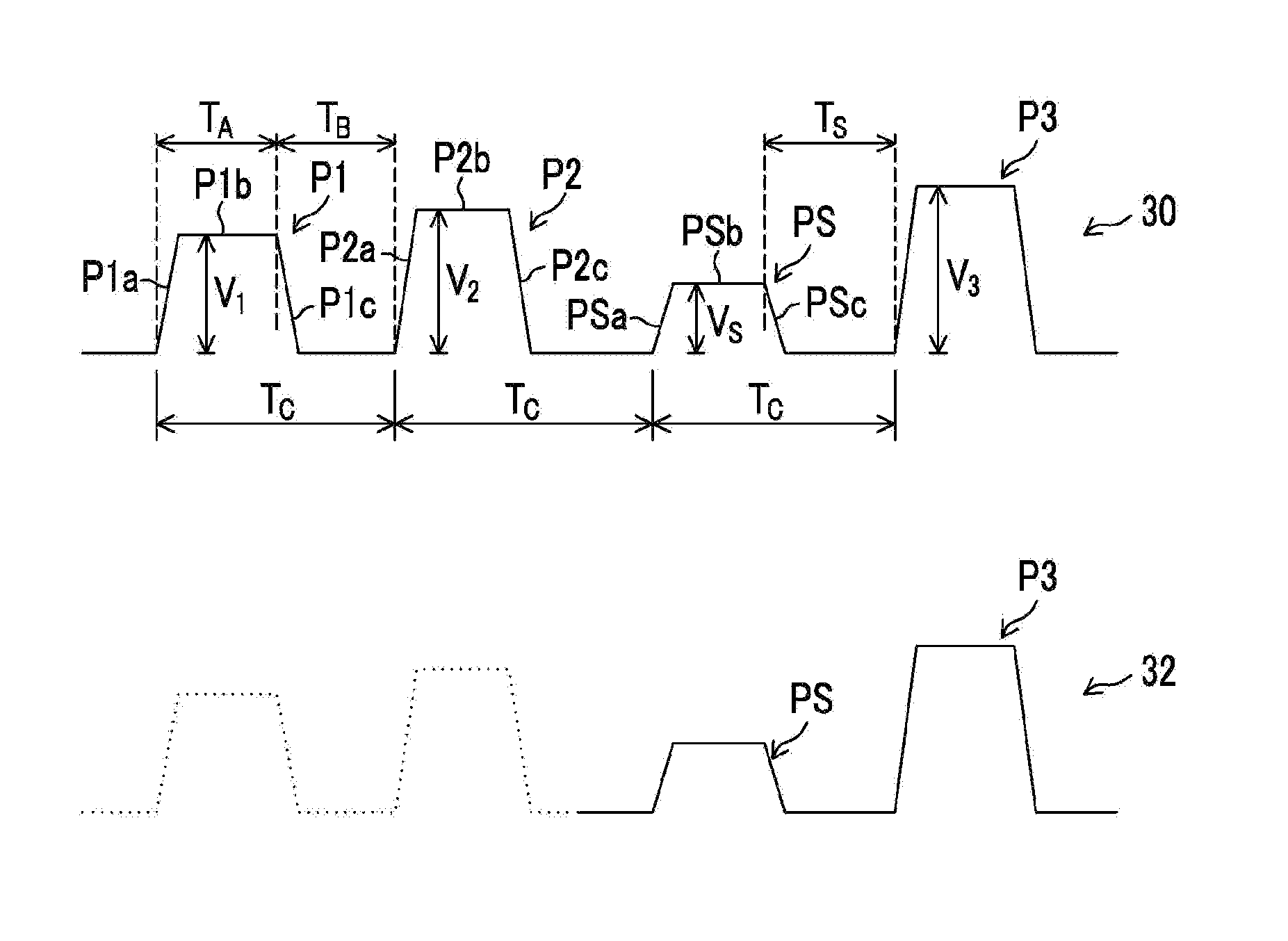

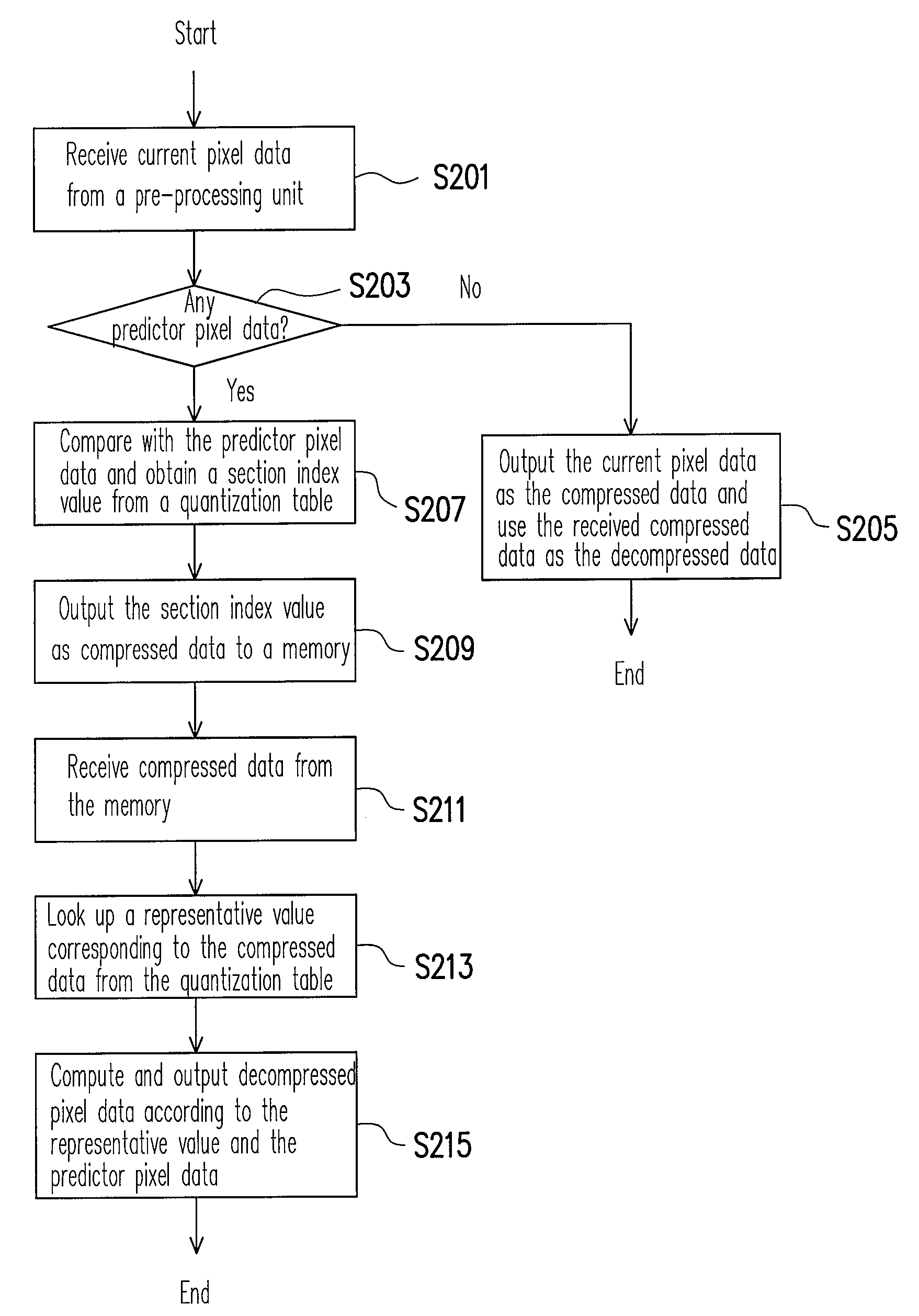

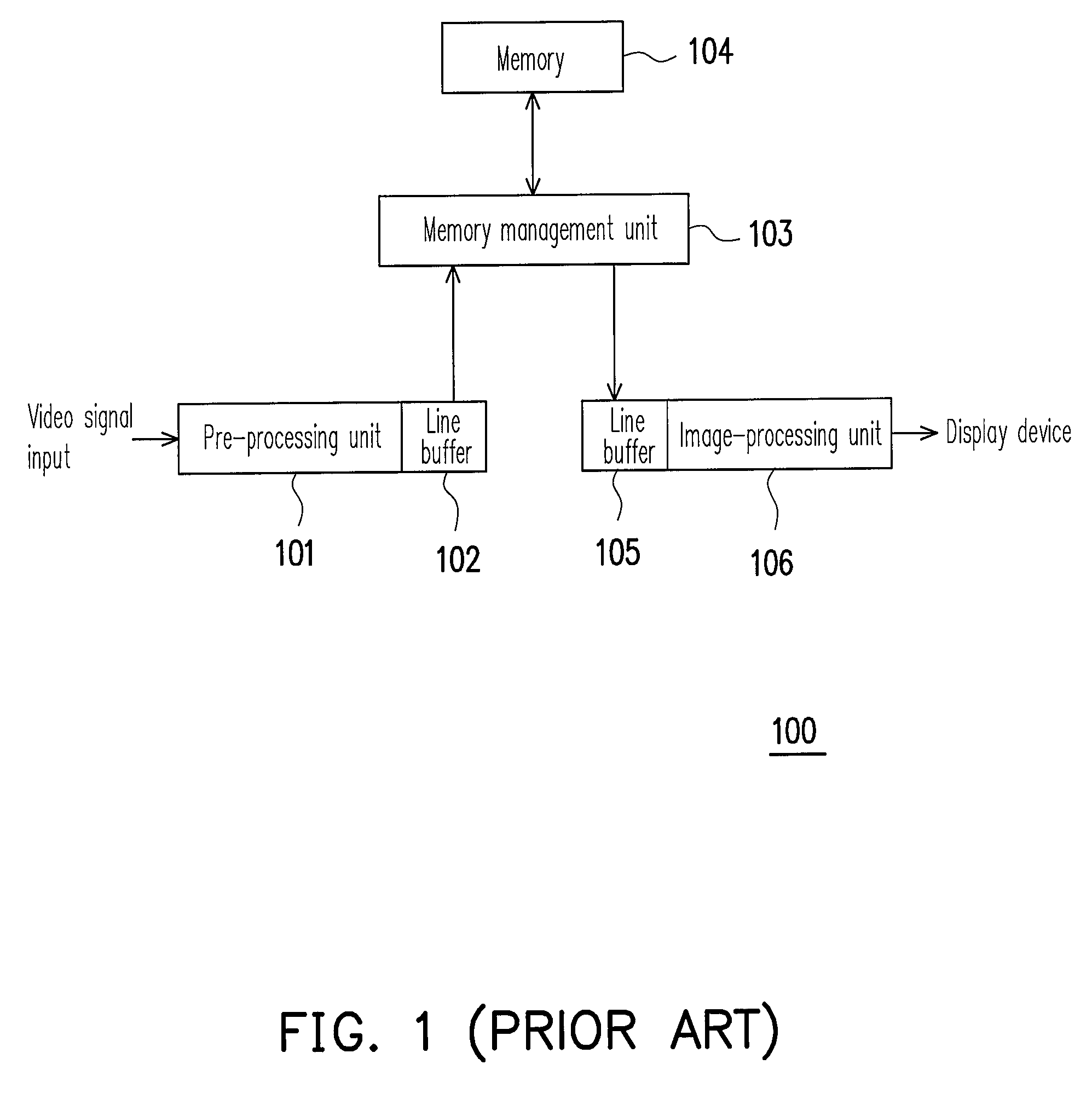

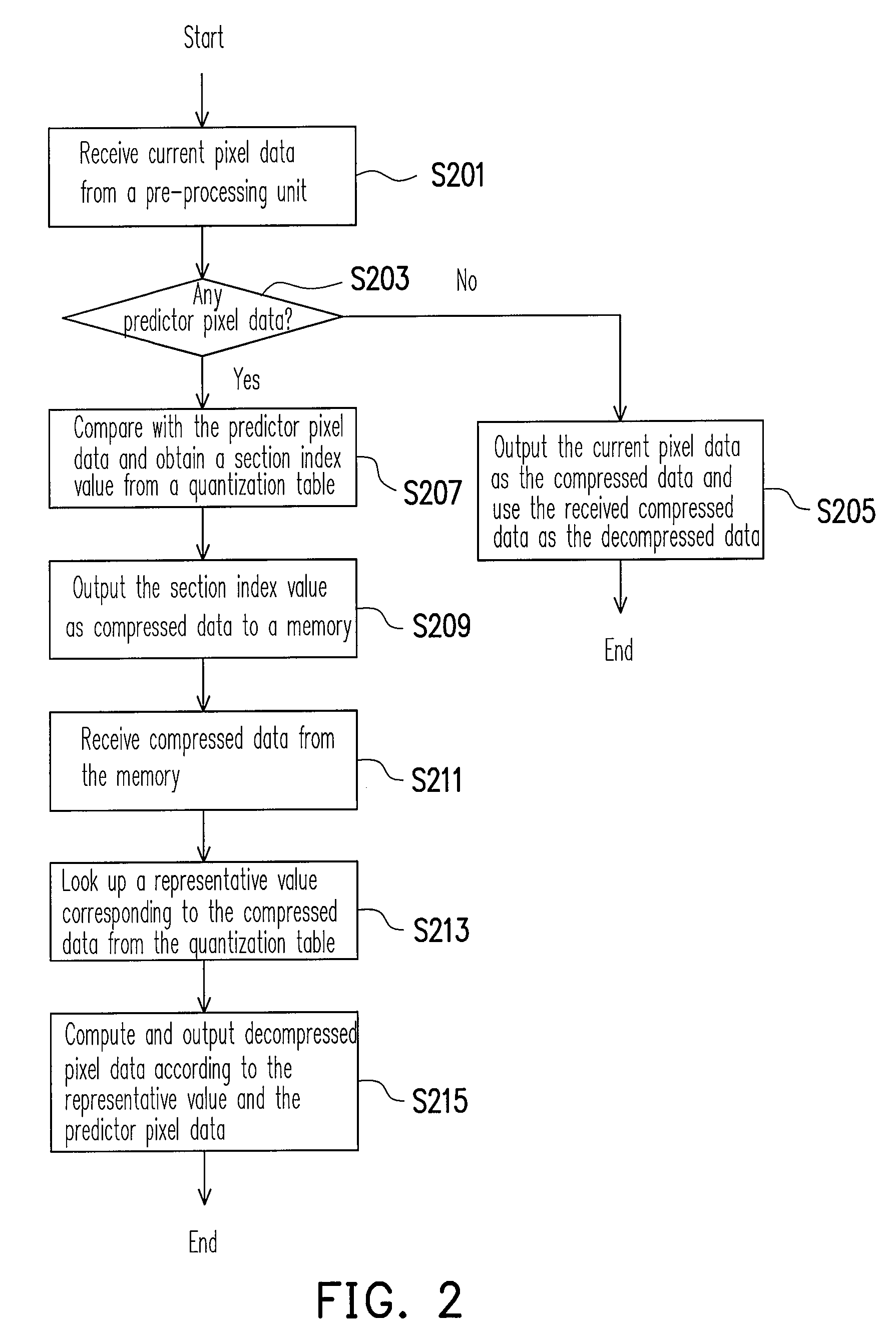

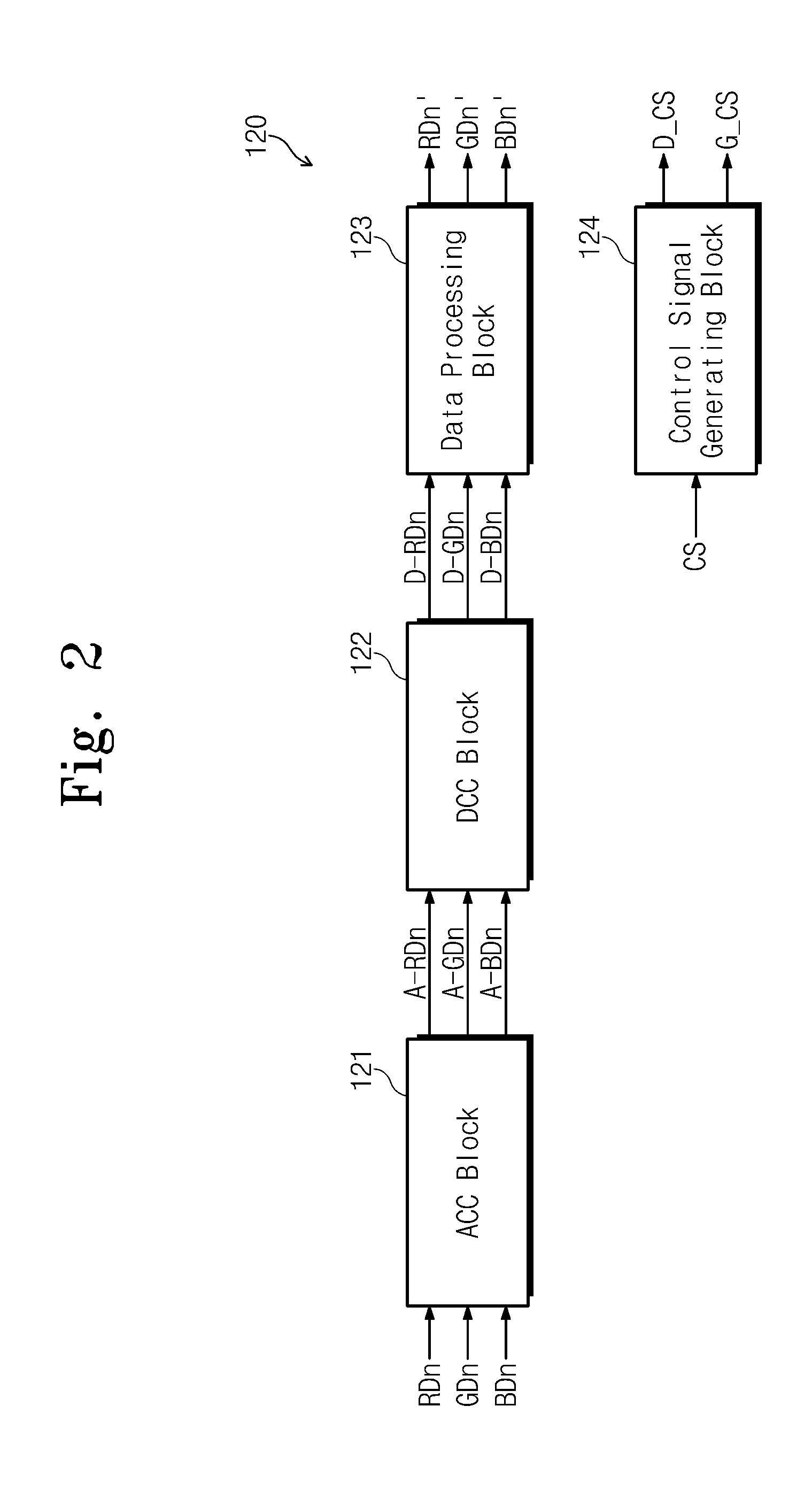

Pixel data compression and decompression method and device thereof

ActiveUS20070189620A1Reduce bandwidthAttenuation bandwidthCharacter and pattern recognitionDigital video signal modificationPacked pixelData compression

The present invention discloses a method for compressing and decompressing pixel data and the device thereof. The method comprises receiving current pixel data from a preprocessor and comparing the current pixel data with predictor pixel data to obtain a section index from a quantization table. Output the section index to a memory as compressed data. Then, receive the compressed data from the memory. Use the quantization table to look up a representative level corresponding to the compressed data and output decompressed pixel data based on the representative level to an image processing unit. The device mentioned above comprises a memory, a compressor and a decompressor. The memory stores compressed data. The compressor quantizes and compresses pixel data and outputs the compressed pixel data to the memory. The decompressor receives the compressed pixel data and decompresses the compressed pixel data and outputs the decompressed pixel data as pixel data.

Owner:NOVATEK MICROELECTRONICS CORP

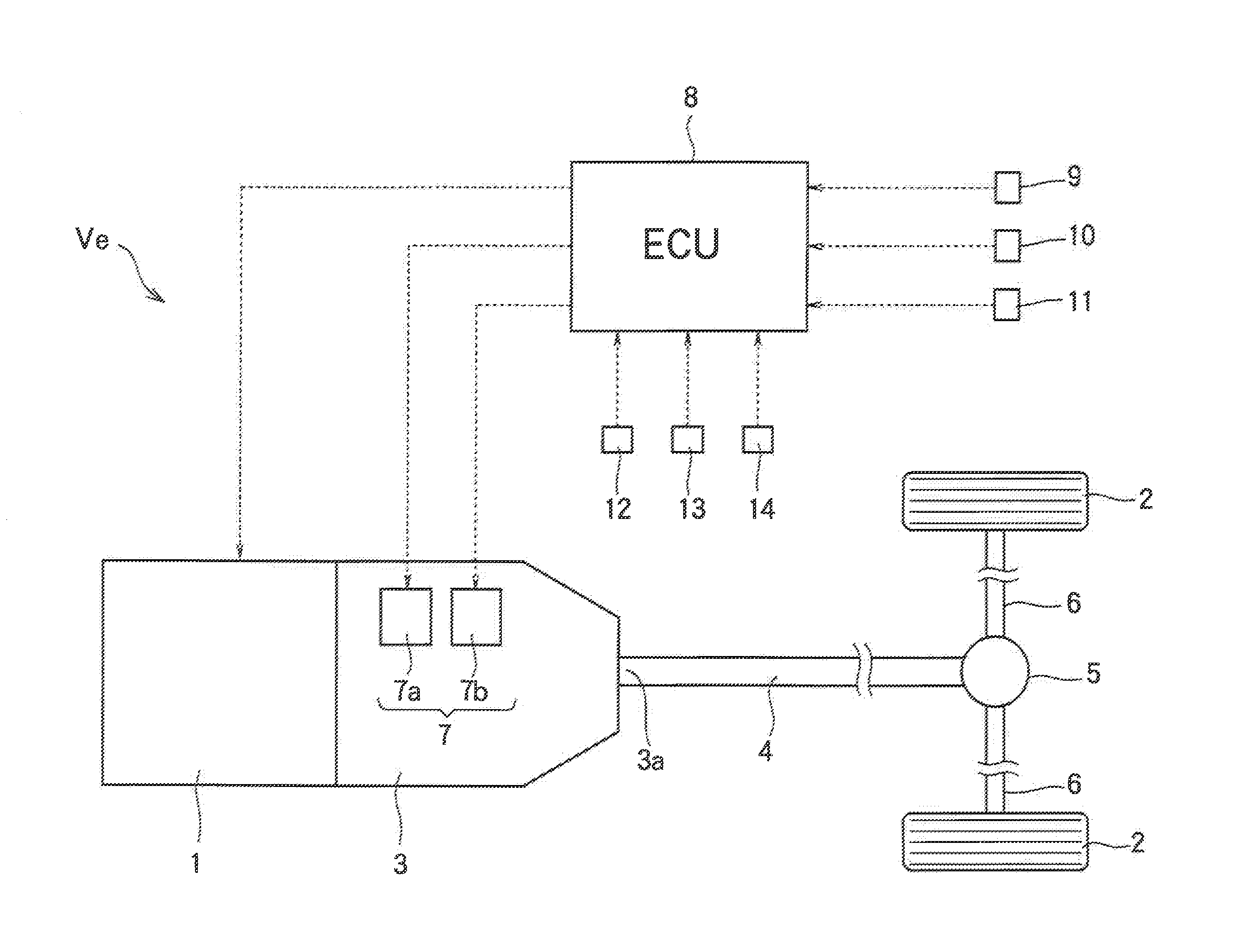

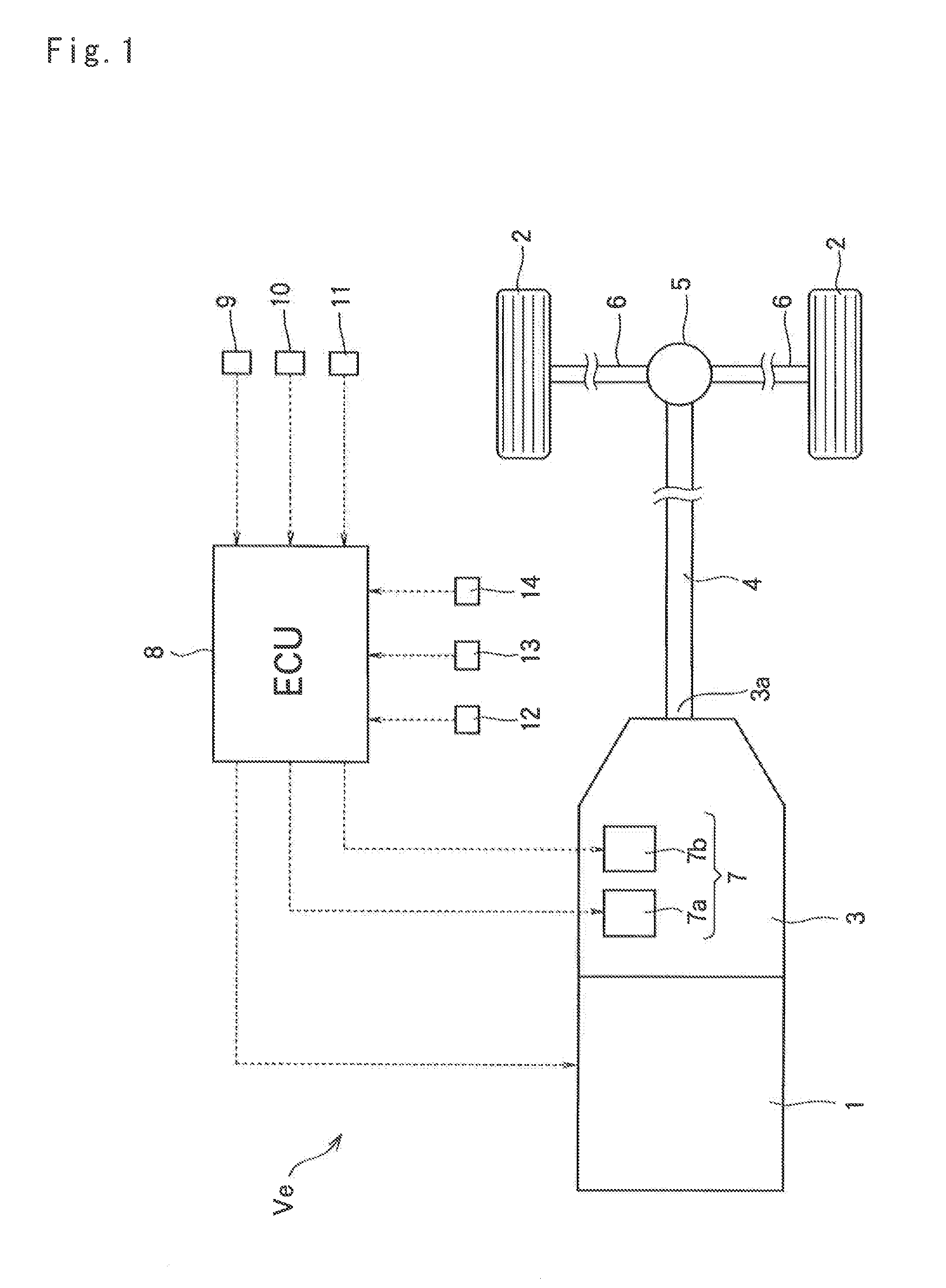

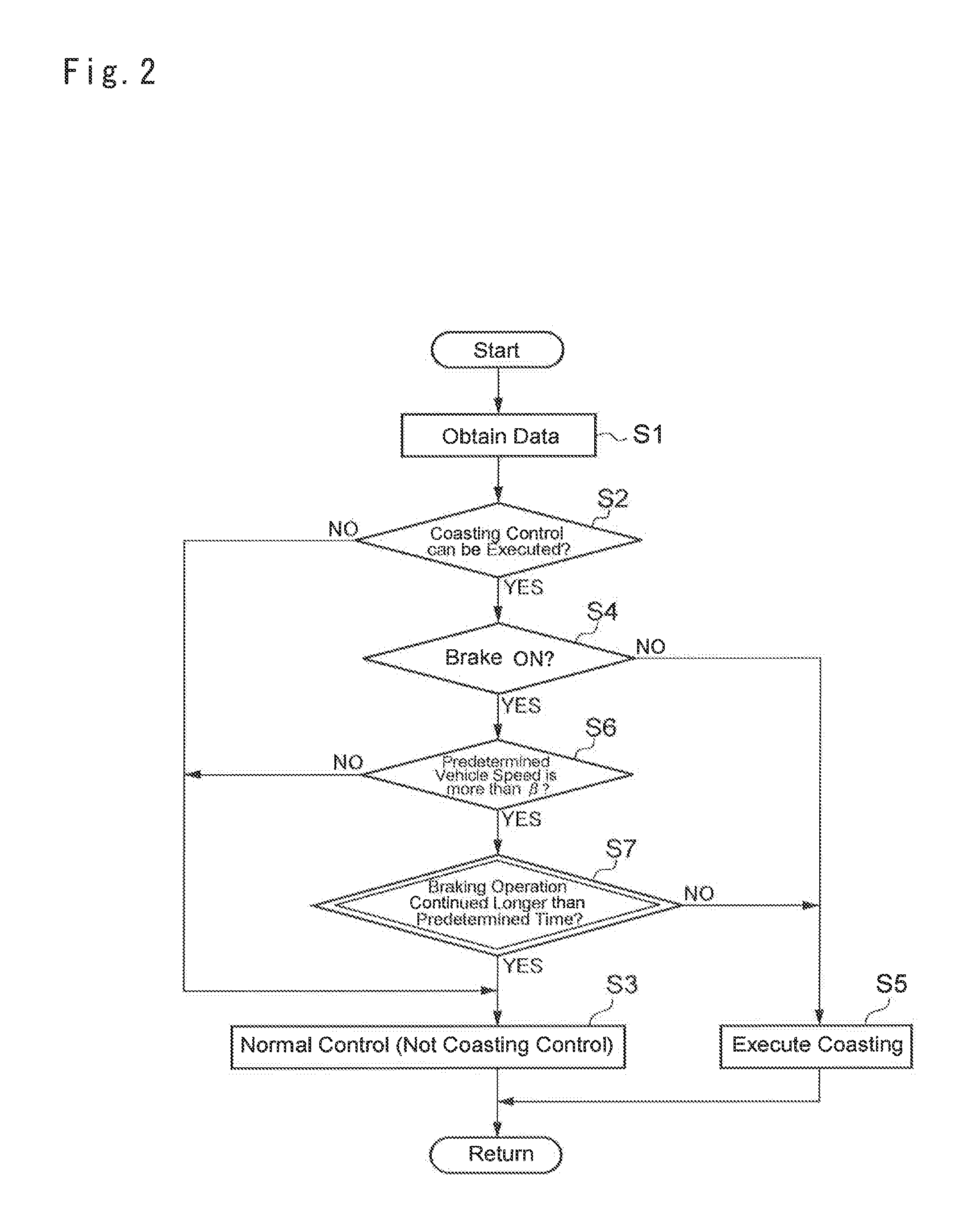

Vehicle control system

ActiveUS20150149058A1Improve energy efficiencyShort durationClutchesDigital data processing detailsDrive wheelControl system

A vehicle control system is provided. The vehicle control system is applied to a vehicle having a clutch device adapted to selectively connect and disconnect a power transmission route between a prime mover and drive wheels. The vehicle control system disconnects the power transmission route during running to allow the vehicle to coast. The vehicle control system is comprised of: a means detecting a vehicle speed; a means detecting an operation of an accelerator by a driver; a means detecting a braking operation of the driver; an execution means executing a coasting control when an operating amount of the accelerator is reduced to be smaller than a predetermined value during running, by bringing the clutch device into disengagement to disconnect the power transmission route so as to allow the vehicle to coast; a determination means determining whether or not a deceleration demand of the driver is larger than a predetermined value during execution of the coasting control based on the vehicle speed and the braking operation; and a termination means determining a fact that the deceleration demand is strong if the deceleration demand is larger than the predetermined value, and that terminates the coasting control by bringing the clutch device into engagement to connect the power transmission route.

Owner:TOYOTA JIDOSHA KK

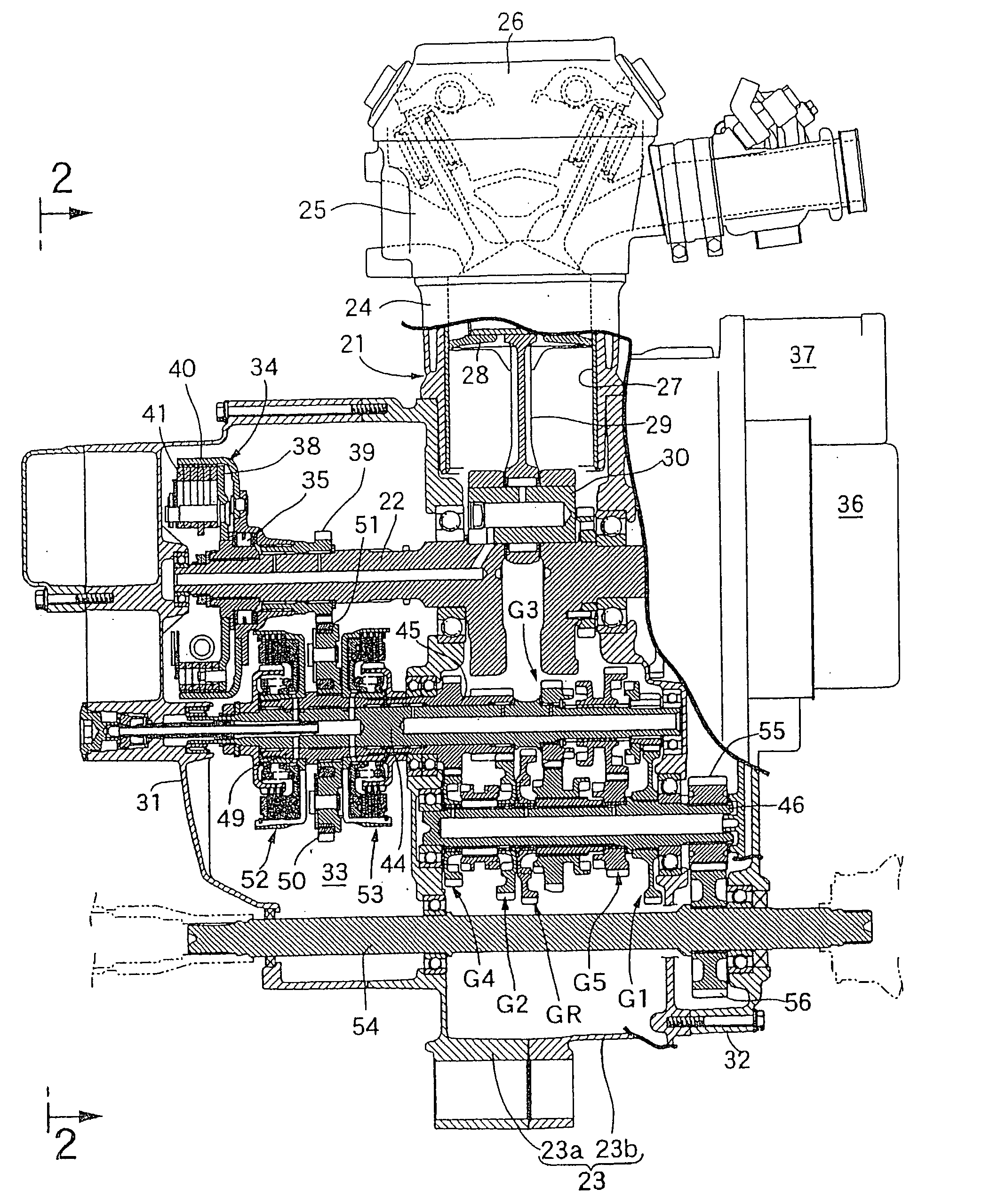

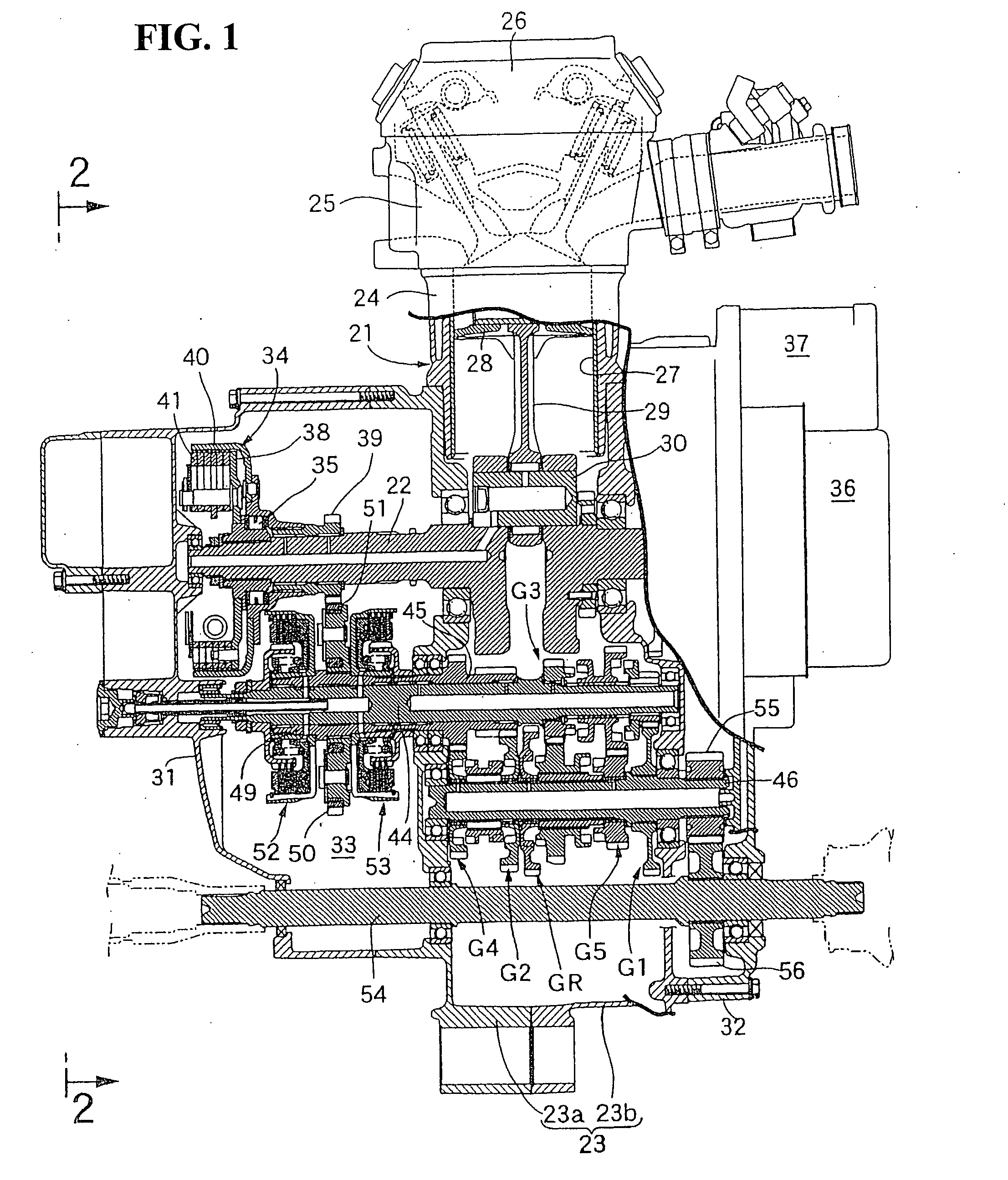

Transmission for vehicle

ActiveUS20080184844A1Reduce speedStop rotatingToothed gearingsGearing controlGear trainElectrical and Electronics engineering

A transmission for a vehicle in which changing a shift position is achieved by sliding a shifter. In sliding the shifter to change the established condition of gear trains respectively corresponding to a plurality of shift positions, the transmission of power from an engine to a main shaft is cut off. A feed mechanism for sliding the shifter is configured to reduce the sliding speed of the shifter or to once stop the sliding operation of the shifter in a neutral condition during the sliding operation of the shifter in changing the established condition of the gear trains. The resulting configuration reduces the engagement noise when changing the shift position.

Owner:HONDA MOTOR CO LTD

Vehicular transmission

A vehicular transmission includes a shift drum center with a plurality of gear train establishment notches disposed, equally spaced apart from each other, on the outer periphery thereof. The gear train establishment notches establish a specific gear train selected from among a plurality of gear trains by selectively engaging a drum stopper arm therein. The shift drum center further includes half neutral notches to be engaged with the drum stopper arm. The half neutral notches are disposed on the outer periphery of the shift drum center and at a central portion between each pair of the gear train establishment notches, respectively. The resulting configuration effectively suppresses an engagement noise during changing of a gear position through a sliding motion of a shifter.

Owner:HONDA MOTOR CO LTD

Transmission for vehicle

A transmission for a vehicle in which changing a shift position is achieved by sliding a shifter. In sliding the shifter to change the established condition of gear trains respectively corresponding to a plurality of shift positions, the transmission of power from an engine to a main shaft is cut off. A feed mechanism for sliding the shifter is configured to reduce the sliding speed of the shifter in a neutral condition, or to cause the sliding operation of the shifter to have a single stopping action in the neutral condition during the sliding operation of the shifter in changing the established condition of the gear trains. The resulting configuration reduces the engagement noise when changing the shift position.

Owner:HONDA MOTOR CO LTD

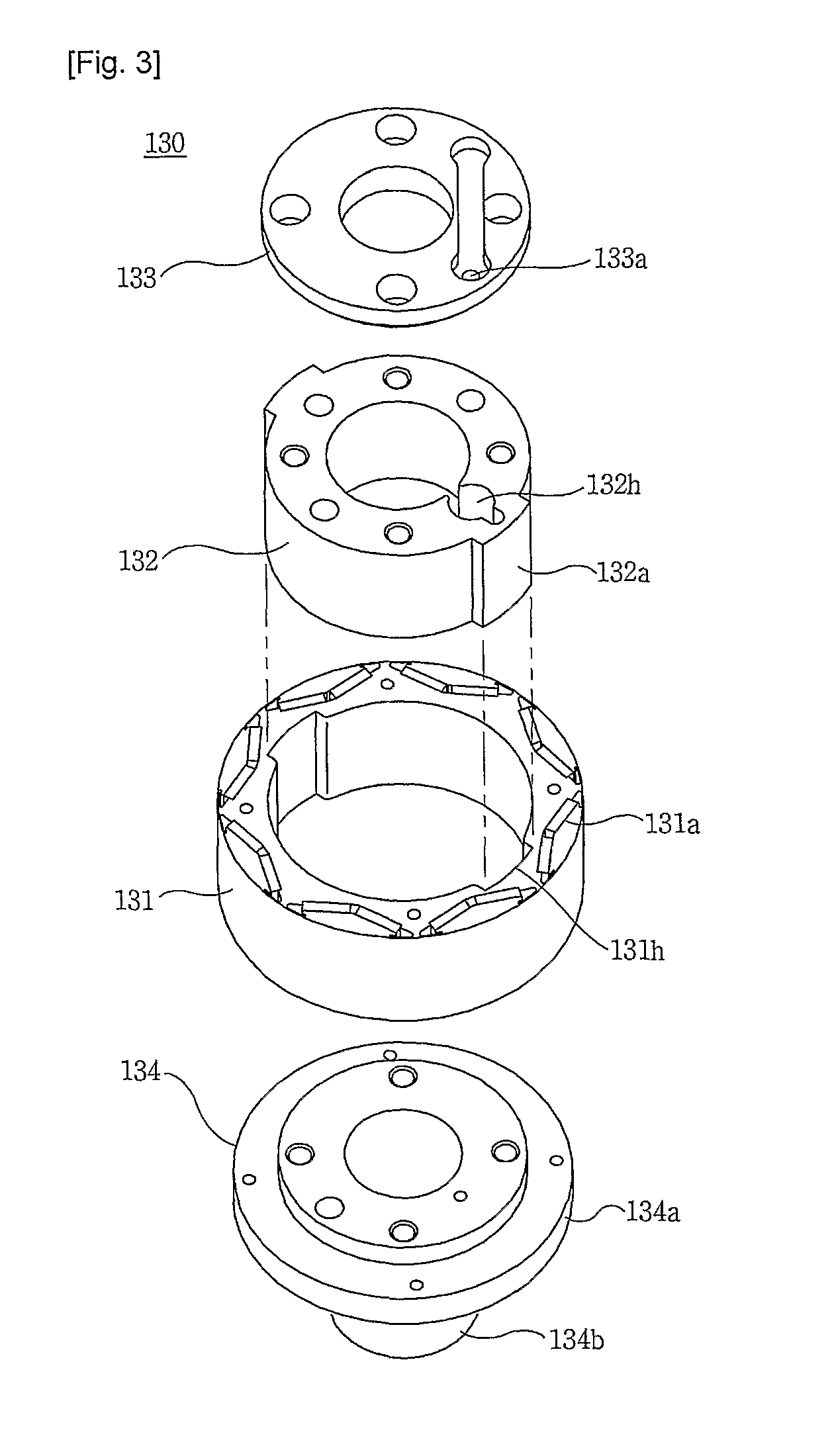

Power transmission system

InactiveUS20150090555A1Improve vibration damping effectIncreasing an inertia momentRotary clutchesFluid gearingsFluid couplingTransmitted power

A power transmission system having a pendulum damper is provided. A rolling member of the pendulum damper is arrange in a rotary member, and a vibration damping performance of the pendulum damper is enhanced by increasing an inertia moment of the rolling member to be larger than that of the rotary member. The power transmission system is comprised of a hydraulic route for transmitting power between an input member and an output member through a fluid coupling, a mechanical route for transmitting power between the input member and the output member by engaging a lockup clutch, a pendulum damper that damps torsional vibrations of the output member by an oscillating motion caused by the torsional vibrations, and an elastic damper that damps the torsional vibrations by a relative rotation between a drive member and a driven member connected through an elastic member. The pendulum damper is disposed on the mechanical route, and one of the lockup clutch and the elastic damper is disposed on an output side of the pendulum damper.

Owner:TOYOTA JIDOSHA KK

Vibration type actuator drive controller and method of controlling drive speed of vibration type actuator

InactiveUS6987345B2Process stabilityReduce drive frequencyMotor/generator/converter stoppersAC motor controlResonanceActuator

This disclosure relates to a technique for smoothly carrying out an acceleration operation and a deceleration operation for a vibration type actuator to prevent a situation where in starting the vibration type actuator, a drive frequency is reduced to become lower than a resonance frequency to stop the vibration type actuator. A first counter performs up-count from a first value to a second value larger than the first value at predetermined time intervals in accelerating the vibration type actuator. A rate multiplier outputs a clock signal having a frequency corresponding to the count value. A second counter measures a period of a pulse signal, the period being adapted to change in correspondence to a drive speed of the vibration type actuator, by counting the clock pulses. The drive speed of the vibration type actuator is controlled such that the measured pulse period becomes a predetermined target value.

Owner:CANON KK

Vehicular transmission

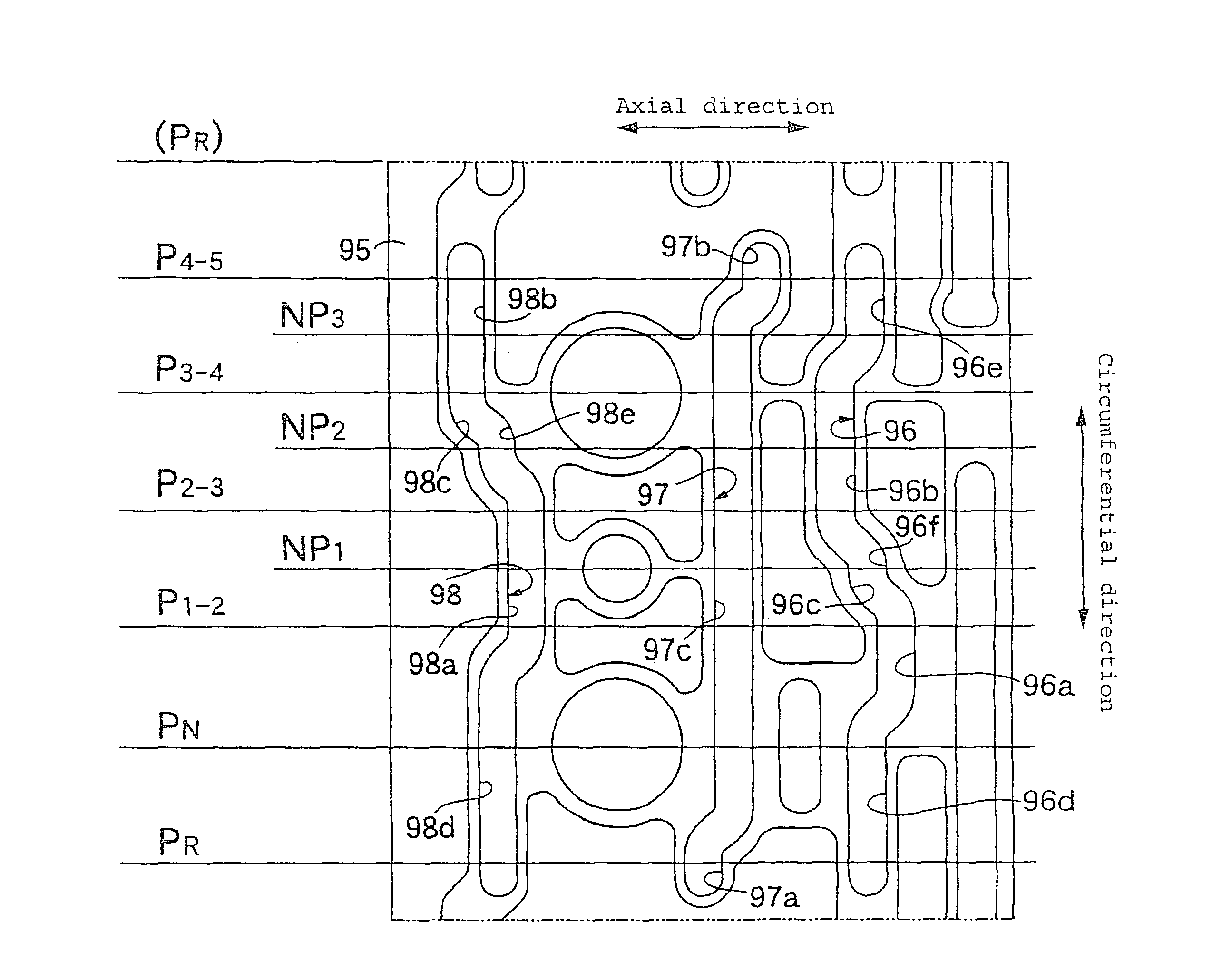

ActiveUS20080078605A1Engagement noise can be prevented largeDifference in speedToothed gearingsGearing controlExternal combustion engineEngineering

A vehicular transmission for an internal combustion engine includes lead grooves disposed on an outer periphery of a shift drum have communication portions connecting a pair of gear train establishment portions extending circumferentially along the shift drum. The communication portions include half neutral portions formed at a center thereof, extending circumferentially along the shift drum. The resulting configuration suppresses an engagement noise to a minimum during changing of a gear position through a sliding motion of a shifter.

Owner:HONDA MOTOR CO LTD

Vehicular transmission

ActiveUS7926373B2Engagement noise can be prevented largeDifference in speedToothed gearingsGearing controlExternal combustion engineEngineering

A vehicular transmission for an internal combustion engine includes lead grooves disposed on an outer periphery of a shift drum having communication portions connecting a pair of gear train establishment portions extending circumferentially along the shift drum. The communication portions include half neutral portions formed at a center thereof, extending circumferentially along the shift drum. The resulting configuration suppresses an engagement noise to a minimum during changing of a gear position through a sliding motion of a shifter.

Owner:HONDA MOTOR CO LTD

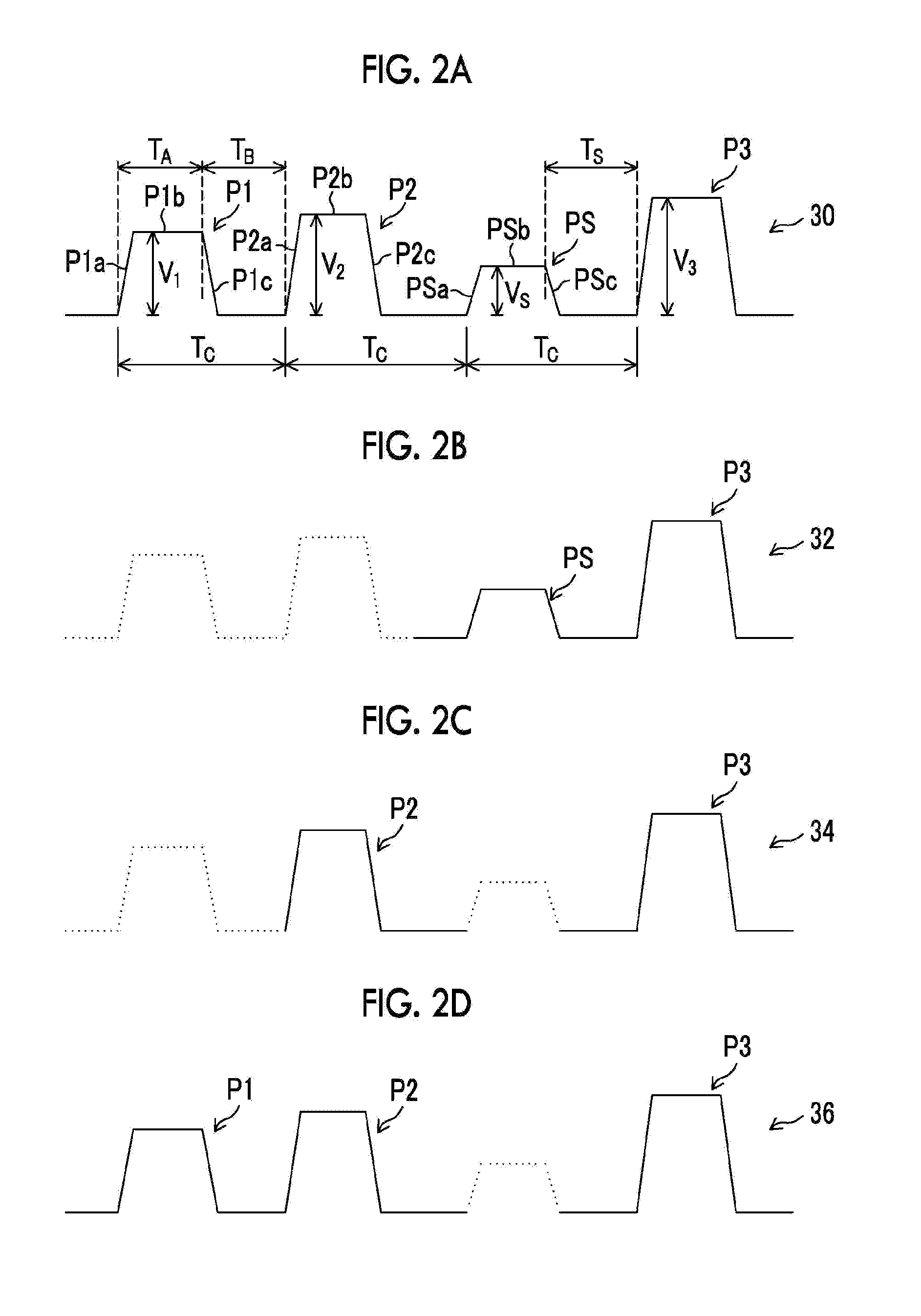

Device and method for driving liquid discharge head, liquid discharge apparatus, and ink-jet apparatus

ActiveUS8801128B2Decrease productivityExtended maintenance periodInking apparatusOther printing apparatusElectrical and Electronics engineering

A basic driving waveform which includes a plurality of jet pulses and a non-jet pulse just before the last jet pulse in one recording period is generated. A part of the pulses is removed from the basic driving waveform by maintaining at least the last jet pulse, and a driving signal that is applied to a discharge energy generation element is generated. In the case of using only the last jet pulse among the plurality of jet pulses is used for the jet, a first driving signal that includes the non-jet pulse just before the last jet pulse is generated. In the case of joining the last jet pulse and at least another jet pulse among the plurality of jet pulses to use the pulses for the jet, a second driving signal that is configured to remove the non-jet pulse is generated.

Owner:FUJIFILM CORP

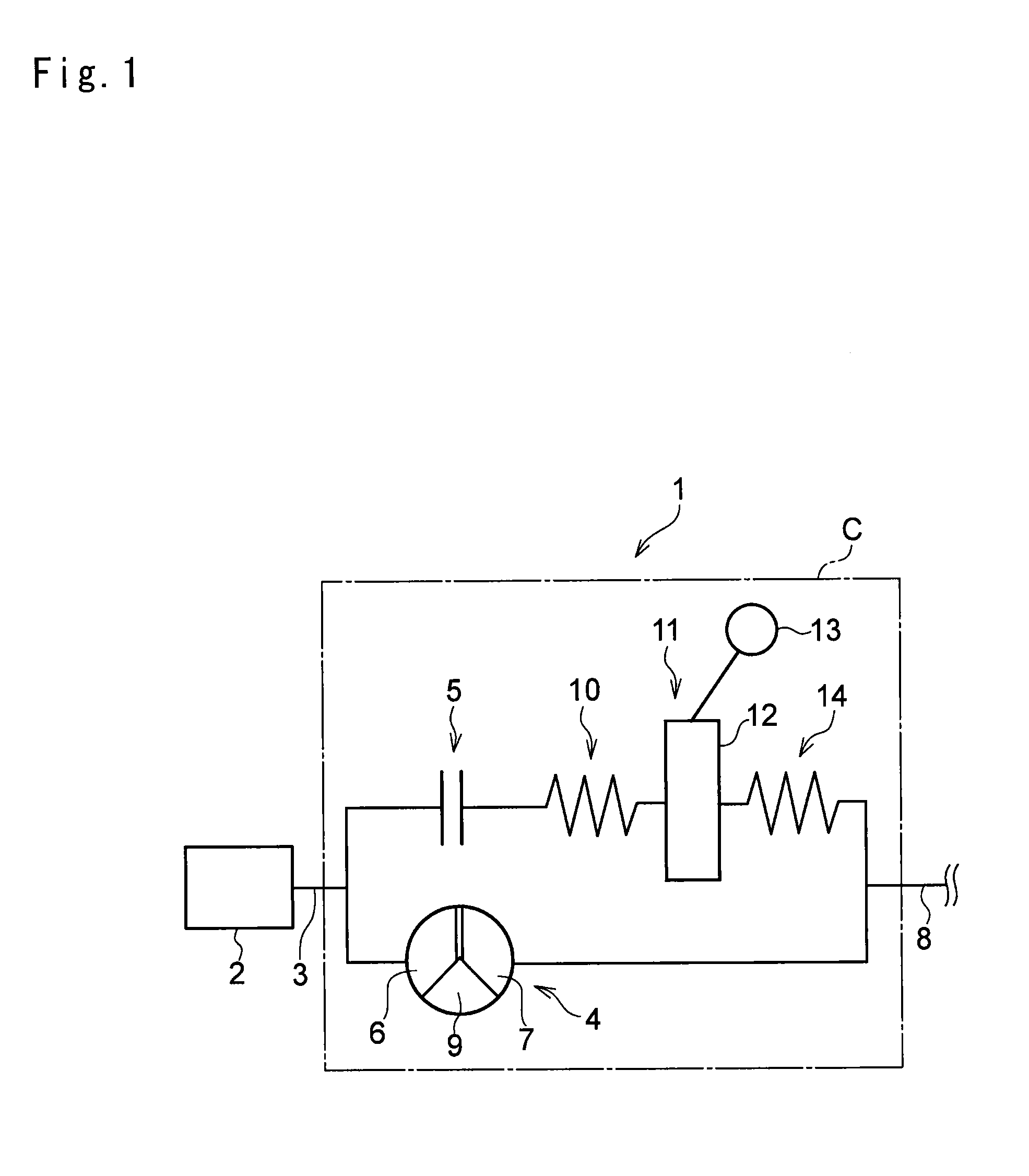

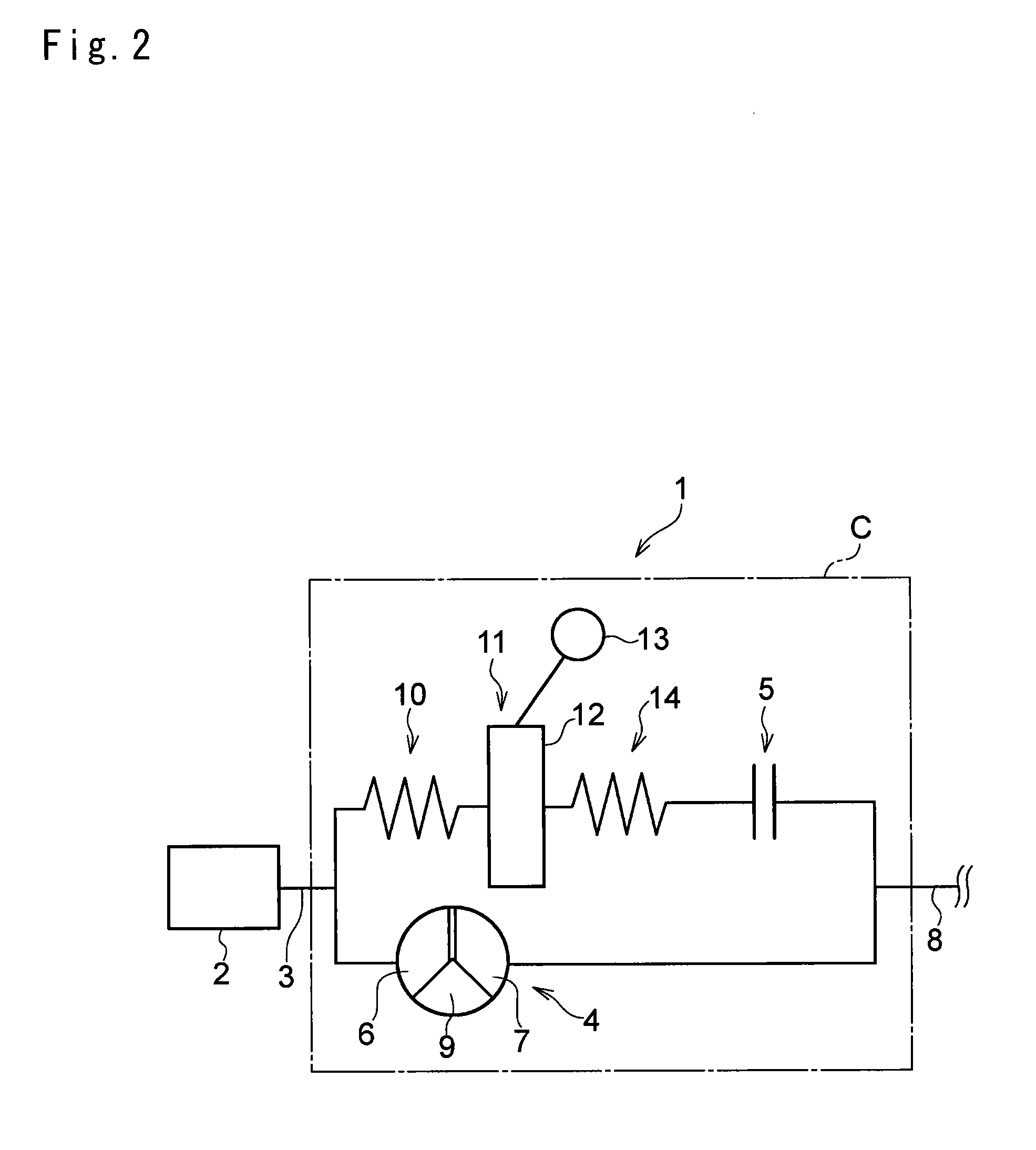

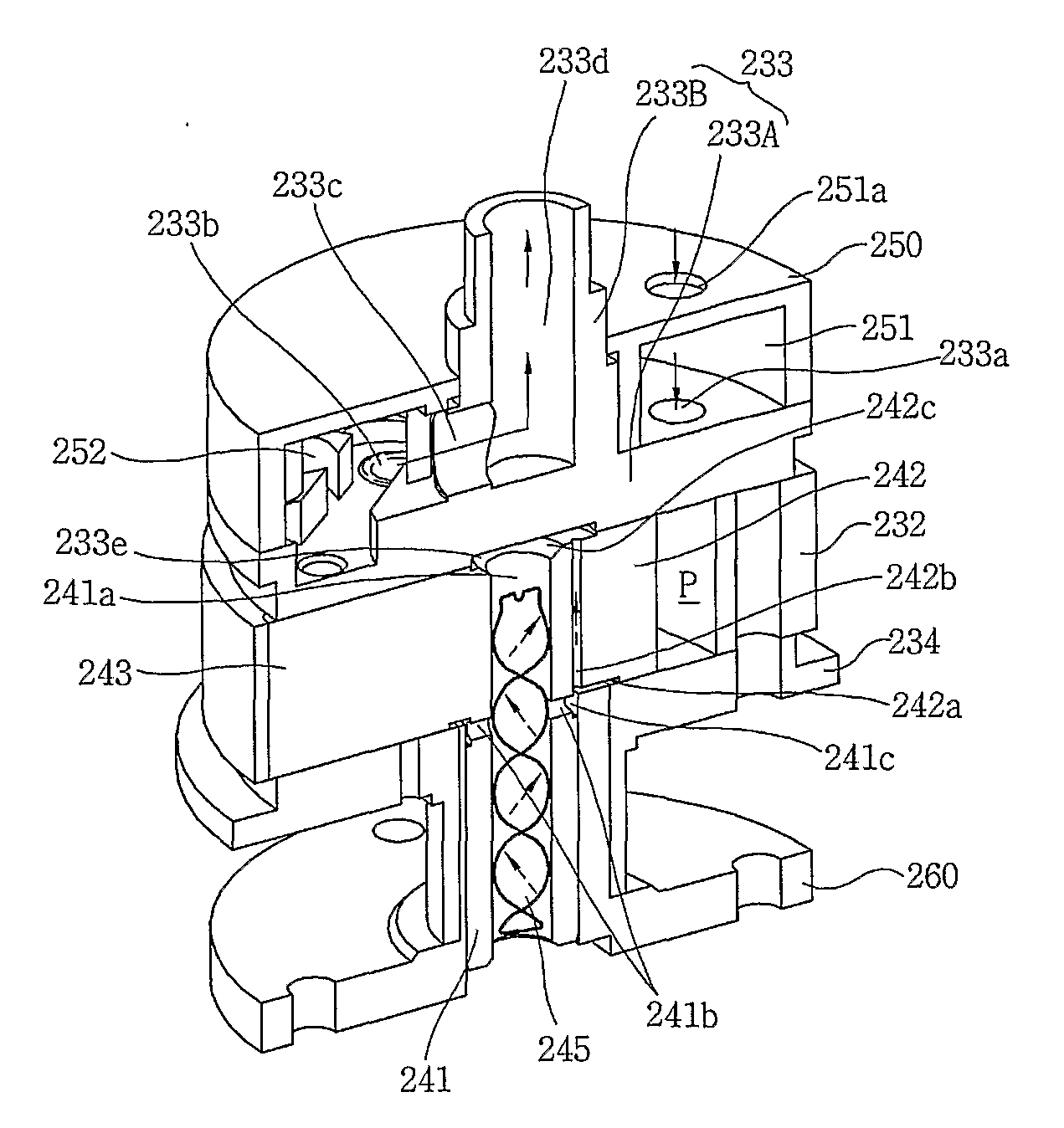

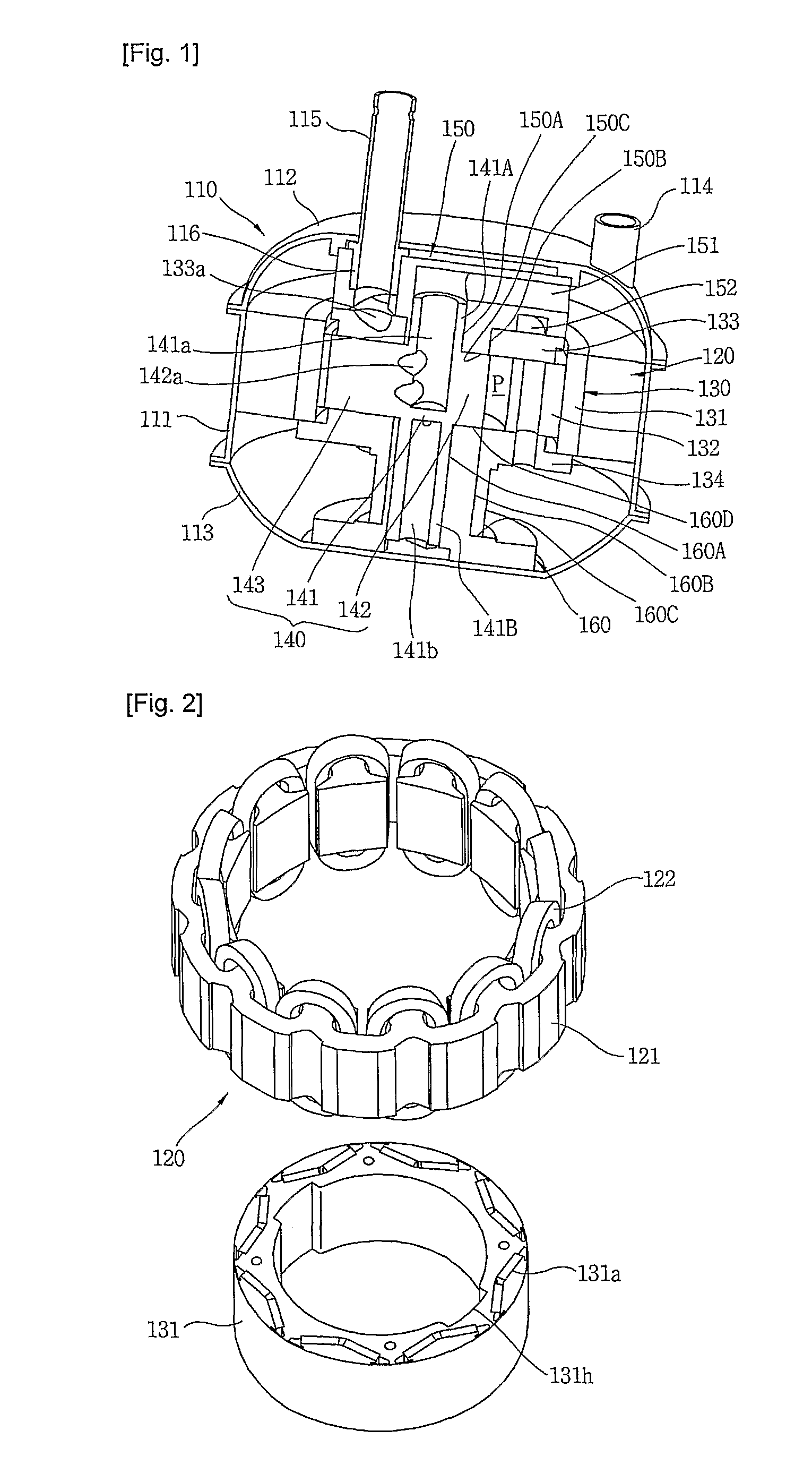

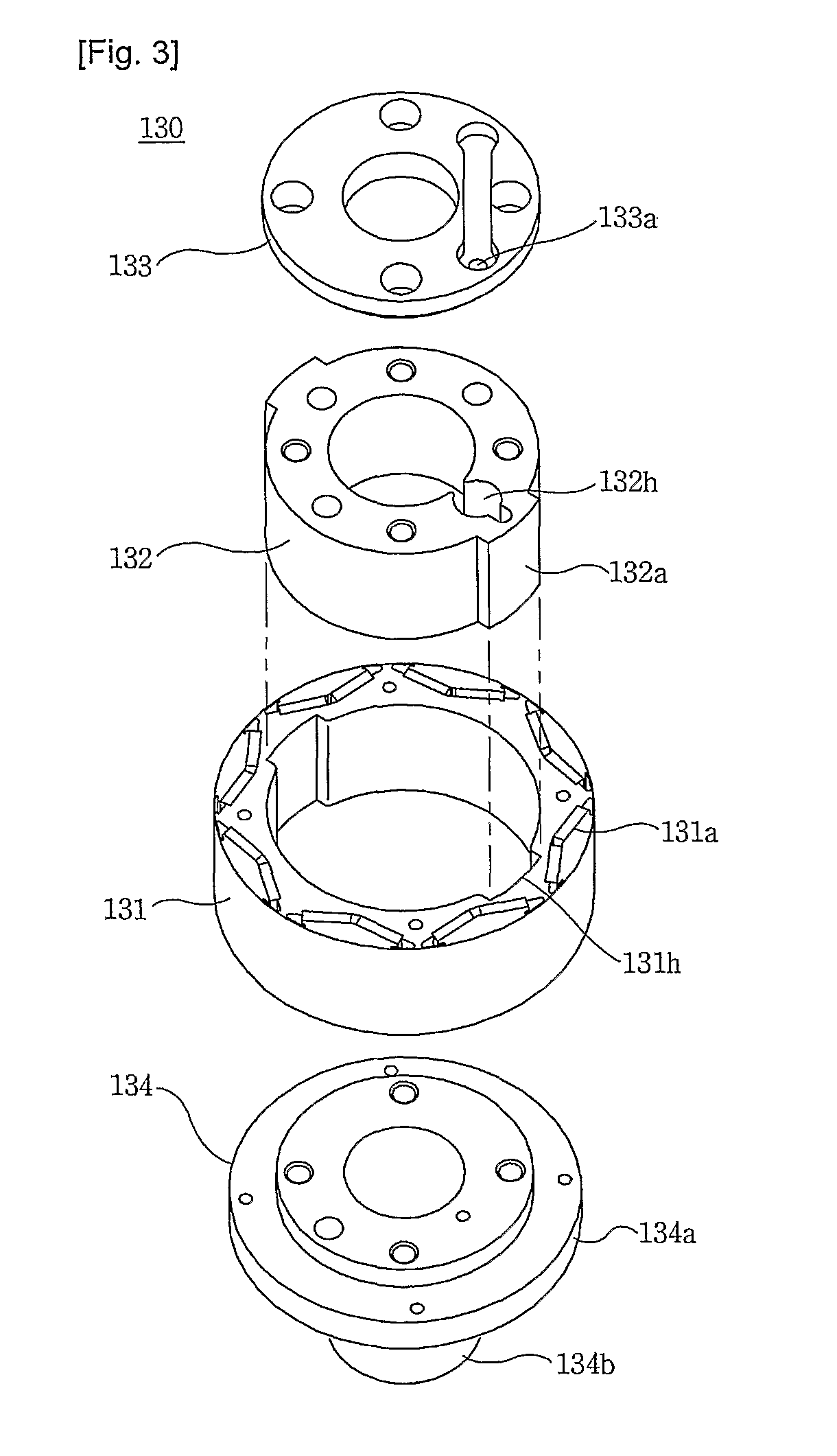

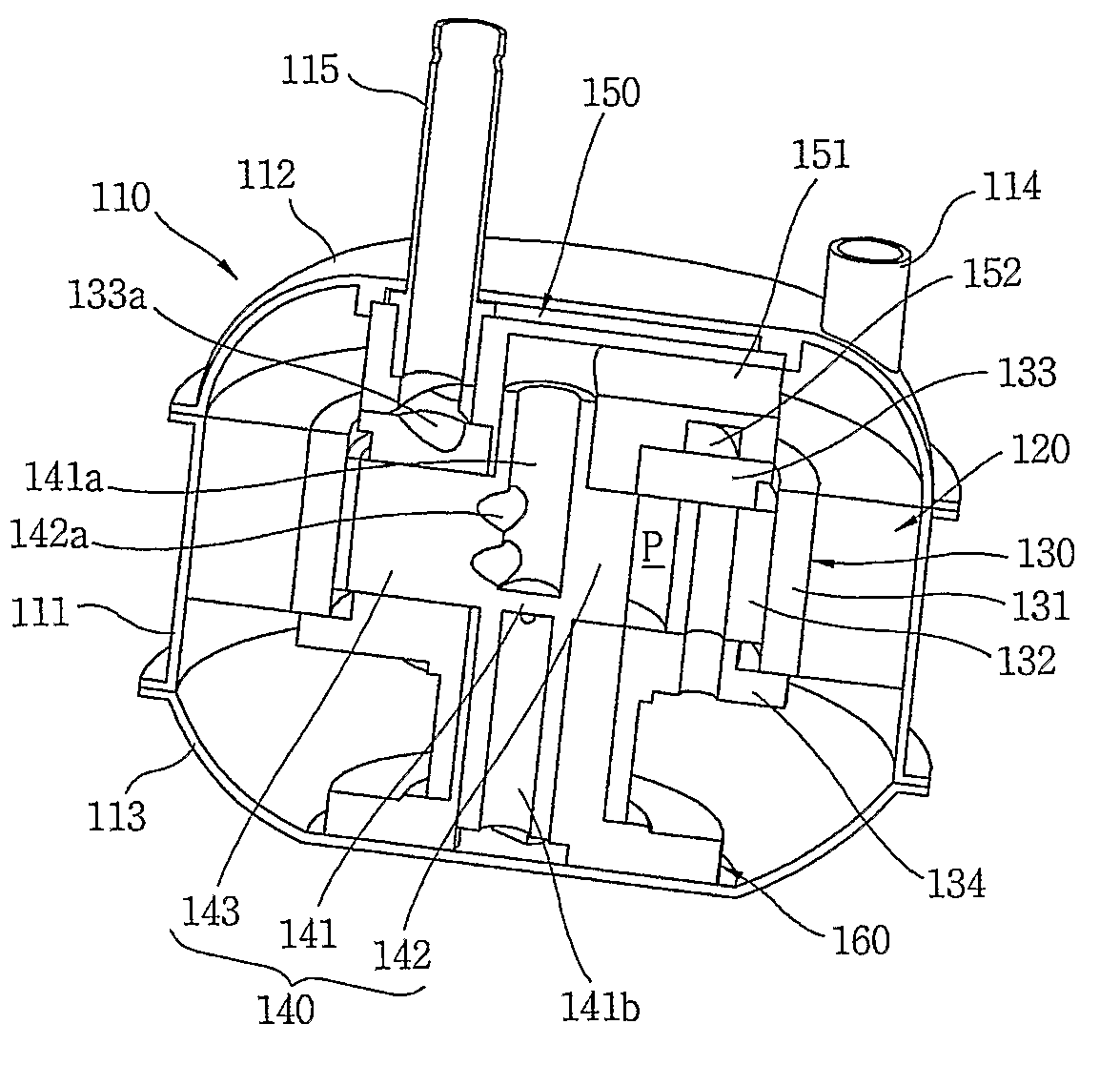

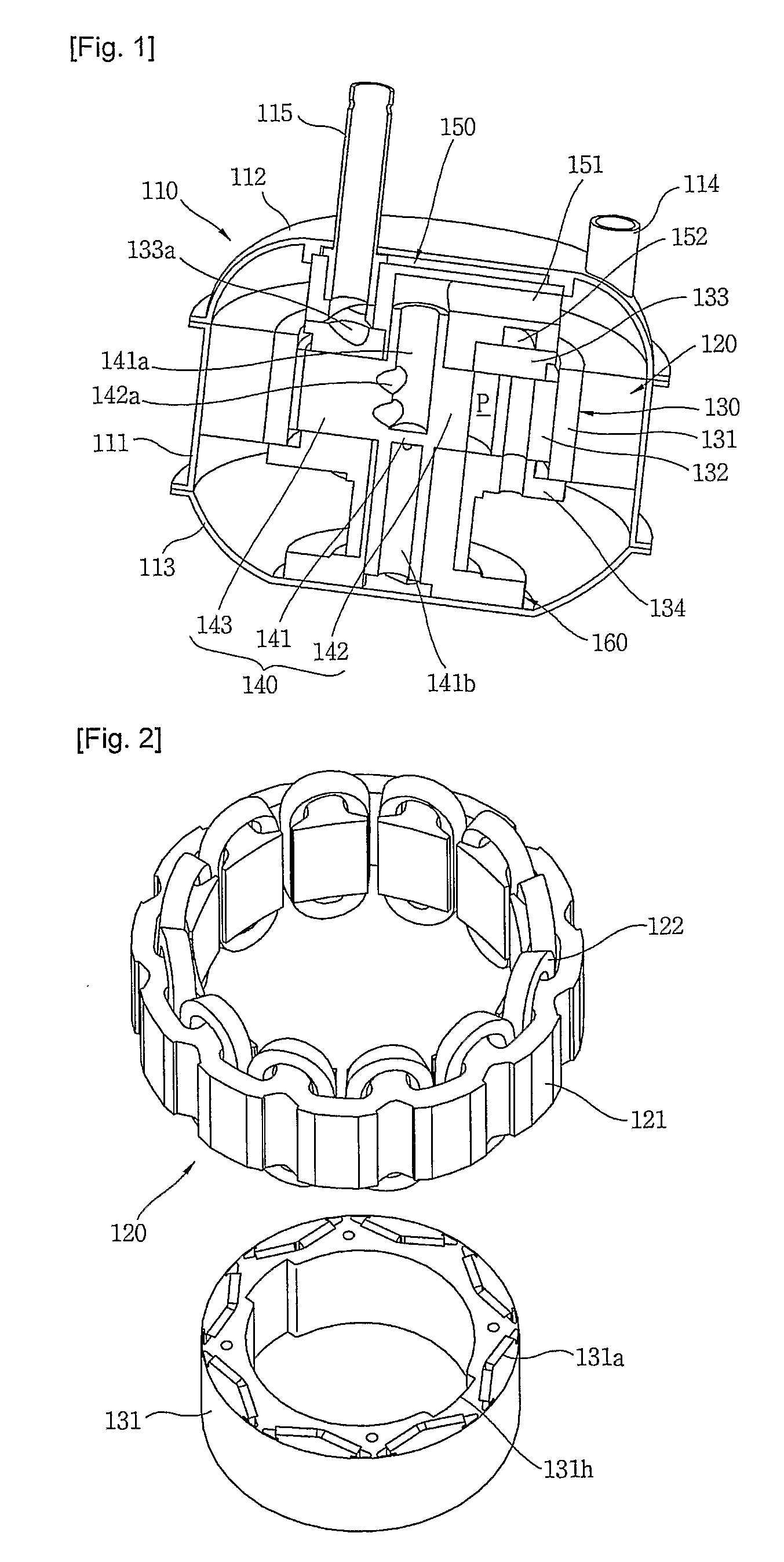

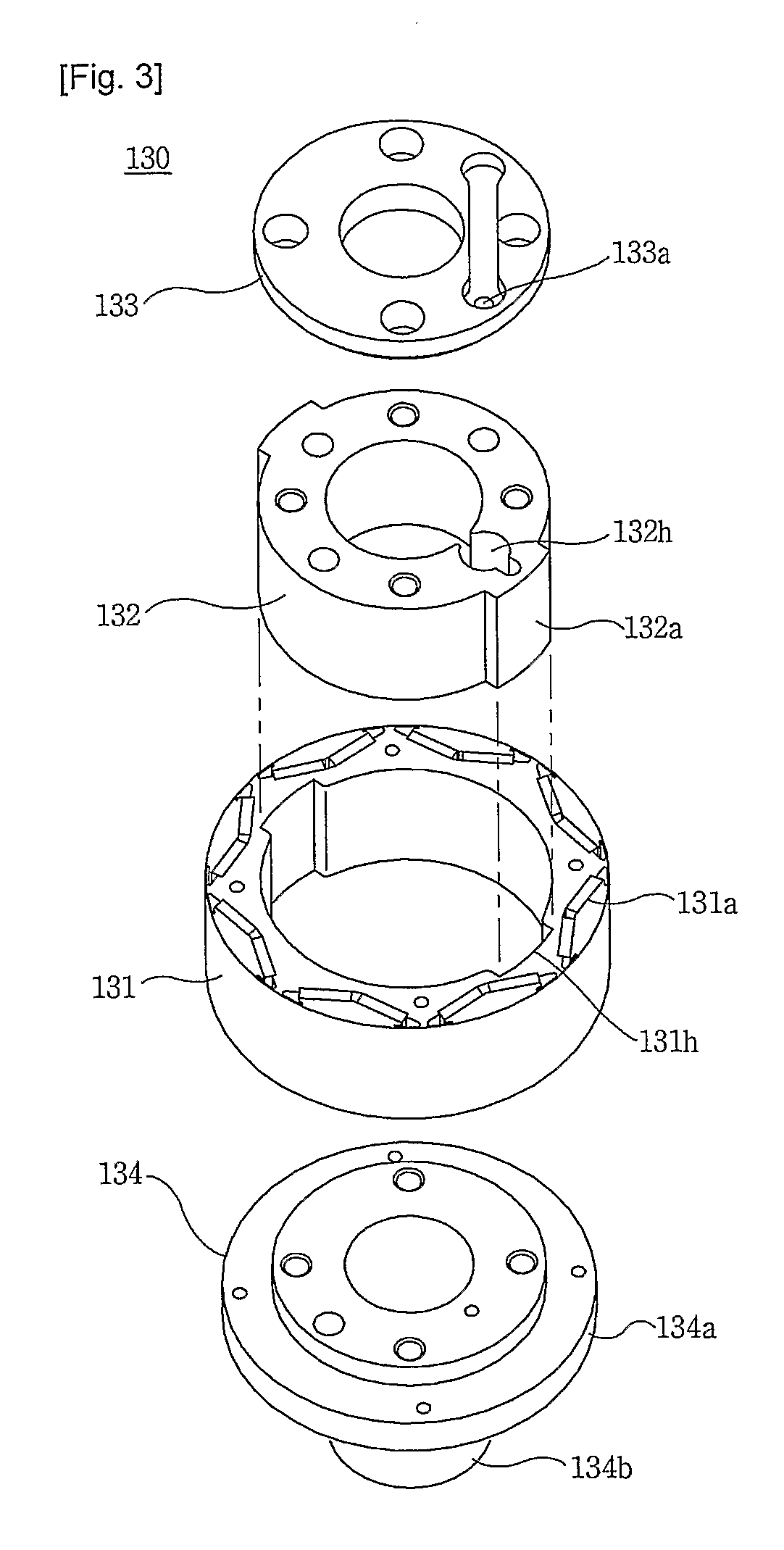

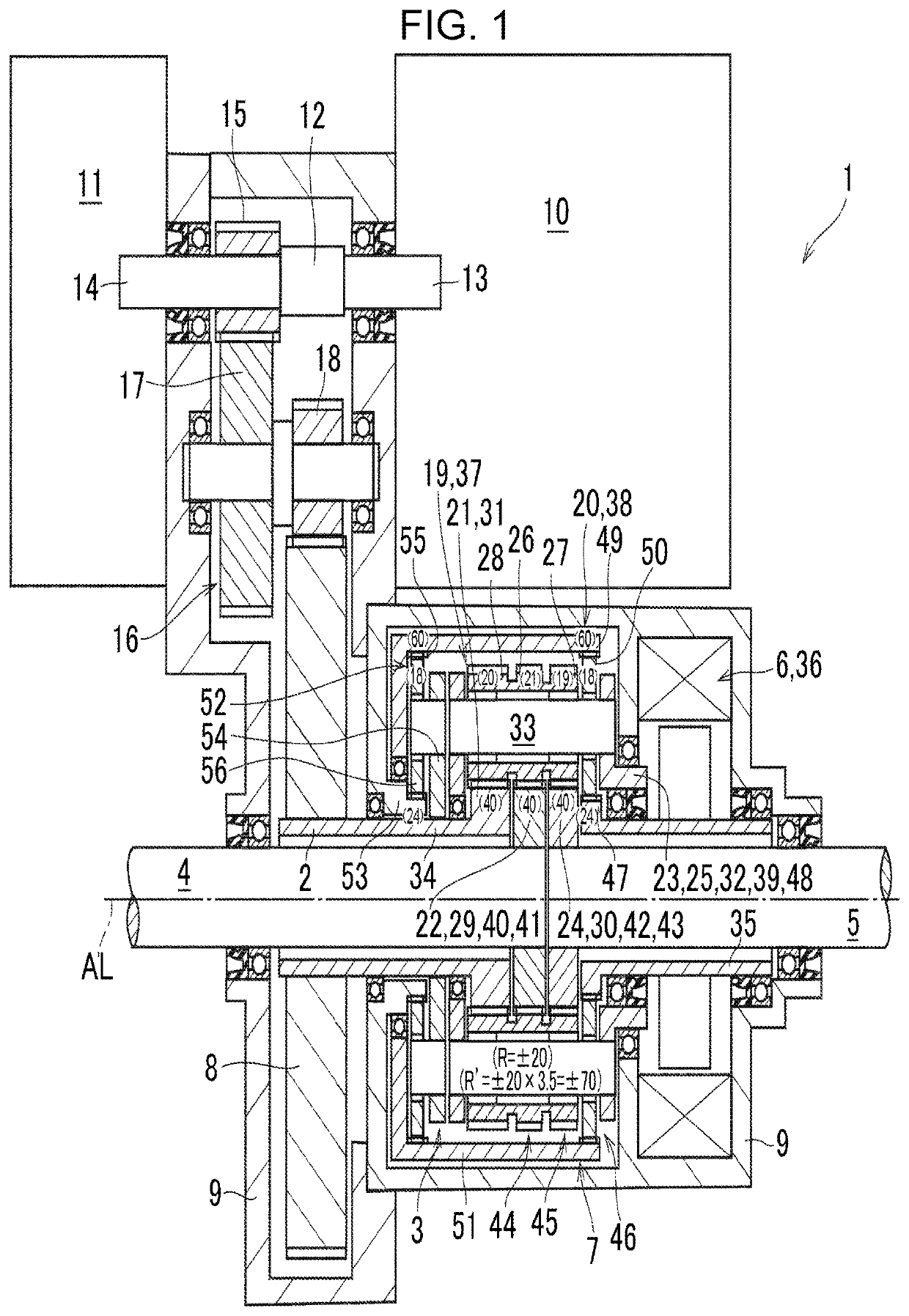

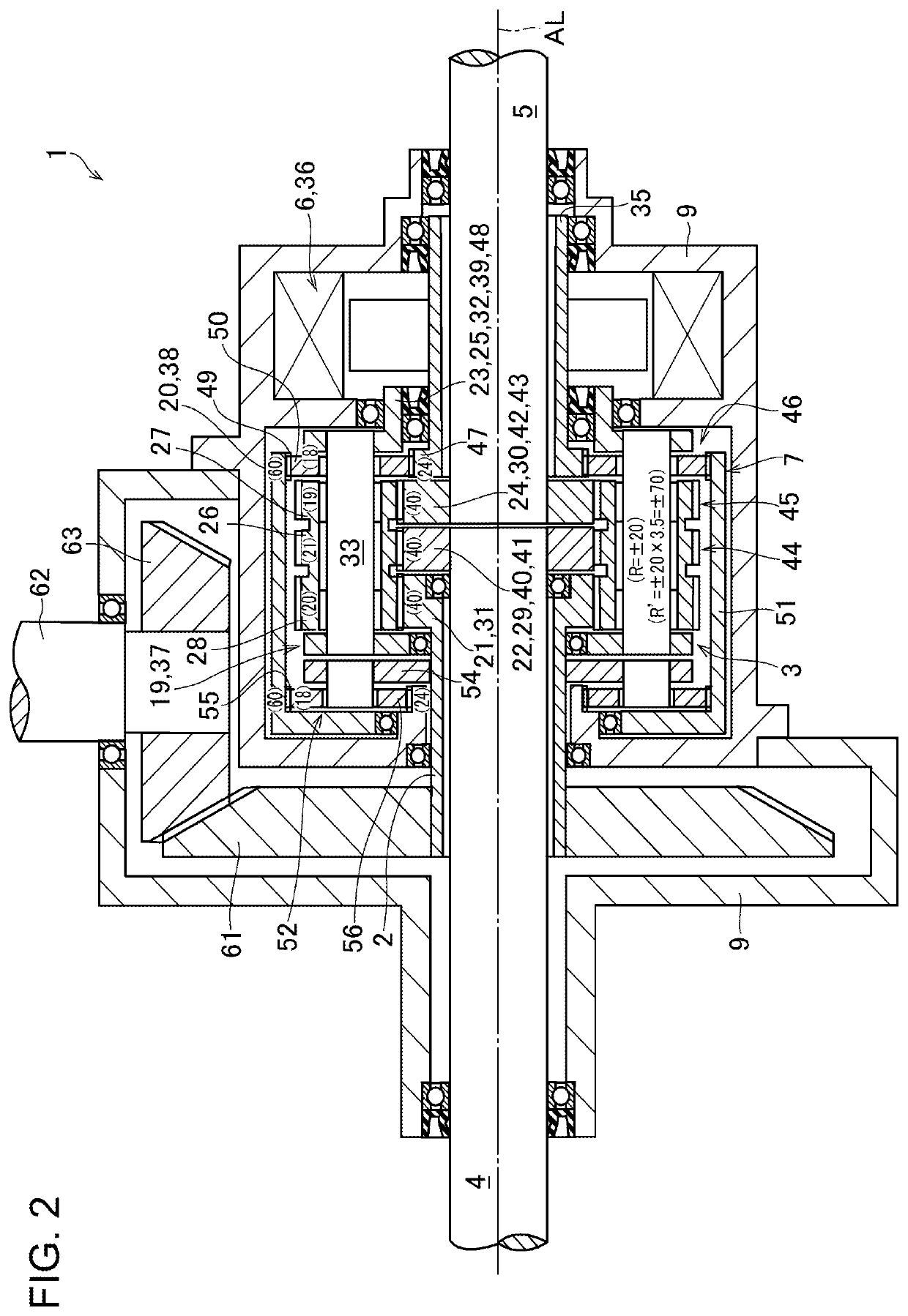

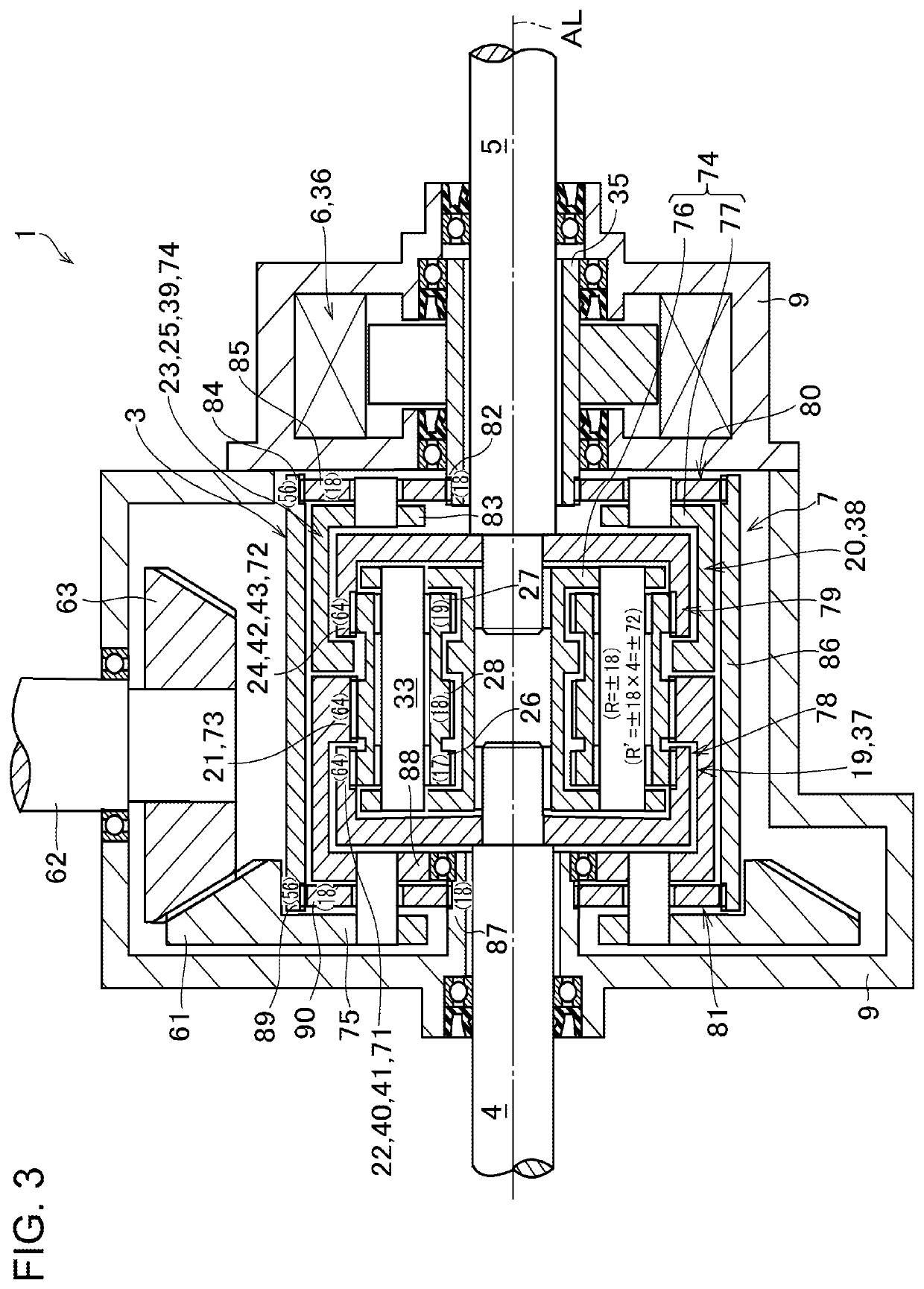

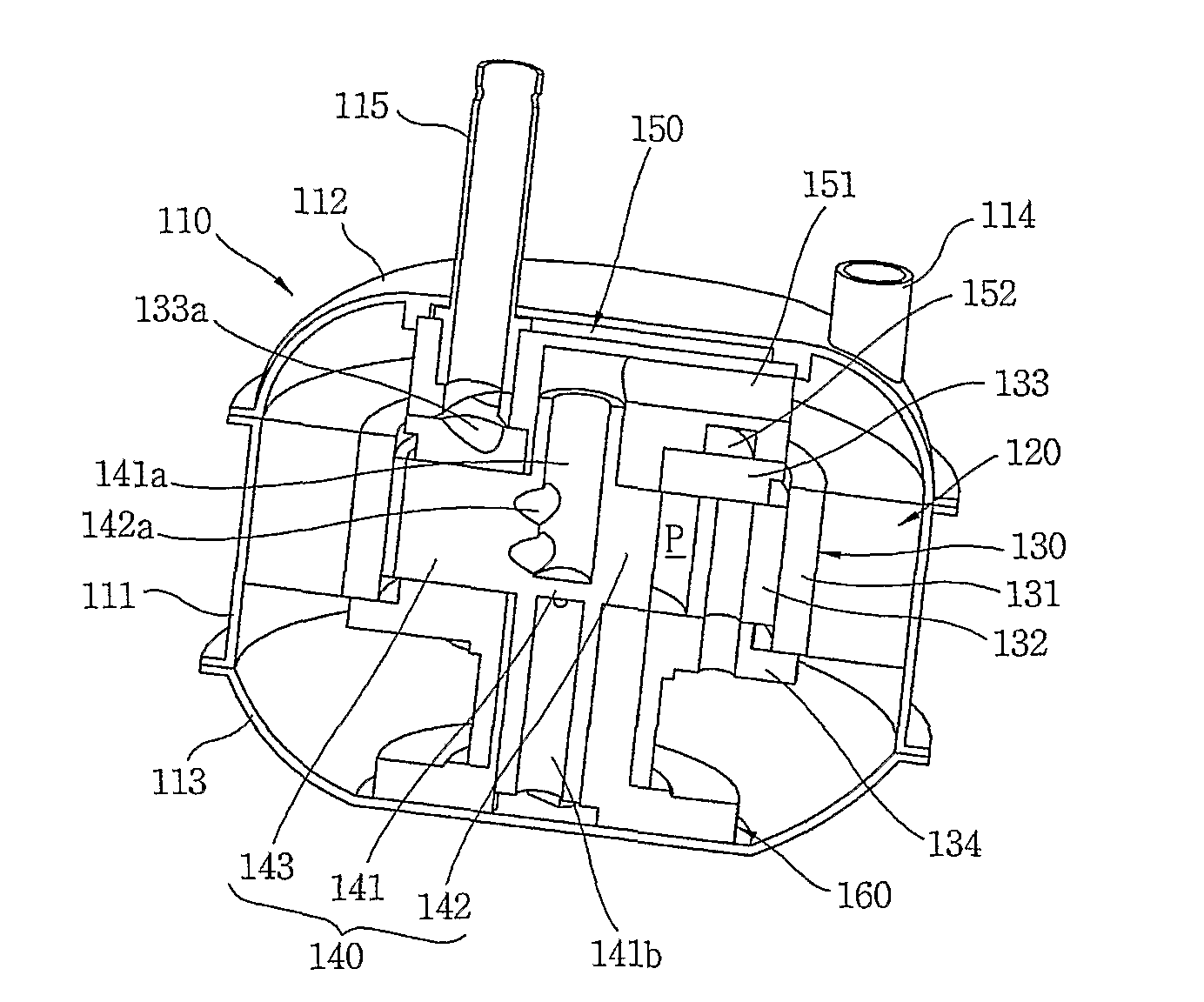

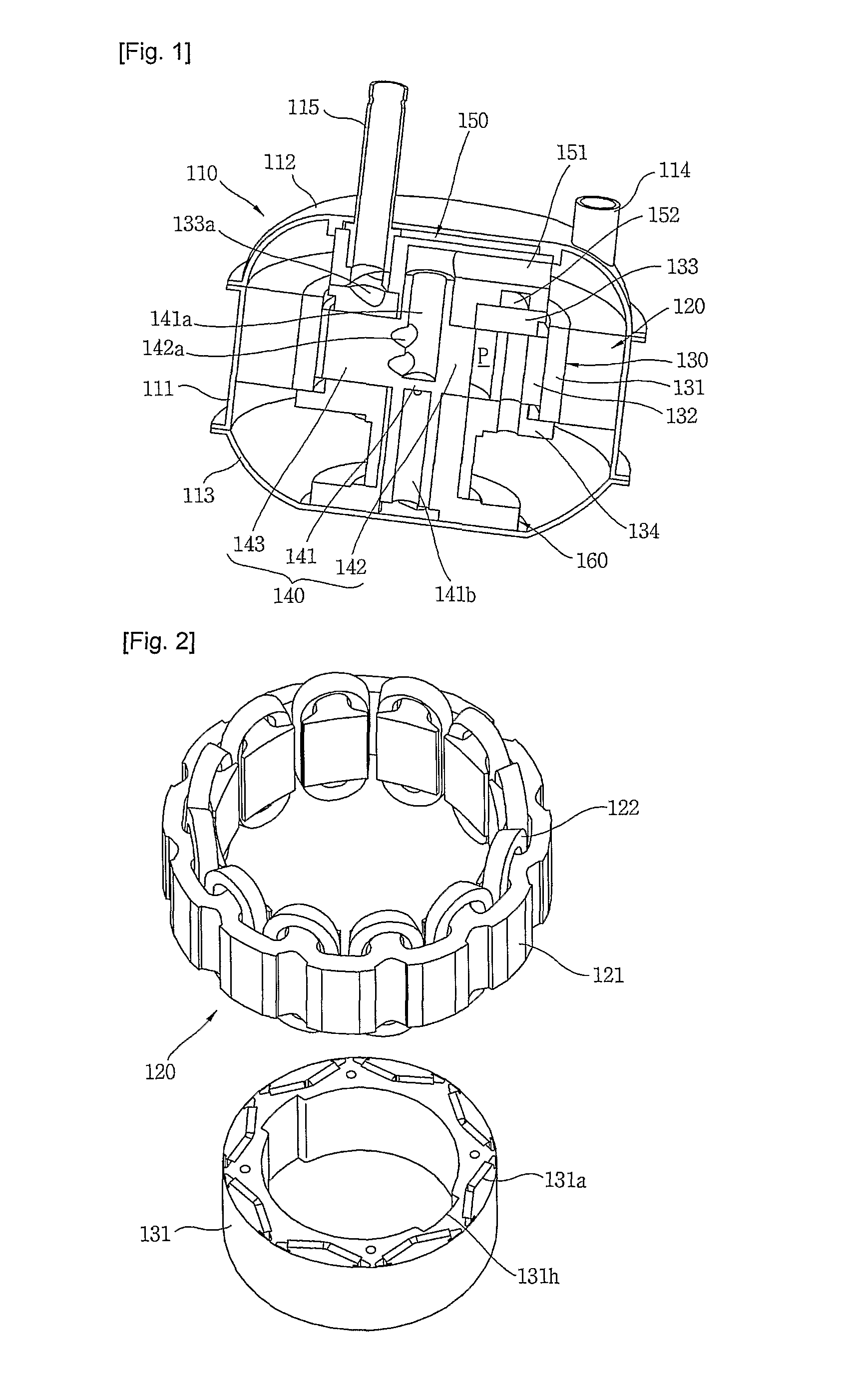

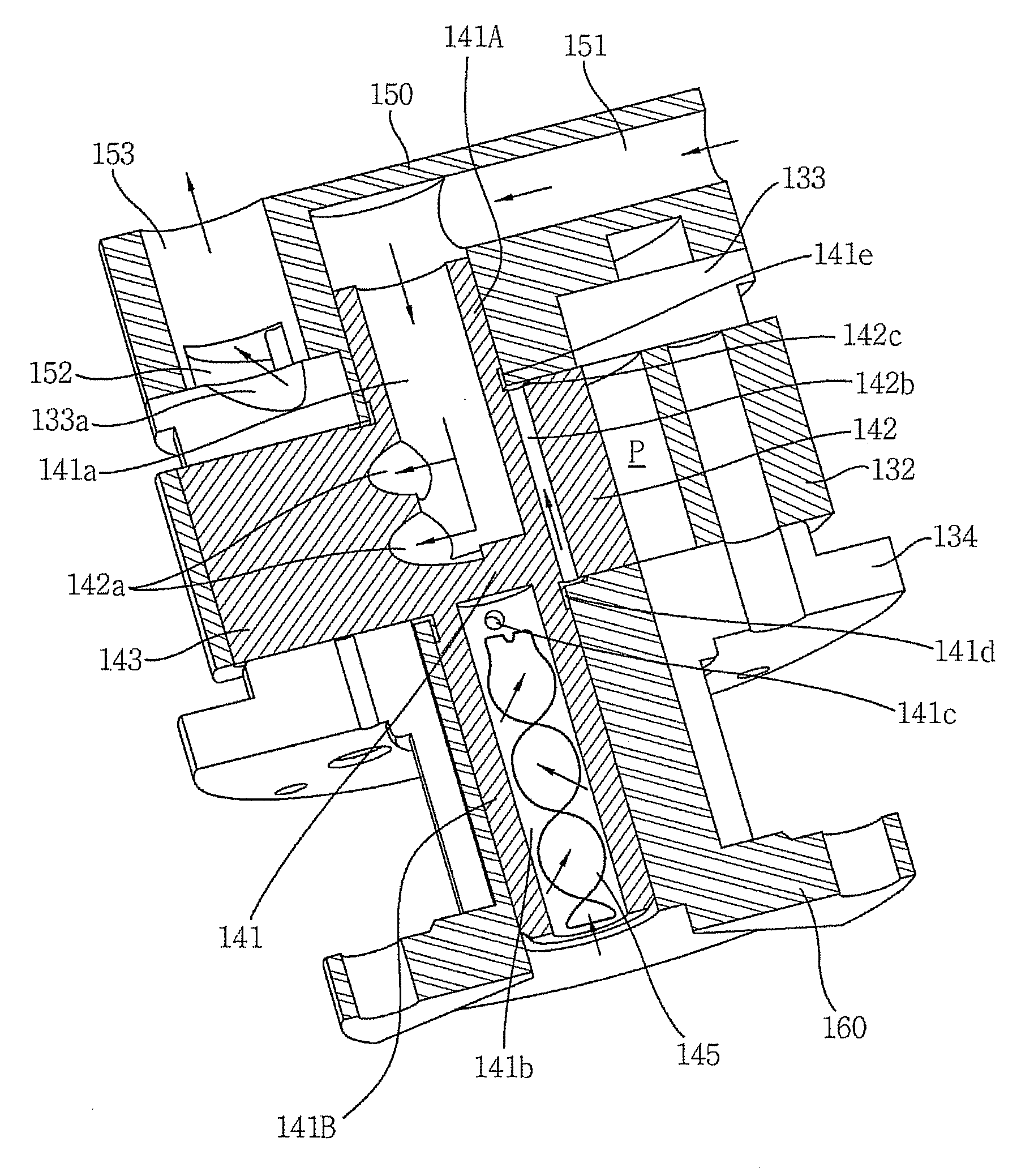

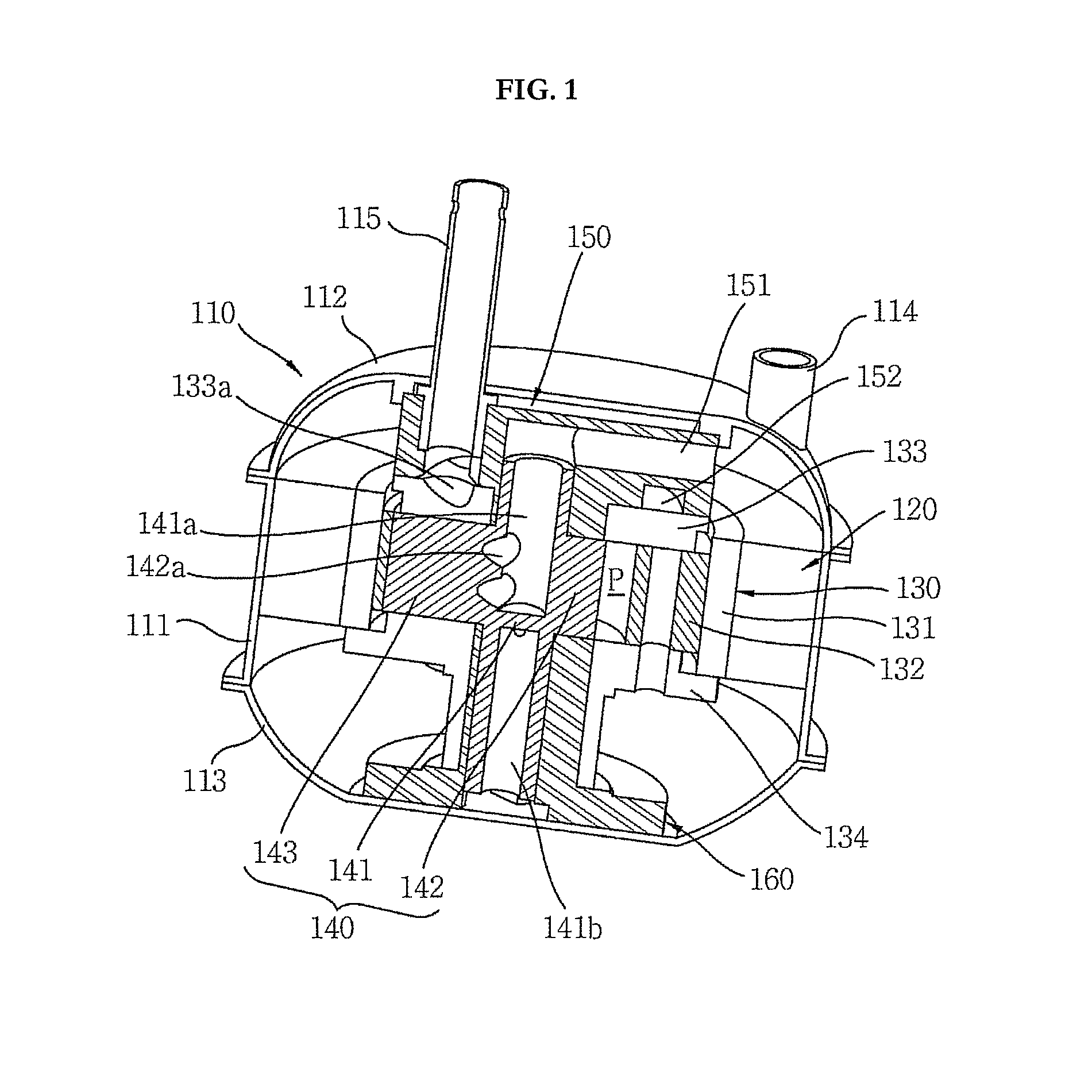

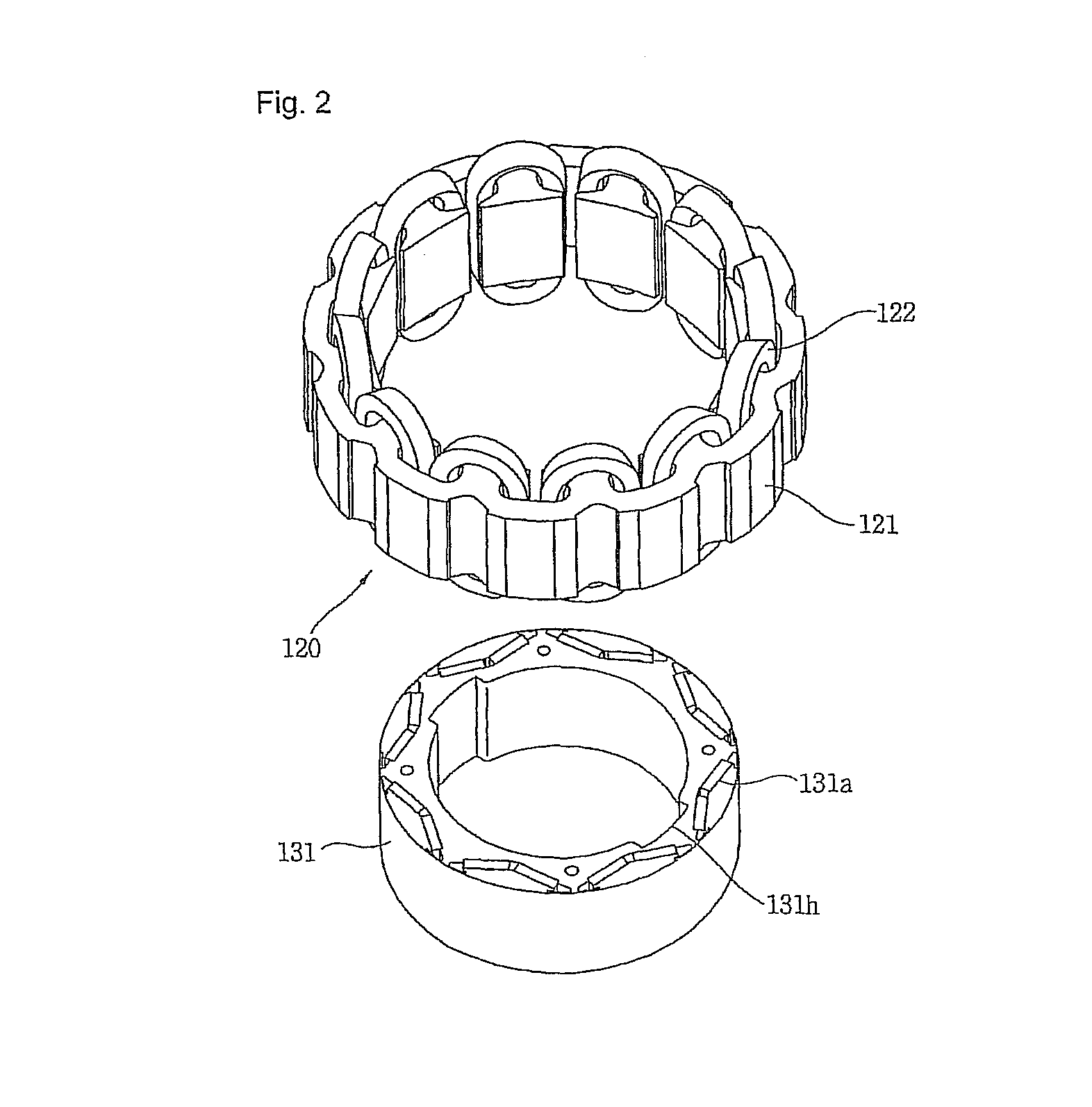

Compressor

ActiveUS20110129370A1Minimize heightSmall sizeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringElectromagnetic field

A compressor comprises: a hermetically sealed container; a stator fixedly installed within the hermetically sealed container; a first rotary member rotating, within the stator, around a first rotary shaft longitudinally extending concentrically with the center of the stator by a rotating electromagnetic field from the stator, and provided with first and second covers fixed to upper and lower parts and rotating integrally with each other; a second rotary member space for compressing a refrigerant in a compression space formed between the first and second rotary members while rotating, within the first rotary member, around the second rotary shaft extending through the first and second covers upon receipt of a rotational force from the first rotary member; a vane for transmitting the rotational force to the second rotary member from the first rotary member, and partitioning the compression space into a suction region for sucking the refrigerant and a compression region for compressing / discharging the refrigerant; and first and second bearings fixed to the inside of the hermetically sealed container, and rotatably supporting the first and second rotary members in an axial direction.

Owner:LG ELECTRONICS INC

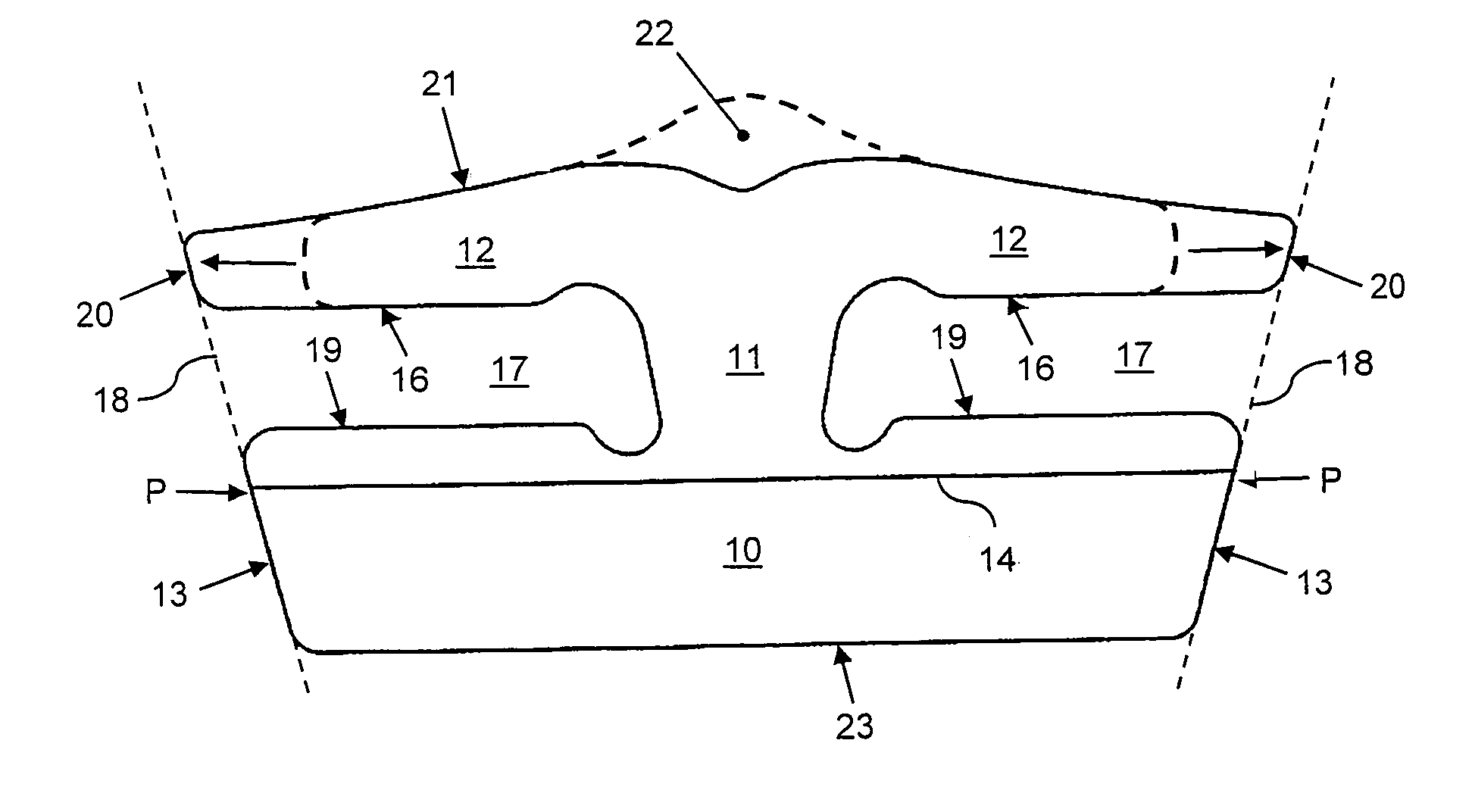

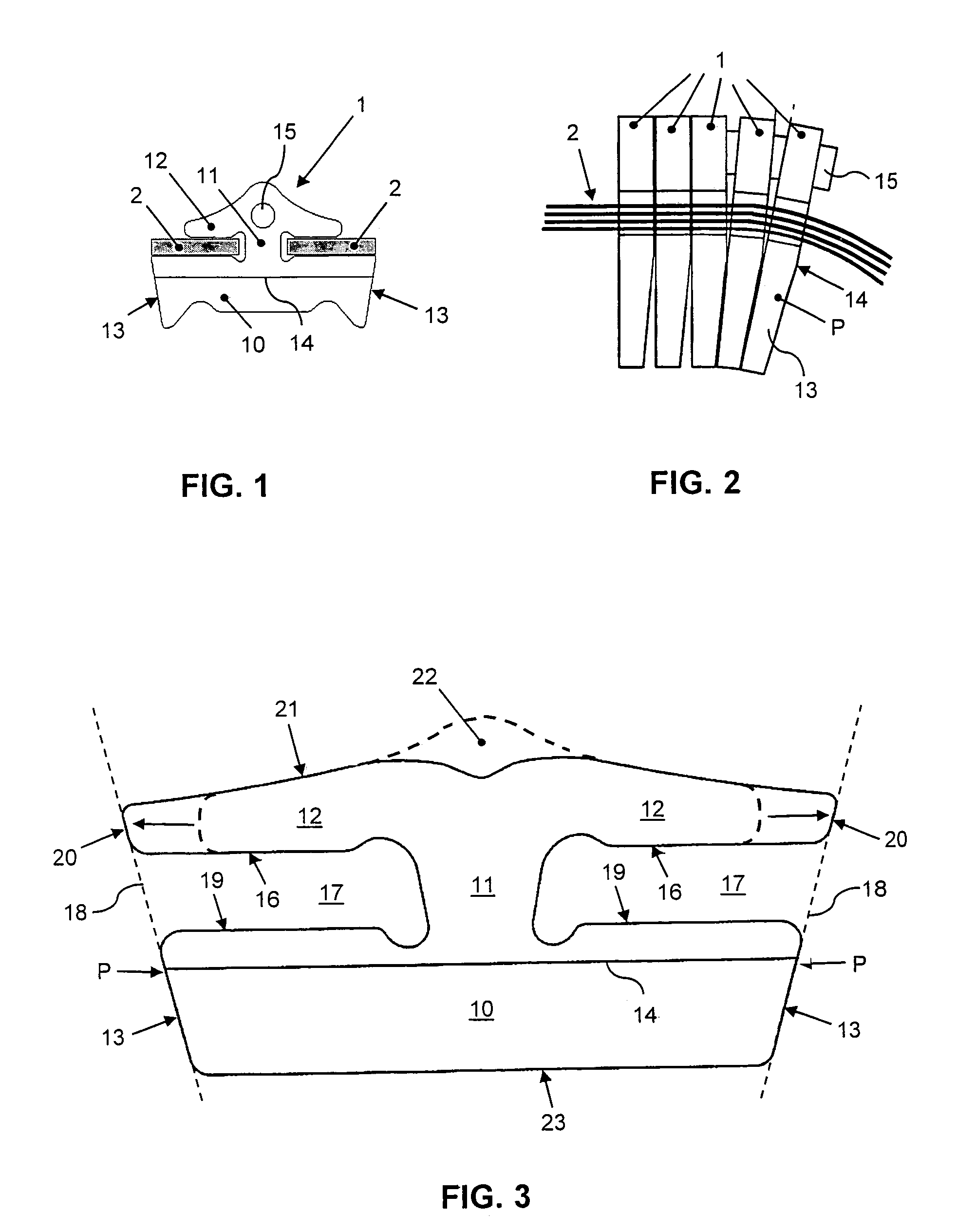

Metal driving belt

InactiveUS7201689B2Low internal friction forceReduce internal frictionV-beltsDriving beltsEngineeringLower limit

Driving belt provided with an enclosed tension element and metal transverse elements accommodated so as to be movable in a longitudinal direction along the tension element. The transverse elements each comprise a body part, a head part and a neck part therebetween. On either side of the neck part between the body part and the head part two axially oriented openings are present, for accommodating in each a part of the tension element. The body part includes side contact surfaces oriented substantially in an axial direction and diverging from each other in the radial direction, and with a substantially axially oriented tilting line and in which an upper limit of an opening formed by the head part extends in the axial direction at least to an imaginary line, which extends from the radially lower limit to the radially upper limit of the respective opening in line with a contact surface.

Owner:VAN DOORNES TRANSMISSIE BV

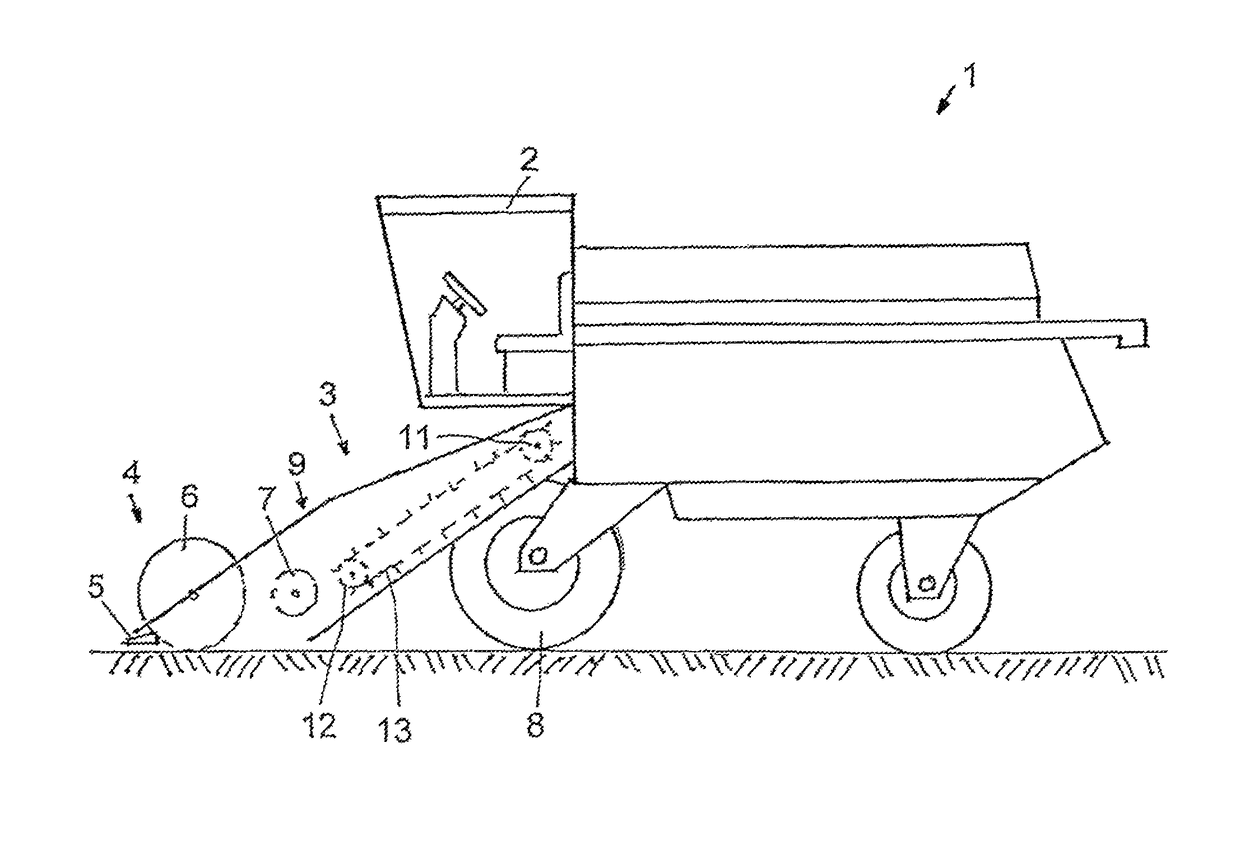

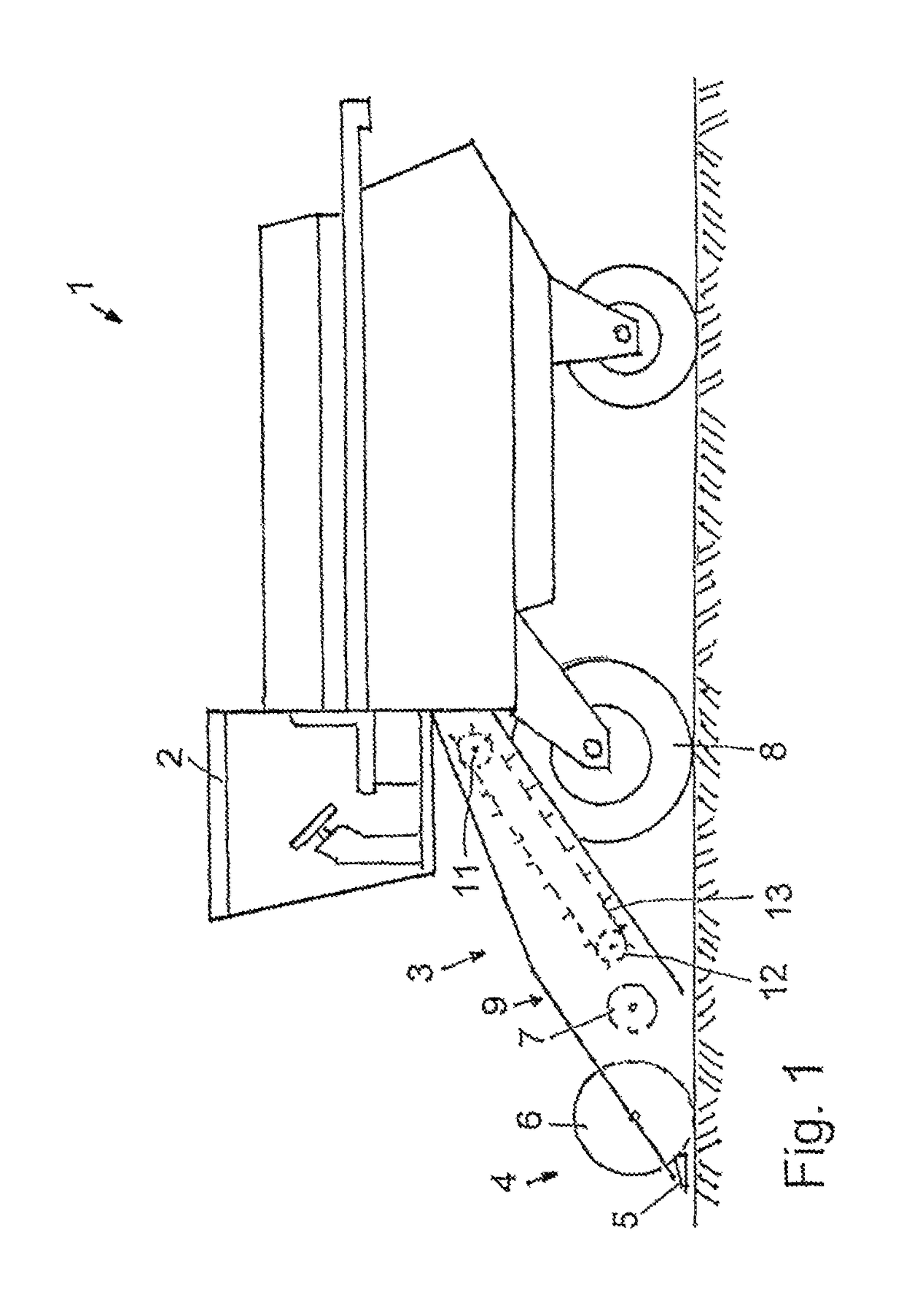

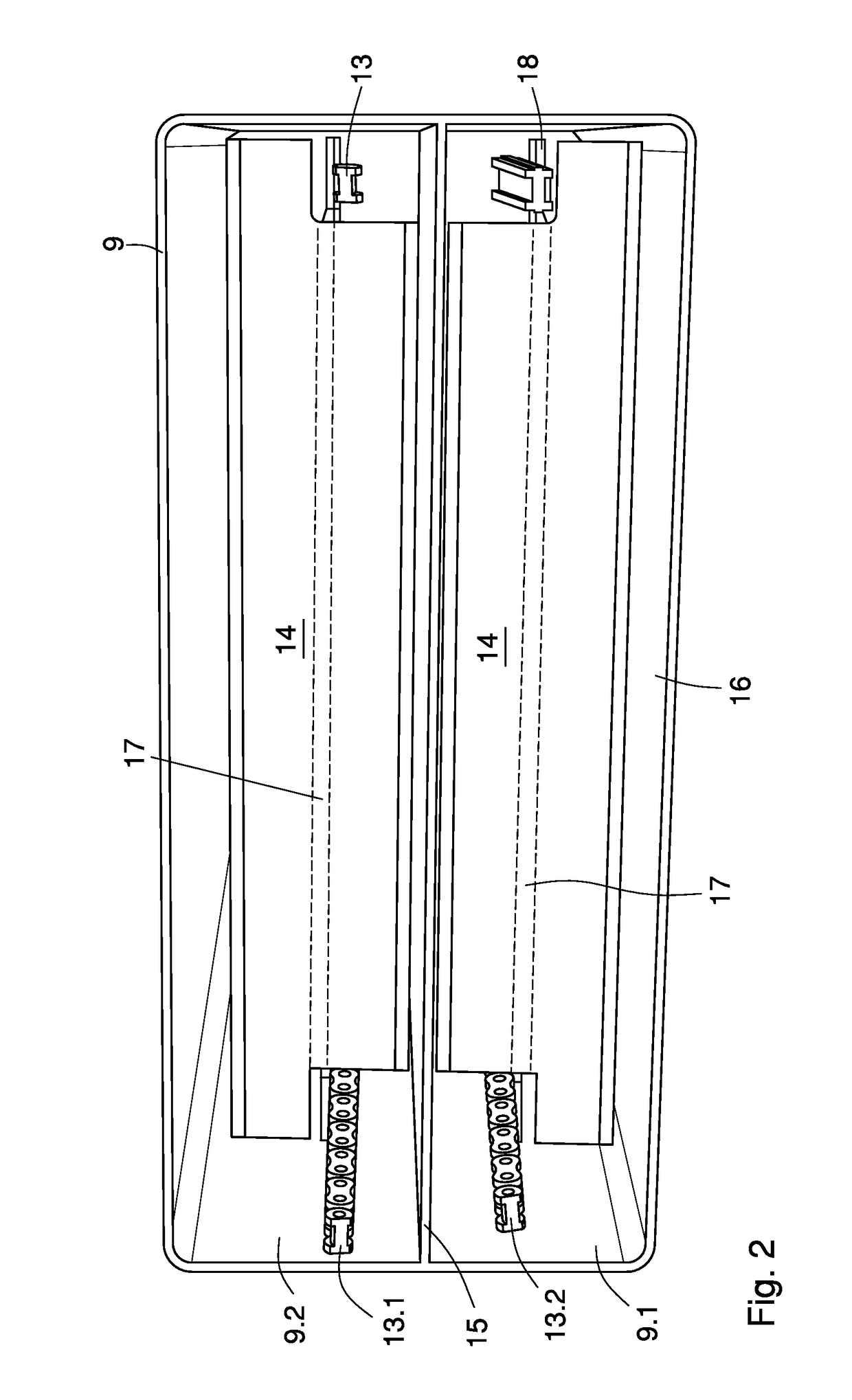

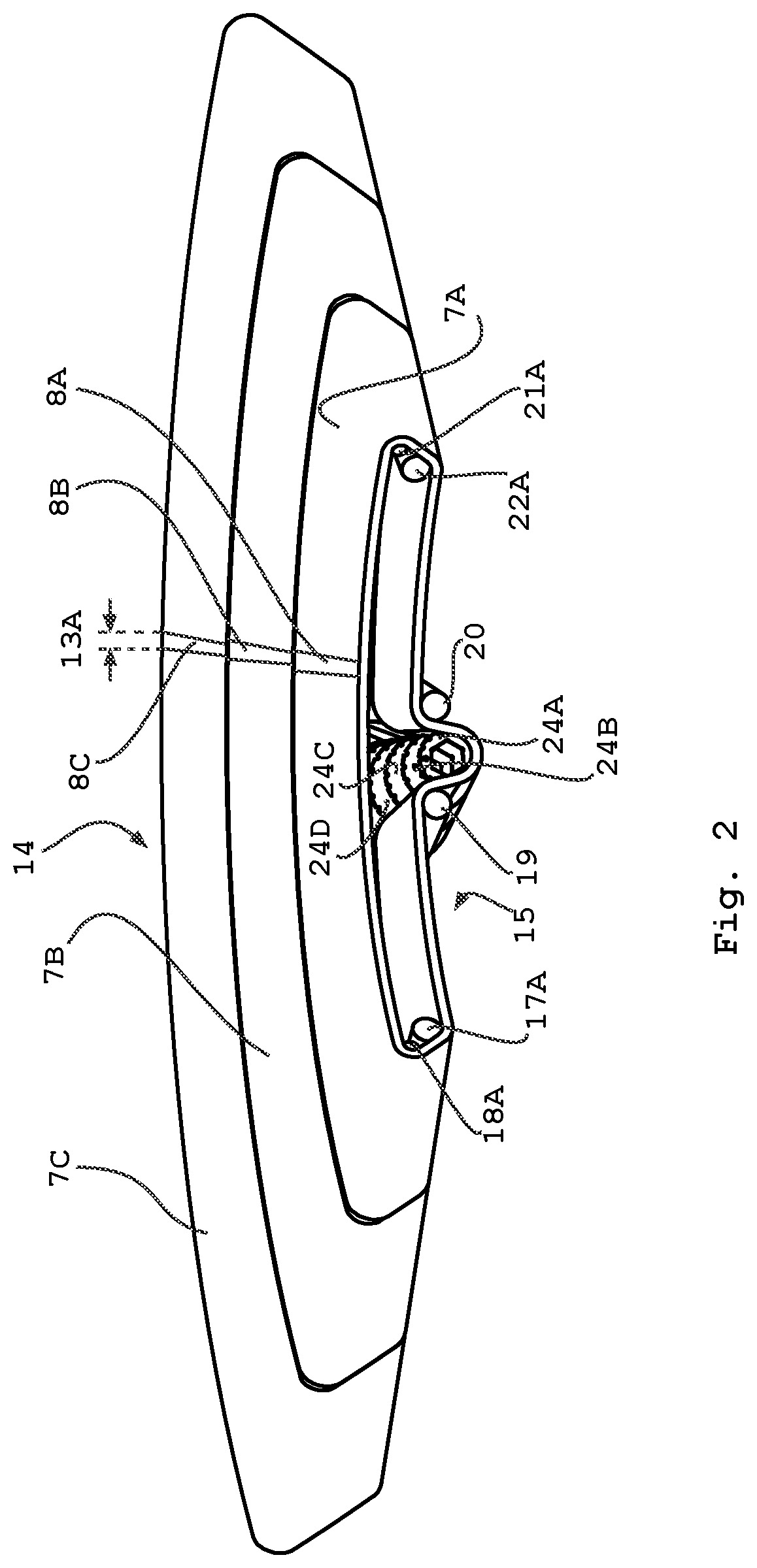

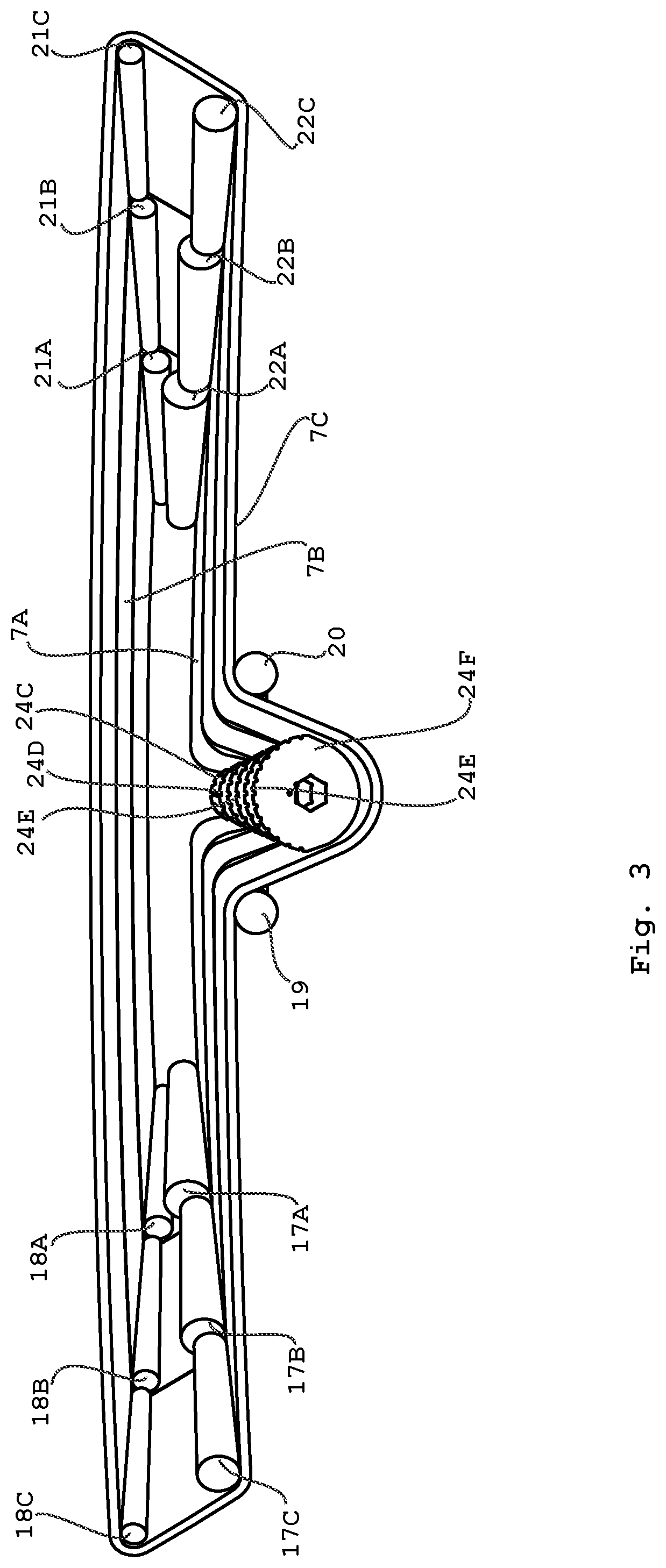

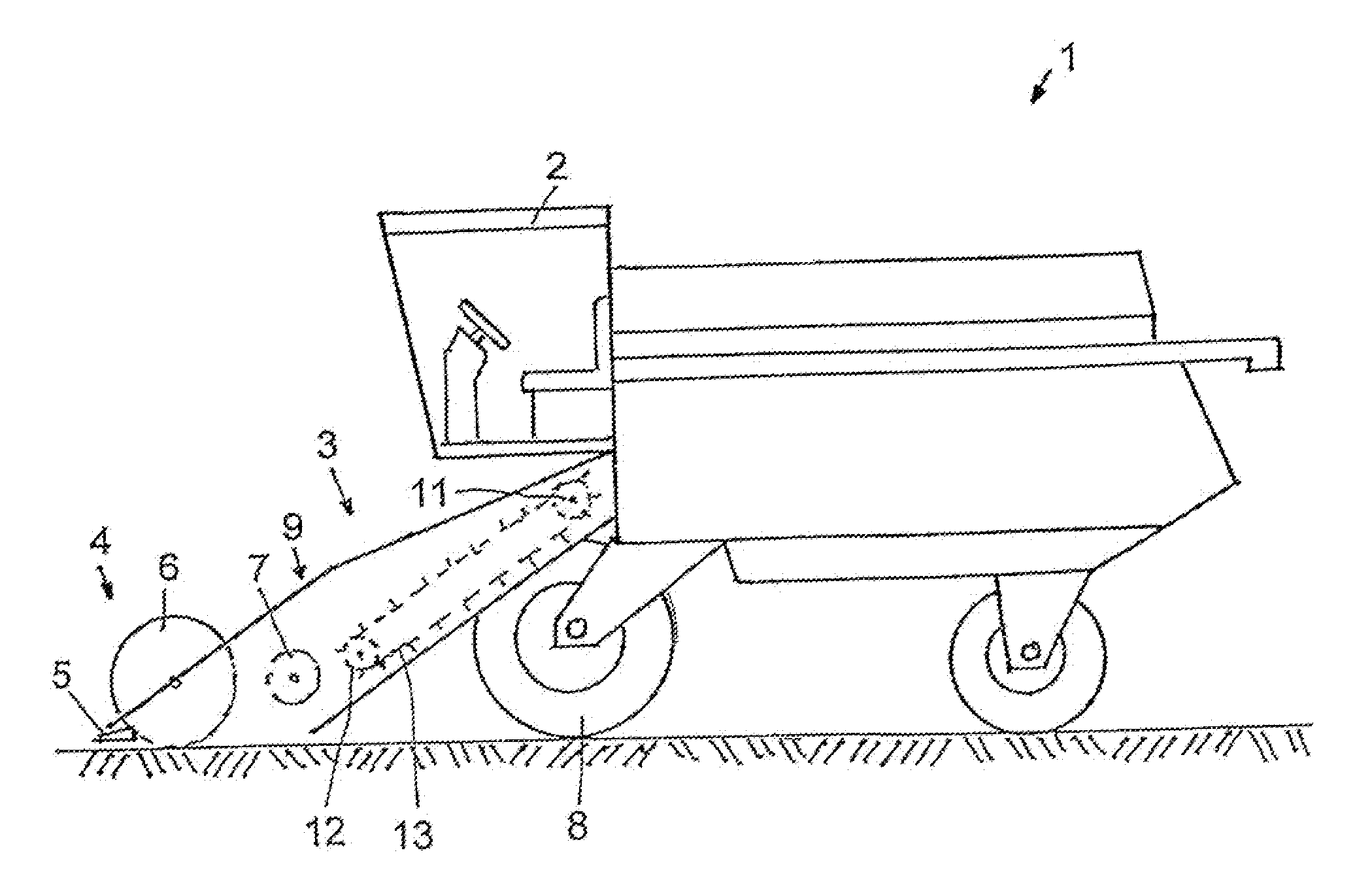

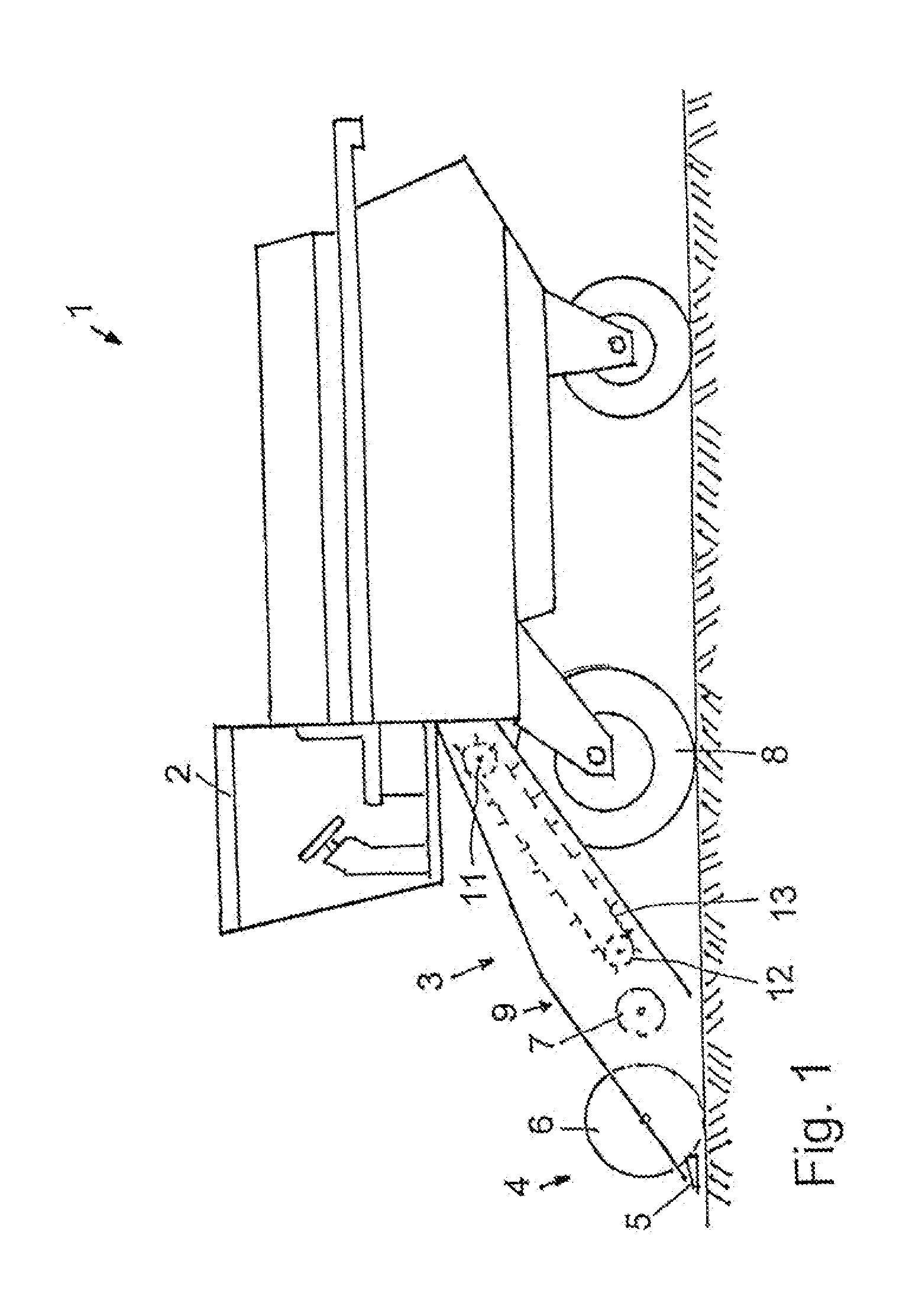

Inclined conveyor for combine harvesters with negative pressure inlet

An inclined conveyor for a combine harvester has two drive elements which define a conveying direction and revolve in a conveying duct. Conveying duct is divided into an overshot return duct and an undershot conveying duct by a separating element situated between the upper run and the lower run of the drive element. Drive element is interconnected by carriers situated transversely with respect to conveying direction that convey harvested crop in undershot conveying duct. The difference in speed between the carrier bars and harvested crop stream is eliminated, and at least reduced, by additional acceleration of harvested crop stream. Carrier bars serve as carriers, and as acceleration elements for the harvested crop. That is because the cross section of each of the carrier bars viewed in conveying direction, occupies at least 30% of the smallest internal cross section of undershot conveying duct.

Owner:ARNOLD JAGER HLDG GMBH

Compressor

InactiveUS20110120174A1Minimize heightReduce in sizeRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsFriction lossRefrigerant

The present invention relates to a rotary compressor comprising an electric motor part for supplying electric power and a compression mechanism part for compressing a refrigerant while first and second rotary members (130,140) rotate upon receipt of the electric power from the electric motor part, and more particularly to, a compressor which enables a compact design by forming a compression space within the compressor by a rotor of an electric motor part driving the compressor, maximizes compression efficiency by minimizing friction loss between rotating elements within the compressor, and has a structure capable of minimizing leakage of refrigerant within the compression space.

Owner:LG ELECTRONICS INC

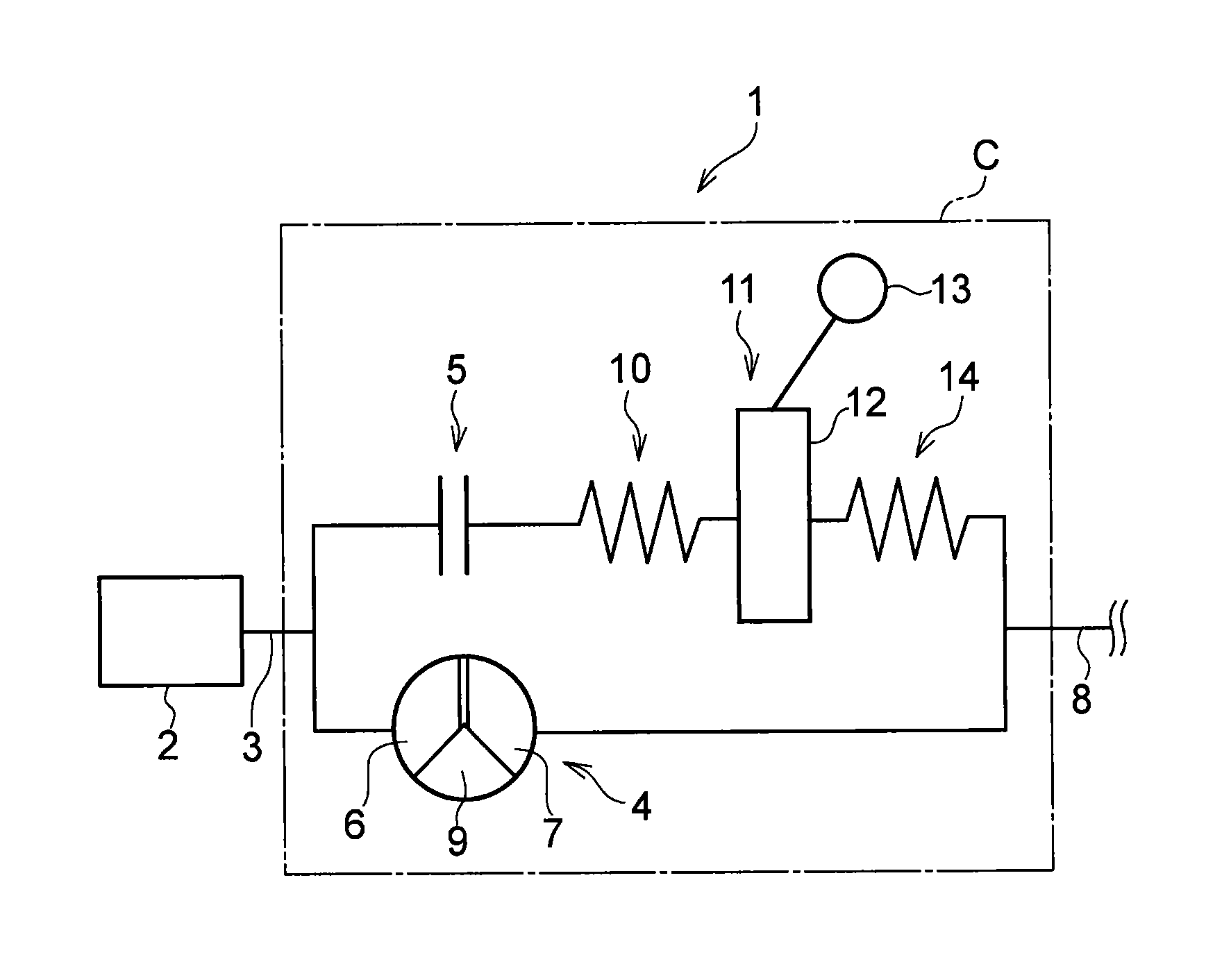

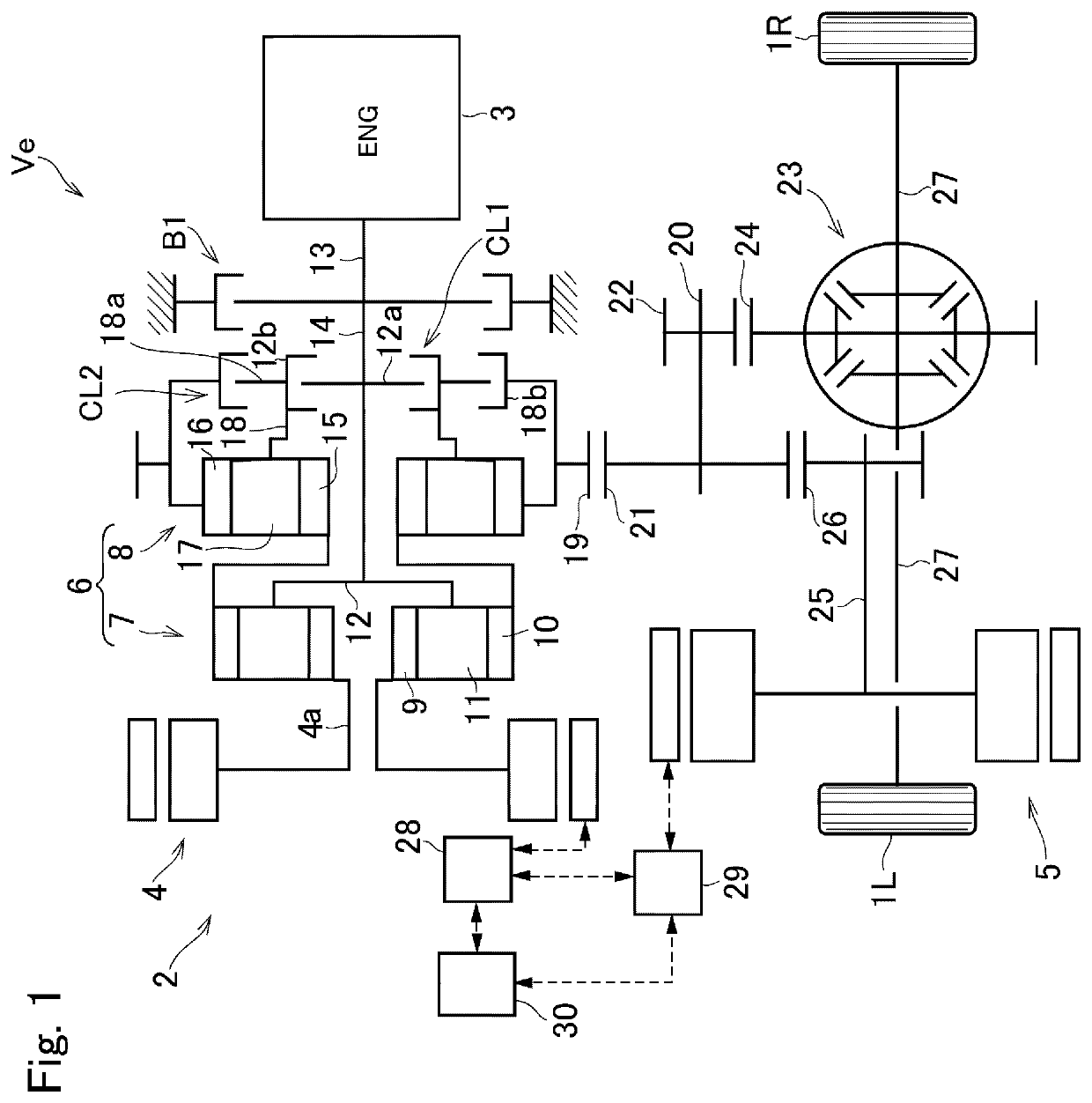

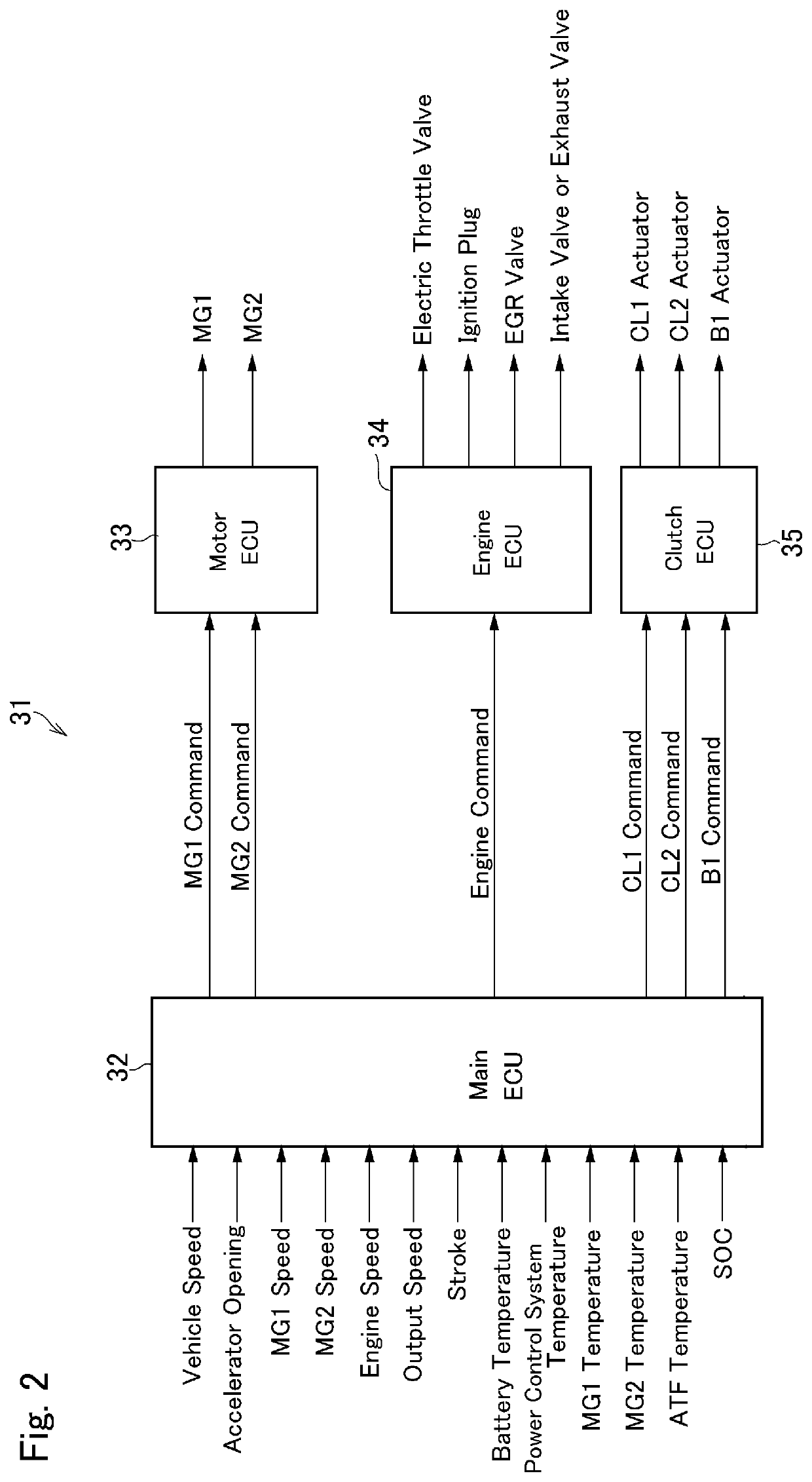

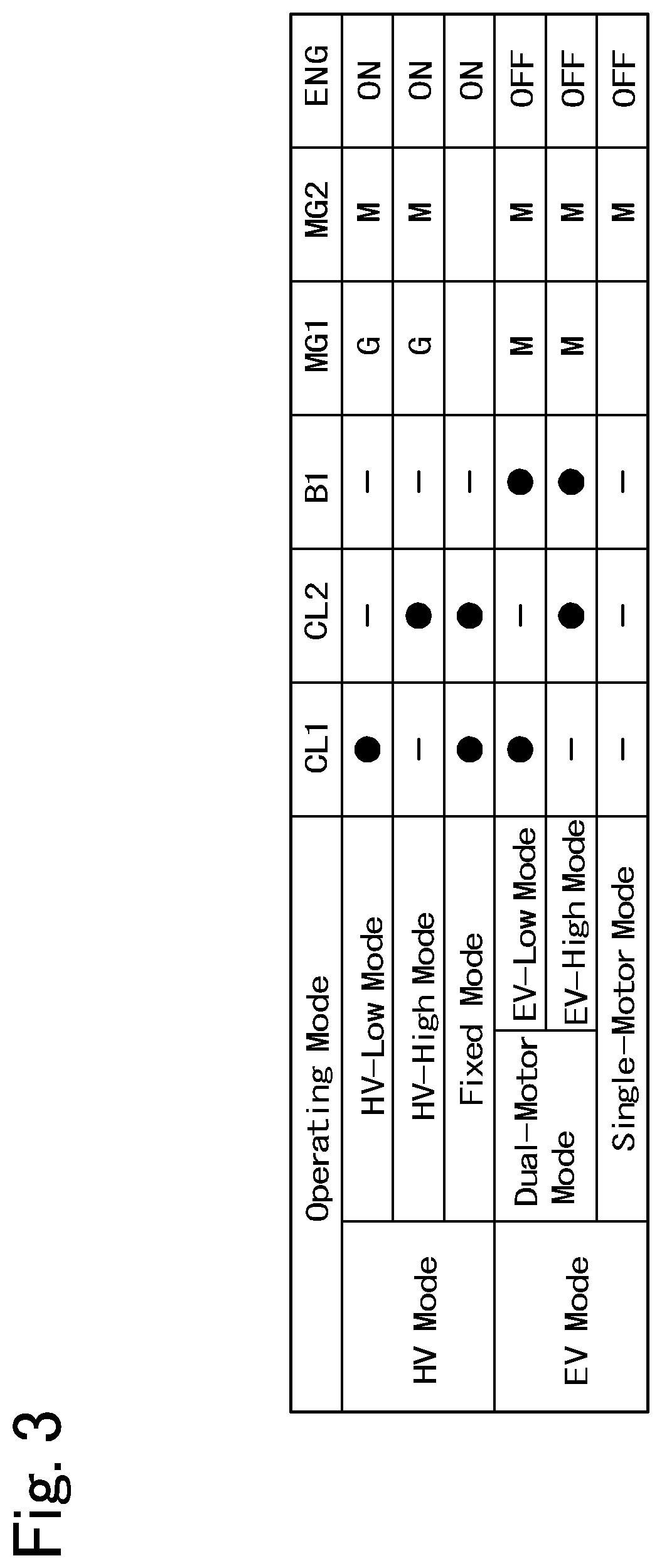

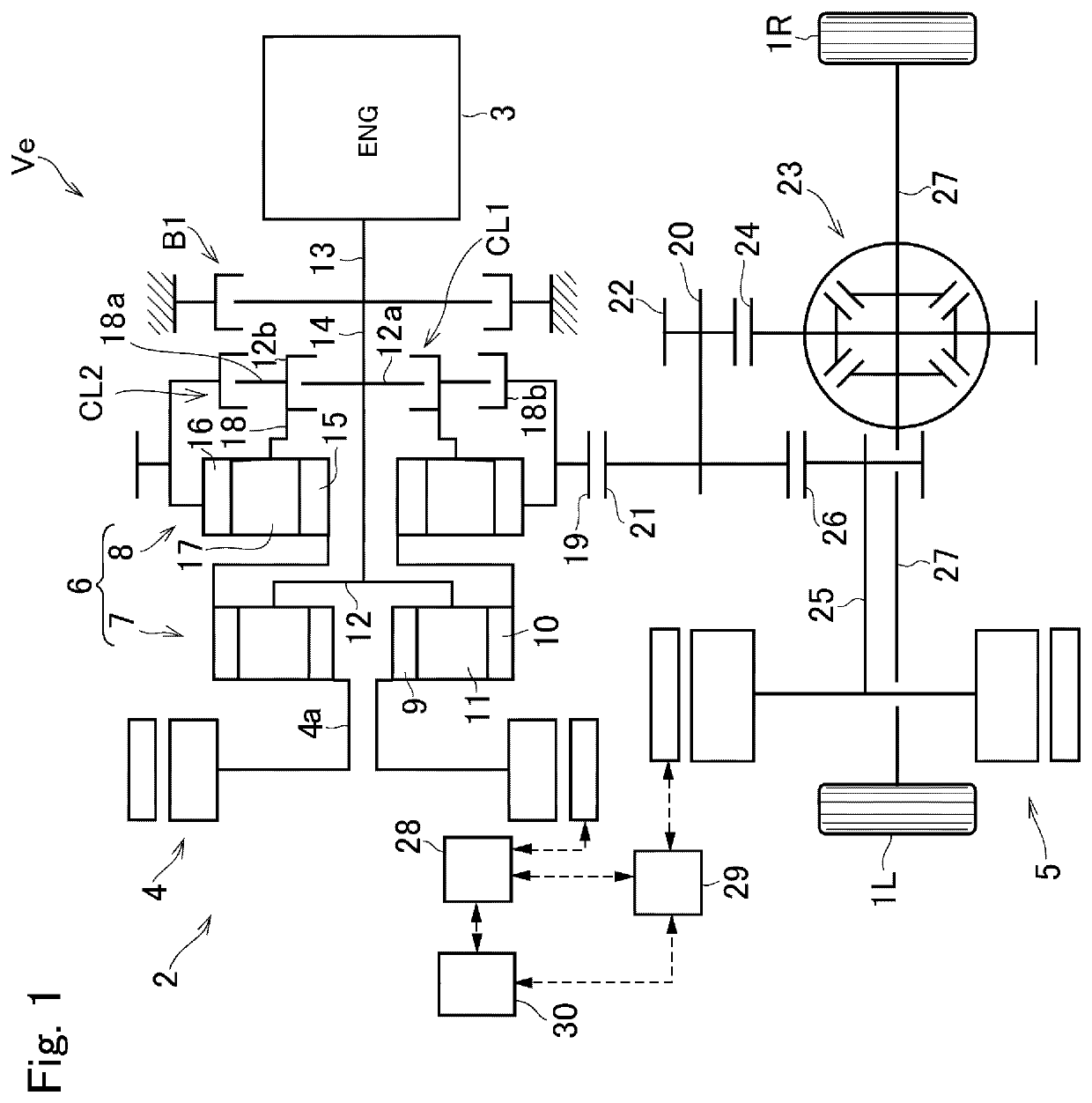

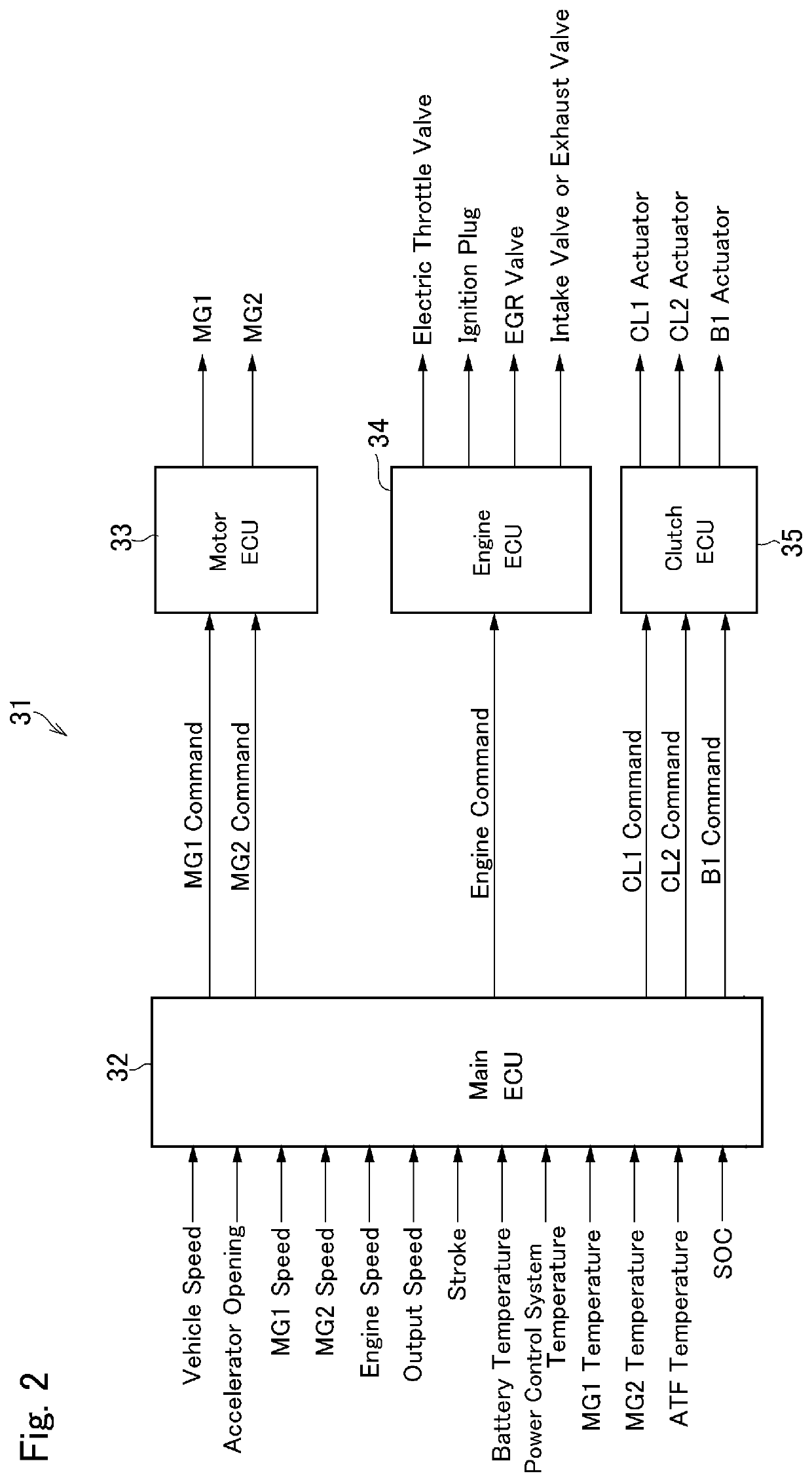

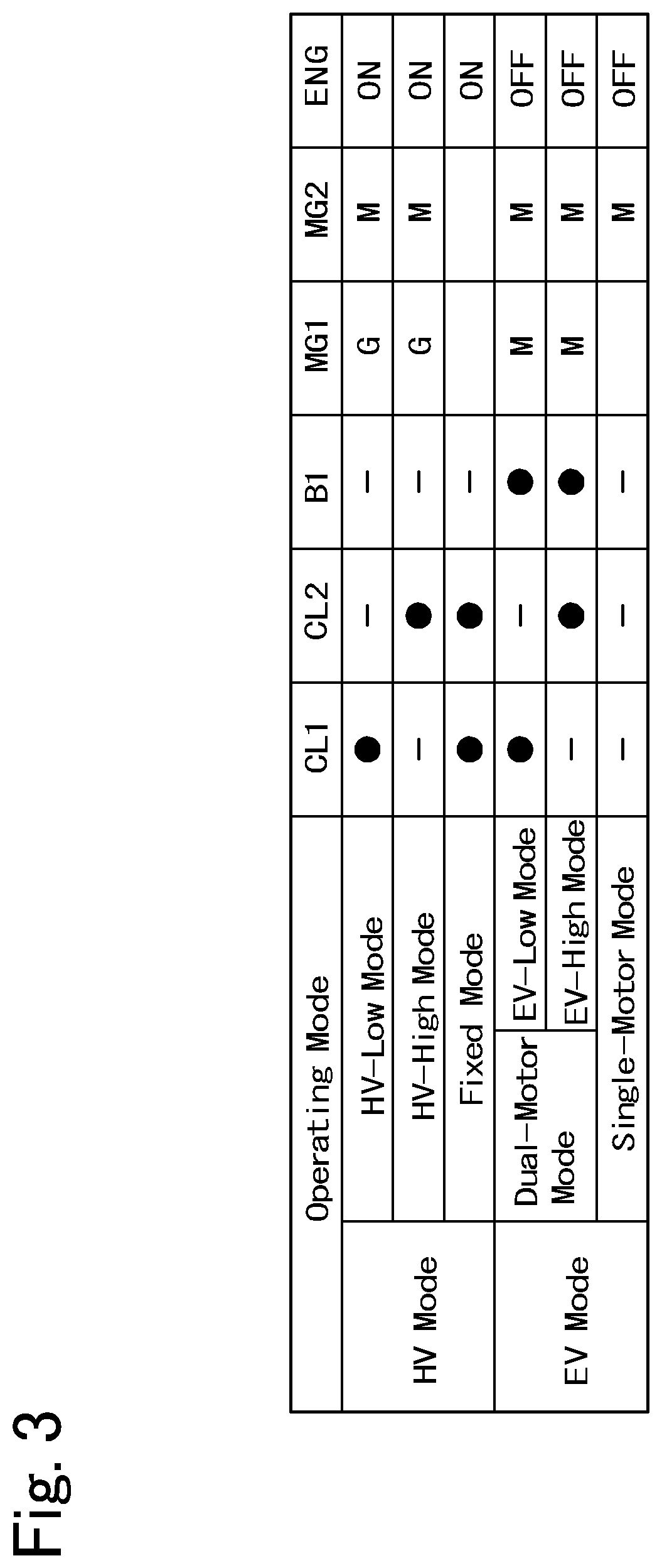

Control system for hybrid vehicle

ActiveUS20200398820A1Eases engagementDifference in speedHybrid vehiclesPlural diverse prime-mover propulsion mountingControl systemElectric machinery

A control system for a hybrid vehicle that reduces delay in engagement of a clutch when shifting an operating mode by manipulating the clutch. A controller is configured to adjust a speed of a first motor to a first standby speed at which the speed difference in a first clutch is reduced when an operating mode will be shifted from a single-motor mode to a first mode, and adjust a speed of the first motor to a second standby speed at which a speed difference in the second clutch is reduced when the operating mode will be shifted from the single-motor mode to a second mode.

Owner:TOYOTA JIDOSHA KK +1

Torque vectoring device

ActiveUS20210301912A1Simple structureConvenient ArrangementElectric propulsion mountingDifferential gearingsPrime moverRotational axis

A downsized torque vectoring device in which a passive rotation of an actuator is prevented. The torque vectoring device comprises: a differential mechanism that allows a differential rotation between a first rotary shaft and second rotary shaft; an actuator that applies torque to the differential mechanism to rotate the rotary shafts at different speeds; and a reversing mechanism that allows the rotary shafts to rotate in opposite directions. The reversing mechanism comprises a first control gear set and the second rotary shaft arranged coaxially around the rotary shafts, and gear ratios of the first control gear set and the second control gear set are set to different values. A speed increasing gear set and a speed reducing gear set are arranged between a prime mover and an output shaft of the actuator, and ring gears of the speed increasing gear set and the speed reducing gear set are connected to each other.

Owner:TOYOTA JIDOSHA KK

Pixel data compression and decompression method and device thereof

ActiveUS7590297B2Attenuation bandwidthAvoid a lot of problemsCharacter and pattern recognitionDigital video signal modificationData compressionImaging processing

The present invention discloses a method for compressing and decompressing pixel data and the device thereof. The method comprises receiving current pixel data from a preprocessor and comparing the current pixel data with predictor pixel data to obtain a section index from a quantization table. Output the section index to a memory as compressed data. Then, receive the compressed data from the memory. Use the quantization table to look up a representative level corresponding to the compressed data and output decompressed pixel data based on the representative level to an image processing unit. The device mentioned above comprises a memory, a compressor and a decompressor. The memory stores compressed data. The compressor quantizes and compresses pixel data and outputs the compressed pixel data to the memory. The decompressor receives the compressed pixel data and decompresses the compressed pixel data and outputs the decompressed pixel data as pixel data.

Owner:NOVATEK MICROELECTRONICS CORP

Compressor

InactiveUS20110126579A1Minimize heightSmall sizeRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectric power systemFriction loss

The present invention relates to a rotary compressor comprising an electric motor part (120) for supplying electric power and a compression mechanism part for compressing a refrigerant while first and second rotary members (130,140) rotate upon receipt of the electric power from the electric motor part, and more particularly to, a compressor which enables a compact design by forming a compression space within the compressor by a rotor of an electric motor part driving the compressor, maximizes compression efficiency by minimizing friction loss between rotating elements within the compressor, and has a structure capable of minimizing leakage of refrigerant within the compression space.

Owner:LG ELECTRONICS INC

Control system for hybrid vehicle

ActiveUS11440533B2Eases engagementDifference in speedHybrid vehiclesPlural diverse prime-mover propulsion mountingControl systemElectric machinery

A control system for a hybrid vehicle that reduces delay in engagement of a clutch when shifting an operating mode by manipulating the clutch. A controller is configured to adjust a speed of a first motor to a first standby speed at which the speed difference in a first clutch is reduced when an operating mode will be shifted from a single-motor mode to a first mode, and adjust a speed of the first motor to a second standby speed at which a speed difference in the second clutch is reduced when the operating mode will be shifted from the single-motor mode to a second mode.

Owner:TOYOTA JIDOSHA KK +1

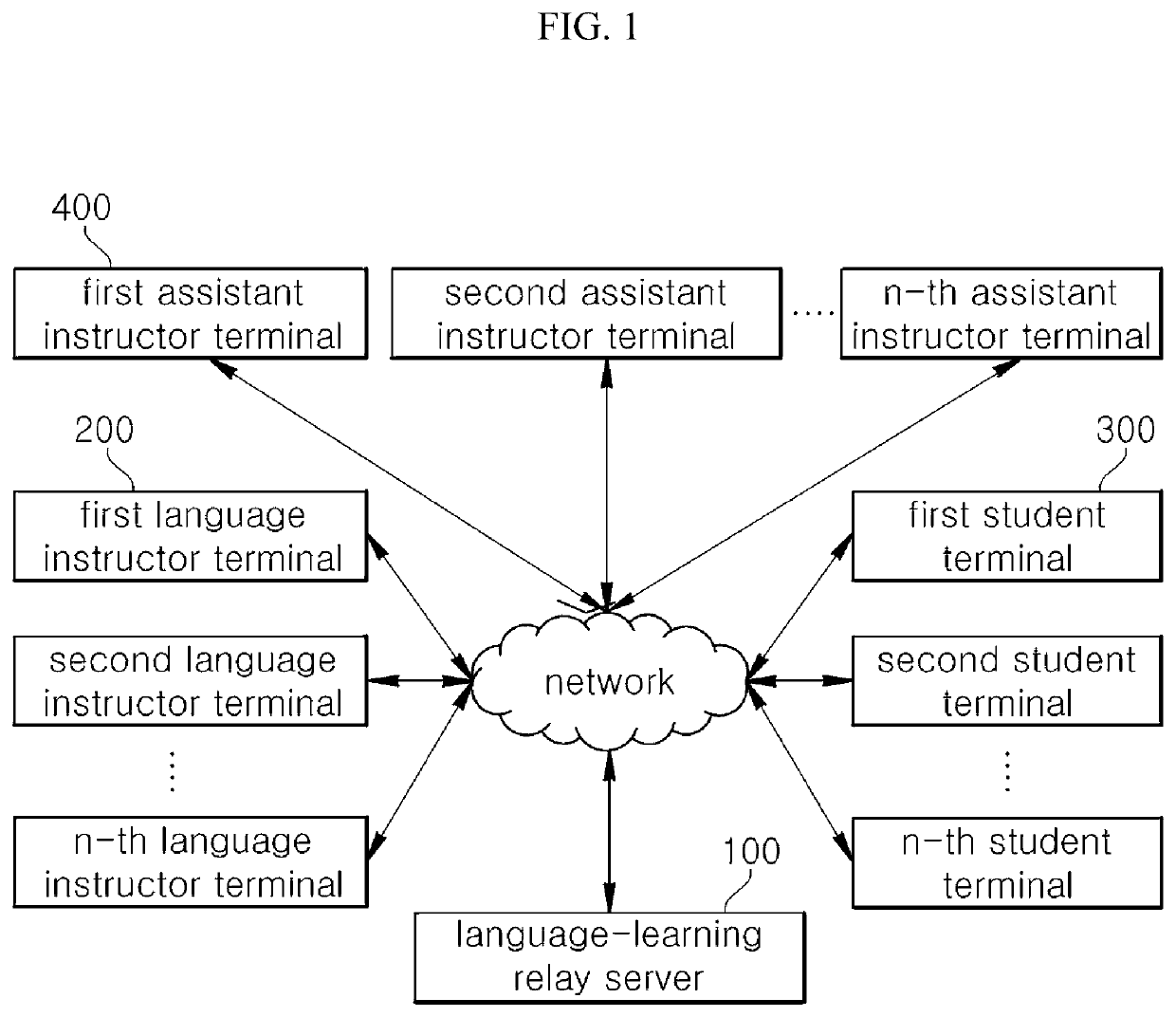

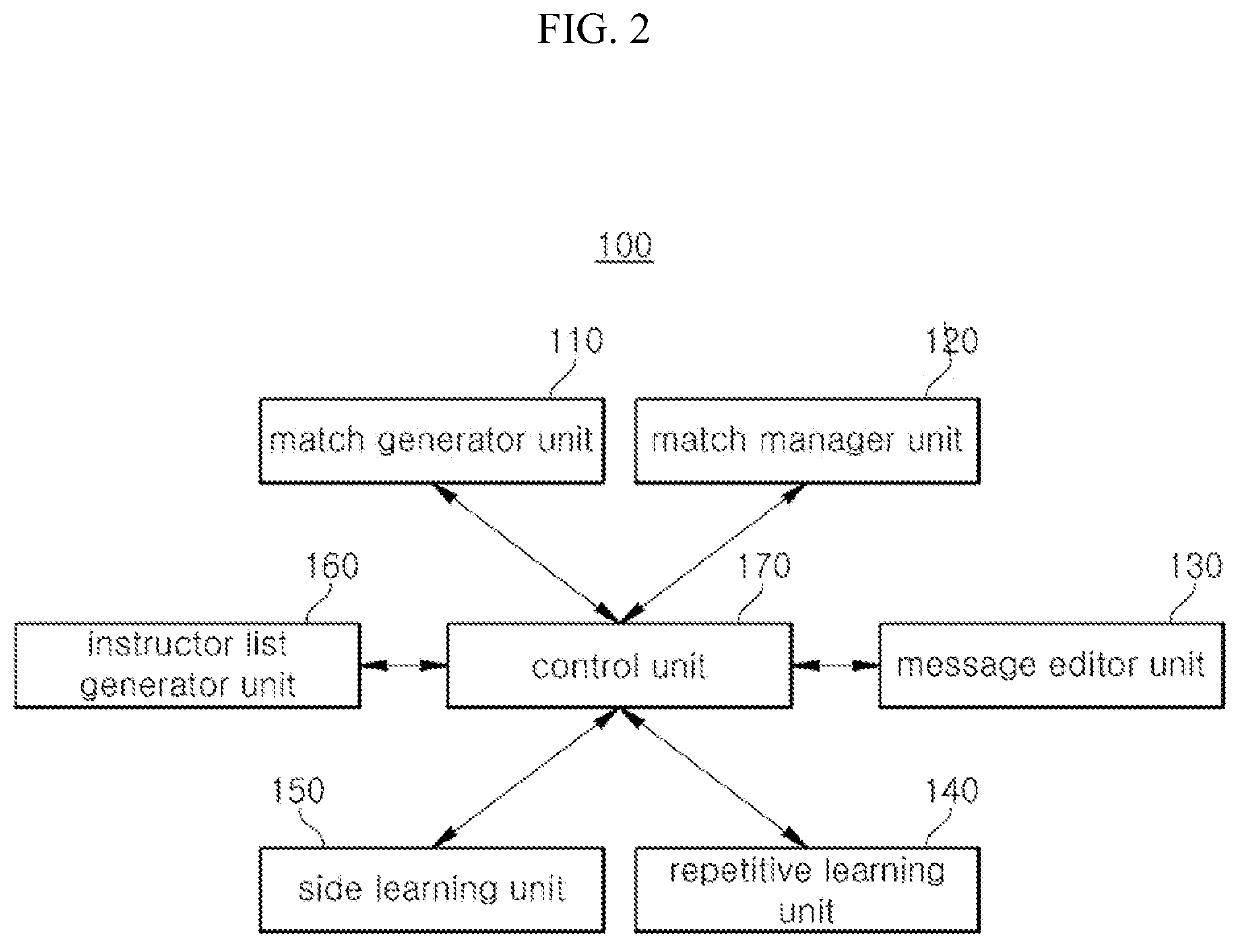

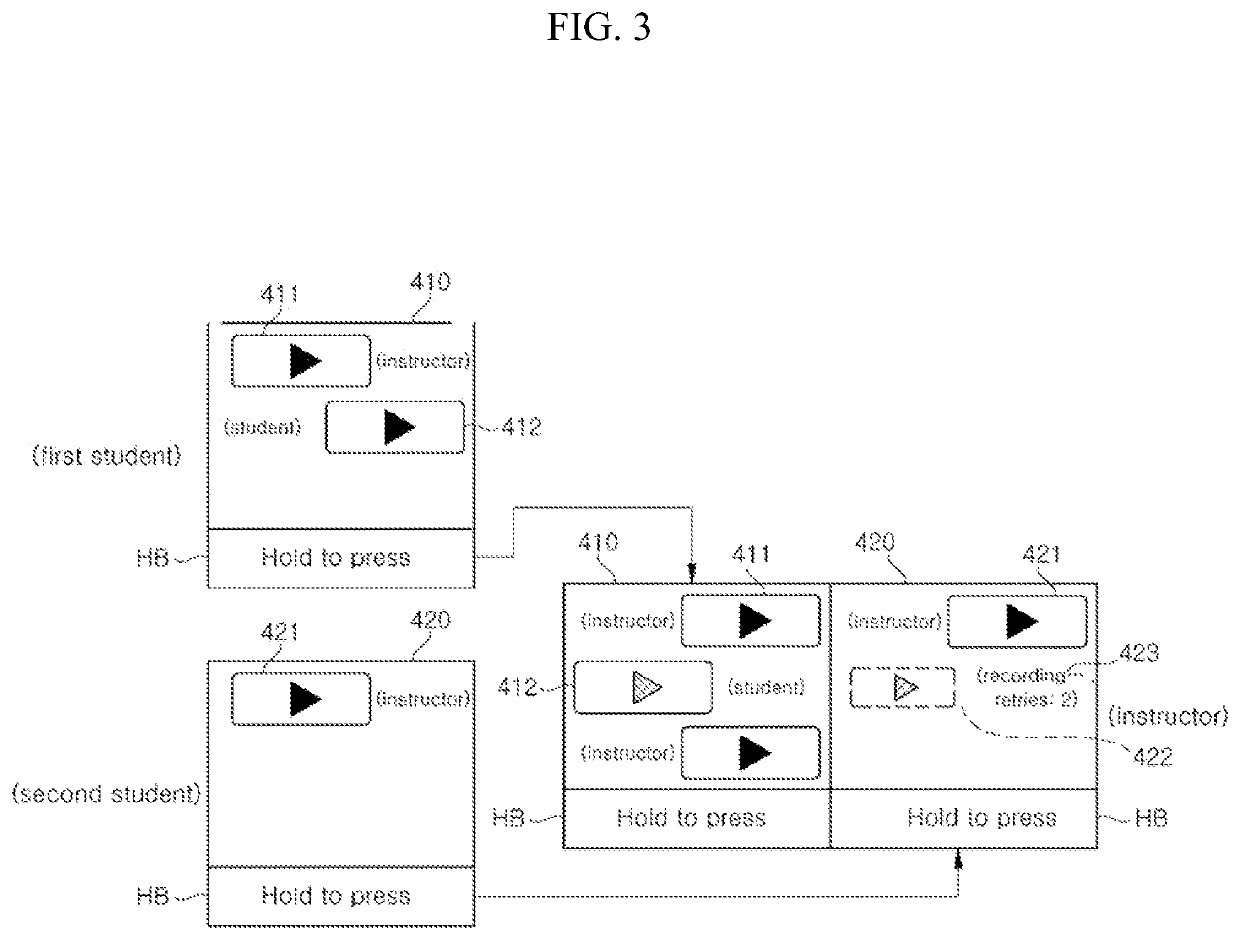

Relay server for one-to-many matched language learning and method for teaching a language

PendingUS20220068151A1Overcome differencesReduce wasteData processing applicationsElectrical appliancesEngineeringQuestions and answers

The present disclosure relates to a technology for providing one-to-many matched language learning between a language instructor and students by using online messages, where, based on the observation that questions and answers are made speedily by the native-speaking instructor whereas questions and answers are made comparatively slowly by the students who are not fluent in the foreign language, a single language instructor leaves lesson channels open for a multiple number of students simultaneously so as to utilize the limited teaching time as efficiently as possible by wasting no time and interacting with another student while a particular student prepares a question or an answer.

Owner:HAYANMIND INC

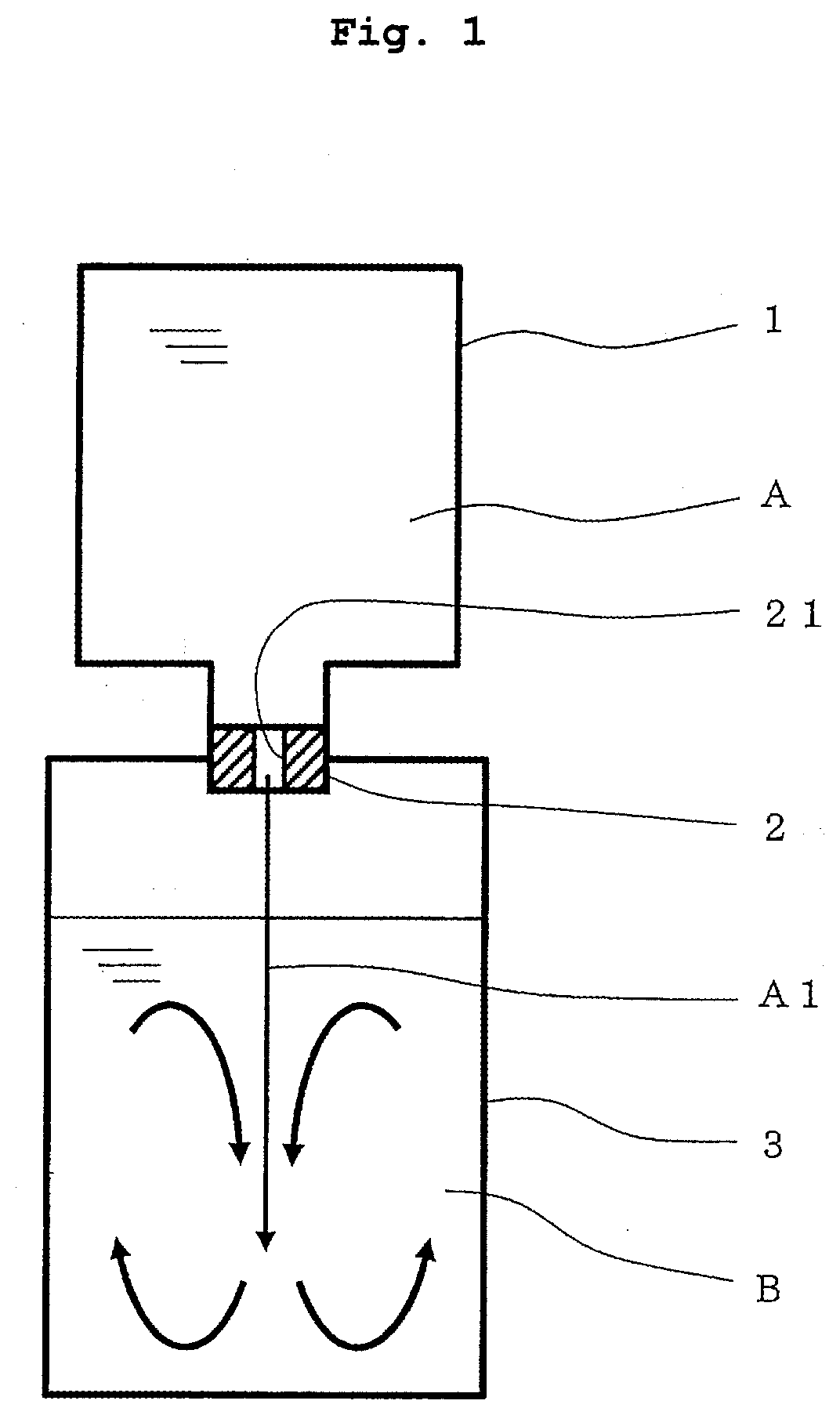

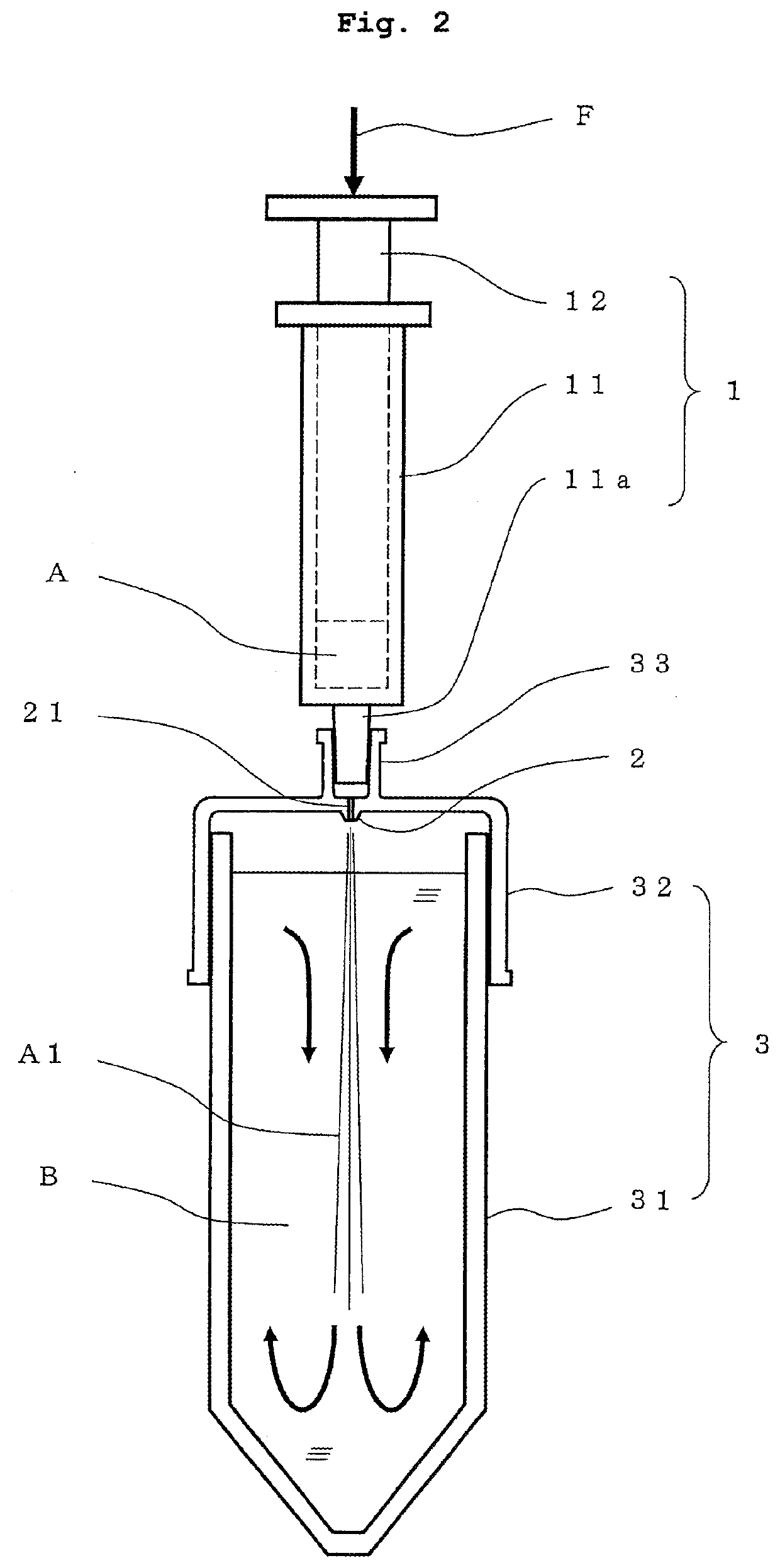

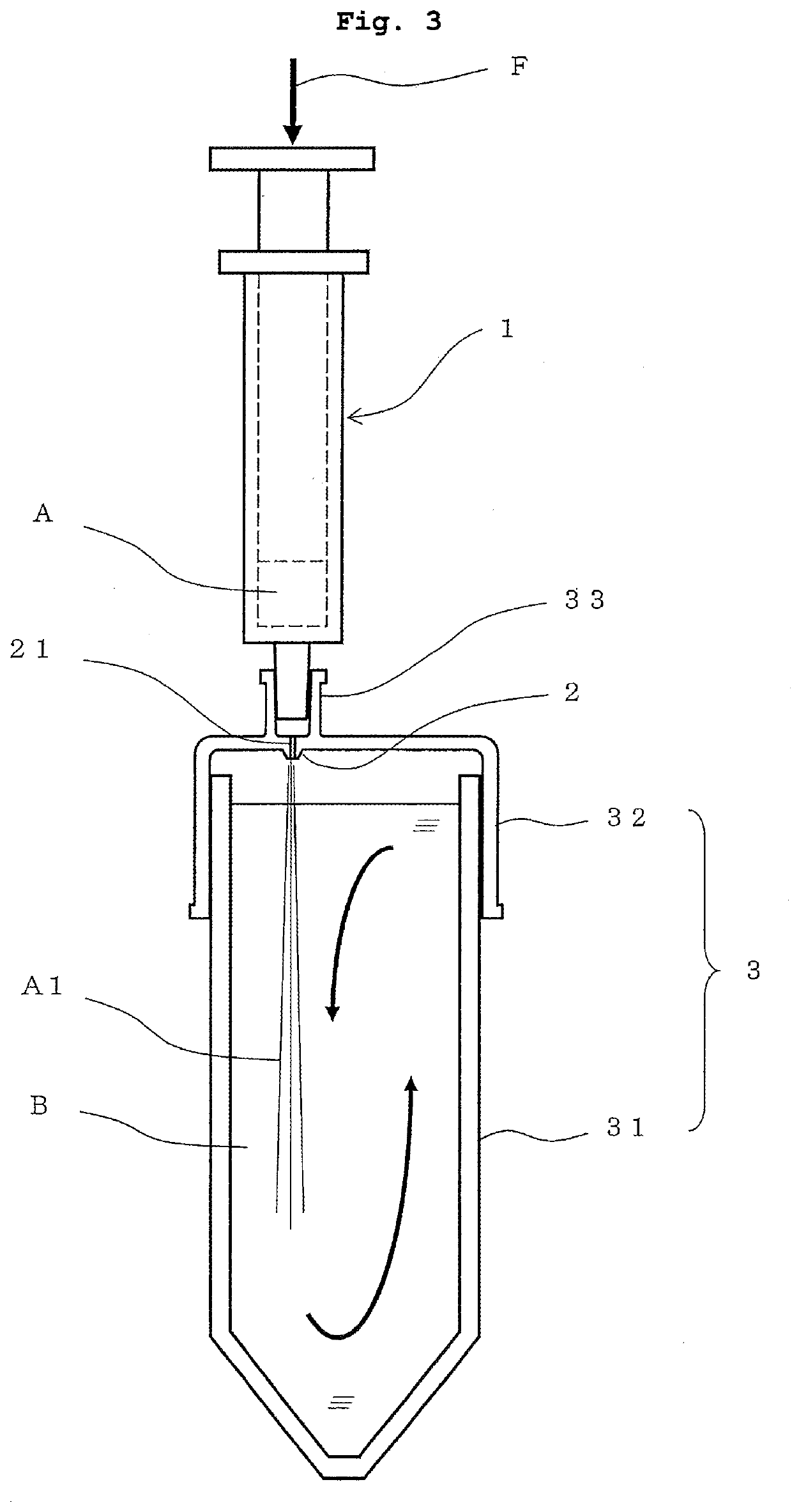

Method for preparing liquid medium composition, and preparation device and kit therefor

PendingUS20220267480A1Avoid biological contaminationIncrease the differenceCulture processPharmaceutical containersHigh concentrationLiquid medium

The present invention provides a method capable of easily mixing any liquid containing a linking substance such as a divalent metal cation and the like with a liquid containing a particular compound at a high concentration, and capable of producing a liquid medium composition comprising fine structures dispersed therein, and a production device therefor and a kit therefor. The first liquid containing a particular compound is passed through a through-hole having a given cross-sectional area formed in a nozzle part at a given flow rate and injected into the second liquid at a given flow rate. By this simple operation, a structure in which the particular compound is bonded via the linking substance is formed, and the structure is preferably dispersed in a mixture of the both liquids.

Owner:NISSAN CHEM IND LTD

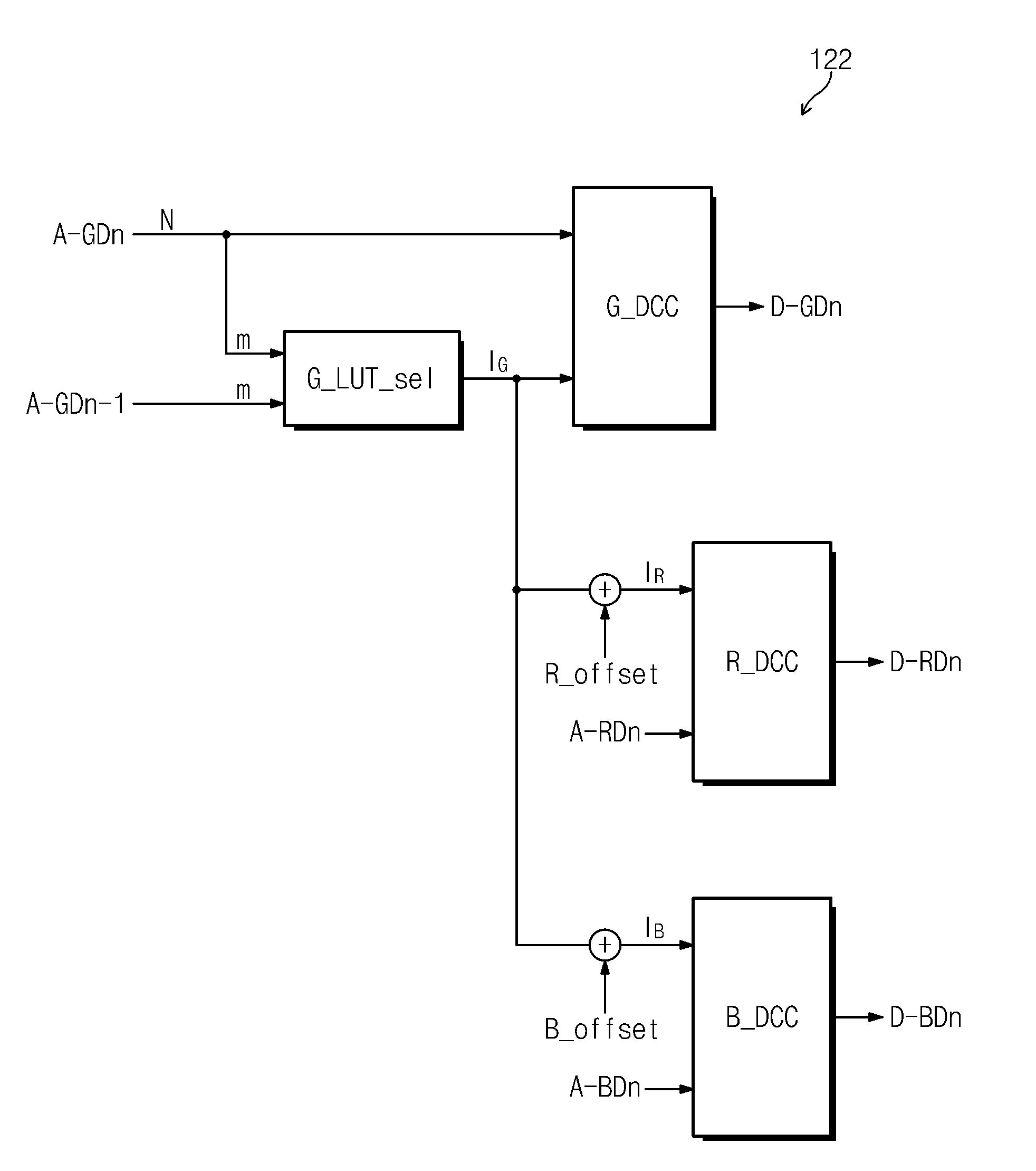

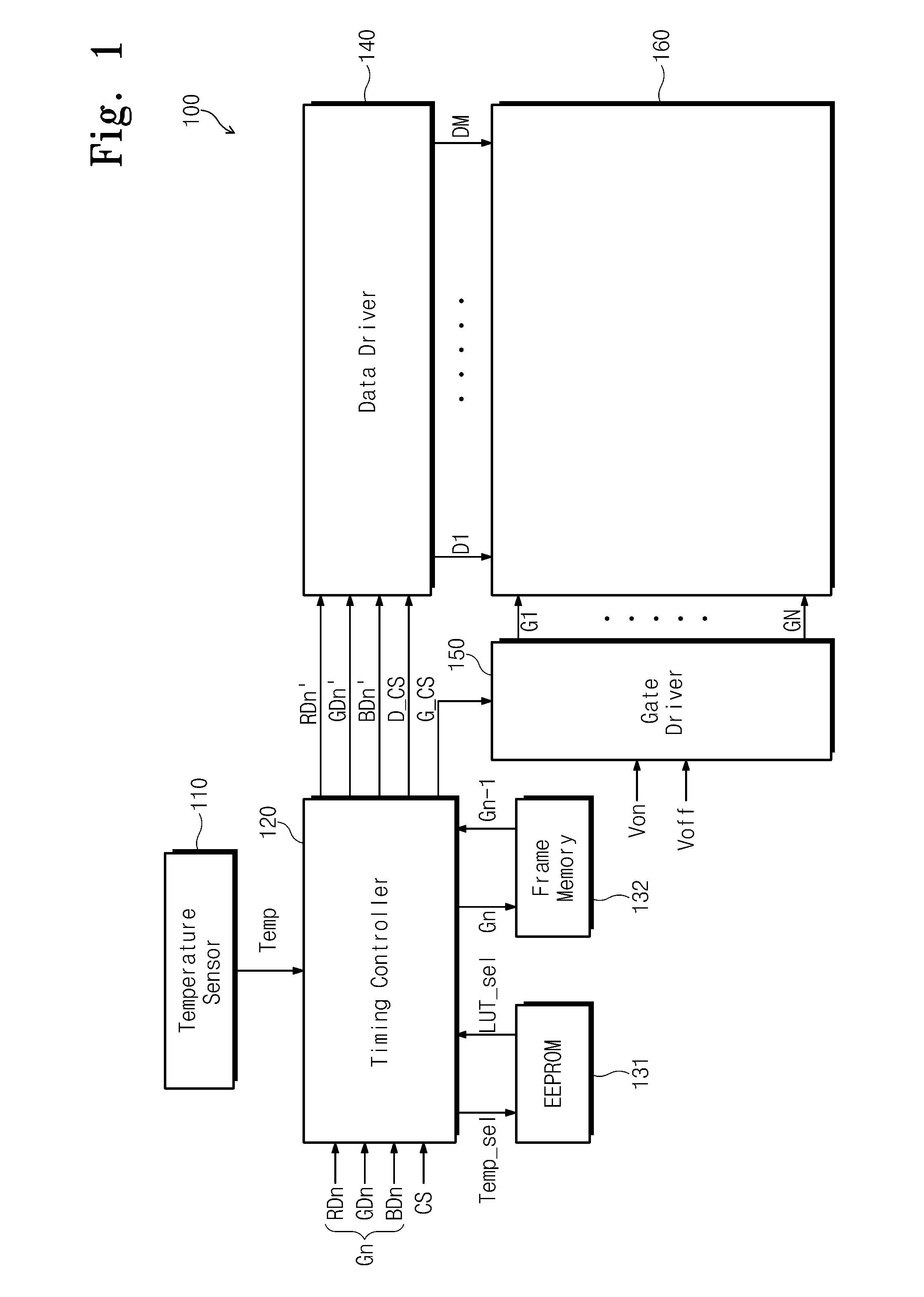

Display apparatus having temperature sensor and method of driving the same

InactiveUS8665297B2Reduce speed differenceInhibit coloringCathode-ray tube indicatorsInput/output processes for data processingCapacitanceComputer science

Owner:SAMSUNG DISPLAY CO LTD

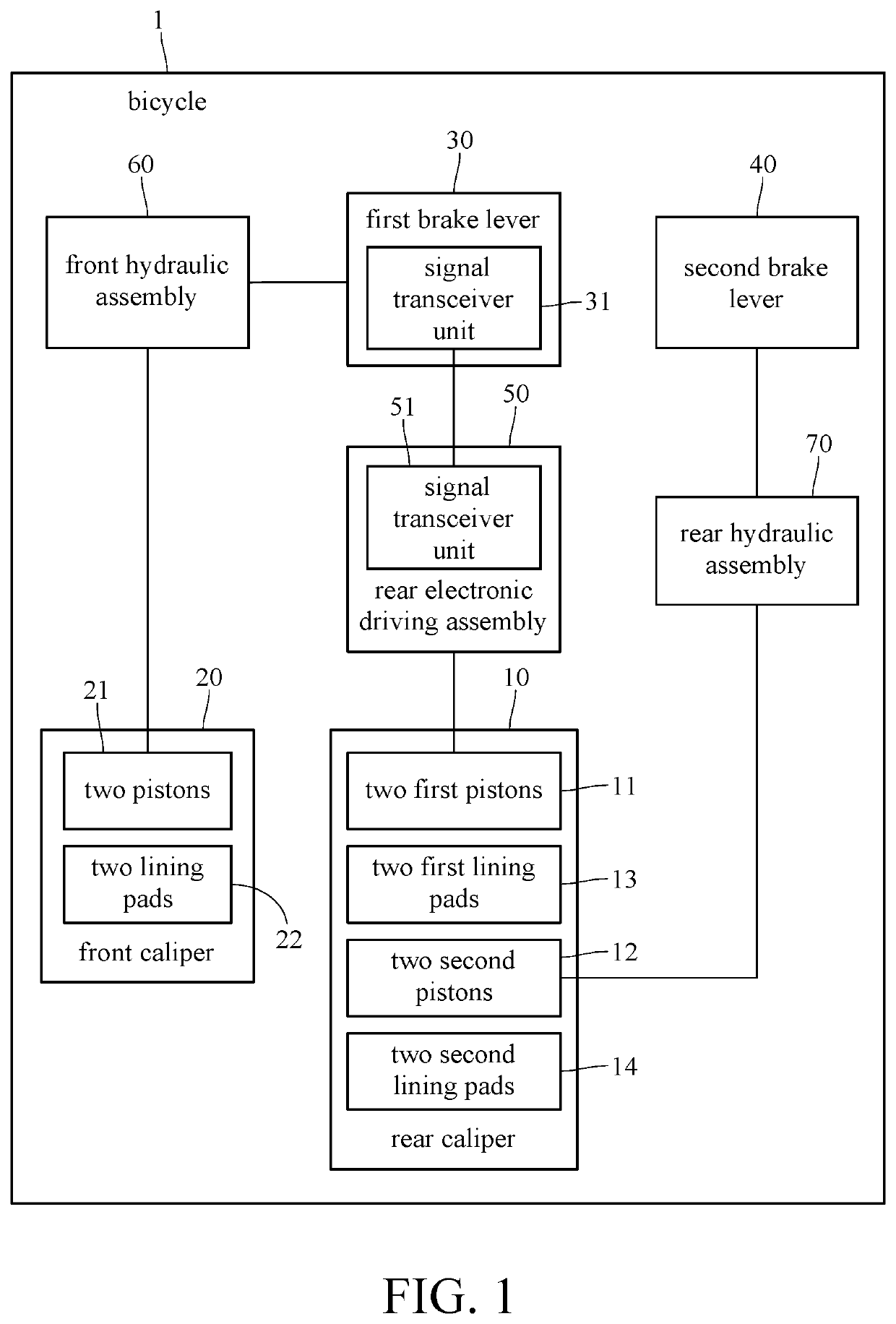

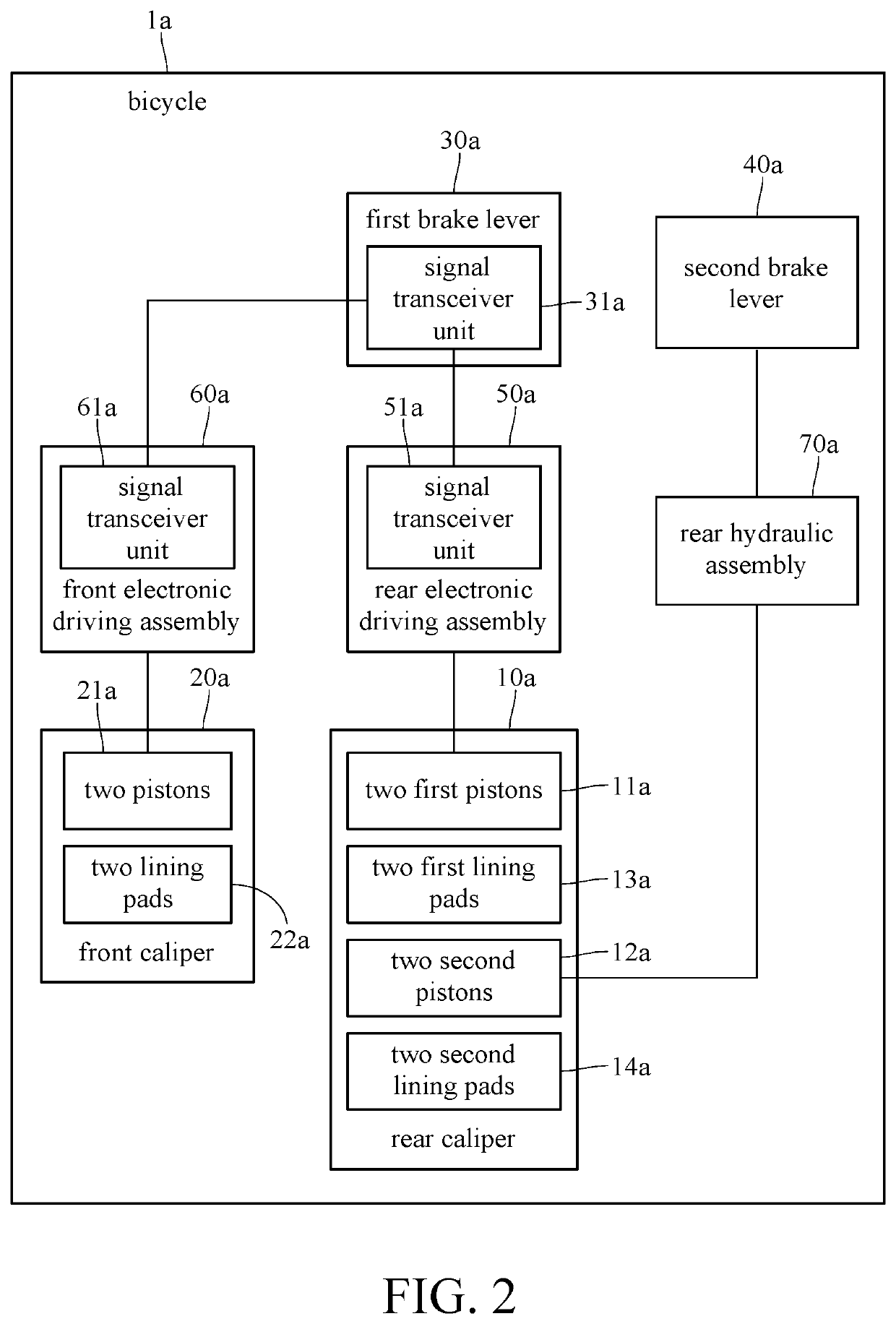

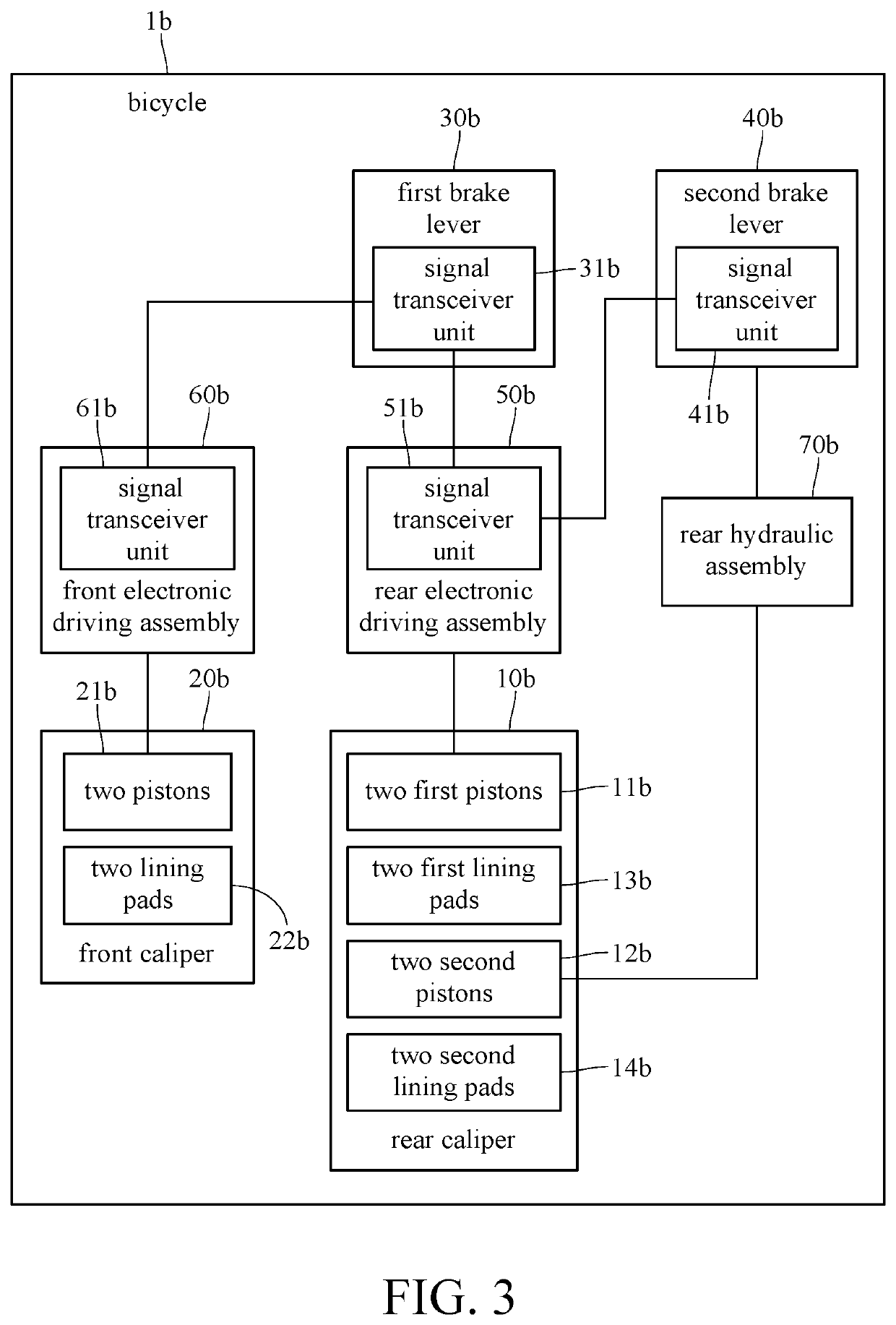

Bicycle caliper, bicycle caliper control method, and bicycle caliper control system

PendingUS20210009231A1Reduce speed differenceDifference in speedAxially engaging brakesCycle brakesControl theoryMechanical engineering

The disclosure provides a bicycle caliper control method. The bicycle caliper control method is configured to control a rear caliper and a front caliper of a bicycle. The bicycle caliper control method includes: when a first brake lever of the bicycle is squeezed, the first brake lever activates the rear caliper and the front caliper; and when a second brake lever of the bicycle is squeezed, the second brake lever activates the rear caliper.

Owner:TEKTRO TECH

Compressor

ActiveUS8636480B2Minimize heightSmall sizeRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringElectromagnetic field

A compressor is provided that includes a hermetically sealed container; a stator fixedly installed within the hermetically sealed container; a first rotary member that rotates, within the stator, around a first rotary shaft that extends concentrically with a center of the stator by a rotating electromagnetic field of the stator, and including first and second covers fixed to upper and lower parts thereof, respectively; a second rotary member that compresses a refrigerant in a compression space formed between the first and second rotary members while rotating, within the first rotary member, around a second rotary shaft; a vane that transmits the rotational force to the second rotary member from the first rotary member, and partitions the compression space into suction and compression regions; and first and second bearings fixed inside of the hermetically sealed container that rotatably support the first and second rotary members in an axial direction.

Owner:LG ELECTRONICS INC

Chain conveyor curve

The invention relates to a transport conveyor curve including a multitude of parallel curved tracks, wherein the separate parallel tracks are driven by a conical drive, wherein the contact angle of each of the individual tracks with the conical drive is substantially equal in comparison to the contact angle of the other individual tracks.

Owner:JONGE POERINK CONVEYORS

Inclined conveyor for combine harvesters

ActiveUS20150141099A1Difference in speedGentler conveyingConveyorsThreshersDriven elementCombine harvester

An inclined conveyor for a combine harvester has two drive elements which define a conveying direction and revolve in a conveying duct. Conveying duct is divided into an overshot return duct and an undershot conveying duct by a separating element situated between the upper run and the lower run of the drive element. Drive element is interconnected by carriers situated transversely with respect to conveying direction that convey harvested crop in undershot conveying duct. The difference in speed between the carrier bars and harvested crop stream is eliminated, and at least reduced, by additional acceleration of harvested crop stream. Carrier bars serve as carriers, and as acceleration elements for the harvested crop. That is because the cross section of each of the carrier bars viewed in conveying direction, occupies at least 30% of the smallest internal cross section of undershot conveying duct.

Owner:ARNOLD JAGER HLDG GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com