Vehicular air-conditioning system

a vehicular air conditioner and heat pump technology, applied in vehicle heating/cooling devices, heating and refrigeration combinations, vehicle machines, etc., can solve the problems of increased cooling and heating system weight, increased amount of coolant used, and insufficient coolant flow rate, etc., to achieve simple and economical structure, increase heat exchange efficiency, and good air-conditioning capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

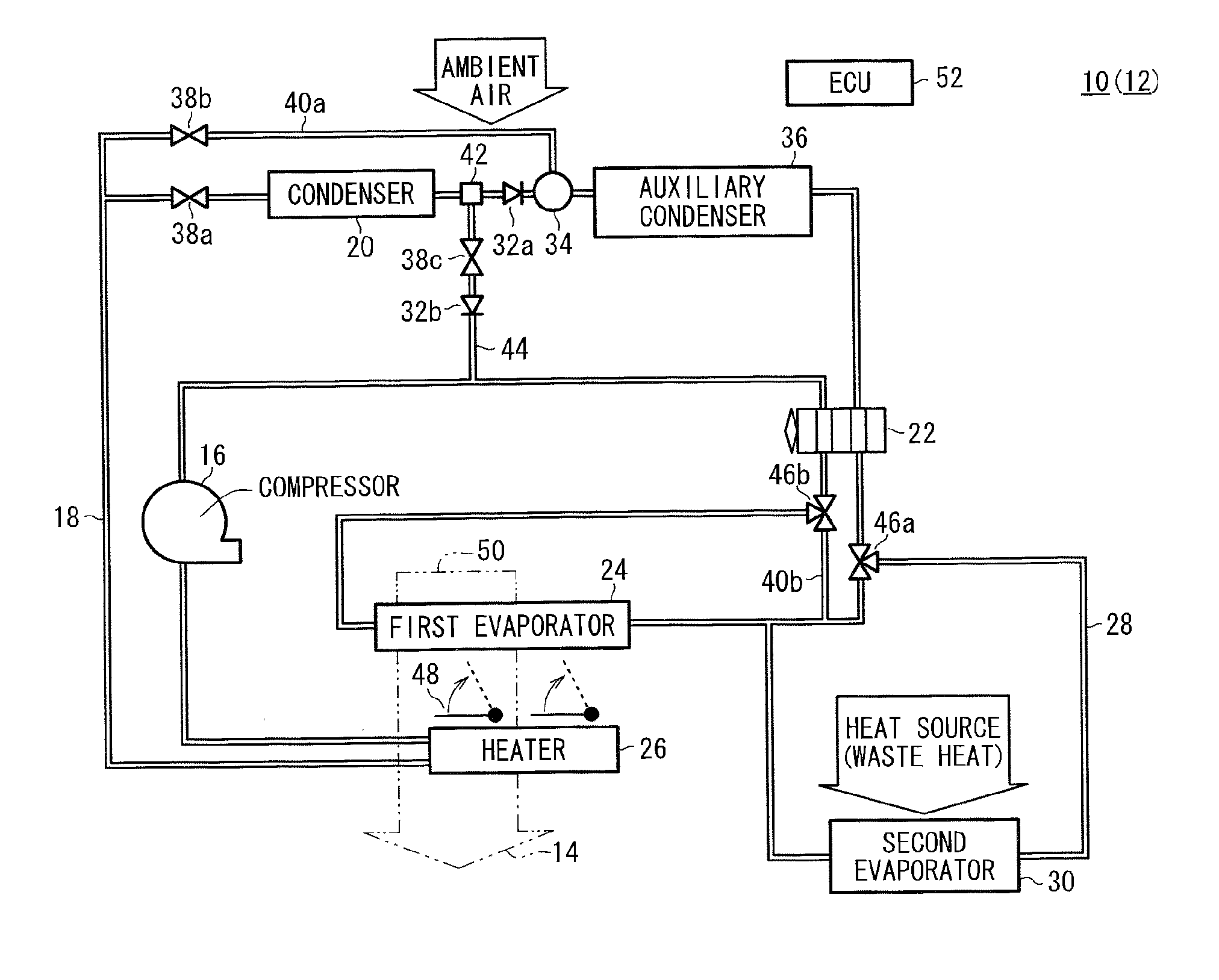

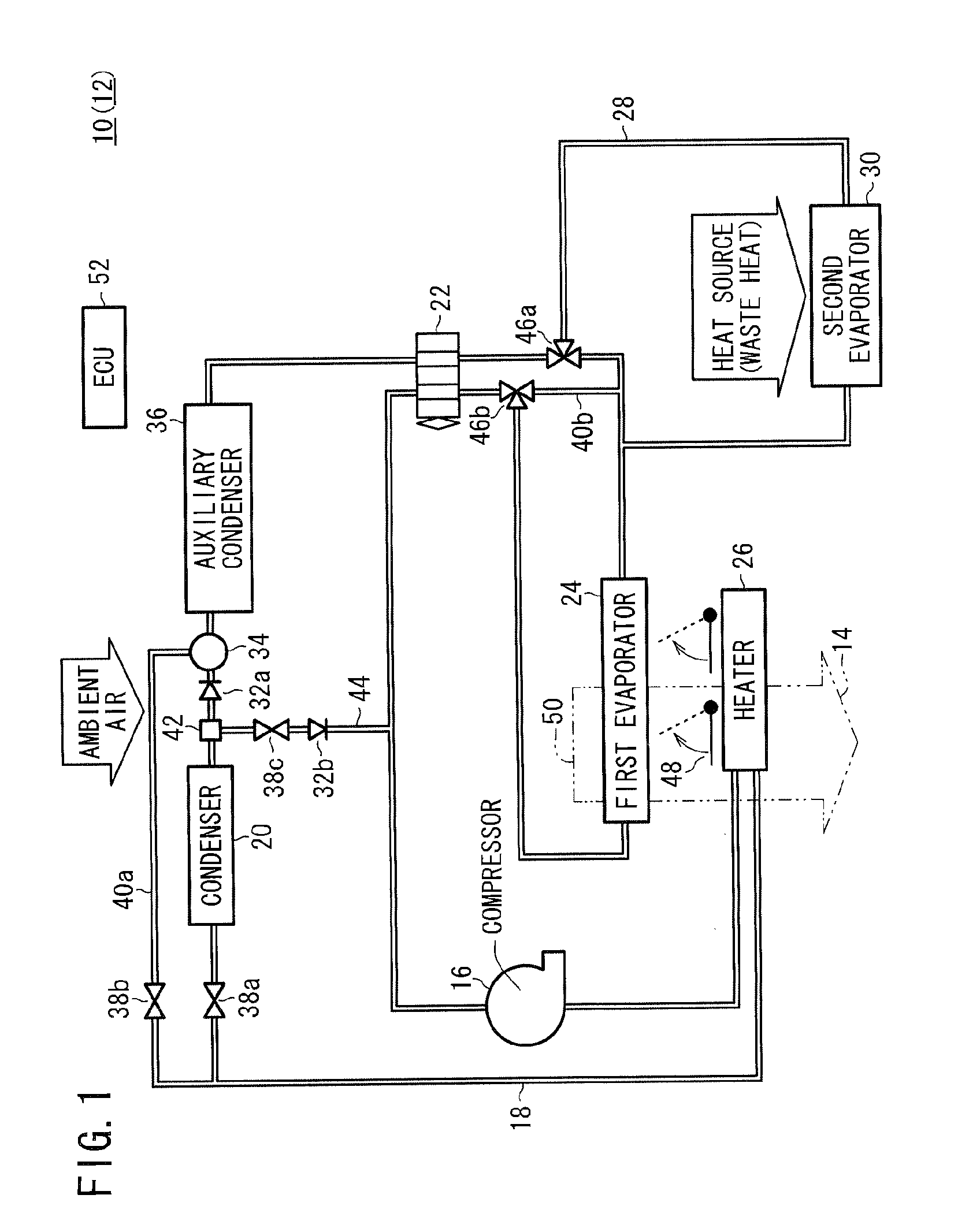

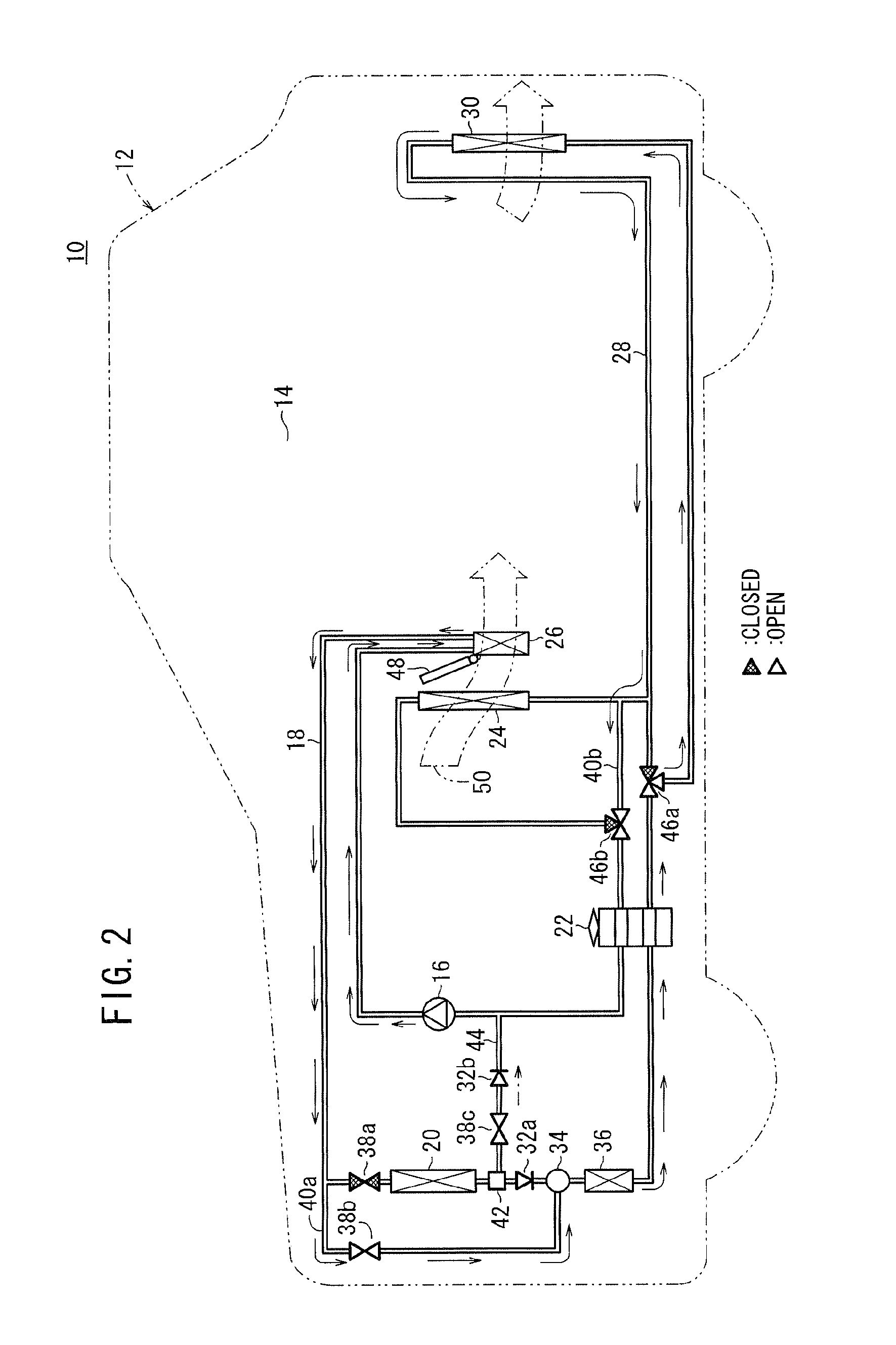

[0027]As shown in FIGS. 1 and 2, a vehicular air-conditioning system 10 according to a first embodiment of the present invention is mounted on an automobile (vehicle) 12 for air-conditioning a passenger's cabin (passenger compartment) 14 of the automobile 12.

[0028]The vehicular air-conditioning system 10 includes a heat pump circulation passage 18 through which a coolant is circulated by a compressor 16. To the heat pump circulation passage 18, there are connected a condenser 20 for performing a heat exchange between the coolant and the ambient air, an expansion valve 22 for depressurizing the coolant sent from the condenser 20, a first evaporator 24 for performing a heat exchange between the coolant that has passed through the expansion valve 22 and air-conditioning air, and a heater 26 for performing a heat exchange between the coolant which has been delivered from the compressor 16 and the air-conditioning air that has passed through the first evaporator 24.

[0029]A branch passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com