Fuse element having damping structure

a technology of damping structure and fuse element, which is applied in the field of fuse element, can solve problems such as failure of the entire modul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

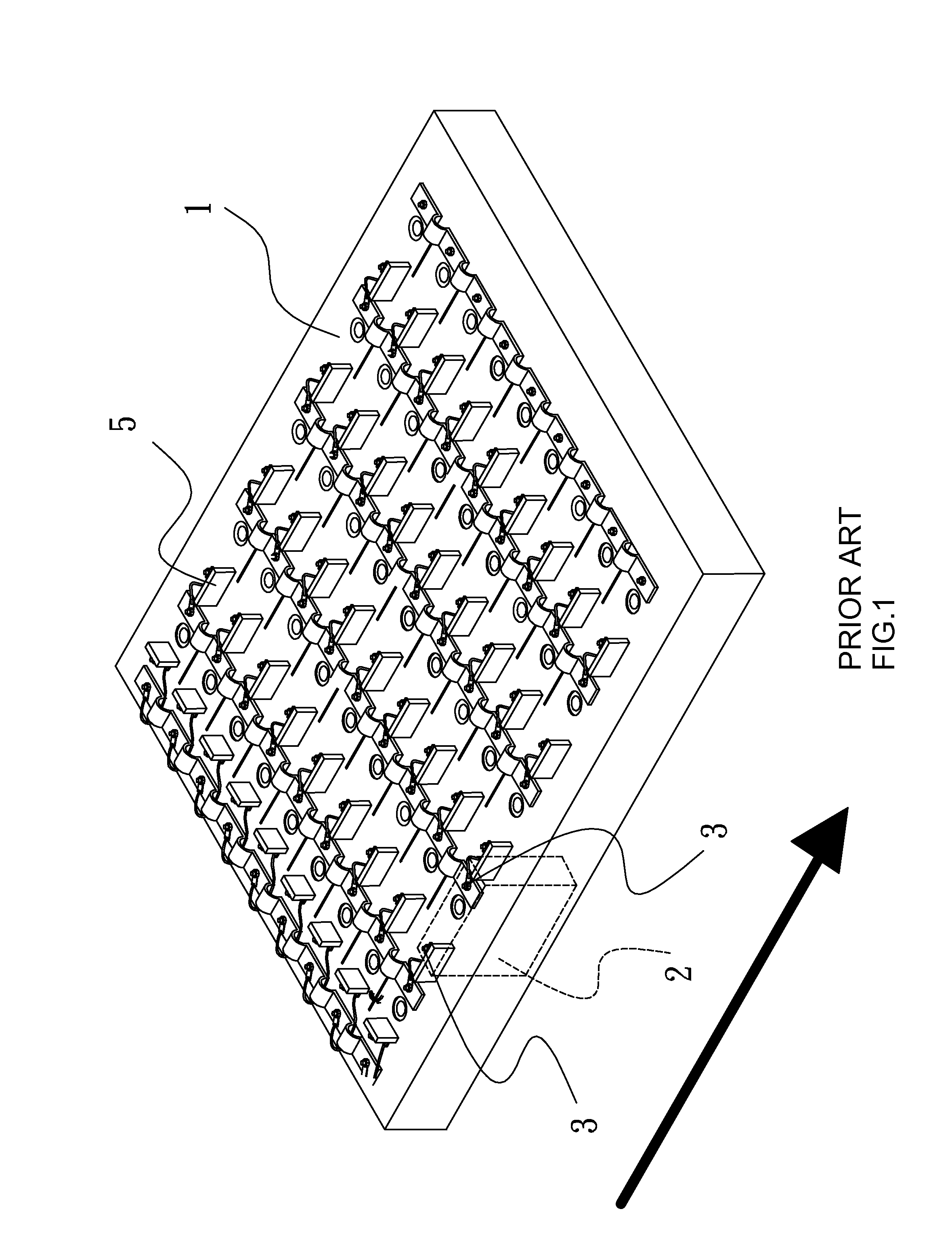

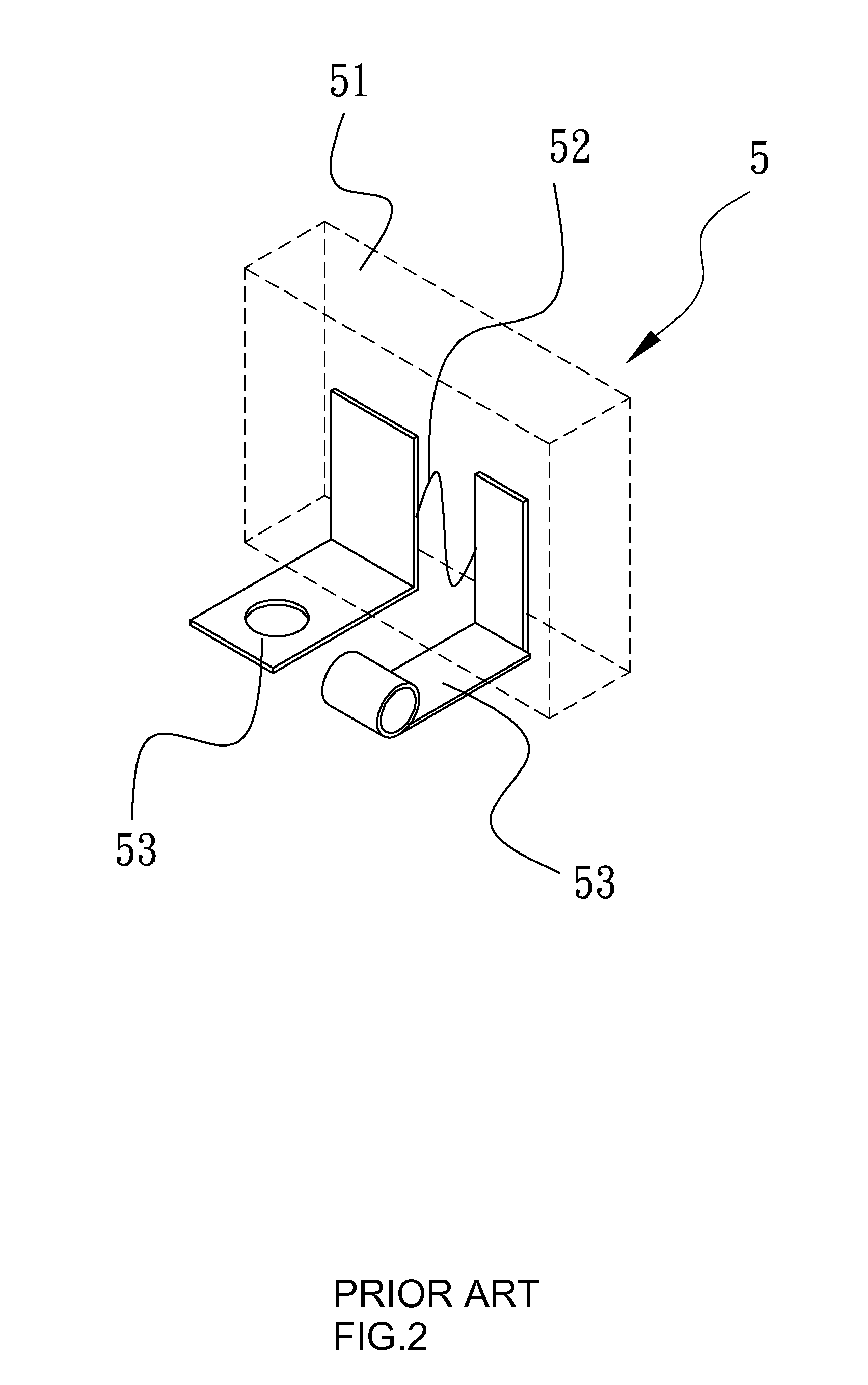

[0024]A fuse element having a damping structure according to the invention is illustrated herein to be mounted in a power source module. In this embodiment, an energy storage unit is illustrated as a battery pack composed of a single battery cell, and a single fuse element is connected correspondingly to a single battery cell. However, it is readily apparent to those skilled in the art that the arrangement described above is not limitative, and that a capacitor or an inductor may store energy in an electric field or in a magnetic field and serve as an energy storage unit for providing electric energy when needed. The fuse element according to the invention is also not limited to be used only in a power source module.

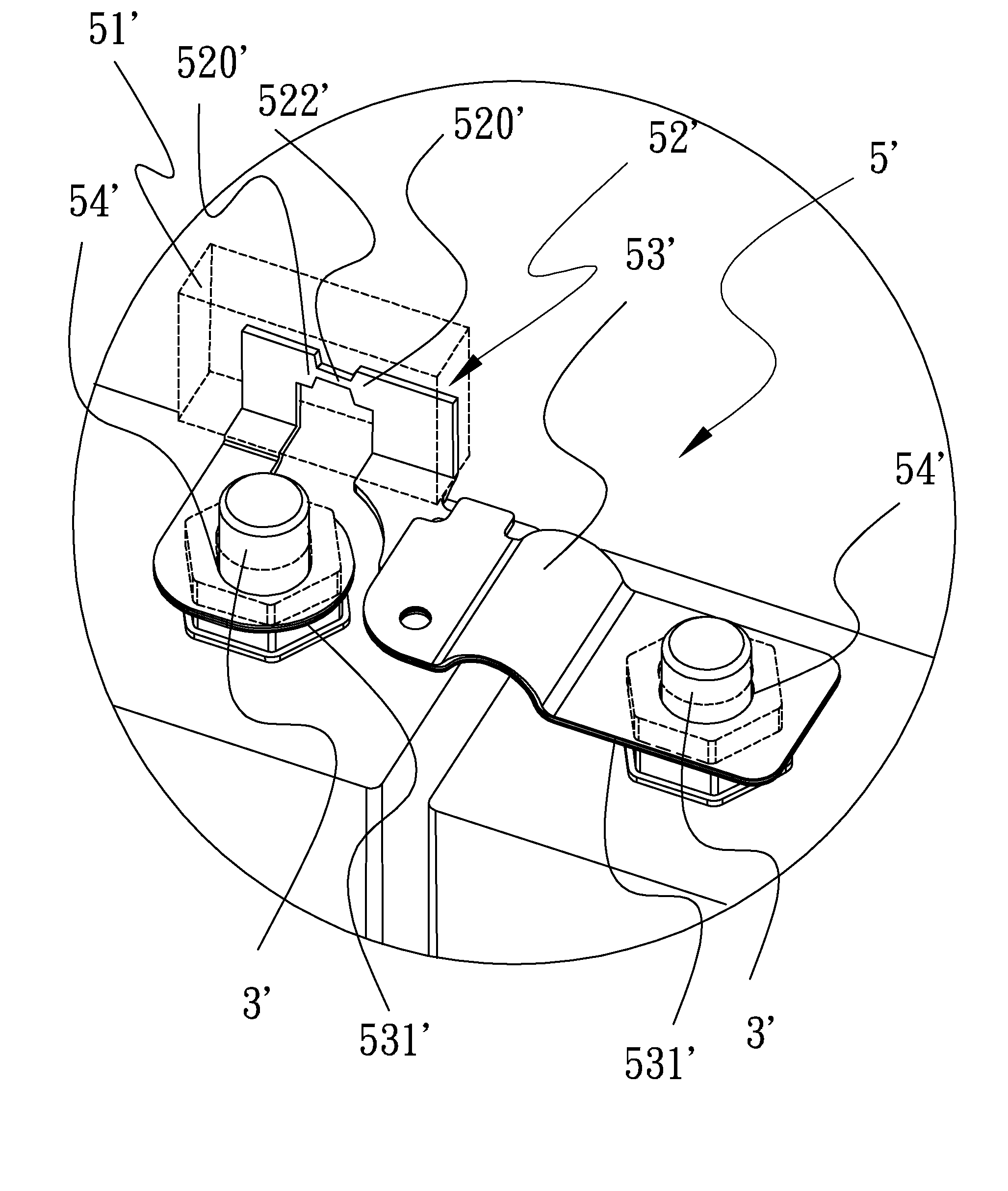

[0025]Referring to the first preferred embodiment shown in FIGS. 5 and 6, a fuse body 52′ includes two ends 522′ and a meltable portion 520′ which is coupled between the two ends 522′ and has a width narrower than that of the ends 522′. The fuse body 52′ is encapsulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com