Four-stroke internal combustion engine lubrication device

a lubrication device and internal combustion engine technology, which is applied in the direction of auxiliary lubrication, lubrication elements, pressure lubrication, etc., can solve the problems of insufficient adjustment of the orientation of the engine, insufficient capacity for collecting excess oil, and insufficient capacity for supplying oil, so as to achieve omnidirectional operation, the ability to collect excess oil within the valve chamber, and the effect of freedom of position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Embodiments of the present invention are described below with reference to the drawings.

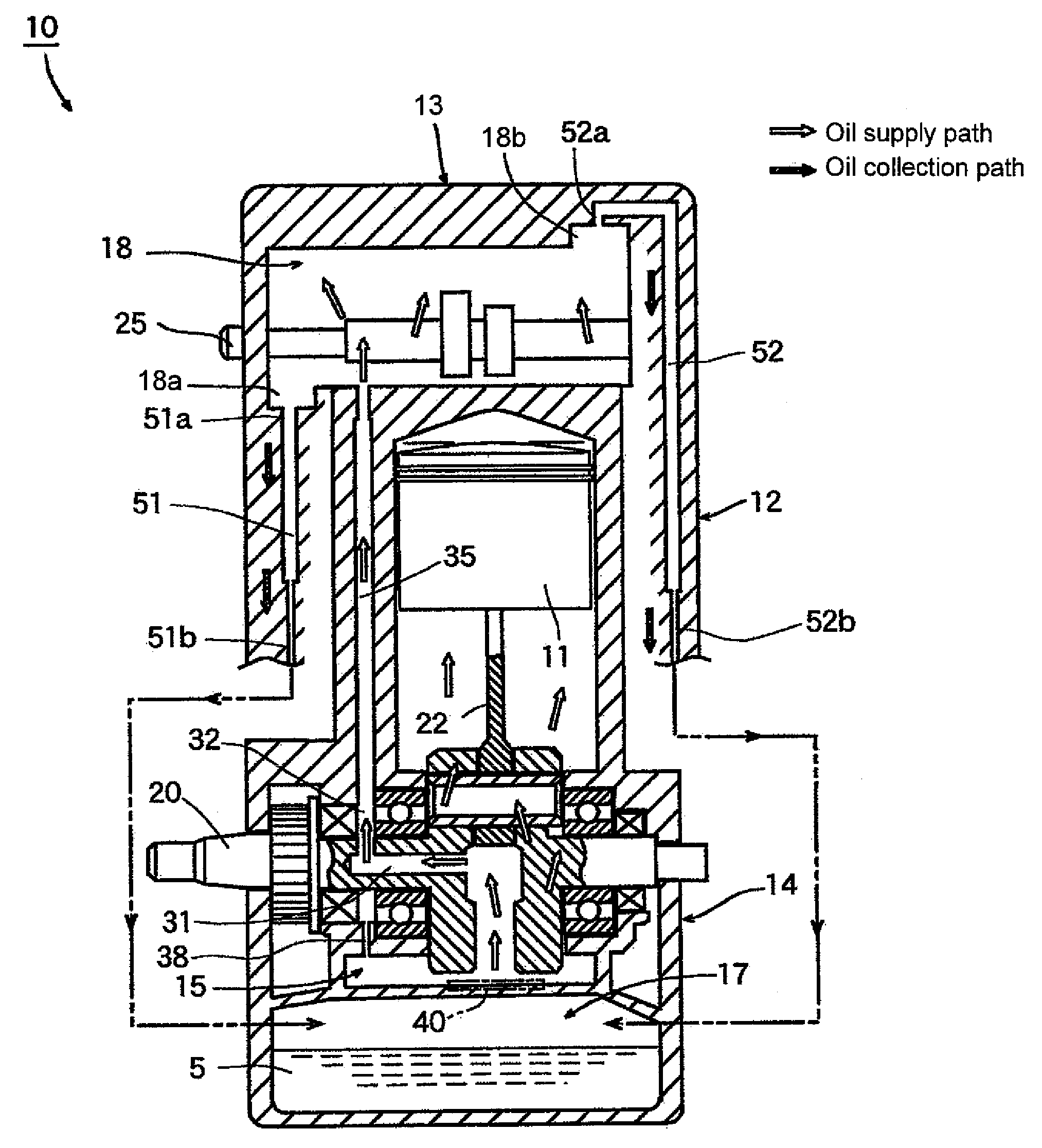

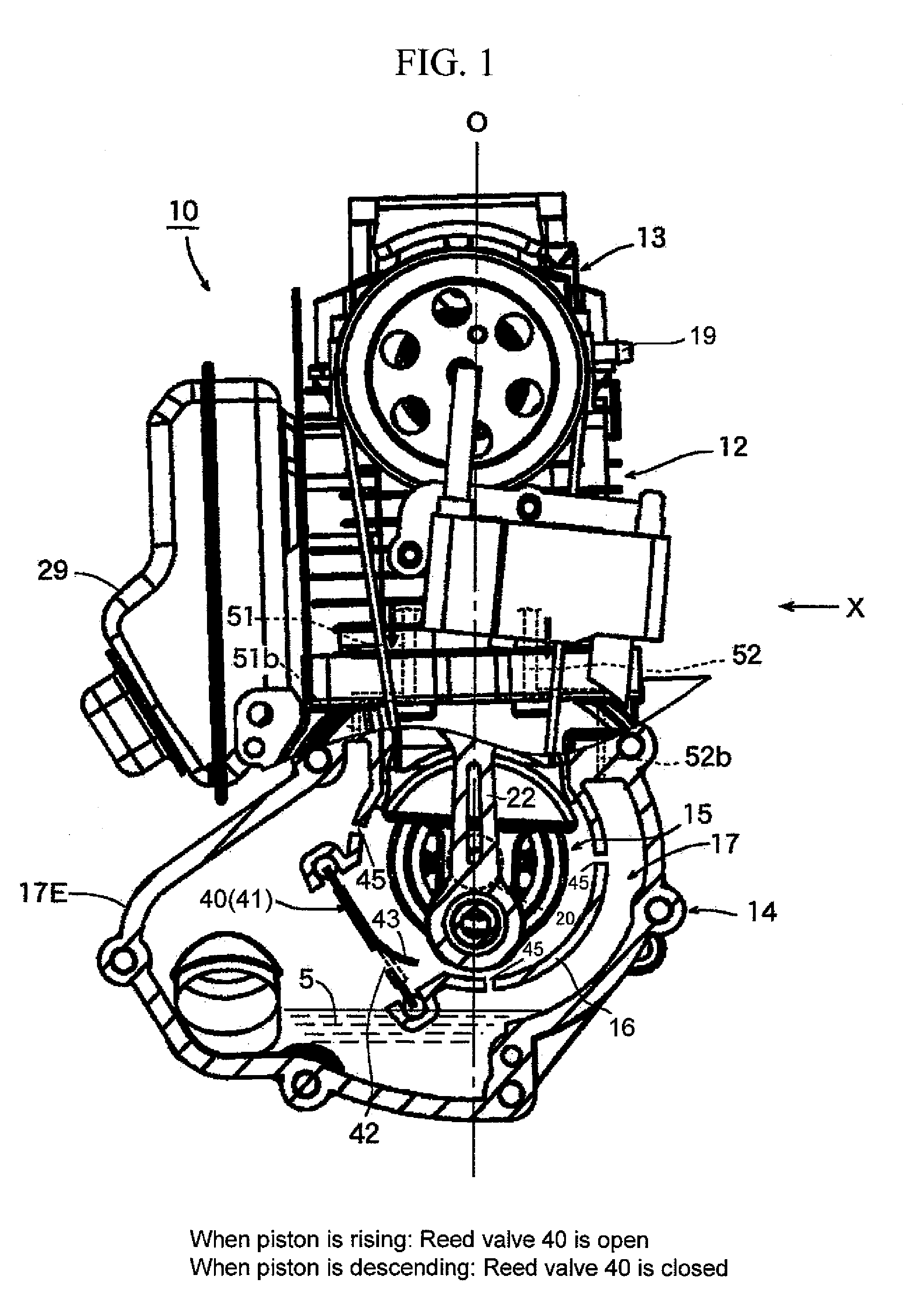

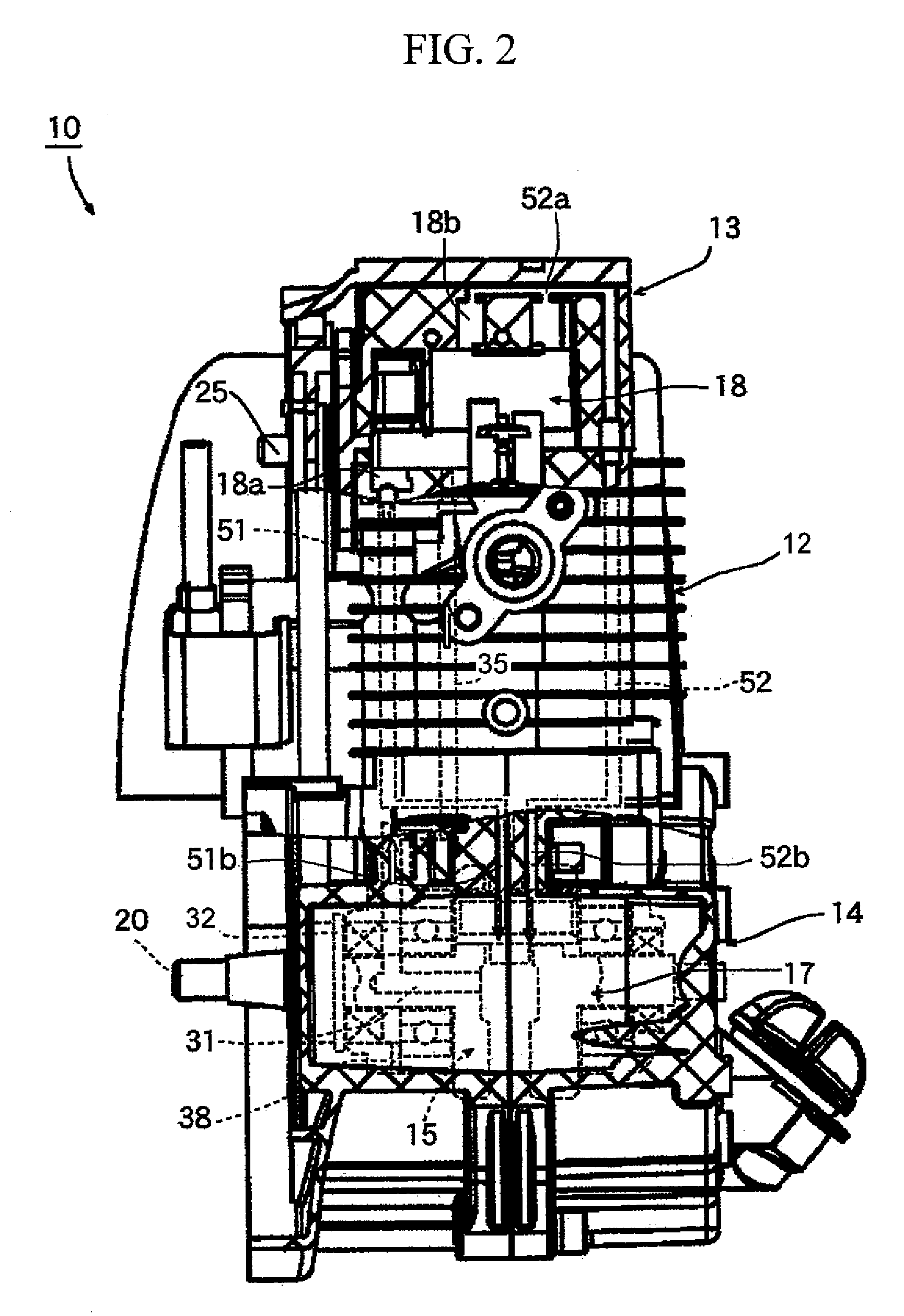

[0037]FIG. 1 is a partially cutaway front view of an overhead cam type four-stroke internal combustion engine to which an embodiment of a lubrication device according to the present invention is applied. FIG. 2 is a partially cutaway side view as viewed in the direction of arrow X in FIG. 1.

[0038]In FIGS. 3 and 4, which are schematic views of FIGS. 1 and 2, respectively, the outlined white arrows indicate the oil supply path, whereas the arrows with hatching indicate the oil collection path.

[0039]The engine 10 in FIG. 1 is an overhead earn type four-stroke internal combustion engine with a displacement of approximately 30 cc that is suitable for use as a power source for a portable work machine such as a brush cutter, a chain saw, etc. The engine 10 comprises: a cylinder portion 12 into which a piston 11 is inserted; an upper chamber defining portion 13 provided above the cylinder portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com